Factory Service Manual For Case 1400 Cotton Harvester. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 210

Number: GSS-1502

Bookmarks: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Case Cotton Harvester

1400

Contents

WORK SAFELY – FOLLOW THESE RULES

STANDARD TORQUE DATA FOR NUTS AND BOLTS

METRIC CONVERSION TABLES

STANDARD TORQUE DATA FOR HYDRAULIC TUBES AND FITTINGS

FLANGETTE BEARING INSTALLATION

SPECIAL SERVICE TOOLS REQUIRED

-GUIDE WHEEL AXLE AND WHEELS

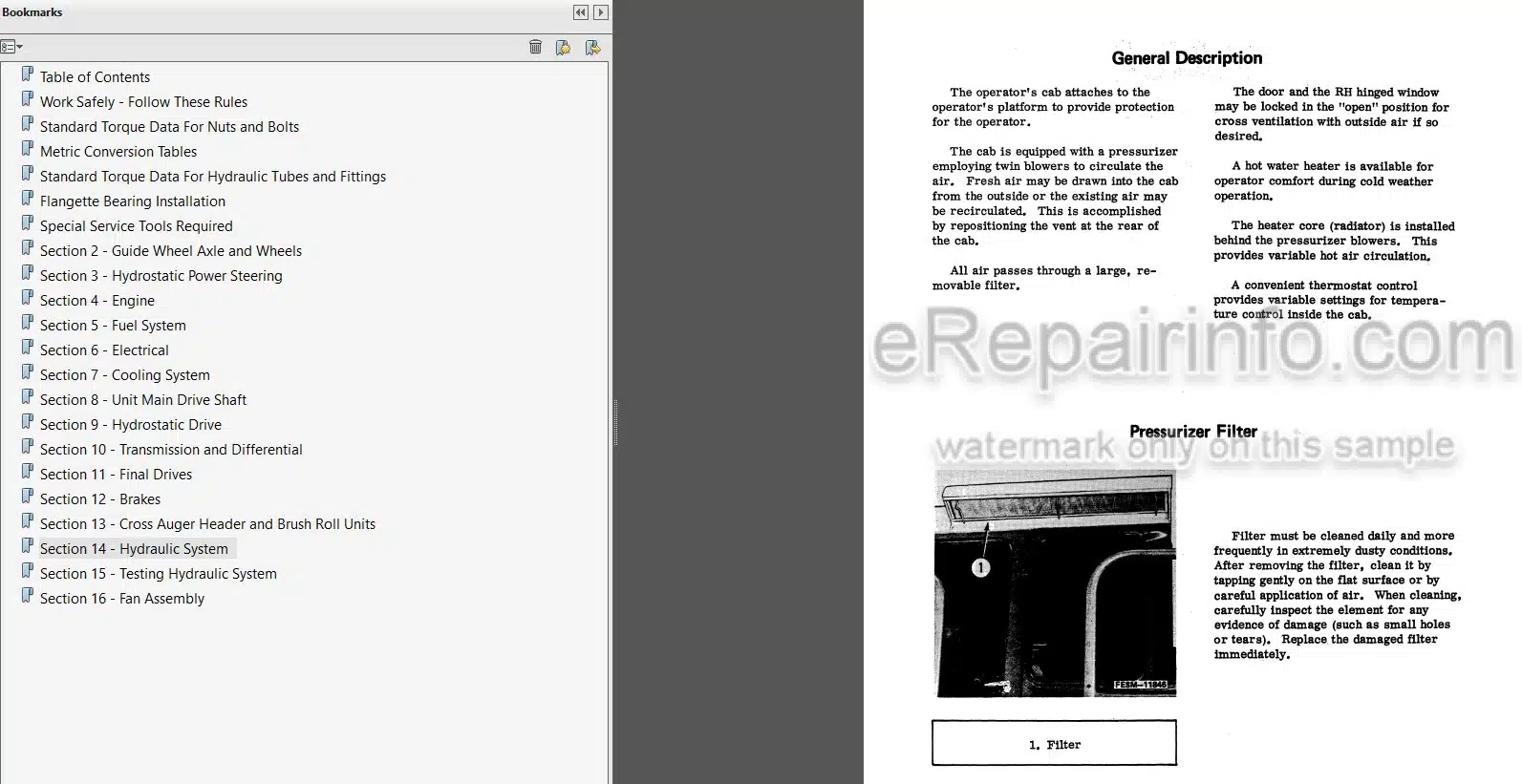

General Description

Pressurizer Filter

Blower Motor

Heater Core

Windshield Wiper Motor

Digital “Read Out” Monitor

Troubleshooting the Digital Monitor

Air Conditioning System

Specifications

Special Torques

Service Tools Required

Evaporator

Receiver-Dryer Assembly

Condenser

Compressor

Troubleshooting

-HYDROSTATIC POWER STEERING

General Description

Principles of Operation

Control Valve

Metering Section

Rotor Operation and the Metering Element

Manual Operation

Steering Hand Pump

Steering Pump Seal Replacement

Steering Check Valve

Venting the Steering System

Steering Cylinder

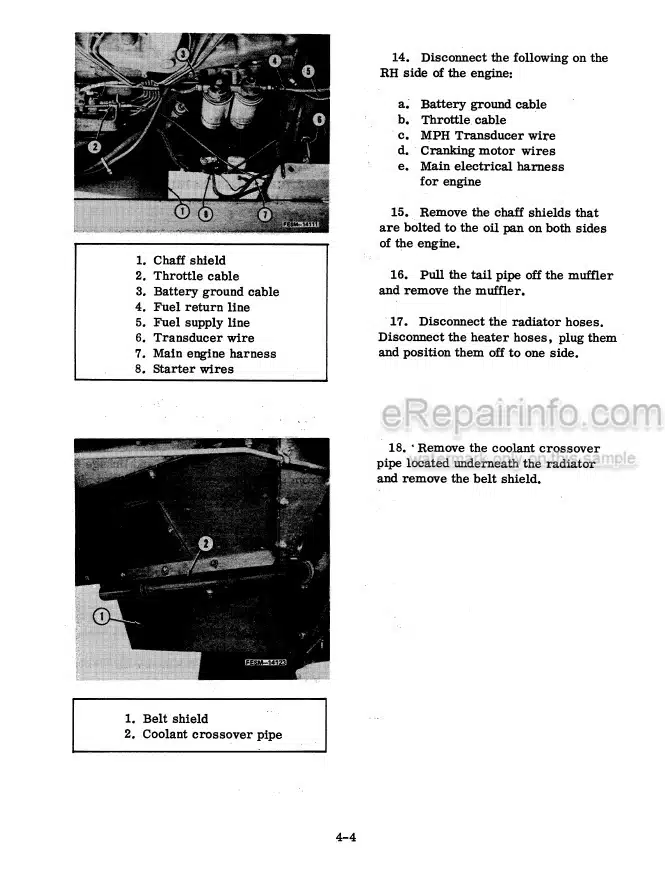

-ENGINE

Specifications

Special Torques

-FUEL SYSTEM

Fuel Tank

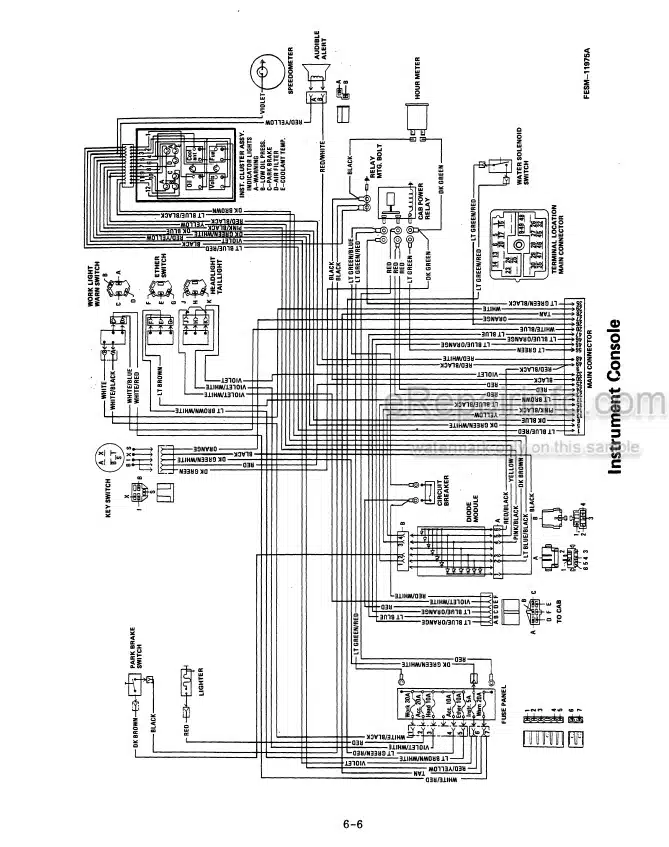

-ELECTRICAL

Specifications

Wiring Diagram

Sensors

Transducer

Neutral Starting Switch Adjustment

Fuse, Cartridge Type

-COOLING SYSTEM

Radiator

-UNIT MAIN DRIVE SHAFT

Unit Main Drive Shaft

Auger Drive Shaft

Green Boll Auger

Drive Belt Replacement

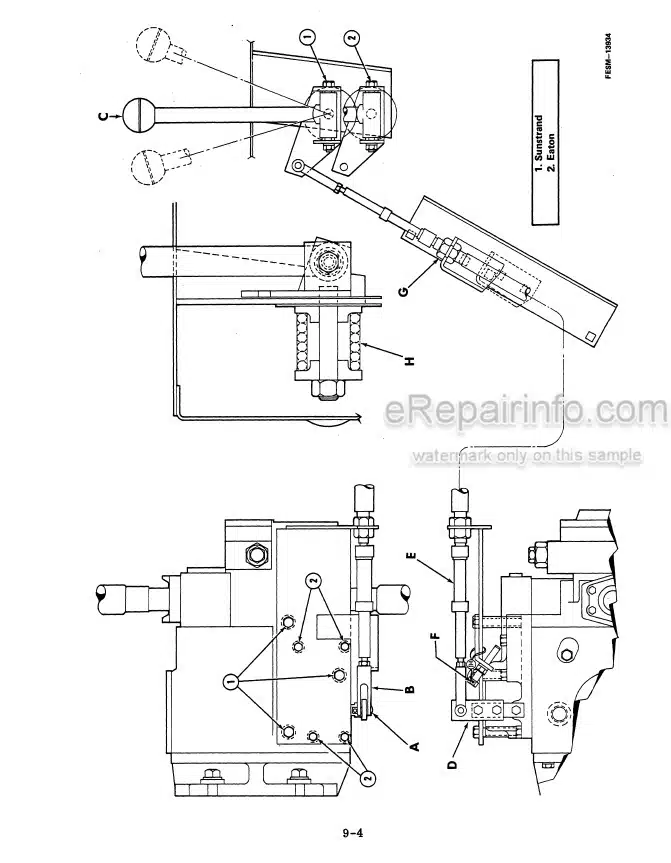

-HYDROSTATIC DRIVE

Specifications

Adjusting the Propulsion Control Lever (In conjunction with Calibrating the Digital Monitor)

Operating Principles of the Foot-N-Inch Valve

Adjusting the Foot-N-Inch Pedal

Test Procedures

Purging the System

-TRANSMISSION AND DIFFERENTIAL

Transmission

Transmission Gear Shift Lever Adjustment

-FINAL DRIVES

Final Drive

Drive Wheel Stud Replacement

Replacing Final Drive Housing-To-Axle Studs

-BRAKES

General Description

Master Brake Cylinder

Brake Cylinders

Servicing the Brake Disc

Bleeding the System

Brake Adjustment

Brake Housing

Parking Brake

-CROSS AUGER HEADER AND BRUSH ROLL UNITS

Cross Auger Header

Automatic Height Sensing Adjustment

Brush Roll Units

Unit Drive Joint Assembly

Cross Auger Drive Pulley

Cross Auger Service

Unit Drive Pulleys

Belt Replacement and Adjustment

Troubleshooting

-HYDRAULIC SYSTEM

Basic Hydraulic System

Unit Control Valve Operating Principles

Schematics of Flow

Reservoir

Component Service

Rotary Flow Divider to Control Valve Operating Units

Service the Automatic Height Control Valve

Basket Compactor and Boll Box Valves

Troubleshooting

-TESTING HYDRAULIC SYSTEM

Testing 1136 litres (3 gpm) Circuit

Testing 5678 litres (15 gpm) Circuit

Testing the Steering Circuit at the Cylinder

-FAN ASSEMBLY

Fan Assembly

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.