Factory Service Manual For Case WX210 WX240 Hydraulic Excavator. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 674

Number: 9-911270

Bookmarks: Yes

Searchable: Yes

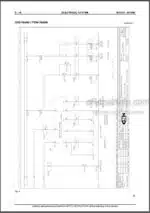

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Case WX210, WX240

Contents

-SAFETY INSTRUCTIONS

Preface

Safety Instructions

-TECHNICAL DATA & SPECIAL TOOLS

–SERVICE DATA GENERAL

Foreword

Technical Characteristics

Si- And Additional Units

Conversions Tables Part 1

Conversions Tables Part 2

Tightening Torques

Calculation Examples

Special Tools For Cylinders

Special Tools For Axles And Gearboxes Spacers

-MACHINE STRUCTURE

–MACHINE CONSTRUCTION

Description Of The Machine (Boom-Adjusting Equipment)

Description Of The Machine (Monoblock Boom)

Superstructure Components, Overview

Engine Assembly Components, Overview

Hydraulic System Components, Overview

Drive Unit Components, Overview

Undercarriage Components, Overview

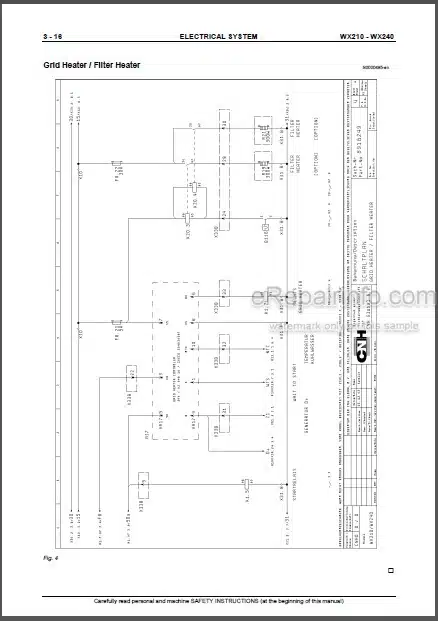

-Electrical System

–ELECTRICAL SYSTEM

Control

The Electrical System

Fuses

Electrical Circuit Diagrams, Part Number 8916249,1-42

Electrical Circuit Diagrams For Supplementary Functions

Layout Of Electrical Components

Electrical System – Central Electronics (Behind Driver’S Seat)

Electrical System For Electro-Hydraulic Pilot Control

Electrical System Of Pilot-Control Unit, Solenoid Valves, Sensors And Switches

Electrical System In Engine Compartment

Electrical System For Undercarriage Control Block

Electrical System For Undercarriage Stabilization, The Fig. Shows Individual Stabilization Variant A4

Electrical Components By Code Numbers

Connector Pin Assignment Table For Connector X33A

Connector Pin Assignment Table For Connector X33B

Connector Pin Assignment Table For Connector X33C

Connector Pin Assignment Table For Connector X33D

Connector Pin Assignment Table For Connector X33E

Connector Pin Assignment Table For Connector X33P

-ELECTRONICS

Control

Electronic Control Unit

Power Supply

Components At Can Bus 1

Components At Can Bus 2

Esx Coding

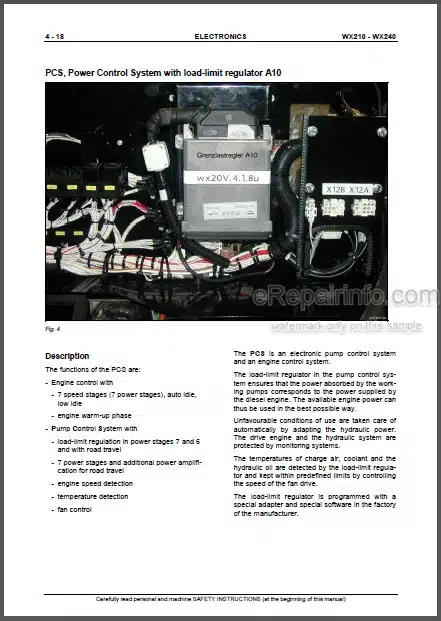

Pcs – Power Control System

Pcs Components

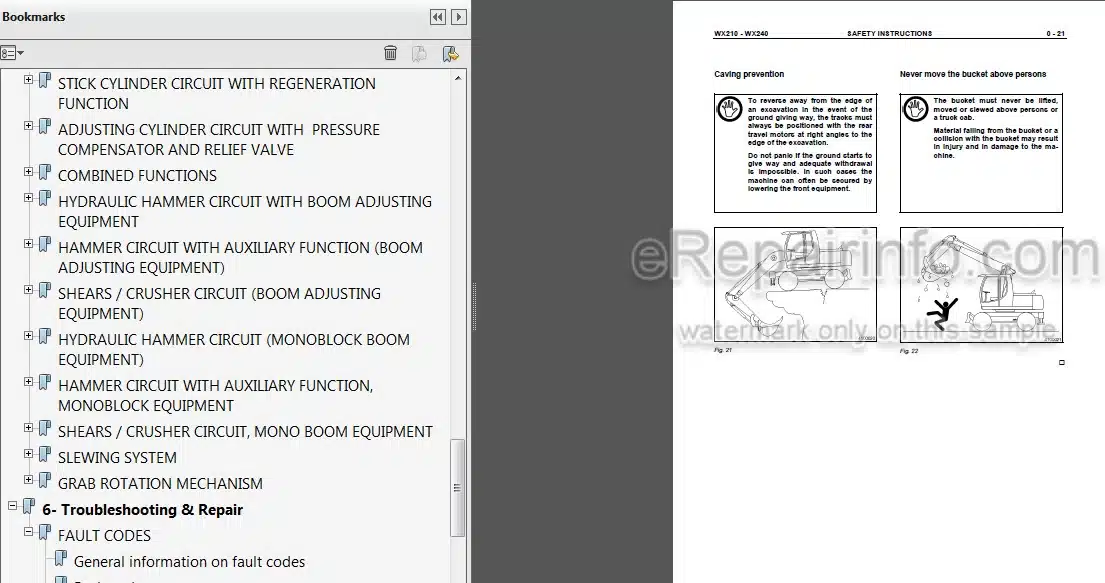

-HYDRAULICS

Control

Hydraulic System

Drive Unit

Control Block

Pilot-Control System

Travel Circuit Of 20 Km/H Version

Travel Circuit Of 25 And 30 Km/H Versions

Braking, Steering And Fan Circuit

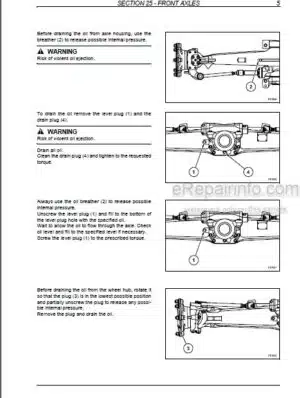

Undercarriage, Stabilizers

Boom Cylinder Circuit

Bucket Cylinder Circuit

Stick Cylinder Circuit With Regeneration Function

Adjusting Cylinder Circuit With Pressure Compensator And Relief Valve

Combined Functions

Hydraulic Hammer Circuit With Boom Adjusting Equipment

Hammer Circuit With Auxiliary Function (Boom Adjusting Equipment)

Shears / Crusher Circuit (Boom Adjusting Equipment)

Hydraulic Hammer Circuit (Monoblock Boom Equipment)

Hammer Circuit With Auxiliary Function, Monoblock Equipment

Shears / Crusher Circuit, Mono Boom Equipment

Slewing System

Grab Rotation Mechanism

-TROUBLESHOOTING & REPAIR

–FAULT CODES

General information on fault codes

Fault codes

Fault codes PCS unit

Fault codes, Central Unit

-REPAIR INSTRUCTIONS

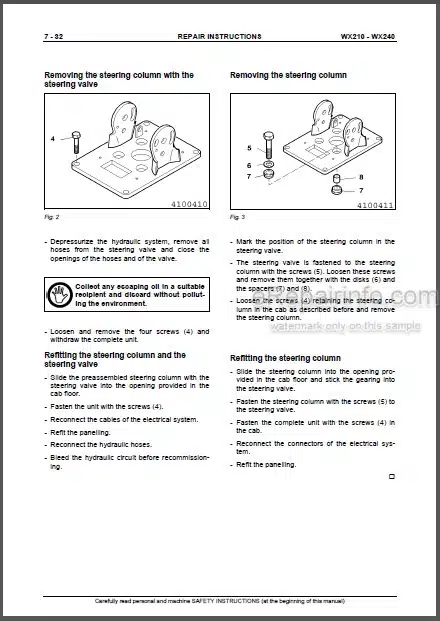

Repair Instructions

Superstructure Components

Link Between Superstructure And Undercarriage Components

Undercarriage Components

Equipment, Components

Wear Parts

Engine

What you get

You will receive a PDF file with a high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.