Factory Service Repair Manual For Claas Nectis 207 SERIES Tractor. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

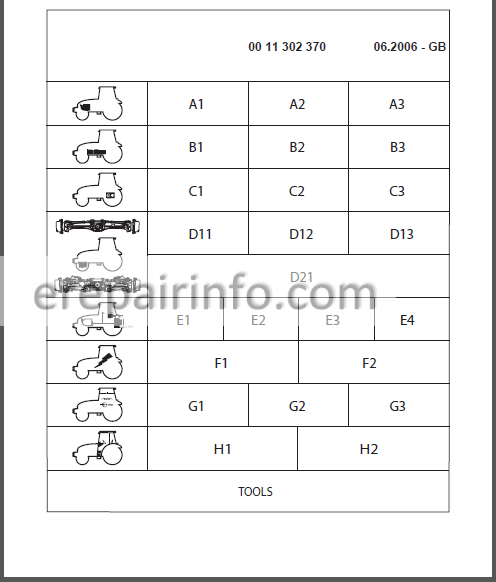

Model

Claas Nectis 217, 227, 237, 247, 257, 267

Contents

–TEST PROCEDURE – INJECTOR INSTRUCTION SHEETS

–TEST PROCEDURE

List Of Checks

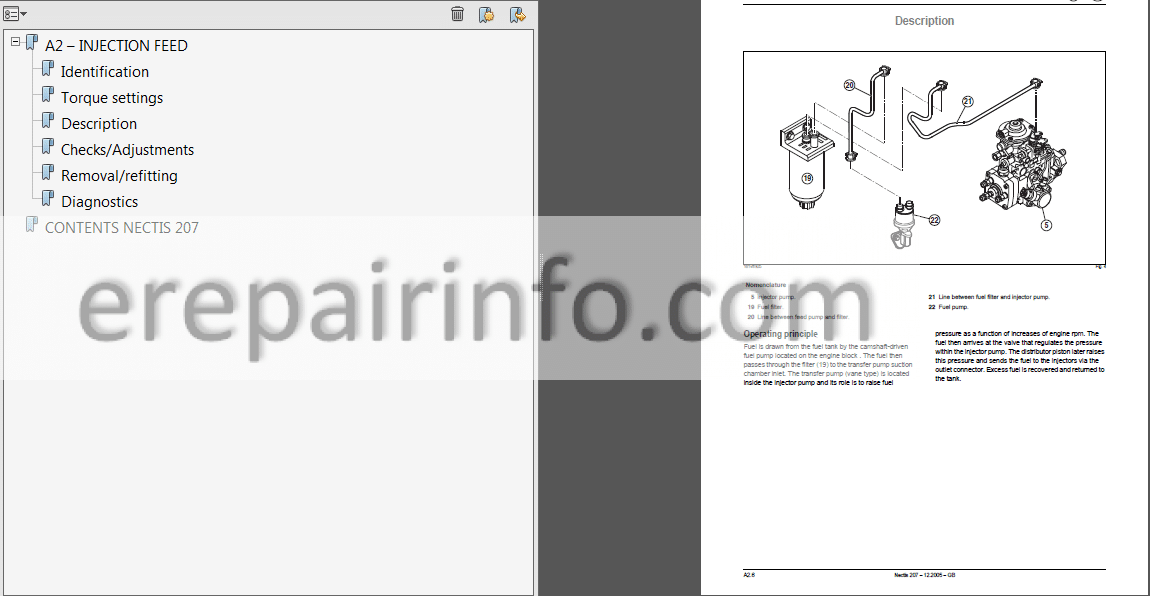

-INJECTION FEED

–IDENTIFICATION

Identification Of Injector Pumps

–TORQUE SETTINGS

Torque Settings

–DESCRIPTION

Injector Pump

Fuel Pump

Line Filter

Fuel Filter

Electrical Components

–CHECKS/ADJUSTMENTS

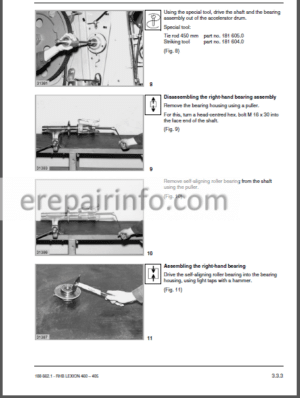

Accelerator Control Adjustment

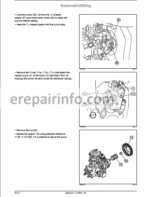

Injector Pump

Injector

Supply Pressure

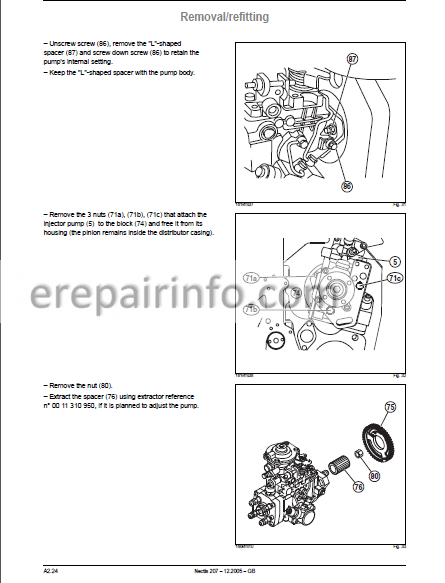

–REMOVAL/REFITTING

Fuel Filter

Injection System

Injector Pump

Injectors

–DIAGNOSTICS

Diagnostic Sheets

-IVECO ENGINE

–GENERAL SPECIFICATION

Engine Identification

3 Cylinder Engines

4 Cylinder Engines

–LUBRICATION

Operation

–COOLING

Operation

–TURBOCHARGER

Operation

–DIMENSIONS

Dimensions – Build Clearances

Valves

–TORQUE SETTINGS

Front Chassis I Engine Link

Enginbtransmission Link

–CHECKS/ADJUSTMENTS

Compression

Engine Oil Pressure

Turbocharger Pressure

Valves

Belt And Tensioner

Cylinder Head

Engine Block

Connecting Rods

Crankshaft

Camshaft

Viscous Fan Coupling

–REMOVAL/REFITTING

Preliminary Operations

Engine/Front Drive Train (Splitting)

Enginb/Gearbox (Splitting)

Engine Replacement

Cylinder Head

Pistons And Connecting Rods

Flywheel

Crankshaft

Front Bearing Oil Seal

Rear Bearing Seal

Camshaft Balance Shafts And Auxiliary Drive Gears

Oil Cooler

Oil Pump

Thermostat

Water Pump

Turbocharger

-GEARBOX

–MECHANICAL PART

—GENERAL SPECIFICATION

Description Of Gearbox With Mechanical Clutch Reverser And Doubler

Description Of Gearbox With Mechanical Pto, Hydraulic Reverser And Doubler

Transmission Kinematics

—DISMANTLING PROCEDURE

Dismantling Procedure

—TIGHTENING TORQUES AND MAIN ADJUSTMENTS

Gearbox With Mechanical Reverser And Doubler

Gearbox With Hydraulic Reverser And Doubler

—TORQUE SETTINGS AND SEALANTS

Interface Between Engine And Clutch Housing

Interface Between Clutch Housing And Gearbox Casing

—TRANSMISION WITH MECHANICAL CLUTCH

Pto And Vehicle Drive Clutch

Mechanical Doubler

Mechanical Reverser

—TRANSMISSION WITH HYDRAULIC REVERSER AND DOUBLER

Power Take-Off Clutch

Hydraulic Reverser And Doubler

—GEARBOX

Gear Casing

Range Change Casing

Removing The Shafts

Refitting The Shafts

–HYDRAULIC PART

—2 PUMP HYDRAULIC SYSTEM

Nomenclature For Mechanical Reverser And Doubler System

Nomenclature For Hydraulic Reverser And Doubler System

Schematic Diagram Of Hydraulic Reverser And Mechanical Doubler

Location Of Reverser And Mechanical Doubler Components

Hydraulic Schematic Of Hydraulic Reverser And Doubler

Location Of Hydraulic Reverser And Doubler Components

—3 PUMP HYDRAULIC SYSTEM

Schematic Diagram Of Hydraulic Reverser And Mechanical Doubler

Location Of Reverser And Mechanical Doubler Components

Hydraulic Schematic Of Hydraulic Reverser And Doubler

Location Of Hydraulic Reverser And Doubler Components

Nomenclature For Mechanical Reverser And Doubler System

Nomenclature For Hydraulic Reverser And Doubler System

—18 BAR LOW PRESSURE SYSTEM WITH CLUTCHLESS REVERSER

Description

Description

Control Logic For Clutchless Reverser And “Twinshift” Doubler

“Safety Patch” Solenoid Valve

—LOW PRESSURE LUBRICATION SYSTEM FOR CLUTCHLESS REVERSER

Description

Transfer Air Pump

Cross-Section Of Clutch Lubrication

Checking Flow From The ‘safety Patch” Solenoid Valve

Checking The Pressure In The Clutchless Reverser Unit

Checking The Pressure In The Slow Forwards Clutch

Checking The Pressure In The Fast Forwards Clutch

Checking The Pressure In The Reverse Clutch

Checking The Clutch Lubrication Pressures

Check Accumulator Pressure

Checking The Flow From The Hydraulic Pump (2-Pump System) Checking The Flow From The 3Rd Pump

Checking The Transfer Air Pump

—“INSPECTION RESULTS” SHEET

Checking Flow From The ‘safety Patch” Solenoid Valve

Checking The Pressure In The Clutchless Reverser Unit

Checking The Pressure In The Slow Forwards Clutch

Checking The Pressure In The Fast Forwards Clutch

Checking The Pressure In The Reverse Clutch

Checking The Clutch Lubrication Pressures

Check Accumulator Pressure

Checking The Flow From The 3Rd Pump

–ELECTRONIC COMPONENTS

—GEARBOX ELECTRONIC CONTROL

Introduction To The ‘ehm 24’

“Ehm 24” Inputs/Outputs

“”Safety Patch’” Safety

Shuttle Reverser

Mechanical Reverser

Clutch Pedal

Twinshift Doubler

—COMPONENT LAYOUT

COMPONENT LAYOUT

—ELECTRICAL TESTS

Supply Circuit Switch

Earthing Switch

Control Lever

Contact Sensor

Temperature Sensor (Thermistor)

Hall Effect Sensor

“Ehm 24” Electronics Unit, “Safety Patch” And Timer Unit

Proportional Solenoid Valve

On/Off Solenoid Valve

—MEASUREMENT AND CHECK POINTS

Checks Of Transmission Oil Pressure Switches, Slow Forward, Fast Forward And Reverse (118A), (118B), (118C)

Checking The Transmission Temperature Sensor (114)

Checking The Speed Sensor (37)

Checking Supply Voltages To Units (184), (306)

Functional Check Of “Safety Patch’

Checking The +/- Control Switches (238)

Checking The Proportional Solenoid Valves (192A), (192B), (192C)

Checking The Reverser Selector (188)

Checking The Clutch Pedal Switch (189)

Checking The Clutch Pedal Position Sensor (187)

Checking The Mechanical Reverser Neutral Switch (314)

Checking The Range Iii Sensor (68)

—“INSPECTION RESULTS” SHEET

Checking Pressure Switches (118A), (118B), (118C)

Checking Temperature Sensor (114)

Checking The Speed Sensor (37)

Checking Supply Voltages To Units (184), (306)

Checking The +/- Control Switches (238)

Checking The Proportional Solenoid Valves (192A), (192B), (192C)

Checking The Reverser Selector (188)

Checking The Clutch Pedal Switch (189)

-REAR AXLE

–Mechanical Part

—Tightening Torques And Main Adjustments

Rear Axle

Axle Tubes

—Drive Pinion

Exploded View

Removal

Refitting

Adjusting Pinion Meshing

—Differential

Exploded View

Removal

Removing’Refitting The Differential Housing

Preload Of Differential Housing Bearings

Adjusting The Backlash

—Axle Tubes

Exploded View Of The Normal Duty Narrow And Wide Vineyardorchard Axle Tube

Exploded View Of The Heavy Duty Wide V1Neyard/Orchard Axle Tube

Removal/Refittlng

Removal/Refittlng The Planet Carriers

Removal/Refitting The Bearings And Seals

Adjusting The Wheel Shaft Ball Bearings (W1Db0Rchard Normal Duty Axle Tube)

Adjusting The Wheel Shaft Taper Bearings (Narrow And Heavy Duty Axle Tube)

Replacing A Wheel Stud

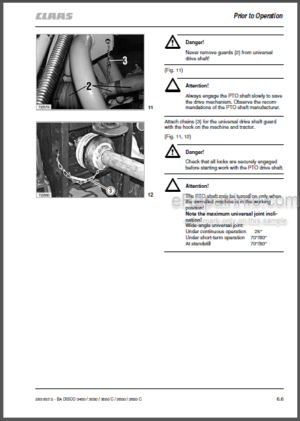

—Power Take-Off (Pto)

Exploded View Of 540 Rpm Version

Exploded View Of 540/1000 Or 540/540 Economic Version

Removal/Refittlng

—BRAKES

Exploded View Of Brake Mechanism

Exploded View Of Main Brake Controls

Removali’refittlng Of Brake Mechanism

Adjusting The Main Brake Control Mechanism

Removal/Refitting Of Brake Pedals

Adjustment Of The Brake Pedals

Removali’refittlng Of Master Cylinders

Adjusting The Master Cylinders

Removali’refittlng Of The Hand Brake

Hand Brake Adjustment

–HYDRAULIC PART

—HYDRAULIC SYSTEM

Nomenclature For Mechanical Reverser And Doubler System

Nomenclature For Hydraulic Reverser And Doubler System

Schematic Diagram Of Hydraulic Reverser And Mechanical Doubler

Component Layout (Mechanical Reverser And Doubler)

Hydraulic Schematic Of Hydraulic Reverser And Doubler

Component Layout (Hydraulic Reverser And Doubler)

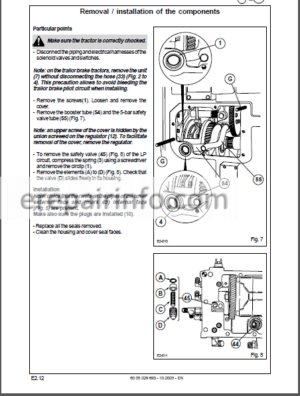

—LOW PRESSURE CIRCUIT 18 BAR

DESCRIPTION OF HYDRAULIC SYSTEM (MECHANICAL REVERSER AND DOUBLER)

DESCRIPTION OF HYDRAULIC SYSTEM (HYDRAULIC REVERSER AND DOUBLER)

—DIFFERENTIAL LOCK

Differential Lock Piston

Functional Logic

—REAR POWER TAKE-OFF

Description Of Control System

Lubrication

Adjustment

—BRAKING SYSTEM

Description

Draining The Primary Brake Circuit

Flushing The Primary Brake System

Bleeding The Primary Brake Circuit

—MEASUREMENT AND CHECK POINTS

Checking The Pressure In The Clutchless Reverser Unit

Checking The Flow From The Hydraulic Pump

Checking The Flow From The 3Rd Pump

Differential Lock Pressure Check

Checking The Pto Clutch Spool Valve Pressure

Brake Valve Check

—“INSPECTION RESULTS” SHEET

Differential Lock Pressure Check

Checking The Pto Clutch Spool Valve Pressure

–ELECTRONIC COMPONENTS

—REAR AXLE ELECTRONIC CONTROL

Differential Monitoring

Rear Pto Control

Adjusting The Micro-Switches (41 5455 308 309)

—COMPONENT LAYOUT

Component Layout

—ELECTRICAL TESTS

Supply Circuit Switch

Earthing Switch

On-Off Solenoid Valve

Speed Sensor

—MEASUREMENT AND CHECK POINTS

Checking Diffential Lock Switch (232)

Checking Clutch Contactor (309) Pto Selector (308 55 5441) And Parking Brake Contactor (204)

Checking Rear Differential Solenoid Valve (102)

Checking The Brake Fluid Level Switch (214)

Checking The Brake Pedal Contactors (203A 203B)

—“INSPECTION RESULTS” SHEET

Checking Diffential Lock Switch (232)

Checking Clutch Contactor (309) Pto Selector (308 55 5441)

Differential Solenoid Valve Voltage (102)

Checking The Brake Fluid Level Switch (214)

Checking Brake Pedal Contactors (203A 2OЗB)

-FRONT AXLE

–MECHANICAL PART

—GENERAL

General Characteristics Of Front Axles

Tables Of Front Axle Static And Dynamic Loadings

Identification Plate

Type Of Axle

Reduction And Front’rear Inter-Axle Ratios

Preponderance

—TORQUE SETTINGS AND SEALANTS

Axle “2009 C” (Narrow Vineyard)

Axle “2009” (3 Cylinder Wide Vineyard)

Axle “2009” (3 Cylinder Orchard)

Axle “2011” (4 Cylinder Wide Vineyard)

Axle “2011” (4 Cylinder Orchard)

—WHEEL ALIGNMENT

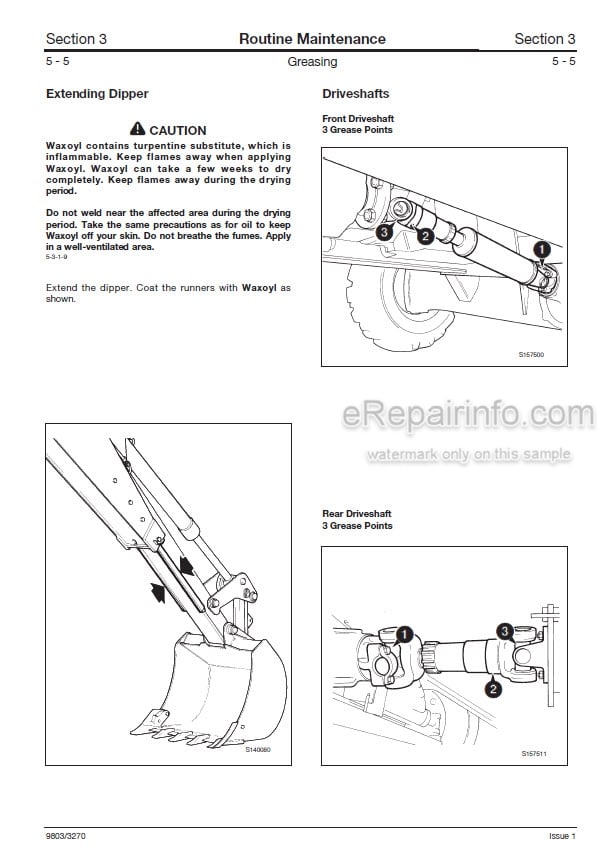

Method Of Adjustment

—REMOVAL/REFITTING OF SUSPENDED FRONT AXLE

Exploded View Of Front Axle Sub-Frame And Mount

Removal

Refitting

—REMOVAL/REFITTING OF AXIAL FRONT AXLE

Exploded View Of Front Axle Sub-Frame And Mount

Removal

Refitting

—STEERING ACTUATOR FOR SUSPENDED AXLE

Exploded View

Removal

Refitting

Dismantling

Refitting

—STEERING ACTUATOR FOR THE AXIAL AXLE

Exploded View

Removal

Refitting

Dismantling

Refitting

—REDUCTION GEAR AND WHEEL HUB FOR “2009 C” AXLE

Exploded View

Removing The Epicyclic Reduction Gear

Refitting The Epicyclic Reduction Gear

Removing The Wheel Hub

Refitting The Wheel Hub

—REDUCTION GEAR AND WHEEL HUB FOR “2009” AND “2011” AXLES

Exploded View Of Reduction Gear And Wheel Hub For ’2009* Axle

Exploded View Of Reduction Gear And Wheel Hub For *2011* Axle

Removing The Epicyclic Reduction Gear

Refitting The Epicyclic Reduction Gear

Removing The Wheel Hub

Refitting The Wheel Hub

—WHEEL KING PINS AND HUB CARRIER

Removal Of King Pins

Refitting The King Pins

Removal Of Hub Carrier

Refitting The Hub Carrier

—CROWN WHEEL AND PINION AND DIFFERENTIAL

Exploded View Of The Pinion Gear For The Suspended Axle

Exploded View Of The Crown Wheel And Pinion For The Suspended Axle

Removal Of Crown Wheel And Pinion

Refitting The Crown Wheel And Pinion

Exploded View Of Differential Case

Dismantling The Differential

Installing The Differential

Adjusting The Crown Wheel And Pinion

—4-WHEEL DRIVE UNIT WITH ELECTRO-HYDRAULIC ENGAGEMENT

Sectional View

Removal

Refitting

Exploded View

Dismantling

Refitting

—4-WHEEL DRIVE UNIT WITH MECHANICAL ENGAGEMENT

Sectional View

Removal

Refitting

Exploded View

Dismantling

Refitting

–HYDRAULIC PART

—HYDRAULIC SYSTEM

2 Pump Hydraulic System (Mechanical Reverser And Doubler)

Component Layout

3 Pump Hydraulic System (Hydraulic Reverser And Doubler)

Component Layout

—FRONT AXLE ENGAGEMENT

Operating Principle

Functional Logic

—MEASUREMENT AND CHECKING POINTS

Checking The Front Axle Engagement Pressure

—“INSPECTION RESULTS” SHEET

Checking The Front Axle Engagement Pressure

–ELECTRONIC COMPONENTS

—ELECTRONIC CONTROL OF FRONT AXLE

Controlling Front Axle Engagement

Input’output

Schematic Diagram

—COMPONENT LAYOUT

Component Layout

—ELECTRICAL TESTS

Supply Circuit Switch

On-Off Solenoid Valve

—MEASUREMENT AND CHECKING POINTS

Checking Diffential Lock Switch (232)

Checking The Front Axle Engagement Switch (234)

Checking The Front Axle Engagement Solenoid Valve (101)

—“INSPECTION RESULTS” SHEET

Checking The Front Axle Engagement Switch (234)

Checking The Front Axle Engagement Solenoid Valve (101)

-COMMON ELEMENTS

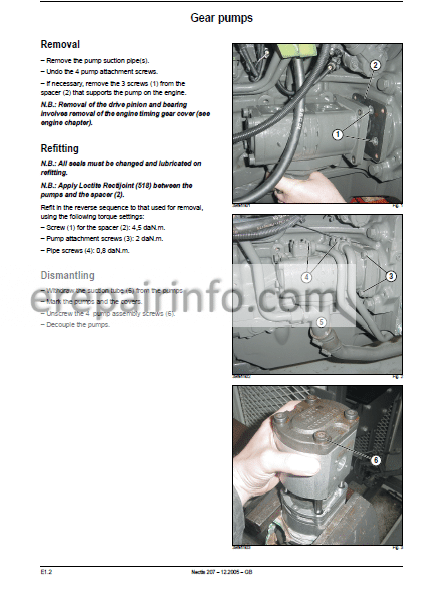

–GEAR PUMPS

Removal

Refitting

Dismantling

Refitting

–STEERING UNIT

Hydraulic Schematic For “Ospc 80 On” Unit

Exploded View Of ‘ospc 80 On’ Pump

Hydraulic Schematic For Rospf 80 Ls* Unit

Exploded View Of ‘ospf 80 Ls” Pump

Removal

Refitting

Dismantling

Refitting

–BRAKE VALVE

Cross Section Of Cee Valve

Hydraulic Schematic For The Cee Valve

Cross Section Of Italy Valve (Cuna)

Hydraulic Schematic Of Italy Valve (Cuna)

Removal

Refitting

–AUXILIARY SPOOL VALVES

Exploded View Of Auxiliary Spool Valves (All Systems)

Spool Valve Hydraulic Schematic (All Systems)

Exploded View Of Spool Valves (2-Pump System)

Spool Valve Hydraulic Schematic (2-Pump System)

Exploded View Of Spool Valves (3-Pump System)

Spool Valve Hydraulic Schematic (3-Pump System)

Cross Section Of A 3 Position Spool Valve

Cross Section Of A 4 Position Spool Valve

Cross Section Of 190 Bar Relief Valve (1-2-Pump System)

Cross Section Of Regulator (2-Pump System)

Cross Section Of Regulator (3-Pump System)

Cross Section Of Regulator (3-Pump System)

Cross Section Of Blanking Plate {2-3-Pump System)

Removal

Refitting

Control Adjustments

–DUAL SPOOL VALVE

Hydraulic Diagram

Sectional View

Removal

Refitting

Control Adjustments

–LINKAGE SWING ACTION SPOOL VALVE (TRACTOR VF 2-ACTUATOR INSTALLATION)

Hydraulic Diagram

Sectional View

Removal

Refitting

–LINKAGE SYSTEM SELECTOR

Hydraulic Diagram

Sectional View

Removal

Refitting

Dismantling

Refitting

–SWING ACTUATOR

Removal

Refitting

–HYDRAULIC JACK

Hydraulic Diagram Exploded View

Dismantling

Refitting

–MECHANICAL LINKAGE SPOOL VALVE

Hydraulic Diagram

Cross Sections

Removal

Refitting

–TCE G ELECTRONIC LINKAGE SPOOL VALVE

Hydraulic Diagram

Cross Sections

Exploded View

Removal

Refitting

–LINKAGE HOUSING

Removing The Linkage Housing

Removing The Linkage Housing

Exploded View Of The Housing And The Arms

Dismantling The Linkage Actuator

Refitting The Linkage Actuator

Exploded View Of Force Control

Dismantling The Linkage Arms

Adjustment To The Force Control Spring

Refitting The Linkage Arms

Exploded View Of The Internal Rods And Levers

Dismantling Internal Rods And Levers

Adjusting Internal Rods And Levers

Refitting Of Internal Rods And Levers

Adjusting The External Controls

Removal Of Additional Actuator

Refitting The Additional Actuator

-PUMP SYSTEM 1

–DESCRIPTION

Characteristics

–COMPONENT LAYOUT

General

Hydraulic Diagram

Circuit Layout On Beam

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking Flow From The 144 Cm3 Pump

Checking Maximum Steering Actuator Pressure

Adjusting The Antishock Valves

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking Flow From The 144 Cm3 Pump

Checking Maximum Steering Actuator Pressure

Adjusting The Antishock Valves

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Brake Valve Check

Electrical Checks On The Solenoid Actuator For The Italie (Cuna) Brake Valve

Checking Maximum Flow And Pressure In Auxiliary Spool Valves

Checking Flow To The Linkage Spool Valve

Checking Pressure At The Primary Linkage Valve

–“HYDRAULIC INSPECTION RESULTS” SHEET

Electrical Checks On The Solenoid Actuator For The Italie (Cuna) Brake Valve

Checking Maximum Flow And Pressure In Auxiliary Spool Valves

Checking Flow To The Linkage Spool Valve

Checking Pressure At The Primary Linkage Valve

-2-PUMP SYSTEM

–DESCRIPTION

CHARACTERISTICS

–COMPONENT LAYOUT

General

Hydraulic Diagram (Mechanical Reverser And Doubler)

Circuit Layout On Beam (Mechanical Reverser And Doubler)

Hydraulic Diagram (Hydraulic Reverser And Doubler)

Circuit Layout On Beam (Hydraulic Reverser And Doubler)

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking Flow From 108 Cm5 Steering Pump

Checking Maximum Steering Actuator Pressure

Adjusting The Antishock Valves

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking Flow From 10,8 Cm5 Steering Pump

Checking Maximum Steering Actuator Pressure

Adjusting The Antishock Valves

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking Flow From The 192 Cm3 Pump

Brake Valve Check

Electrical Checks On The Solenoid Actuator For The Italie (Cuna) Brake Valve

Checking Maximum Flow And Pressure In Auxiliary Spool Valves

Checking The Flow From The Dual Spool Valve

Checking The Maximum Pressure From The Dual Spool Valve

Electrical Checks Of Linkage Arm Swing Acton Solenoid Valves

Checking Flow To The Linkage Spool Valve

Checking Pressure At The Primary Linkage Valve

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking Flow From The 192 Cm3 Pump

Electrical Checks On The Solenoid Actuator For The Italie (Cuna) Brake Valve

Checking Maximum Flow And Pressure In Auxiliary Spool Valves

Checking The Flow From The Dual Spool Valve

Checking The Maximum Pressure From The Dual Spool Valve

Electrical Checks Of Linkage Arm Swing Acton Solenoid Valves

Checking Flow To The Linkage Spool Valve

Checking Pressure At The Primary Linkage Valve

-3-PUMP SYSTEM

–DESCRIPTION

CHARACTERISTICS

–COMPONENT LAYOUT

General

Hydraulic Diagram (Mechanical Reverser And Doubler)

Circuit Layout On Beam (Mechanical Reverser And Doubler)

Hydraulic Diagram (Hydraulic Reverser And Doubler)

Circuit Layout On Beam (Hydraulic Reverser And Doubler)

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking Flow From The 192 Cm3 Pump

Checking Maximum Steering Actuator Pressure

Adjusting The Antishock Valves

Brake Valve Check

Electrical Checks On The Solenoid Actuator For The Italie (Cuna) Brake Valve

Checking The Maximum Flow And Pressure For Auxiliary Spool Valves № 12 Or 3

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking Flow From The 192 Cm3 Pump

Checking Maximum Steering Actuator Pressure

Adjusting The Antishock Valves

Electrical Checks On The Solenoid Actuator For The Italie (Cuna) Brake Valve

Checking The Maximum Flow And Pressure For Auxiliary Spool Valves № 1 2 Or 3

–HYDRAULIC MEASUREMENT AND CHECKING POINTS

Checking Flow From The 144 Cm3 Pump

Checking The Maximum Flow And Pressure For Auxiliary Spool Valve № 4

Checking The Flow From The Dual Spool Valve

Checking The Maximum Pressure From The Dual Spool Valve

Electrical Checks Of Linkage Arm Swing Acton Solenoid Valves

Checking Flow To The Linkage Spool Valve

Checking Pressure At The Primary Linkage Valve

–“HYDRAULIC INSPECTION RESULTS” SHEET

Checking Flow From The 144 Cm3 Pump

Checking The Maximum Flow And Pressure For Auxiliary Spool Valve № 4

Checking The Flow From The Dual Spool Valve

Checking The Maximum Pressure From The Dual Spool Valve

On/Off Solenoid Valve For Linkage Bar Swing Function

Checking Flow To The Linkage Spool Valve

Checking Pressure At The Primary Linkage Valve

-ELECTRICAL SERVICES

–SCHEMATIC DIAGRAMS

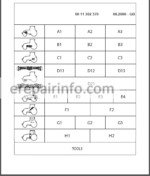

—ITEM LIST

Designation

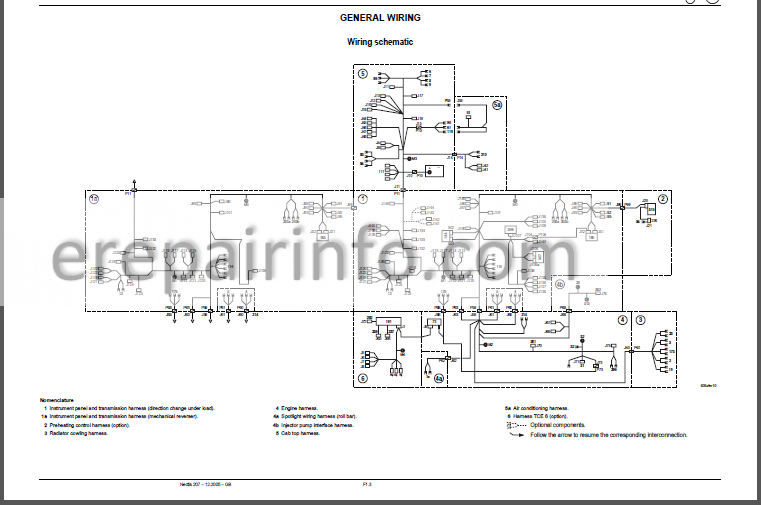

—GENERAL WIRING

Wiring Schematic

—FUSES AND RELAYS

Fusebox (A) And Relays

Fuses And Relays For “Clutchless” Reverser Version

Fuses And Relays For Mechanical Transmission Version

Fusebox (B) And Cab Relays

—EARTHS

Earthing Locations

Designation Of Earths

—FUNCTIONS

Starting Systen Charging Circuit Pre-Heaters Engine Rpm On ‘under Torque- Reverser TransmissionI

Starting Systen Charging Circuit Pre-Heaters Engine Rpm On Mechanical Transmission I Dipped Headlights – Headlights – HornI

Front And Rear Working LightsI

Stop Lights – Front Axle Engaged – Theoretical SpeedI

Side Light Indicator – Rear Work Lights (Roll Bar)I

Flashing Lights And Warning Lights I

Rotating Beacon – Cigarette Lighter – Radio – Cab Light And SpotI

Front And Rear Windscreen Wiper/WasherI

Instrument Panel Ventilation And Air ConditioningI

Engine Oil Pressure – Air Filter Blocked – Handbrake – Brake Fluid Level – Coolant

Temperature – Fuel GaugeI

4-Wheel Drive Control – Differential – Rearjproportional PtoI

25 A Power Socket – Pneumatic SeatI

Hydraulic Oil Temperature And PressureI

Revershift/Doubler Clutch And Drive ControlsI

Management Of “Clutchless- Reverser TransmissionI

Injection Pump – Fuel FilterI

Dashboard Display Selector – Diagnostic Plug

Tce6 Linkage

Linkage Arms Stabiliser

–HARNESS AND CONNECTOR PATHS

Harness And Connector Paths

1Instrument Panel And Transmission Harness

2Preheating Control Harness (Option)

3Radiator Cowling Harness

4Engine Harness

4A Rotating Beacon Harness (Roll Bar)

4B Injector Pump Interface Harness

5Cab Top Harness

5A Air Conditioning Harness

6.Tce 6 Harness

-INSTRUMENT PANEL

–DESCRIPTION

Instrument Cluster

Input’output

Connection And Functions Of The Wires Of Connectors Jx1 And Jx2

–CHARACTERISTICS

Indicator Operation

Engine Temperature And Fuel Gauges

Warning Lights

–REMOVAL/REFITTING

Instrument Cluster

–MEASUREMENT AND CHECKING POINTS

Check Of Transmission Oil Pressure Sensor

Check Of Air Filter Blockage Indicator

Check Of Engine Oil Pressure Sensor

Check Of Transmission Oil Temperature Sensor

Check Of Speed Sensor

Check Of Fuel Water-Content Sensor

Check Of Engine Temperature Sensor

Check Of Engine Rpm

Check Of Fuel Gauge

-ELECTRONIC LINKAGE TCE 6

–DESCRIPTION

Version Tce 6

Electrical Architecture

Tce 6 Inputs/Outputs

Connections To Tce 6 Unit

Self-Checking

–ADJUSTMENTS

Position Sensor And End Stop Switch

Load Sensor

–MEASUREMENT AND CHECKING POINTS

Check Of End Stop Switch (310)

Check Of Position Sensor (237)

Check Of Force Sensor (236)

Check Of Up Solenoid Valve (99)

Check Of Down Solenoid Valve (100)

External Up/Down Selector (56A) (56B) (57A) (57B)

-RECORD SHEET FOR MEASURED SENSOR AND SWITCH VALUES FOR THE TCE 6 SOLENOID VALVE

Record Sheet For Measured Sensor And Switch Values For The Tce 6 Solenoid Valve

-RAISING THE CAB AND PLATFORM

–DESCRIPTION OF THE CAB

Identification

Safety Instructions

Location Of Operations

Summary Of Operations

–REMOVING THE CAB

Preliminary Operations

Removal Operations

Installing The Spreader Bar

Partial Removal

–REFITTING THE CAB

Torque Settings

Adjustments

–REMOVING/REFITTING THE ROOF

Complete Removal Of The Roof

–DESCRIPTION OF THE PLATFORM

Identification

Safety Instructions

Location Of Operations

Summary Of Operations

–REMOVAL OF THE PLATFORM

Preliminary Operations

Removal Operations

Installing The Spreader Bar

Partial Removal

–REFITTING THE PLATFORM

Torque Settings

Adjustments

-HEATING/AIR CONDITIONING

–CHARACTERISTICS

Characteristics

–GENERAL DESCRIPTION

Diagram Of Operating Principle

Component Location

–DESCRIPTION AND OPERATION

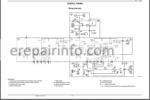

Electrical Schematic

Control Panel

–SAFETY INSTRUCTIONS

Safety Instructions

–GAS CHARGING AND DISCHARGING

Drain Points

–REMOVAL/REFITTING

Engine Layout

Cab Layout

Removing The Expansion Valve

Removing The Thermostat

Removing The Fan

Removing The Heating/Ajr Conitioning Unit

Removing The Evaporator And Radiator

Removing The De-Humidifier, Condenser And Fans

Refitting

Quantity Of Oil To Be Added When Replacing Components

–MEASUREMENT AND CHECK POINTS

Checking Air Conditioning System Pressures

Checking The Thermostat

–DIAGNOSTICS

Table Of Symptoms

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

That’s exactly what I needed