Factory Service Training For Bomag Single Drum Roller. The Bomag Service Training Manual Describes The Disassembly, Dismantling, Assembly, Installation And Repair Of Components And Assemblies. Manual Addresses The Professionally Qualified Personnel Or The After Sales Service Of Bomag, And Should Be Of Help And Assistance In Correct And Efficient Repair And Maintenance Work.

Format: PDF

Language: English

Pages: 752

Number: 00892433 (ocotber 2013)

Bookmarks: Yes

Searchable: Yes

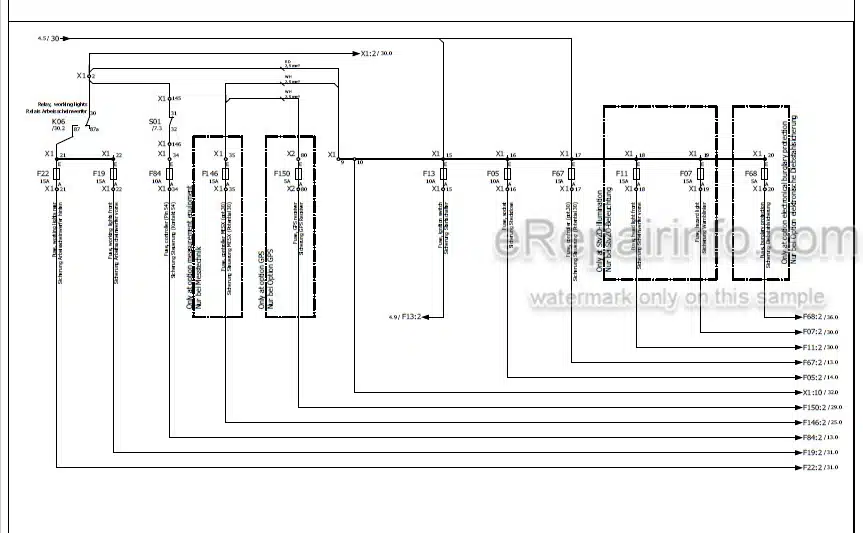

Wiring Diagram: Yes

Hydraulic Diagram: Yes

Model

Bomag Single Drum Roller

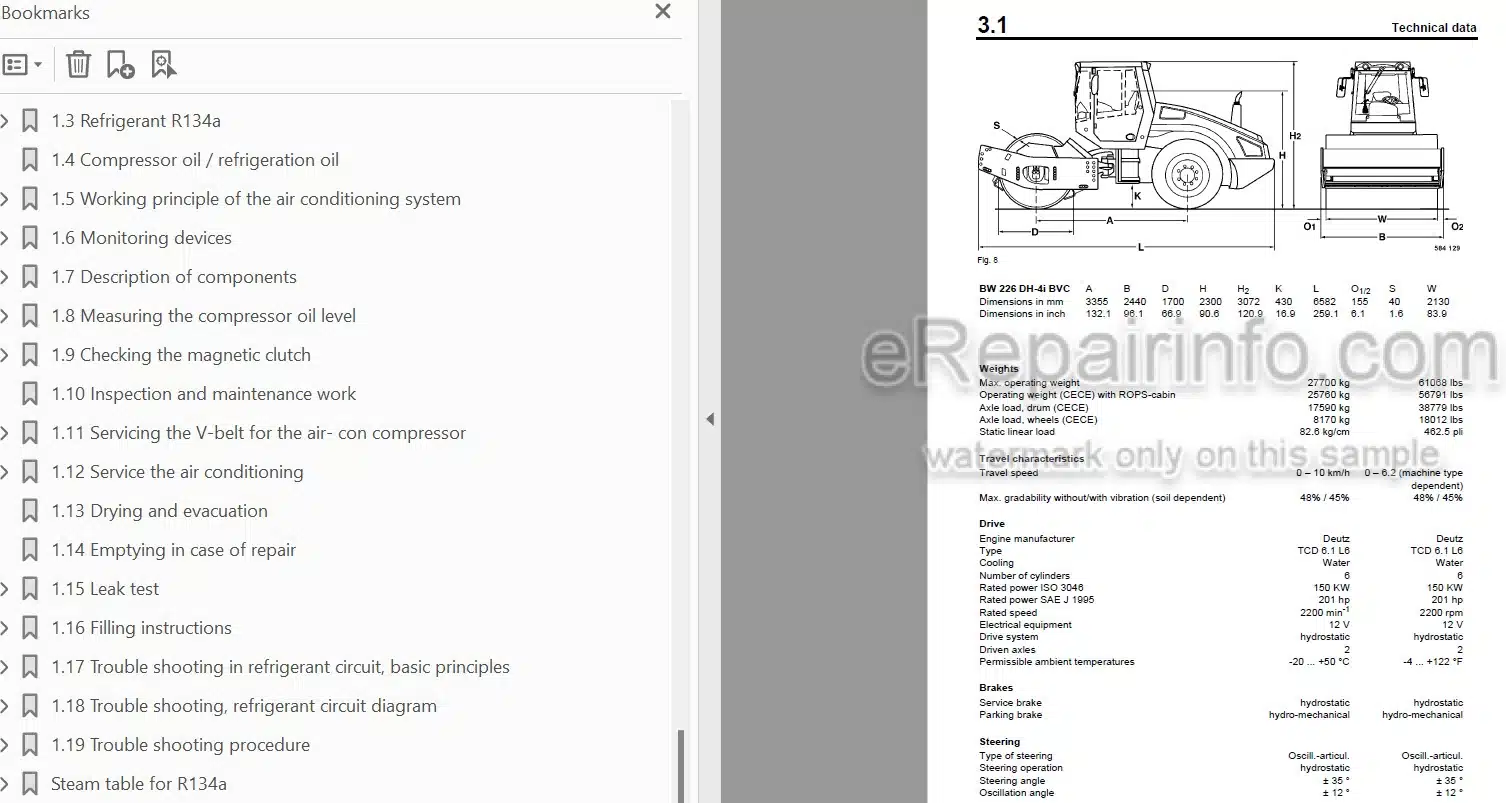

BW226DH-4I BVC

S/N 101 585 01 ….

S/N 101 585 44 ….

Contents

Single Drum Roller

Introduction

Safety Regulations

General Repair Instructions

Tightening Torques

Bomag Single Drum Rollers

Technical Data

General Notes On Maintenance

Fuels And Lubricants

Table Of Fuels And Lubricants

Running-In Instructions

Maintenance Table

Overview

Acceleration Transducer

Battery Service

Starting The Engine With Jump Leads

Main Battery Switch

Overview Of Electric Components

Description Of Indicators And Control Elements

Fuse Assignment

Electronic Control Units

Checking The Voltage Supply For The Control Unit

6Diagnostics Concept

Emr4 System Overview

Emr4 System Components

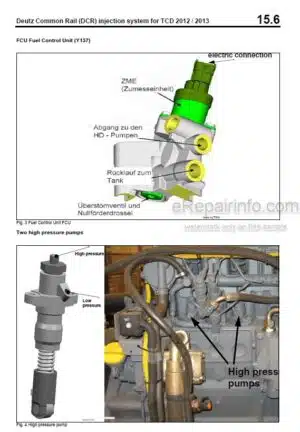

Fuel Control Unit (FCU)

Injector

Crankshaft Speed Sensor

Camshaft Speed Sensor

Rail Pressure Sensor

EMR Coolant Temperature Sensor

Fuel Pressure Sensor

Charge Air Temperature – Charge Air Pressure Sensor

Oil Pressure Sensor

Sensor, Water In Fuel

Sensor, Water In Fuel

Fuel Pre-Heating

Heating Flange On Engine

Rotary Switch For Engine Speed

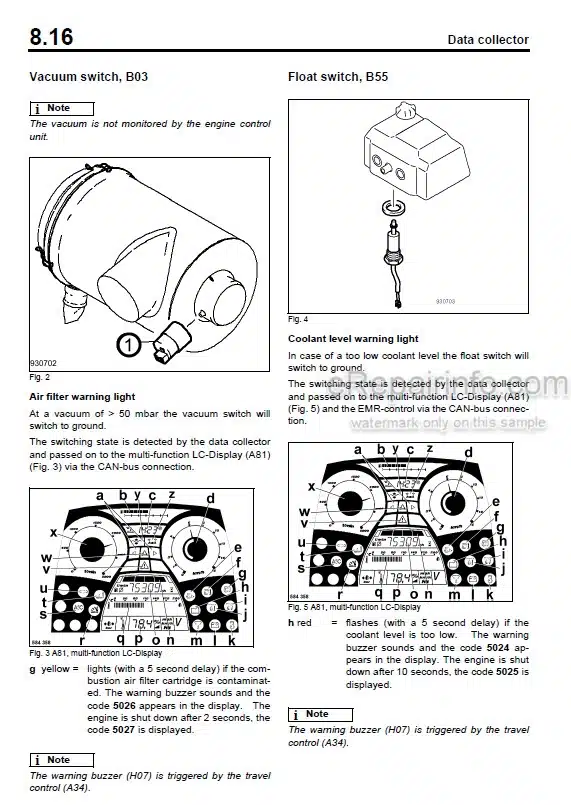

Data Collector

Fault Display

Variocontrol

Control Circuit And MESX

Acceleration Transducer

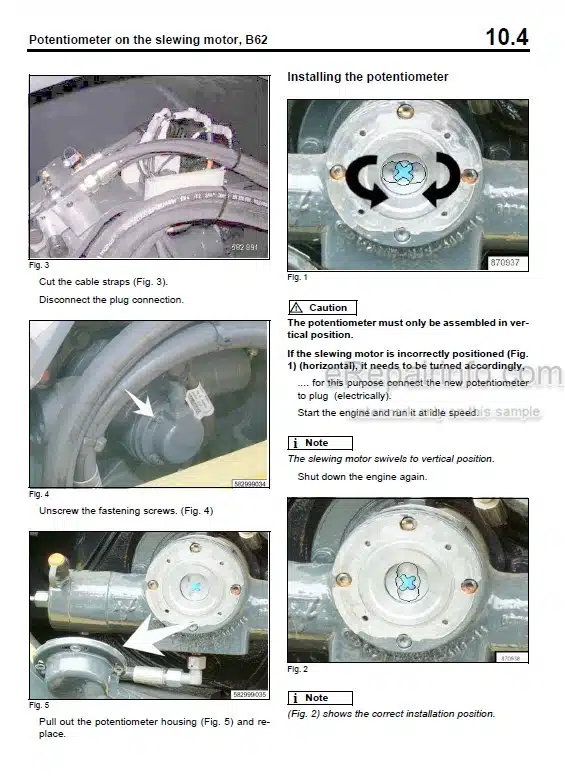

Potentiometer On The Slewing Motor, B62

Display And Control Elements Variocontrol

Description Of Indicating And Control Elements Variocontrol

Bvc/Btm05 Settings Before Start-Up

Variocontrol, Selecting The Operating Mode

Variocontrol, Selecting The Operating Mode

Variocontrol. Selecting The Operating Mode

Measuring Pass With Variocontrol

Teaching Distance Pulses

Amplitude Limitation (BVC Only)

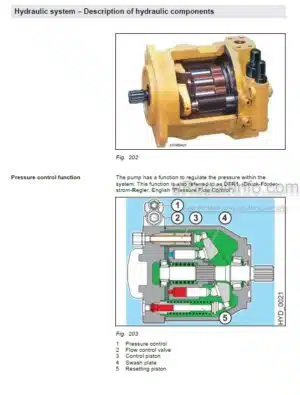

Hydraulic Circuit

Travel And Vibration Pump, H1

Troubleshooting Axial Piston Pumps

Travel Motor 51 C/D 110

Vibration Motor A2FM80

Trouble Shooting, Variable Displacement Axial Piston Motor

External Gear Pumps

Slewing Motor

Travel Circuit

Towing In Case Of An Engine Failure

Adjust The Parking Brake

Change The Oil In The Drive Axle

Changing The Oil In The Wheel Hubs

Changing The Oil In The Axle Reduction Gear

Change The Oil In The Drum Reduction Gear

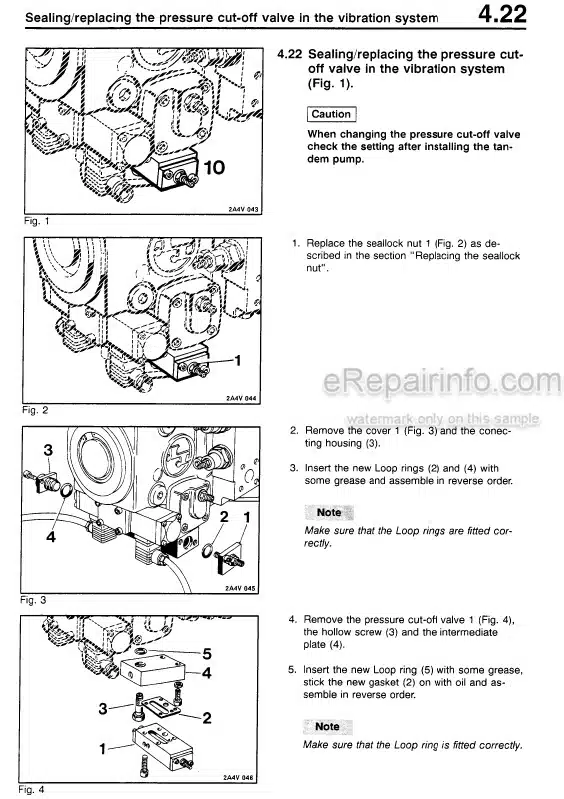

Vibration Circuit

Vario Exciter Oil Change

Check The Hydraulic Oil Level

Changing Hydraulic Oil And Breather Filter

Replace Hydraulic Oil Filter

Changing The Bypass Filter

Steering Circuit

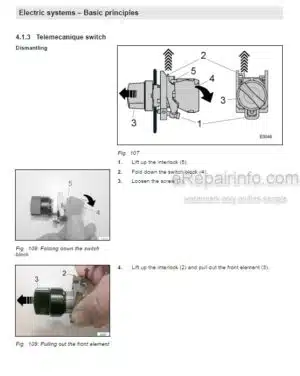

Electric Steering Wheel

Steering Circuit

Special Tools, Tests And Adjustments

Activate Service Mode

Driving Against The Closed Brake

Turn The Steering Against An End Stop.

Check The Leakage Rate Of The Vibration Motor

Pressure Test In Steering Circuit

Special Tools For Flushing

Flushing – General

Flushing Schematic Travel Circuit (Distribution Axle Motor)

Flushing The Travel Circuit (Axle Motor Distribution)

Flushing Schematic For Vibration Drive

Flushing The Vibration Circuit

Bleeding The Travel Circuit

Bleeding The Vibration Circuit

Diesel Engine

Engine Description TCD 6.1 L6

Lubrication Oil Circuit TCD 4.1 / 6.1

Coolant Circuit TCD 4.1 / 6.1

Common Rail System (CRS) TCD 4.1 / 6.1

Exhaust Gas Aftertreatment DPF (Diesel Particulate Filter) With Burner

DPF-Regeneration

Adjust The Valve Clearance

Check The Engine Oil Level

Changing Engine Oil And Oil Filter Cartridge

Check The Coolant Level

Check The Anti-Freeze Concentration And The Condition Of The Coolant

Changing The Coolant

Checking, Cleaning The Water Separator

Replace The Fuel Filter Cartridge

Change The Fuel Filter, Bleed The Fuel System

Replacing Ribbed V-Belt And Idler Pulley

Air Filter Maintenance

Checking The DBF-Burner

Servicing The DBF-Burner

Checking The Crankcase Ventilation Valve

Engine Problems

Special Tools, Deutz Engine (TCD 6.1 L6)

Overview

Physical Basics

Refrigerant R134A

Compressor Oil / Refrigeration Oil

Working Principle Of The Air Conditioning System

Monitoring Devices

Description Of Components

Measuring The Compressor Oil Level

Checking The Magnetic Clutch

Inspection And Maintenance Work

Servicing The V-Belt For The Air- Con Compressor

Service The Air Conditioning

Drying And Evacuation

Emptying In Case Of Repair

Leak Test

Filling Instructions

Trouble Shooting In Refrigerant Circuit, Basic Principles

Trouble Shooting, Refrigerant Circuit Diagram

Trouble Shooting Procedure

Steam Table For R134A

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.