Factory Service Manual For Case Articulated Truck. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 647

Number: 9-93760 (november 2005)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Case Articulated Truck

340

Contents

-CONDITIONS OF USE

Introduction

Information On This Handbook

Scheduled Use

Vehicle Operators

Waste Disposal

Scrapping The Vehicle

Warranty And Liability Of The Manufacturer

Service

General Operation Rules

-SAFETY INSTRUCTIONS

Introduction

Preventing Fires

Rollover Accidents

Instructions For Use

Maintenance

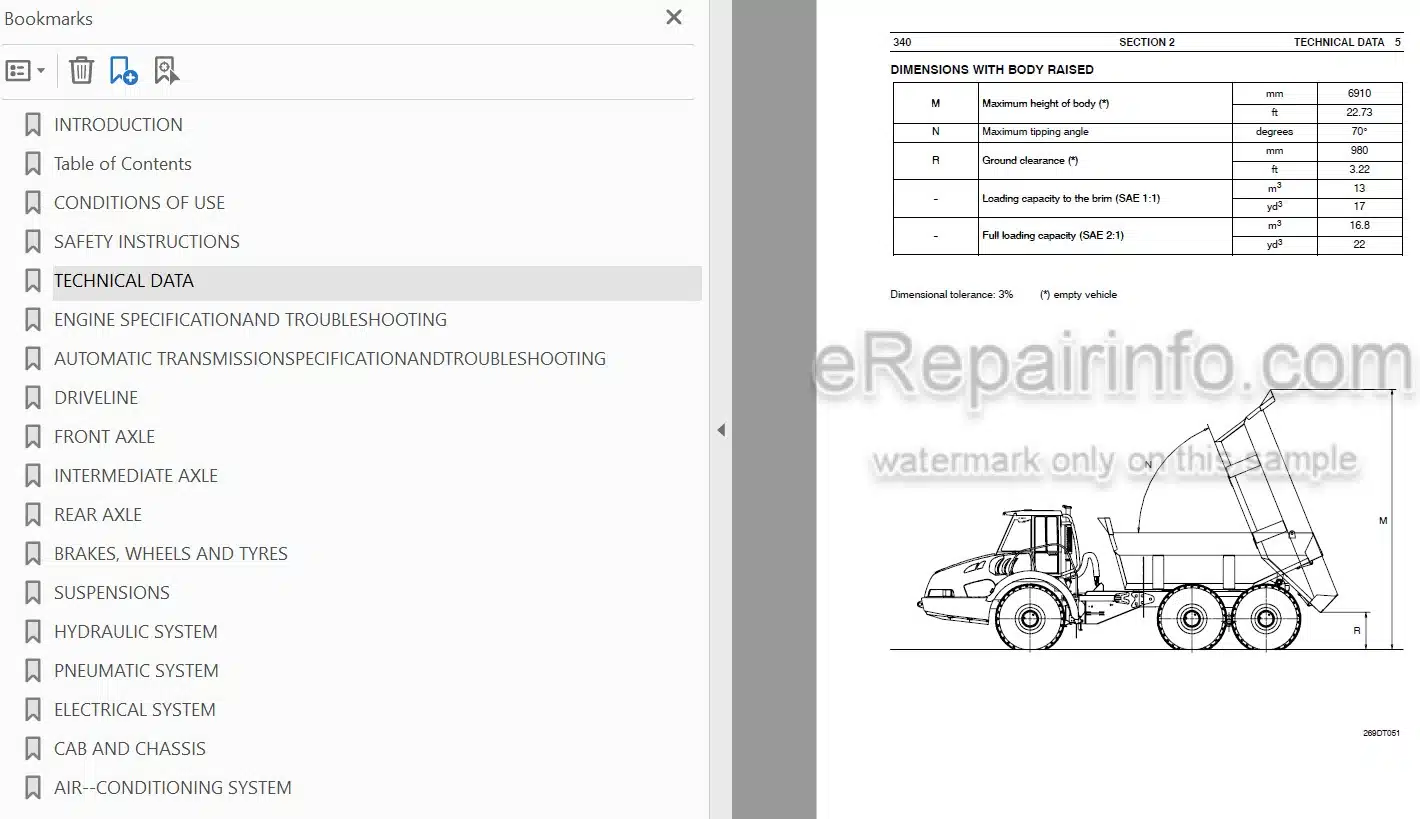

-TECHNICAL DATA

Vehicle Composition

Dimensions

Dimensions With Body Raised

Weights

Centre Of Gravity (Horizontal Position)

Performance

Performance Alignment Chart

Main Technical Specifications

Position Of Identification Data On Main Groups

Main Technical Specifications

List Of Bulbs

Capacities

Tire Pressure Table

Antifreeze Concentration In Engine Coolant

Antifreeze Concentration In Windscreen Washer Fluid

Battery Electrolyte Density Table

Tightening Torque

Plates Applied To The Vehicle

European Version

Inside Engine Hood Plate

USA Version

Inside Engine Hood Plate

Inside Cab Plate

Standard Tightening Torques

Measures (International System)

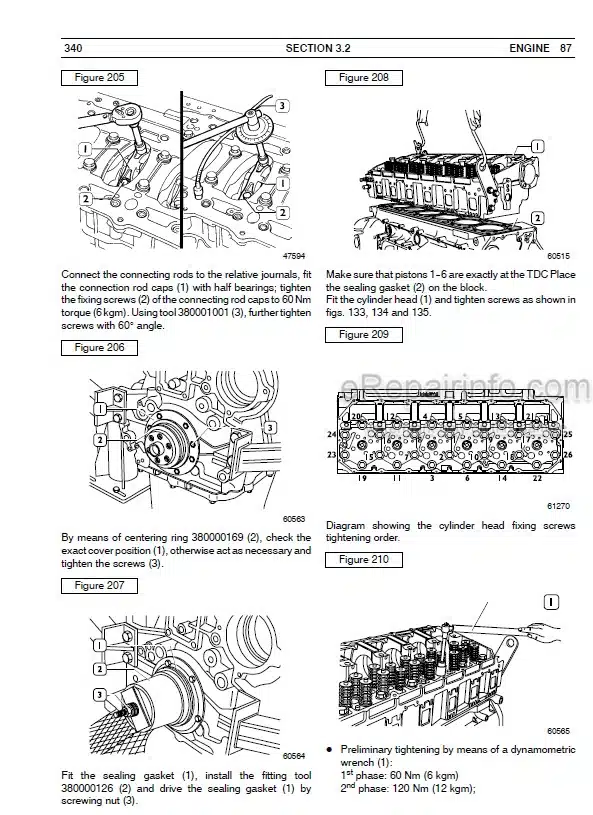

-ENGINE SPECIFICATION AND TROUBLESHOOTING

Technical Specification

Walk Around

Transversal Section

Longitudinal Section

Electronic System Control

EDC Engine Control Unit Location

EDC Control Unit Pin – Out

EDC Control Unit Pin — Out

General Characteristics

Assembly Clearance Data

Diagnostic Connector Pin-Out

Fault Display

Engine Failure List

Error Codes Table

Cursor Trouble Shooting Guide

Blink Code

Troubleshooting By Symptoms

Tightening Torques

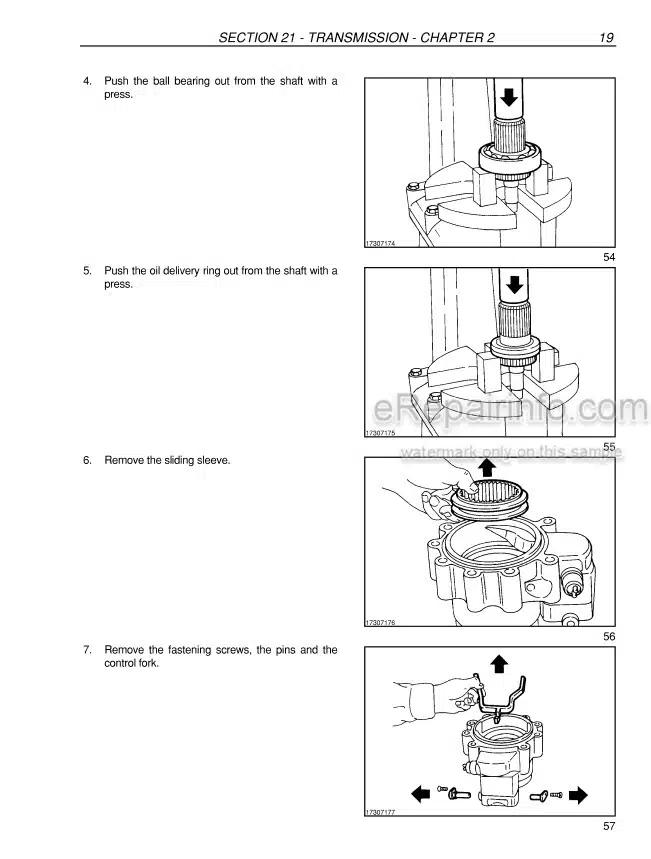

-AUTOMATIC TRANSMISSION SPECIFICATION AND TROUBLESHOOTING

Description

Automatic Transmission Cross-Section View

Automatic Transmission External Pipe Arrangement View

Transmission Speed Sensors

Fundamental Components

Operation

Front Differential Fitting

Transmission Oil Cooling System

Transmission Control System Components

Diagnostic

Fault Display

Transmission Failure List

Technical Data

AEB Procedure

-DRIVELINE

Description

Tightening Torques

Propeller Shaft Removal-Replacement

Maintenance

Central Bearing Overhaul

-FRONT AXLE

Description

Specifications And Data

Tightening Torques

Front Hub Removal-Refit

Special Maintenance

Front Differential

Front Hubs

-INTERMEDIATE AXLE

Description

Specifications And Data

Tightening Torques

Intermediate Axle Removal-Refit

Maintenance

-REAR AXLE

Description

Specifications And Data

Tightening Torques

Rear Axle Removal-Refit

Maintenance

-BRAKES, WHEELS AND TYRES

Brakes

Description

Specifications And Data

Tightening Torque

Wheels

Description

Specifications And Data

Tightening Torque

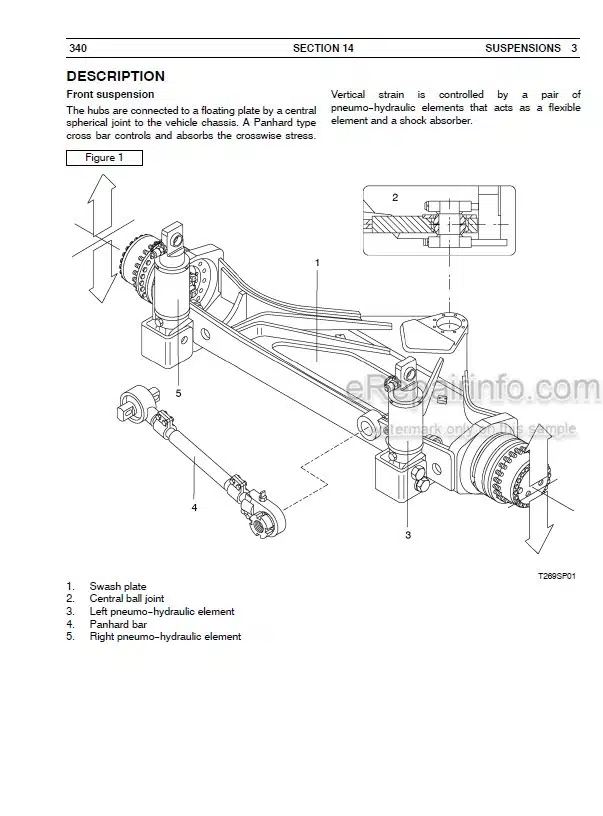

-SUSPENSIONS

Description

Front Suspension Removal-Replacement

Front Suspension Cylinder Removal-Replacement

Rear Suspension Removal-Replacement

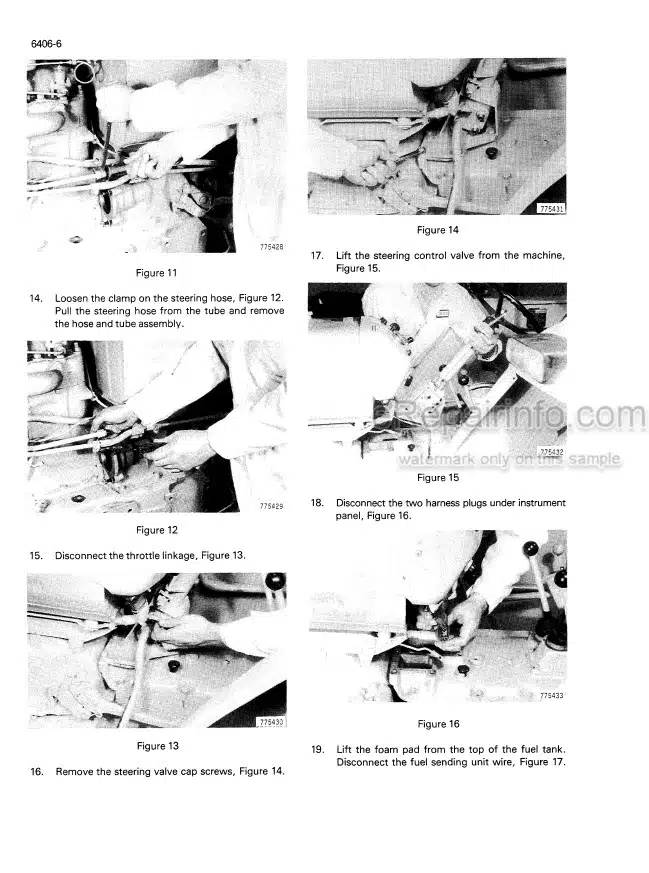

-HYDRAULIC SYSTEM

Description

Tipping And Steering System

Emergency Steering System

Braking System

Brakes Cooling System

Engine Cooling Fan Operating System

Technical Data

Control Procedures

Pressure Testing Procedure

Main Pump (Kawasaki) Removal-Replacement

Brake Pump Removal-Replacement

Emergency Steering Pump Removal-Replacement

Steering Valve Removal-Replacement

Tipping Valve Removal-Replacement

Brake Cooling Circuit Pump-Motor(Casappa Group) Removal-Replacement

Steering Cylinder Removal-Replacement

Tipping Cylinder Removal-Replacement

-PNEUMATIC SYSTEM

Description

Pneumatic Diagram

Main Components Location

Diagnostic

Drier

Tools

Main Components Pneumatic System

Compressor

Air Intake Valve

Pressure Relief Valve

Parking Brake Engaging Distributor

Manual Condensation Discharge Valve

Pipes And Couplings

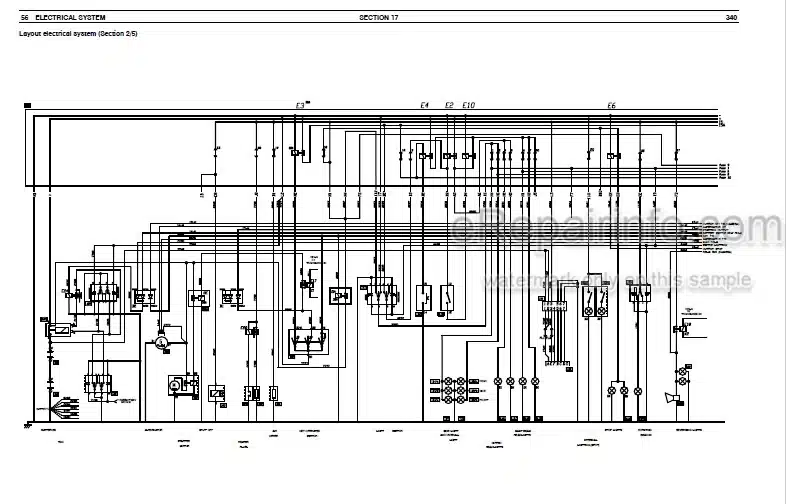

-ELECTRICAL SYSTEM

Electrical Supply

Ground Points

Relays And Fuses Interconnection Control Unit

Relays And Fuses

Bulkhead Connectors

Multiplex System Overview

Can Line

Multiplex System General Diagram

Can Open Line

Body Computer System Components Topographic Diagram

Can Open Line Circuit Diagram

Body Computer System Components

Midac

Midac Location

Can J1939 Line

Can J1939 Line Circuit Diagram

Diagnostic

Diagnostic Connector Pin–Out

Fault Display

List Of Multiplex System Faults

Electrical System

-CAB AND CHASSIS

Description

Hood And Cab Hydraulic Tilting System

Tightening Torques

Cab Removal-Replacement

Cab Components Removal-Replacement

Description

Tightening Torques

Articulation Joint Removal-Replacement

Tests And Checks

Automatic Greasing System (Front Chassis)

Automatic Greasing System (Rear Chassis)

Manual Greasing System

-AIR-CONDITIONING SYSTEM

Air-Conditioning System

Electrical Circuit Diagram

Technical Data

Equipment

Diagnostics

Maintenance

General Servicing

System Draining And Recharging Procedures

R134A Refrigerant Recharging And Recovery Station OEM-1418

Control Panel

Charge Cylinder And Oil Tank

Safety Standards

Operations Flow Diagram

Recovering Refrigerant From System On Vehicle

Creating Vacuum In System

Restoring System Oil

Charging The System With Refrigerant

Checking System Pressures

Operations Prior To Removing Station From System

Leak Detector For Air Conditioning Systems With HFC R134A

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.