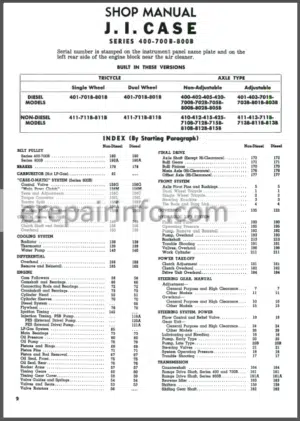

Factory Service Manual For Case Small Wheel Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 565

Number: 7-29290 (september 2001)

Bookmarks: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Case Small Wheel Loader

321D

Contents

-GENERAL

Foreword

Fundamental Safety Instructions

Operating, Safety Instructions

Maintenance, Safety Instructions

Warning Of Special Dangers

Transporting And Towing – Recommissioning

Repair Work – Safety Instructions

Accumulators

Engine

Welding Operations

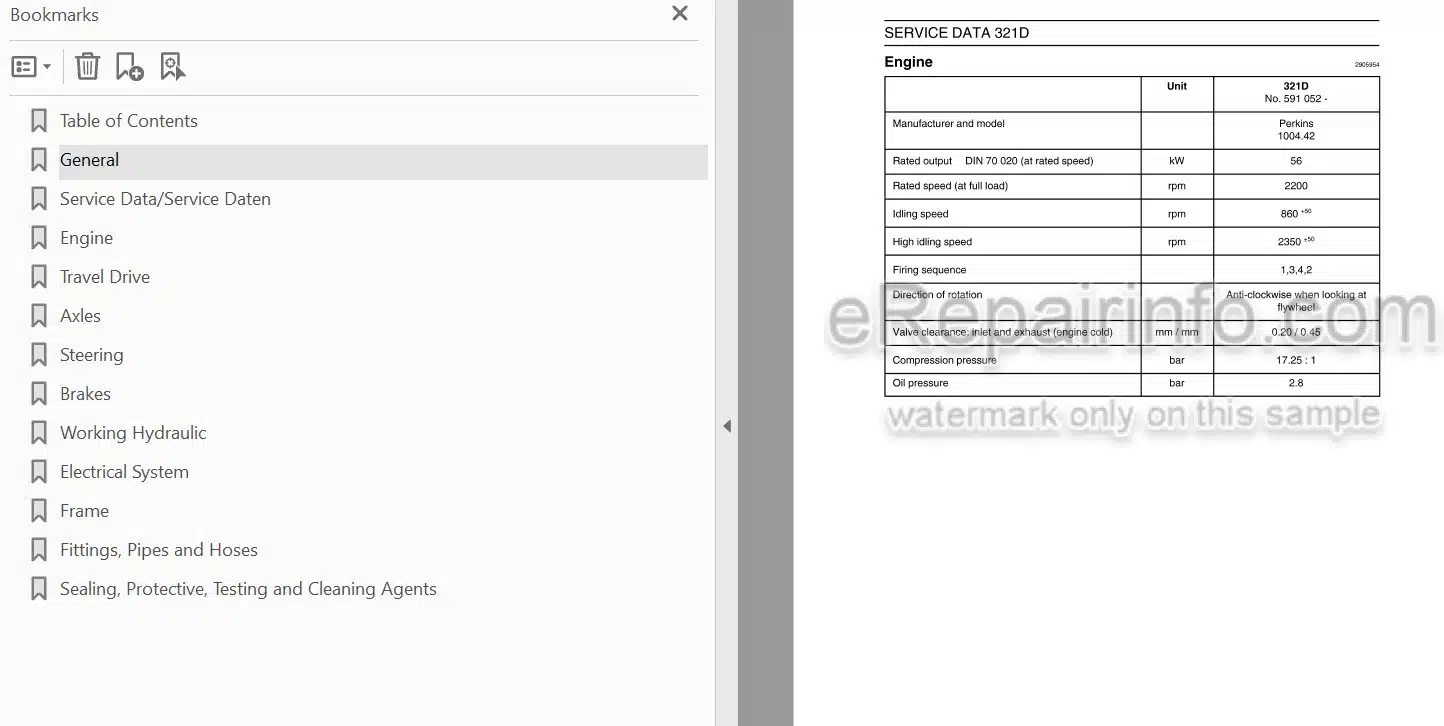

-SERVICE DATA/SERVICE DATEN

Service Data General

Service Data 321D

-TRAVEL DRIVE

Hydraulic System, Safety Instructions

Explanations Of Circuit Diagrams And Illustrations

Depressurizing The Hydraulic System

Principle: Hydrostatic Travel Drive

Hydraulic Circuit Diagram – Travel Drive

Hydraulic Circuit Diagram, Legend

Functional Description: Hydrostatic Travel Drive Of Wheel Loader 321D

Adjusting Work At The Hydrostatic Travel Drive

Repair Instructions, Hydraulic Pump

Repair Instructions, Hydraulic Motor

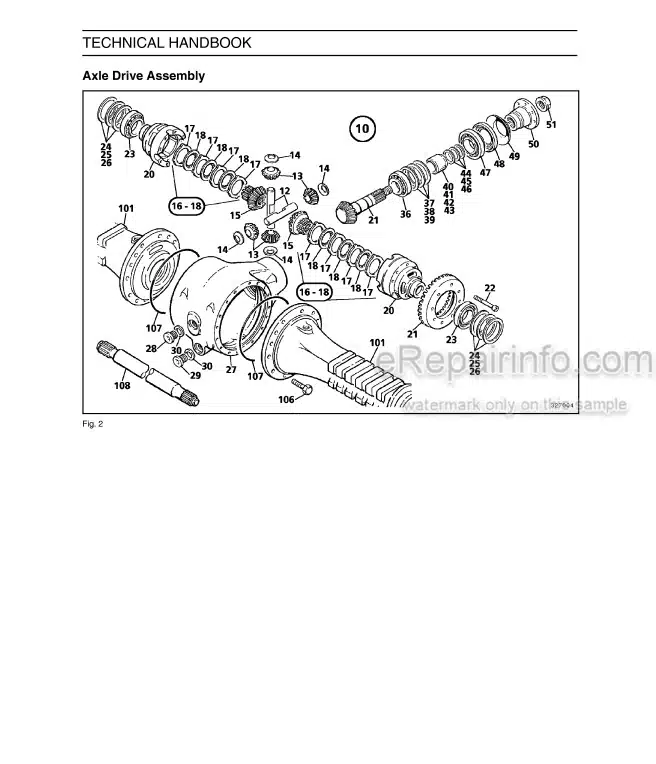

-AXLES

Preface

General

Survey

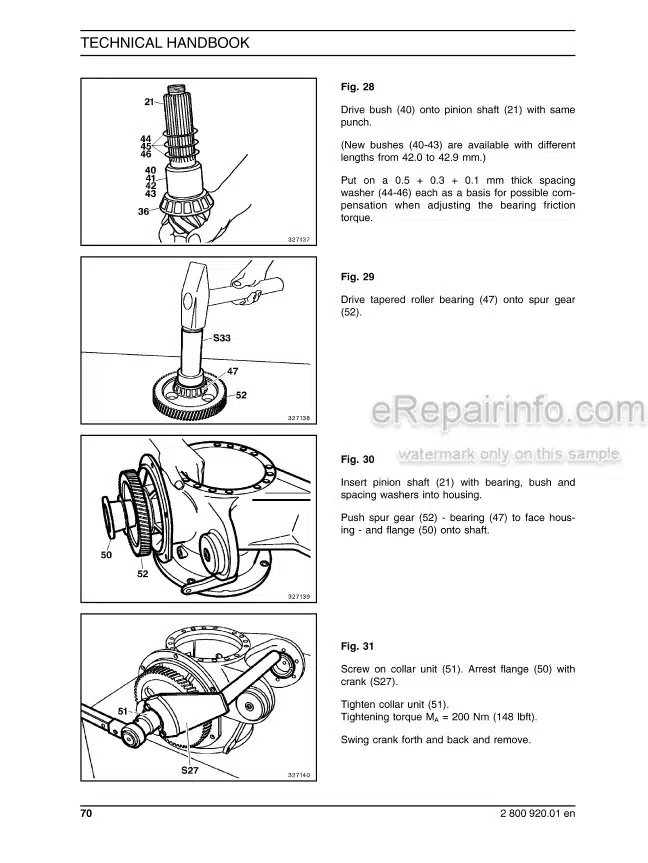

Dismantling And Reassembling The Axles

Dismantling The Front Axle

Dismantling The Rear Axle

Assembling The Front Axle

Assembling The Rear Axle

Gleason Toothing Surface Appearances

List Of Special Tools

Screw Tightening Torques (Din Tables)

Screw Tightening Torques

-STEERING

Hydraulic System, Safety Instructions

Explanations Of Circuit Diagrams And Illustrations

Depressurizing The Hydraulic System

Hydraulic Circuit Diagram – Steering Hydraulics

Hydraulic Circuit Diagram, Legend

Overview Of The Steering System

Functional Description

Double Pump (2), Steering And Working Hydraulics, Braking System

Priority Valve (L6)

Steering Cylinder (L1)

Steering Valve (L2)

Installing The Steering System

Testing And Adjusting The Steering System

-BRAKES

Safety Instructions

Explanations Of Circuit Diagrams And Illustrations

Braking System, Circuit Diagram

Braking System, Legend

Functional Description Of The Braking System

Testing And Adjusting The Service Brake

Accumulators

Safety Instructions

Checking The Brake Disks

Testing And Adjusting Operations On The Auxiliary Brake

Testing And Adjusting Operations On The Parking Brake

Bleeding The Braking System

-WORKING HYDRAULIC

Hydraulic System, Safety Instructions

Explanations Of Circuit Diagrams And Illustrations

Depressurizing The Hydraulic System

Hydraulic Circuit Diagram – Working Hydraulics

Hydraulic Circuit Diagram, Legend

Functional Description, Working Hydraulics

Control Block (H6)

Double Pump (2), Steering And Working Hydraulics, Braking System

Lifting Cylinder (H1)

Dumping Cylinder (H2)

Quick Change Locking Cylinder (H3)

Hydraulic Tank (T1) / Hydraulic Filter (T3)

Distributor (T5)

Testing And Adjustment Work

Hydraulic Circuit Diagram, Cooling

Hydraulic Circuit Diagram, Legend

Functional Description Of Hydraulic System Cooling

Practical Checking

Combined Cooler (T2)

Pipe-Burst Protection (Optional)

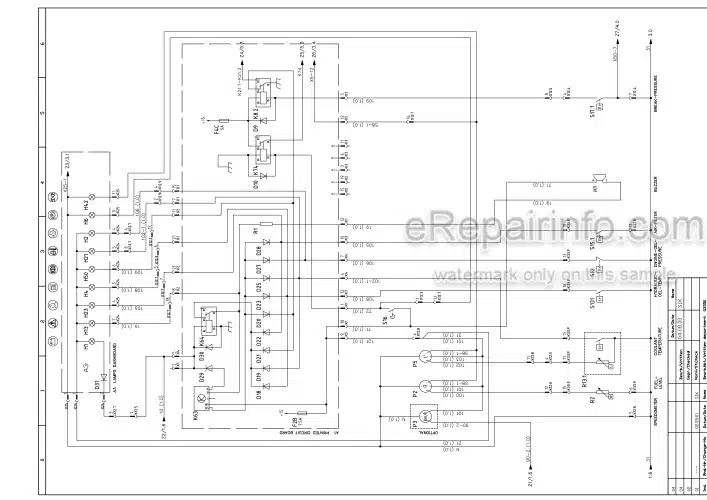

-ELECTRICAL SYSTEM

Electrical Components In Circuit Diagram, P/No 3 004 820

Technical Handbook “Fundamentals Of Electrical Engineering”

Technical Handbook “Interpretation Of Wiring Diagrams”

-FRAME

Repairing The Loader Frame

-FITTINGS, PIPES AND HOSES

Introduction

Fundamental Safety Instructions

Warnings And Symbols

Organizational Measures

Selection And Qualification Of Personnel

Operating Safety Instructions

Maintenance Safety Instructions

Warning Of Special Dangers

Transporting And Towing – Recommissioning

Working Equipment

Assembling Working Equipment – Safety Instructions

Repair Work – Safety Instructions

Lines For Various Media

Materials For Pipes And Hoses

Conditions And Deviations In The Line System

Steel Pipes

Hoses

Plastic Pipes

Connections

Pipe Couplings

Bulkhead Couplings

Stud Couplings And Male Nipples

Swivel Couplings

Fixed Angle Couplings

Banjo Couplings

Flange Couplings With Sae Bolt Pattern

Flanged Hose Couplings

Sealing And Connecting Components

Assembly Aids For Wedge Rings

Appendix

Accessories

-SEALING, PROTECTIVE, TESTING AND CLEANING AGENTS

Introduction

Fundamental Safety Instructions

Warnings And Symbols

Safety Instructions

Preservation Of Gearboxes

Preservation Of Cylinder Piston Rods

Corrosion Protection For Pins And Bearings (Bushings And Hubs)

Solution 1 Corrosion Inhibitor For Cylinder Rod Threads

Rivolta WSX, Nu Corrosion Inhibitor For Electrical Systems

Surface Sealing Agents

Hylomar Sq 32/M Sealing Agent (Thread Sealer)

Liquid Thread Adhesives

Metal Adhesives

Adhesives For Plastics

Adhesive For O-Rings

Lubricants

Solid Lubricant For Molycote-Coated Bolts

Silicon-Corundum Powder (Redurit)

P3 Cold Cleaner

Surface Crack Checking Agent (Metal-Check)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.