Factory Service Manual For Case Diesel Tractor And Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 587

Number: 5675

Bookmarks: Yes

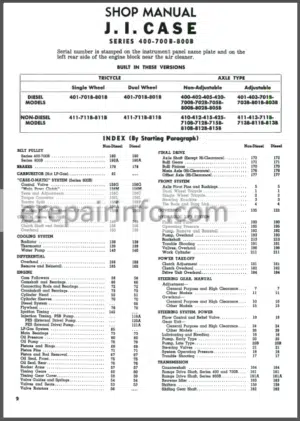

Model

Case Diesel Tractor And Engine

500 Series

Contents

PROFIT THROUGH “QUALIFIED CASE DIESEL SERVICE”

REQUIREMENTS FOR A “QUALIFIED CASE DIESEL SERVICE DEPARTMENT”

SERVICE AND WARRANTY POLICY BETWEEN CASE DEALERS AND OFFICIAL AMERICAN BOSCH DIESEL FUEL INJECTION SERVICE STATIONS

OUTLINE FOR PERFORMING A PERIODIC CHECK-UP ON A “500” SERIES CASE DIESEL TRACTOR

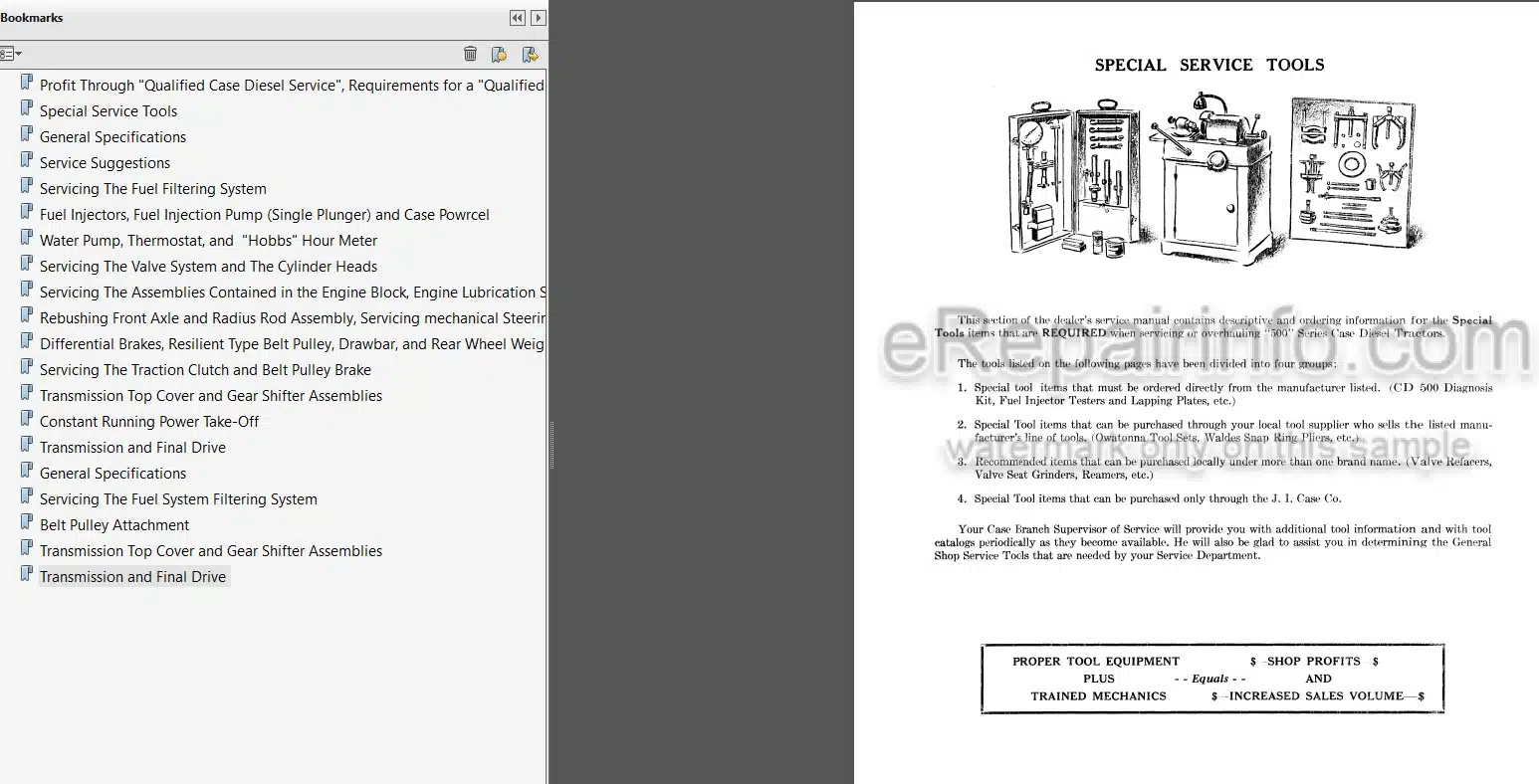

-SPECIAL SERVICE TOOLS

Introduction

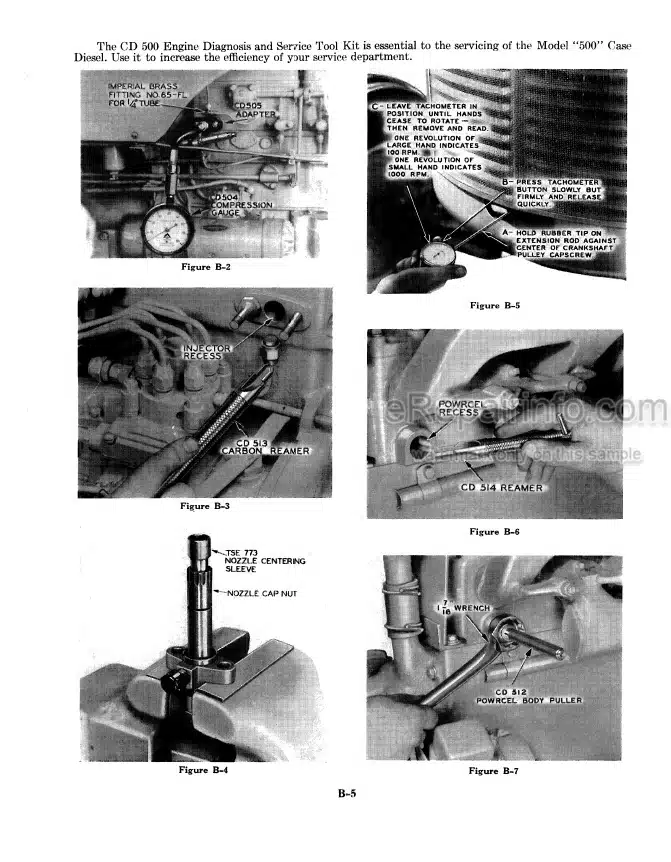

Model “500” Case Diesel Engine Diagnosis and Service Tool Kit

Fuel Injector Test Stand and Lapping Plate

Owatonna Service Tool Set

Special Snap Ring Tools (Purchased Locally)

Valve and Cylinder Head Service Tools

Miscellaneous Shop Service Tools (Purchased Locally)

Special Wrenches (Purchased Through J I Case Company or Local Snap-On Tool Company Representatives)

Special Service Tools (Purchased Through J I Case Company)

Special Hydraulic Service Tools (Purchased Through J I Case Company)

-GENERAL SPECIFICATIONS

General Dimensions, Speeds, Weights, and Capacities

General Engine Specifications

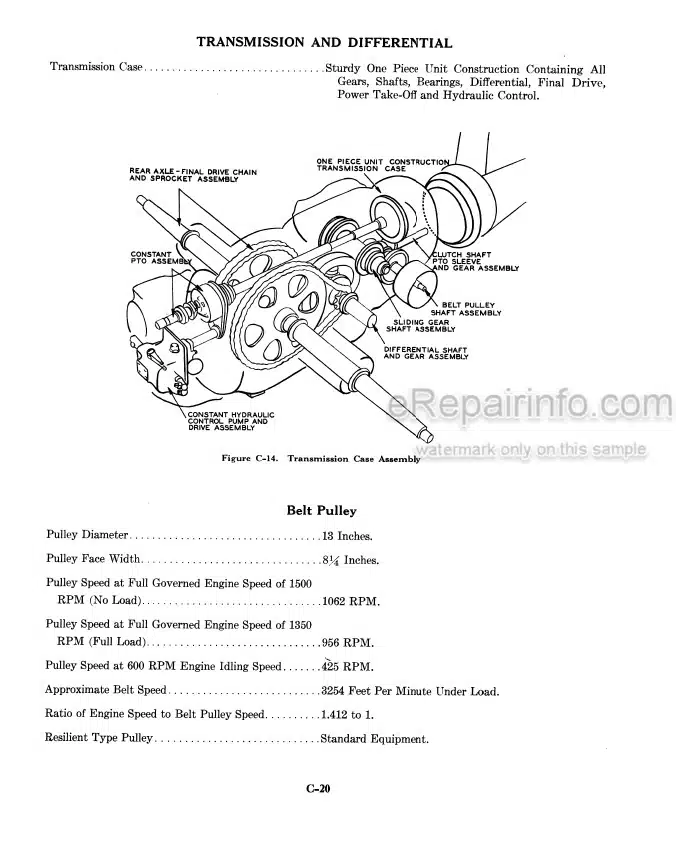

Transmission and Differential

Tightening Specifications

-SERVICE SUGGESTIONS

Engine Will Not Start or is Difficult to Start

Smoke From Engine Exhaust

Excessive Fuel Consumption

Excessive Oil Consumption

Contamination in the Crankcase Oil

Engine Will Not Stop When Fuel Is Shut Off

Traction Clutch

Generator

Starting Motor

Noise, Knocks and Vibration

Difficulty in Shifting

Constant Running Power Take-off

Hydraulic Power Steering

Engine Hour Meter

Oil Leakage

-SERVICING THE FUEL FILTERING SYSTEM

Fuel Flow Diagram

General Description of Fuel Filtering System

Checking Fuel Flow Through Filtering System

Visual Inspection of Fuel System

Servicing Fuel Lincs

Bleeding the Fuel System

Fuel Tank Breather Air Filter

Fuel Tank Screen

Fuel Tank Water Trap

Cleaning the Fuel Tank

Servicing First Stage Filter

Servicing Second Stage Filter

Servicing Final Fuel Filter and Pressure Relief Valve

-FUEL INJECTORS, FUEL INJECTION PUMP (SINGLE PLUNGER) AND CASE POWRCEL

Fuel Injectors

American Bosch Model PSB Single Plunger Fuel Injection Pump

Case Powrcel

-WATER PUMP, THERMOSTAT, AND “HOBBS” HOUR METER

Water Pump

Thermostat

Hobbs Hour Meter

-SERVICING THE VALVE SYSTEM AND THE CYLINDER HEADS

General Description of Valve System and Cylinder Head

Service Operations That Can Be Performed Without Removing

Service Operations That Require Removal of Cylinder Head From Engine

Hood Removal and Installation

Valve (/Over Removal and Installation

Crankcase Breathers

Valve Tappet Clearance Adjustment

Rocker Arm and Decompressor Assembly

Manifolds (Intake, Exhaust and Water)

Cylinder Head Removal and Installation

Servicing the Valves and Valve Seats

-SERVICING THE ASSEMBLIES CONTAINED IN THE ENGINE BLOCK

Engine Lubrication System

Pistons – Connecting Rods and Cylinder Sleeves

Crankshaft – Main Bearings and Flywheel

Camshaft and Push Rod Lifters

Fuel Injection Pump Drive and Timing Gear Train

REBUSHING FRONT AXLE AND RADIUS ROD ASSEMBLY

SERVICING MECHANICAL STEERING ASSEMBLIES

SERVICING POWER STEERING

DIFFERENTIAL BRAKES

RESILIENT TYPE BELT PULLEY

DRAWBAR

REAR WHEEL WEIGHTS

-SERVICING THE TRACTION CLUTCH AND BELT PULLEY BRAKE

Clutch Specifications

Reassembling the Traction Clutch on the Tractor

Servicing the Traction Clutch

Traction Clutch and Belt Pulley Brake

-TRANSMISSION TOP COVER AND GEAR SHIFTER ASSEMBLIES

Removing and Servicing the Gear Shift Lever

Servicing the Shifter Assembly

Transmission Top Cover

-CONSTANT RUNNING POWER TAKE-OFF

Constant Running Power Take-off

Crankcase Oil Passing Into The Transmission and Transmission

-TRANSMISSION AND FINAL DRIVE

Transmission and Final Drive

-GENERAL SPECIFICATIONS

Diesel Engine

Spark Ignition Engine

-SERVICING THE FUEL SYSTEM FILTERING SYSTEM

Fuel Flow Diagram

General Description of Fuel Filtering System

Checking Fuel Flow Through Filtering System

Visual Inspection of Fuel System

Servicing Fuel Lines

Bleeding the Fuel System Fuel Tank Breather Air Filter Fuel Tank Screen

Fuel Tank Water Trap

Cleaning the Fuel Tank

Gum and Varnish In the Fuel

Servicing First Stage Filter

Servicing Second Stage Filter

Servicing Final Fuel Filter and Pressure Relief Valve

-BELT PULLEY ATTACHMENT

Servicing the Belt Pulley Attachment

Tools Required

Service Diagnosis

Removing the Belt Pulley Attachment

Disassembly of the Belt, Pulley

Replacing the Pilot Bushing in the First Reduction Shaft

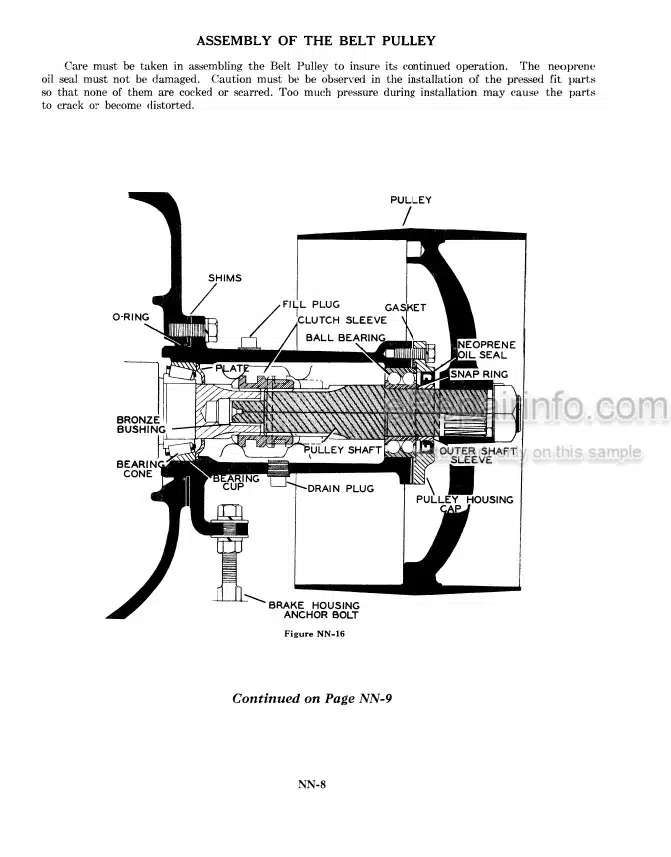

Assembly of the Belt Pulley

Assembly of the Belt Pulley Clutch

Installing the Belt Pulley Attachment, on Case “GOO” Series Tractors

-TRANSMISSION TOP COVER AND GEAR SHIFTER ASSEMBLIES

Transmission Top Cover

Removing and Servicing the Gear Shift Lever

Transmission Shifter Assemblies

-TRANSMISSION AND FINAL DRIVE

Transmission And Final Drive

Sliding gear Shaft

First Reduction Shaft

Reverse Idler Gear

Differential Gear Assembly

Systematic Checks for Isolating Transmission Noise

Rear Axle Assembly

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.