Factory Service Manual For Bomag Tandem Vibratory Roller. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG

Pages: 1184

Number: 00891096 (january 2008)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Bomag Tandem Vibratory Roller

BW161AD-4

BW202AD-4

BW161ADH-4

BW203AD-4

BW190AD-4

BW161AC-4

S/N 101 920 02 ….>

S/N 101 920 03 ….>

S/N 101 920 04 ….>

S/N 101 920 05 ….>

S/N 101 920 06 ….>

S/N 101 920 11 ….>

Contents

-GENERAL

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

-MAINTENANCE

General Notes On Maintenance

Fuels And Lubricants

Fuels, Lubricants And Filling Capacities

Running-In Instructions

Maintenance Chart

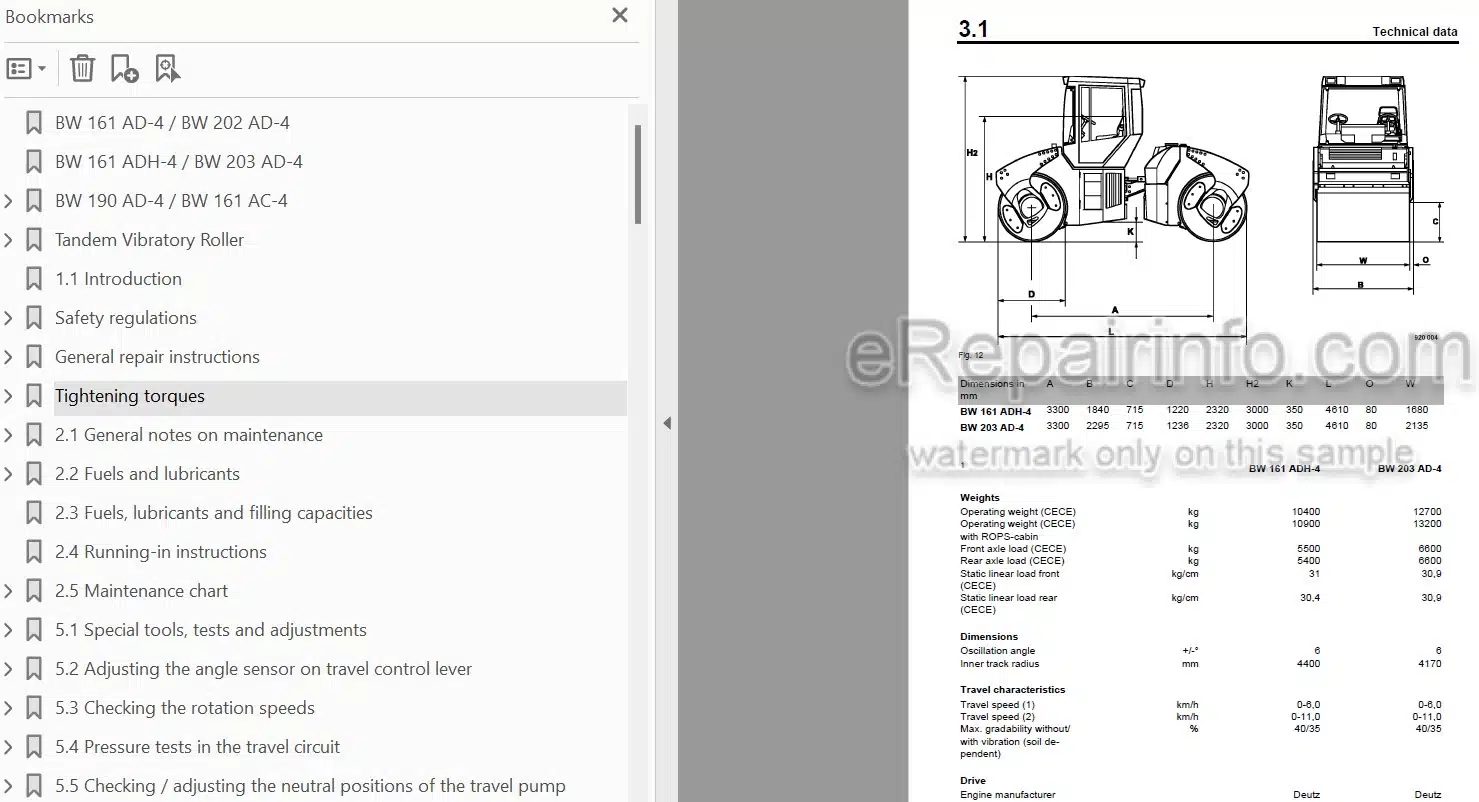

-TECHNICAL DATA

Technical Вata

-CONNECTION OVERVIEW

Connection Overview

-TESTS AND ADJUSTMENTS

Special Tools, Tests And Adjustments

Adjusting The Angle Sensor On Travel Control Lever

Checking The Rotation Speeds

Pressure Tests In The Travel Circuit

Checking / Adjusting The Neutral Positions Of The Travel Pump

Check The Setting Of The High Pressure Relief Valves In The Travel Circuit

Pressure Tests In The Vibration Circuit

Check The Setting Of The High Pressure Relief Valves In The Vibration Circuit

Checking / Adjusting The Vibrator Shaft Speeds

Check The Leakage Rate Of The Vibration Motor

Pressure Test In Steering Circuit

-FLUSHING AND BLEEDING

Special Tools For Flushing

Flushing – General

Flushing Schematic For Front Drum Drive

Flushing The Front Drum Drive

Flushing Schematic For Rear Drum Drive System

Flushing The Rear Drum Drive

Flushing Schematic For Wheel Drive Motors, AC-Machines

Flushing The Rear Wheel Drive On AC Machines

Flushing Schematic For Vibration Drive On AD-Machines

Flushing Schematic For Vibration Circuit On AC-Machines

Flushing The Vibration Circuit

Bleeding The Travel Circuit

Bleeding The Vibration Circuit

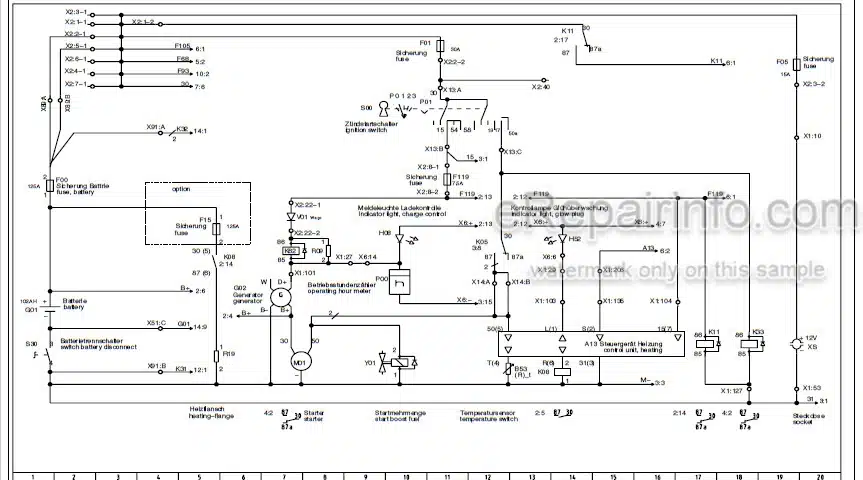

-FUNDAMENTAL ELECTRICS

Understanding Circuit Diagrams

Terminal Designations

Current And Voltage

CAN-BUS

Resistance

Series / Parallel Connection

Ohm’s Law

Electrical Energy

Formula Diagram

Metrology

Diodes, Relays, Fuses

Batteries

Three-Phase Generator

Electric Starter

Telemecanique Switch

Inductive Proximity Switches

Angle Sensor With Current Output

Plug Connectors

Deutsch Plug, Series DT And DTM

Plugs And Terminals In Spring Clamping Technology

-SPECIAL TOOLS, ELECTRICS

Special Tools, Electrics

-ELECTRONIC MODULES

BEM, Bomag Evib-Meter

Electrics Module A03

Electrics Module A68

Electrics Module A71

Electrics Module A04

Heating/Air Conditioning Control

-SPEEDOMETER MODULE

Speedometer Module

-SERVICE TRAINING

Service Training

-ENGINE

General Information On Diesel Engine

Service Side

Starter Side

Lubrication Oil Circuit

Oil Pressure Switch And Low Oil Pressure Circuitry

Coolant Circuit

Coolant Temperature Switch

Disassembling And Assembling The Coolant Temperature Switch

Replacing The Thermostat

Checking The Thermostat In Disassembled State

Three-Phase Generator

Fuel Supply

Injection System

Injection Pump Replacement During Service

Injection Valve Replacement During Service

Checking / Repairing Injection Valves

Fuel Filter

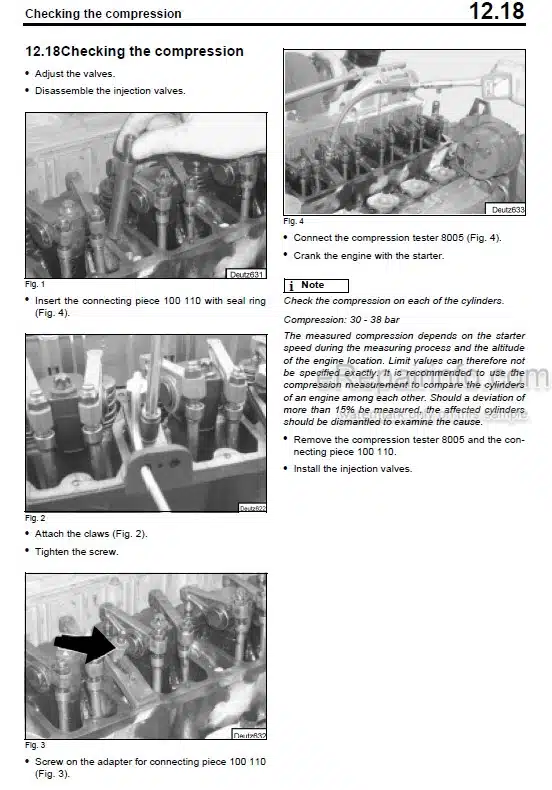

Checking The Compression

Boost Fuel Solenoid Valve

Engine Shut-Down Solenoid

Air Filter, Differential Pressure Switch

Heating Flange On Engine

Checking The Heating Flange Control

Electric Throttle Control

Engine Monitoring

Engine

Check The Engine Oil Level

Change The Engine Oil

Change The Engine Oil Filter Cartridge

Check The Coolant Level

Change The Coolant

Checking The Anti-Freeze Concentration

Check, Clean Radiator, Fuel Cooler, Hydraulic Oil Cooler And Intercooler

Check, Clean The Water Separator

Change The Fuel Pre-Filter Cartridge

Change The Fuel Filter Cartridge

Check, Adjust The Valve Clearance

Check, Clean, Change The Combustion Air Filter

Special Tools, Deutz Engine (BFM 2012)

-AIR CONDITIONING SYSTEM

Physical Basics

Refrigerant Rl34A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

Description Of Components

Checking The Compressor Oil Level

Checking The Magnetic Clutch

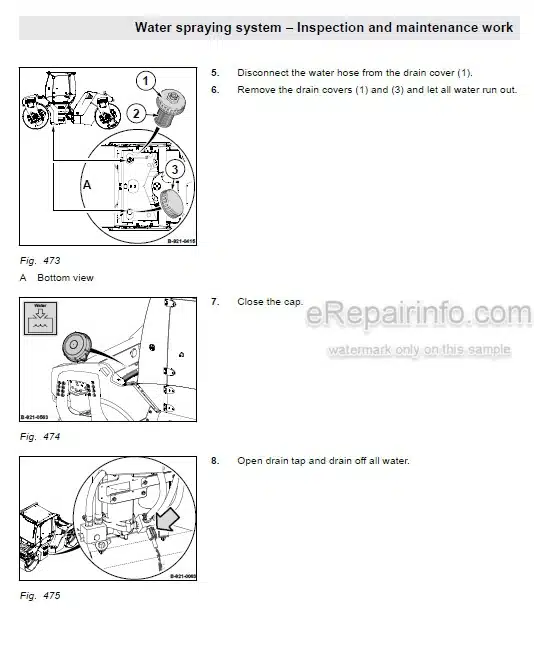

Inspection And Maintenance Work

Checking, Tensioning, Replacing The Refrigerant Compressor V-Belt

Servicing The Air Conditioning (Summer Operation)

Drying And Evacuation

Emptying In Case Of Repair

Leak Test

Filling Instructions

Trouble Shooting In Refrigerant Circuit, Basic Principles

Trouble Shooting, Refrigerant Circuit Diagram

Trouble Shooting Procedure

Steam Table For Rl34A

-REPLACING THE CAB WINDOW PANES

Assembly Of Window Panes

Special Tools

Auxiliary Materials

Removing And Installing The Window Pane

-FRAME CRACKS IN FRONT FRAME

Repair Overview For Welding The Frame

Welding The Frame

-REPLACING THE TRAVEL CONTROL CABLE

Replacing The Travel Control Cable

-DRUM

Special Tools, Drum (BW161-4 To BW203-4)

Repair Overview AD-Drum

Removing And Installing The Drum

Dismantling The AD-Drum

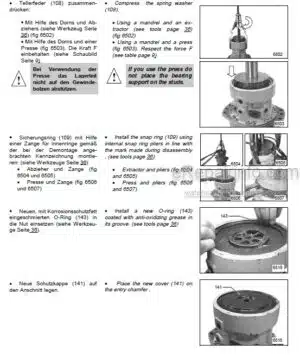

Dismantling, Assembling The Ad Exciter Unit

Assembling The AD-Drum

-OSCILLATING ARTICULATED JOINT

Repair Overview Oscillating Articulated Joint

Removing – Disassembling The Oscillating Articulated Joint

Assembling The Oscillating Articulated Joint

-VIBRATION VALVE Y54/Y55

Vibration Control Valve, Repair Overview

-SUPPLIERS DOCUMENTATION

Travel Pump

Vibration Pump

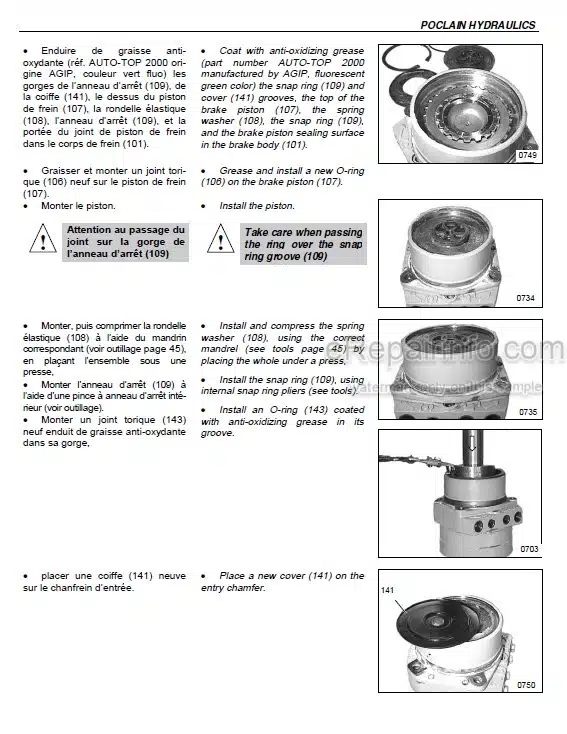

Drum Drive

Drum Reduction Gear

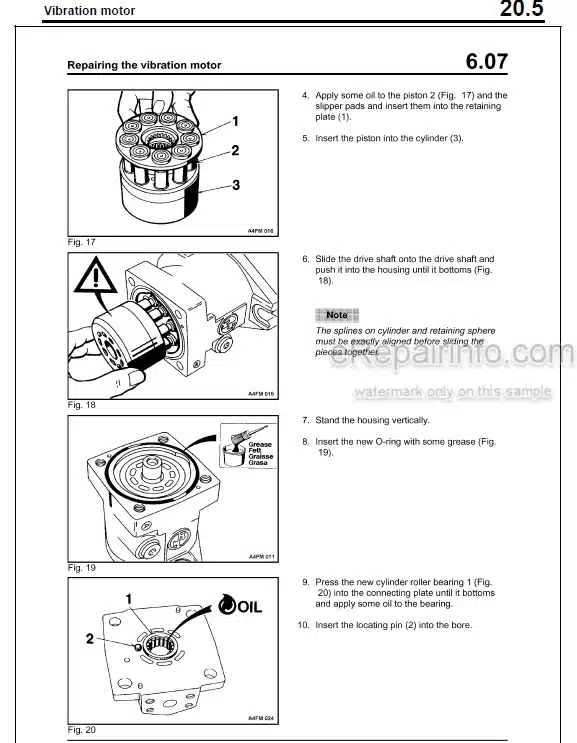

Vibration Motor

Wheel Drive

-CIRCUIT DIAGRAMS

Hydraulic Diagram

Wiring Diagram

-SUPPLEMENT TO CIRCUIT DIAGRAM

Control Elements, Old Design

Control Elements, New Design

Control Elements, Cabin

Monitoring Module A15, Old Design

Monitoring Module A15, New Design

Machine

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.