Repair Manual For Case 40XT Skid Steer Loader. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 627

Bookmarks: Yes

Searchable: Yes

Number: 6-45070

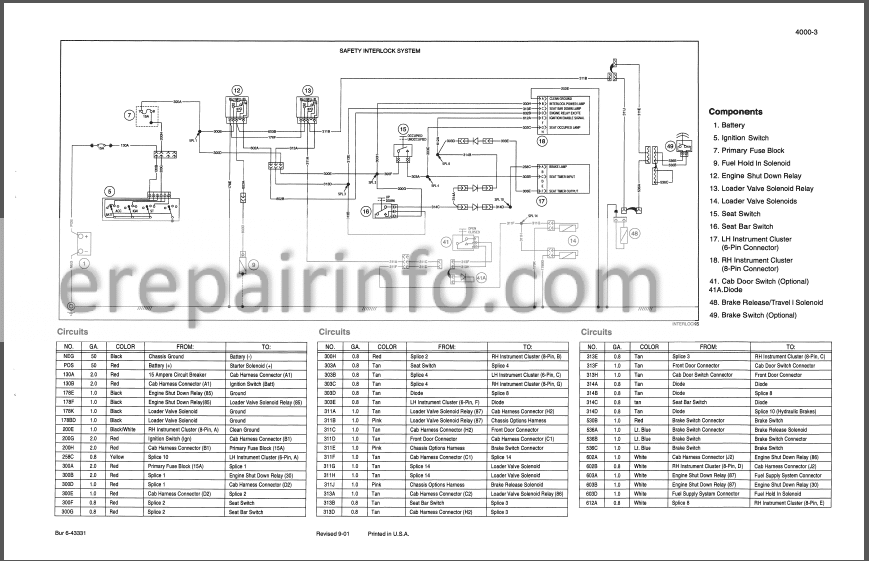

Wiring Diagrams: Yes

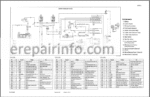

Hydraulic Diagrams: Yes

Model

Case 40XT

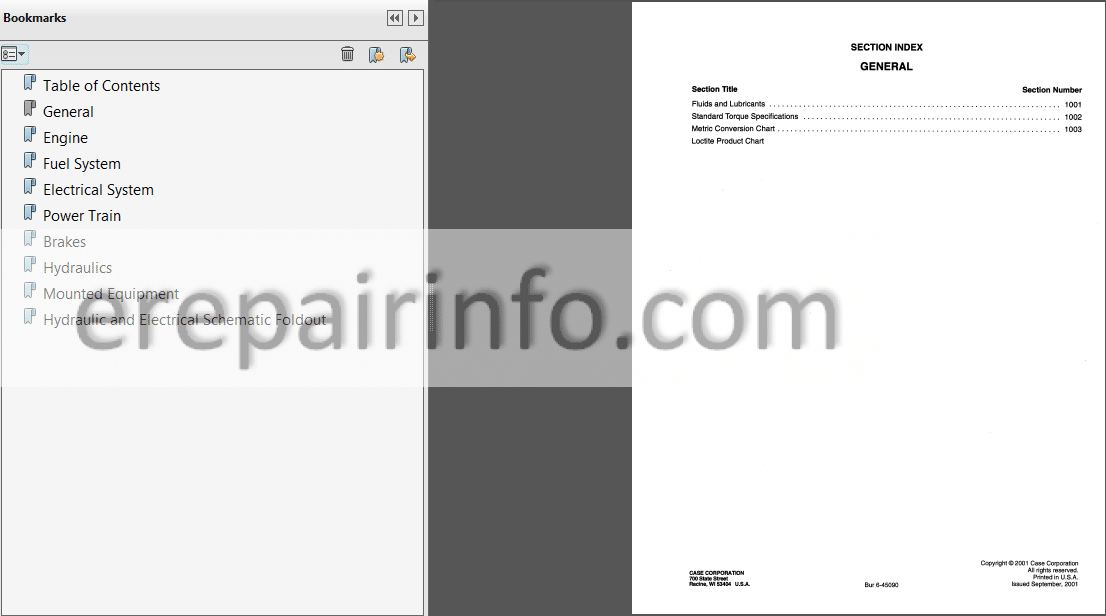

Contents

- General

- Engines

- Electrical

- Power Train

- Brakes

- Hydraulics

- Mounted Equipment

- Schematic Set

Fill contents

– General

–FLUIDS AND LUBRICANTS

CAPACITIES AND LUBRICANTS

ENVIRONMENT

ENGINE LUBRICATION

Engine Oil Selection

Oil Viscosity/Temperature Ranges

DIESEL FUEL SYSTEM

Fuel Storage

Specifications For Acceptable No 2 Diesel Fuel

–STANDARD TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS-DECIMAL HARDWARE

Grade 5 Bolts, Nuts, And Studs

Grade 8 Bolts, Nuts, And Studs

TORQUE SPECIFICATIONS – METRIC HARDWARE

Grade 88 Bolts, Nuts, And Studs

Grade 129 Bolts, Nuts, And Studs

Grade 109 Bolts, Nuts, And Studs

TORQUE SPECIFICATIONS-STEEL HYDRAULIC FITTINGS

37 Degree Flare Fitting

Straight Threads With O-Ring

Split Flange Mounting Bolts

O-Ring Face Seal End

O-Ring Boss End

Fitting Or Lock Nut

Pipe Fittings

–METRIC CONVERSION CHART

CONVERSION FACTORS

Metric To US

US To Metric

–LOCTITE PRODUCT CHART

-Engines

–RADIATOR

Removal

Installation

–ENGINE

Removal

Installation

-Fuel Systems

Section Index – Fuel Systems

For Fuel System Repair – See the Engine Service Manual

-Electrical

–ELECTRICAL SPECIFICATIONS AND TROUBLESHOOTING

Interlock System

–ELECTRICAL SYSTEM SPECIFICATIONS AND TROUBLESHOOTING

GENERAL INFORMATION

Circuit Diagram Legends

Fuses

LEFT HAND INSTRUMENT PANEL

Standard RIGHT HAND INSTRUMENT PANEL

Optional Engine Shutdown System

Right Hand INSTRUMENT PANEL

CONTROL LEVERS

Left Hand Control Lever

Right Hand Control Lever

HOW TO TEST A WIRING HARNESS

Visual Inspection

Testing For Open Circuits

Finding An Open Circuit

Testing For Short Circuits

Finding A Short Circuit

Testing For A High Resistance Circuit

Finding A High Resistance Circuit

TROUBLESHOOTING EXAMPLE

TROUBLESHOOTING

–Battery

SAFETY RULES

MAINTENANCE

Electrolyte Level

Inspecting and Cleaning a Battery

NONSPILL CAPS

BATTERY TEST

Visual Checks

Specific Gravity Check

Capacity (Load) Test

CHARGING A BATTERY

CHARGING GUIDE FOR MAINTENANCE FREE BATTERIES

PREPARING A DRY CHARGED BATTERY FOR USE

CHARGING GUIDE FOR BATTERIES OTHER THAN

MAINTENANCE FREE BATTIERES

–STARTER AND STARTER SOLENOID

SPECIFICATIONS

LUBRICATION

NO-LOAD TEST

General Information

Test Equipment

Test Procedure

DISASSEMBLY

INSPECTION

Brushes and Brush Springs

Brush Holder

Armature

Field Coil Test

ASSEMBLY

STARTER SOLENOID TEST

Starter Solenoid Test Procedure

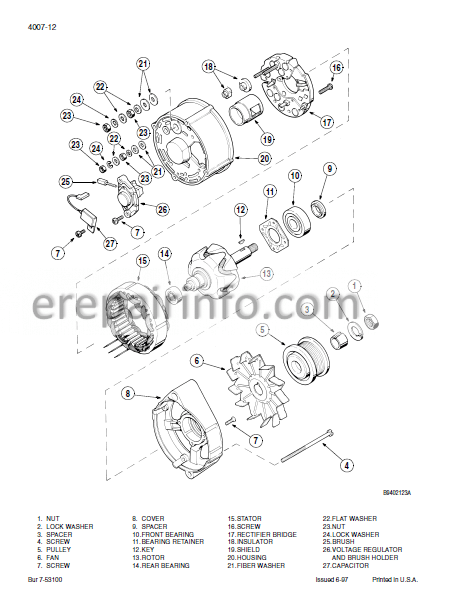

–ALternator

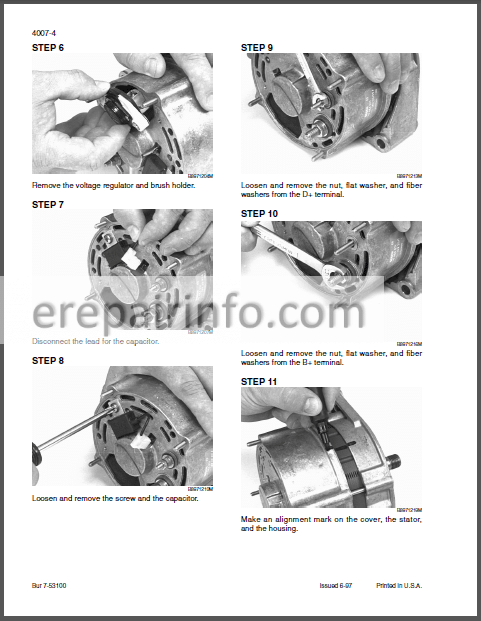

ALTERNATOR

Disassembly

Inspection of Brushes

Inspection and Testing of Rotor

Inspection and Testing of Stator

Testing the Capacitor

Testing the Rectifier Bridge

Inspection and Replacement of Bearings

Assembly

-Power Train

–HYDROSTATIC SYSTEM – “HOW IT WORKS”

System Overview

Hydrostatic Pump

Hydrostatic Drive Motor

Mechanical Parking Brake Overview

Hydraulic Brake Option

Hydrostatic Control Levers

Hydrostatic System Cleanup

Hydrostatic Start-Up Procedure

–HYDROSTATIC SYSTEM TROUBLESHOOTING

SPECIFICATIONS

SPECIAL TOOLS

SAFETY RULES

CHECKS TO DO BEFORE TROUBLESHOOTING

HYDROSTATIC SYSTEM TROUBLESHOOTING

One Transmission (Right Or Left) Works Correctly And The Other Does Not

Machine Does Not Have Enough Power

HYDROSTATIC SYSTEM TROUBLESHOOTING CHECKS

Check 1- Checking Charge Pressure/Flow

Check 2 – Checking Circuit Relief Valve Pressure

–REMOVAL AND INSTALLATION OF HYDROSTATIC COMPONENTS

TORQUE SPECIFICATIONS

TANDEM (HYDROSTATIC) PUMP

Removal

Installation

HYDRAULIC (DRIVE) MOTOR

Removal

Installation

HYDRAULIC (DRIVE) MOTOR

(EUROPEAN MACHINES AND OPTIONAL NORTH AMERICAN MACHINES)

Removal

Installation

–DRIVE COUPLER

TORQUE SPECIFICATIONS

DRIVE COUPLER

Disassembly

Inspection

AssemblY

–PISTON PUMP

SPECIFICATIONS

SPECIAL TORQUES

GENERAL INFORMATION

SEPaRATING THE PUMPS

ASSEMBLING THE PUMPS

REAR PUMP

Disassembly

Inspection

Assembly

FRONT PUMP

Disassembly, Inspection, and Assembly

–DRIVE MOTORS

Disassembly

Inspection

Assembly

–SPROCKET. CHAINS, AND AXLE ASSEMBLIES

TORQUE SPECIFICATIONS

ADJUSTING THE DEFLECTION OF THE CHAINS

REMOVAL AND INSTALLATION OF AXLES

Removal

Installation

AXLE DISASSEMBLY

AXLE INSPECTION

AXLE ASSEMBLY

–WHEELS AND TIRES

WHEELS AND TIRES

Tire Pressure

Inflating The Tire

Wheel Nut Torque

-Brakes

–BRAKE SYSTEM – “HOW IT WORKS”

(Spring Applied-Cable Release Park Brakes)

EXPLODED VIEW OF SPRING APPLIED – CABLE RELEASE PARK BRAKES

Brake System Overview (Spring Applied – Hydraulic Release Park Brakes)

EXPLODED VIEW OF SPRING APPLIED – HYDRAULIC RELEASE BRAKES AND HYDROSTATIC DRIVE

MOTOR

BRAKE SYSTEM HYDRAULIC DIAGRAM

–BRAKE SYSTEM TROUBLESHOOTING

SPECIFICATIONS

SPECIAL TOOL

Safety Rules

Brake System Troubleshooting (Pin Lock – Cable Release Park Brakes)

Checks To Do Before Troubleshooting

Brake System Troubleshooting

Spring Applied – Hydraulic Release (European Machines And Optional For North American Machines)

–REMOVAL AND INSTALLATION OF PARK BRAKE COMPONENTS

SPECIFICATIONS

Safety Rules

Removal of Pin Lock Park Brakes

Installation of Pin Lock Park Brakes

Removal of Spring Applied, Hydraulic Release Park Brakes

Installation of Spring Applied, Hydraulic Release Park Brakes

–BRAKE SOLENOID VALVE

SOLENOID VALVE

Disassembly

Assembly

–BRAKES – SPRING APPLIED – HYDRAULIC RELEASE(EUROPEAN AND OPTIONAL NORTH AMERICAN MACHINES)

Disassembly

Assembly

–BRAKES – PIN LOCK – CABLE RELEASE

Disassembly

Inspection

Assembly

–BRAKE PUMP

Disassembly

Assembly

-Hydraulics

–HYDRAULIC SYSTEM – “HOW IT WORKS”

HYDRAULIC SYSTEM OVERVIEW

HYDRAULIC COMPONENTS

Components Defined

Reservoir

Hydraulic Pump

LOADER CONTROL VALVE

Functional Overview Of The Loader Control Valve

Component Overview Of The Loader Control Valve

MAIN RELIEF VALVE

Operation: Closed Position

Operation: Open Position

CIRCUIT RELIEF VALVE / ANTI-CAVITATION CHECK VALVE

Direct Acting Circuit Relief Valve

LOADER CONTROL VALVE FUNCTION

Loader Spool Actuated To Raise Loader

Loader Spool Actuated To Lower Loader

Loader Spool Actuated To Raise, Bucket Spool To Rollback

Loader Spool Actuated To Lower, Bucket Spool To Rollback

Loader Spool Actuated To Float

SPOOL LOCK SOLENOIDS

AUXILIARY CIRCUIT

AUXILIARY CONTROL VALVE

HIGH FLOW HYDRAULICS

FILTER RESTRICTION INDICATOR

BI-DIRECTIONAL SELF-LEVELING (BDSL) SYSTEM

Bucket Self-Leveling

Functional Overview Of The Bi-Direction Self-Level Loader Control Valve

Loader Raise & Bucket Self-Leveling

Loader Raise-Bucket At Full Dump

Loader Lower & Bucket Self-Leveling

Loader In Float

Loader Raise & Bucket Dump Self-Leveling Off

BI-DIRECTIONAL SELF-LEVELING SYSTEM TROUBLESHOOTING

–HYDRAULIC SYSTEM TROUBLESHOOTING

SPECIFICATIONS

SPECIAL TOOLS

PRESSURE CHECKS

Loader Main Relief

TESTING CIRCUIT RELIEF VALVES WITH A HAND PUMP

FLOWMETER TESTS

General Information

Test No 1 – Gear Pump

Test No 2 – Loader Circuits and Main Relief Valve

METRIC MEASURE CHECK SHEET

US MEASURE CHECK SHEET

–CLEANING THE HYDRAULIC SYSTEM AND HYDROSTATIC SYSTEM

General Information

Types Of Contamination

Cleaning The Hydraulic System

Lushing Water From The Hydraulic System

Cleaning The Hydrostatic System

Cleaning Hoses, Tubes, And Fittings

–REMOVAL AND INSTALLATION OF HYDRAULIC COMPONENTS

GEAR (EQUIPMENT) PUMP

Removal

Installation

LOADER CONTROL VALVE

Removal

Installation

HYDRAULIC FILTER BASE ASSEMBLY

Removal

Inspection

Installation

HIGH FLOW PUMP (IF EQUIPPED)

Removal

Installation

HIGH FLOW VALVE (IF EQUIPPED)

Removal

Installation

AUXILIARY VALVE (IF EQUIPPED)

Removal

Installation

RIDE CONTROL ACCUMULATOR (IF EQUIPPED)

Removal

Installation

RIDE CONTROL SOLENOID VALVE (IF EQUIPPED)

Removal

Installation

SOLENOID VALVE FOR HYDRAULIC COUPLER

(IF EQUIPPED)

Removal

Installation

HYDRAULIC OIL COOLER

Removal

Installation

–GEAR (EQUIPMENT) PUMP

GEAR (EQUIPMENT) PUMP

Disassembly

Inspection

Assembly

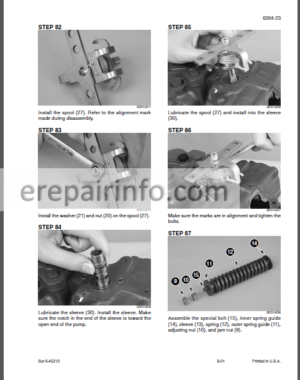

–LOADER CONTROL VALVE

CONTROL VALVE

Disassembly

Inspection

Assembly

DUAL SELF-LEVELING CONTROL VALVE

Disassembly

Inspection

Assembly

–Cylinders

SPECIFICATIONS

SPECIAL TOOLS

GENERAL

Retaining Screw – Tube To Gland Procedure

LOADER LIFT CYLINDER

Disassembly

Inspection

Assembly

LOADER BUCKET CYLINDER

Disassembly

Inspection

Assembly

BACKHOE SWING CYLINDER

Disassembly

Inspection

Assembly

BACKHOE BOOM AND DIPPER CYLINDER

Disassembly

Inspection

Assembly

BACKHOE BUCKET CYLINDER

Disassembly

Inspection

Assembly

BACKHOE FOLD DOWN STABILIZER CYLINDER

Disassembly

Inspection

Assembly

BACKHOE VERTICAL STABILIZER CYLINDER

Disassembly

Inspection

Assembly

–FLAT FACED COUPLERS

FEMALE COUPLER

Disassembly

Assembly

MALE COUPLER

Disassembly

Assembly

–High Flow Valve

HIGH FLOW VALVE

Disassembly

Inspection

Assembly

–D-125 BACKHOE CONTROL VALVE – NA ONLY

SEPARATING THE PARTS OF THE BACKHOE CONTROL VALVE

Inspection

Assembly

CHECK VALVE ASSEMBLY

Disassembly

Assembly

MAIN RELIEF VALVE

CIRCUIT RELIEF VALVE

ASSEMBLING THE PARTS OF THE BACKHOE CONTROL VALVE

–ACCUMULATOR FOR RIDE CONTROL

SPECIFICATIONS

SPECIAL TOOLS

DISCHARGING AN ACCUMULATOR

Disassembly

Inspection

Assembly

CHECKING THE NITROGEN CHARGE IN THE ACCUMULATOR

CHARGING THE ACCUMULATOR WITH DRY NITROGEN

-Mounted Equipment

–PEDALS AND LEVERS

SPECIFICATIONS

SPECIAL TORQUES

THROTTLE CONTROL LINKAGE ADJUSTMENT

Throttle Lever Tension Adjustment

Hand Throttle Adjustment (Without Foot Throttle Option)

Hand Throttle Adjustment (With Foot Throttle Option)

Foot Throttle Adjustment

LOADER CONTROL LINKAGE ADJUSTMENT

Fore/Aft Adjustment

Loader And Bucket Adjustment

LAP BAR HEIGHT ADJUSTMENT

AUXILIARY HYDRAULIC PEDAL

DRIVE CHAINS

Checking The Drive Chain Tension

Drive Chain Tension Adjustment

–LOADER

REPLACING THE CUTTING EDGE ON 40XT BUCKETS

Replacing Welded Cutting Edges

Replacing Bolt-On Cutting Edges

WELD SPECIFICATIONS FOR 40XT BUCKETS

REMOVAL OF THE 40XT LOADER FRAME

INSPECTION OF THE 40XT LOADER FRAME

INSTALLATION OF THE 40XT LOADER FRAME

–ATTACHMENT COUPLER

ATTACHMENT COUPLER (MECHANICAL)

Disassembly

Inspection

Assembly

ATTACHMENT COUPLER (HYDRAULIC)

Disassembly

Inspection

Assembly

–ROPS Canopy, Seat, Seat Belts, and Operators Compartment

Possible Damage To The Rops Canopy

Maintenance And Inspection Of The Rops Canopy

Removal Of The Rops Canopy

Installation Of The Rops Canopy

Removal Of The Rear Window

Installation Of The Rear Window

Removal Of The Side Windows

Installation Of The Side Windows

Removal Of Top Window

Installation Of Top Window

Removal Of The Door Frame Window

Installation Of The Door Frame Window

Removal Of The Front Door

Installation Of The Front Door

Removal Of The Xt Non-Suspension Seat

Installation Of The Seat Belts

Installation Of The Xt Non-Suspension Seat

Removal Of The Xt Suspension Seat

Installation Of The Seat Belts

Installation Of The Xt Suspension Seat

–HEATER

BASIC HEATER

Removal

Inspection

Installation

DELUXE HEATER

Removal

Inspection

Installation

–Backhoe (D125 Backhoe)

BACKHOE

Removal

Installation

PIVOT PIN INSTALLATION

BUCKET TEETH

Tooth Shank Replacement

Tooth Point Replacement

CUTTING EDGES

Bottom Cutting Edge Replacement

Side Cutting Edge Replacement

-Schematic Set

Hydraulic and Electrical Schematic Foldout

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Well worth the price. Clear copies