Factory Service Manual For Clark Forklift. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 222

Number: SM568 (december 1991)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

Clark Forklift

PWD25

PWD30

PWD36

HWD25

HWD30

HWD36

Contents

-PLANNED MAINTENANCE PROCEDURES

H.P.M. CHECK SHEET

Visual Inspection

Operational Tests

-LUBRICATION & PLANNED MAINTENANCE

Lubrication Specifications

Hydraulic System

Lubrication Chart Rider Models

Lubrication Chart Walkies Models

Optional Equipment

Miscellaneous Linkage

-BATTERY

Battery Handling

Battery Removal

Battery Vents

Battery Cleaning

Battery Maintenance

Battery Charging

Battery Electrolyte

Clean Battery Compartment

Install -Battery

Keeping Battery Records

-ELECTRIC MOTORS

Electric Motor Maintenance

Test For Motor Insulation Resistance To Ground

Brush And Commutator Inspection

Operating Conditions

Drive Motor

Pump Motor

Electrical Motor Maintenance General Procedures

Adjustment

Drive Motor Installation

Pump Motor Installation

-CONTACTORS

Replacement Of Contact Tips

Install New Tips

Check Operation

Forward & Reverse Contactor Assemblies

-CONTACTOR AND EV-T5 CONTROL PANELS

Control Panel Removal

Disconnect Panels

Control Card Removal & Installation

Replacement Control Card Data

Capacitors

Control Box Internal Wiring

-EV-T5 CONTROL

Description

Control Features

Maintenance

Troubleshooting

Trouble Shooting Notes

-CHECKING COMPONENTS AND CONTROL CARD ADJUSTMENTS

EV-T5 Card Adjustments And Input/Output Connections

EVT5 Component Identification

EV-T5 Internal Wiring

Checking Components

-SEQUENCE OF OPERATION

-EV-T5 FLOW CHART TROUBLE SHOOTING PROCEDURES

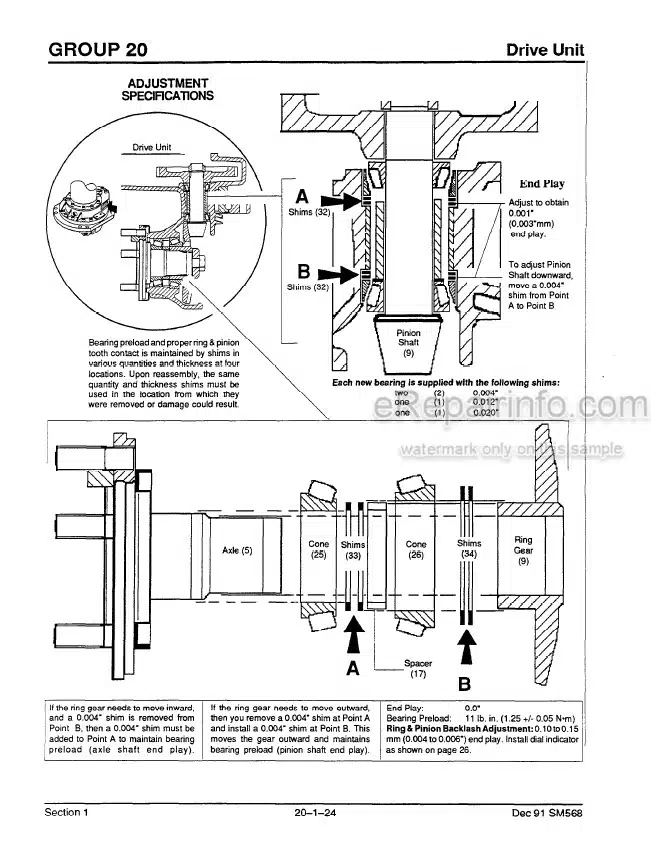

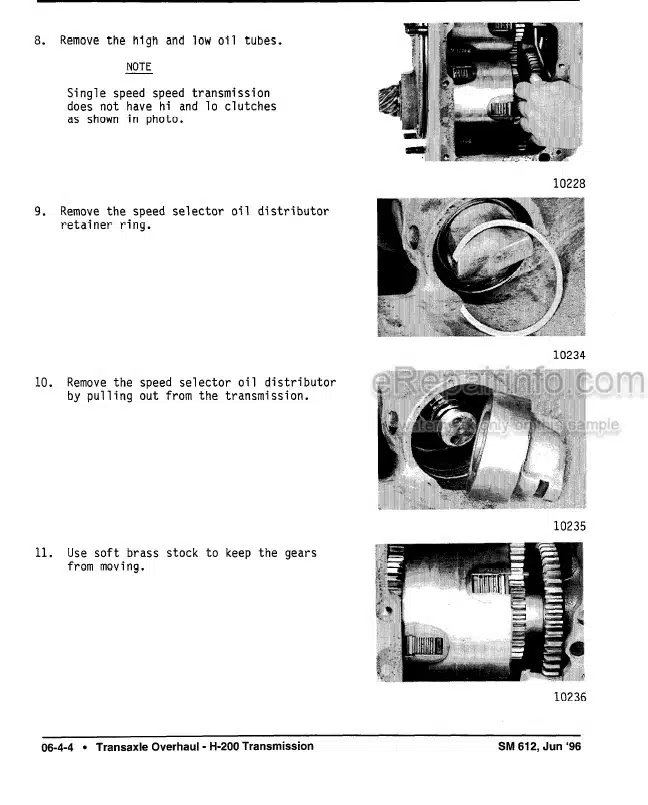

-DRIVE UNIT ASSEMBLY

Description

Removal

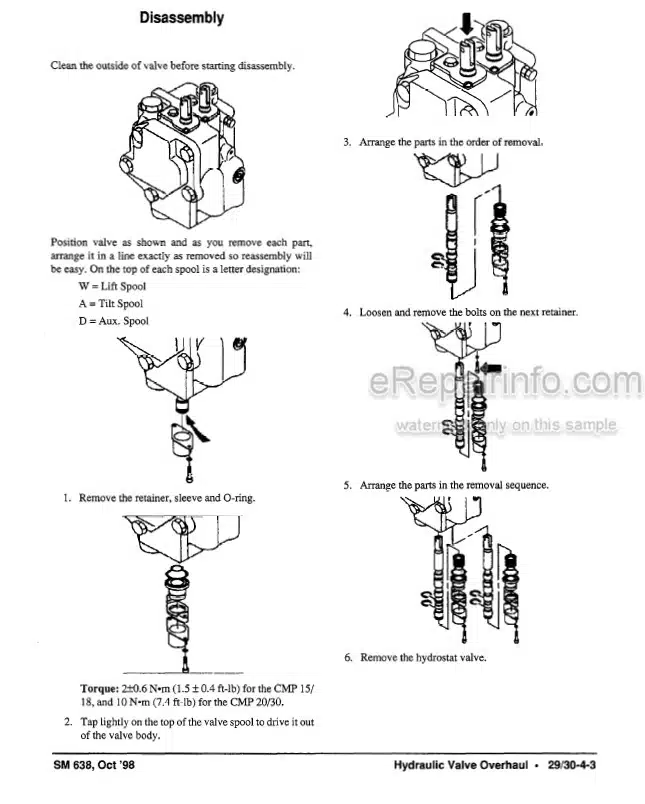

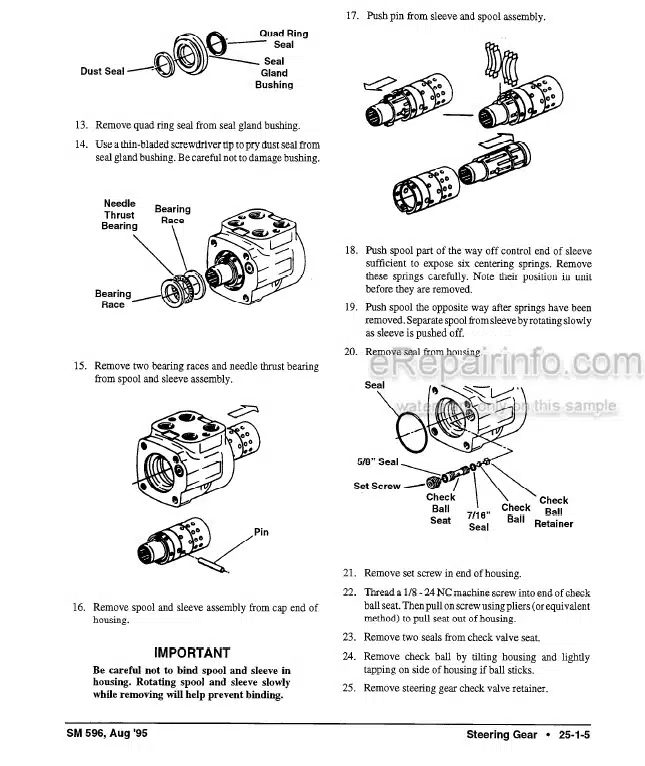

Disassembly

Cleaning & Inspection

Reassembly

Adjustment Specifications

Backlash

Installation

-DRIVE MOTOR BRAKES

Motor Brake Assembly

Motor Brake Inspection

Brake Installation

Brake Linkage Installation

Brake Switch

Brake Switch Adjustment

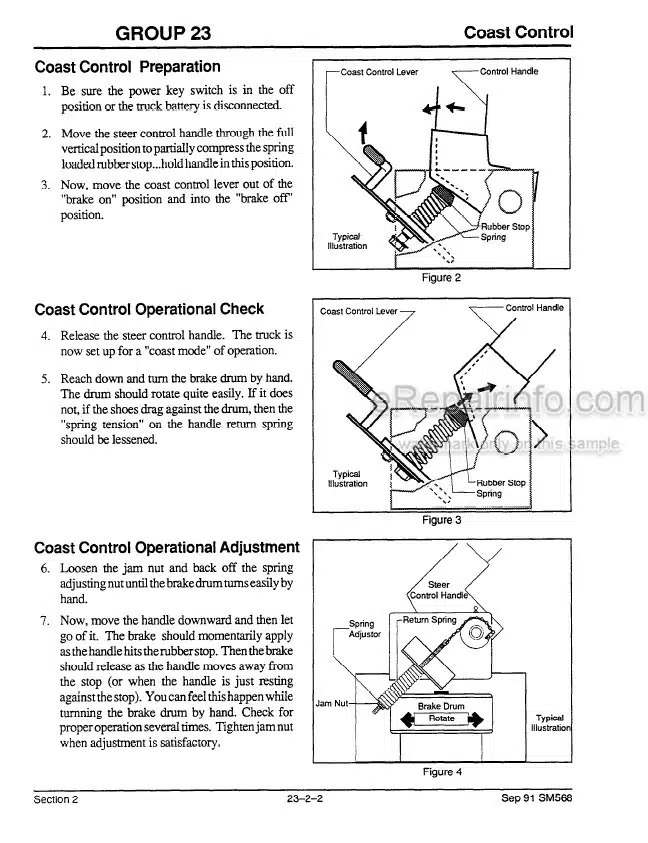

-COAST CONTROL

Coast Control Description

Coast Control Preparation

Coast Control Operational Check

Coast Control Operational Adjustment

-CASTER ASSEMBLY

Torque Specification

Caster Adjustment

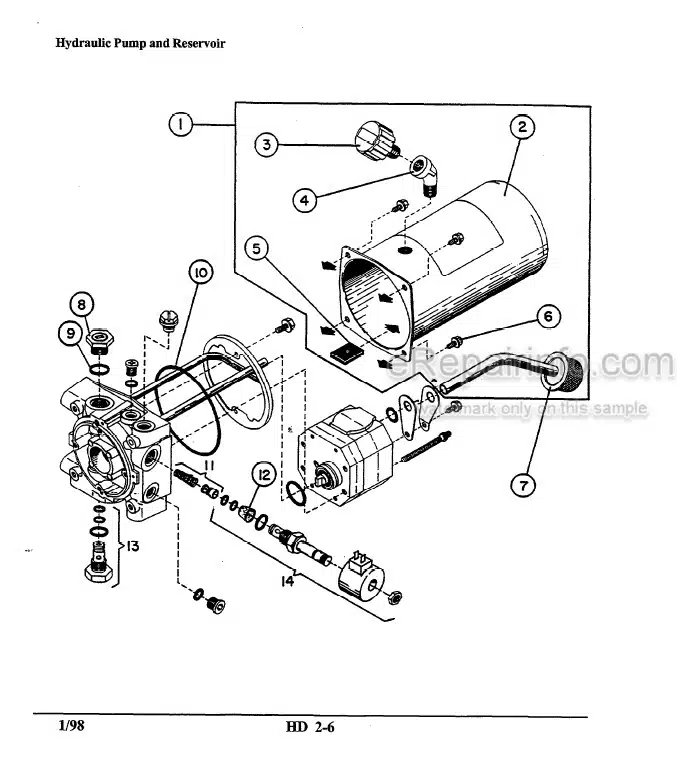

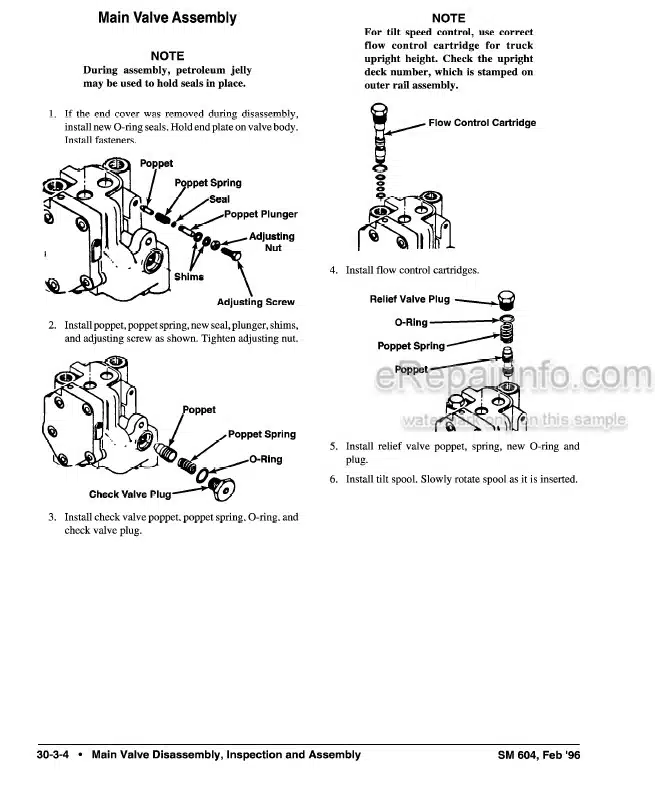

-HYDRAULIC SYSTEM

Removal

Installation

Torque Specifications

-HYDRAULIC UNIT

Assembly Of Hydraulic Unit

Specifications

-LIFT CYLINDER

Lift Cylinder Removal

Block Lift Frame

Disconnect Hoses

Disconnect Lift Cylinder

Disassembly

Inspection

Reassembly

Installation Specifications

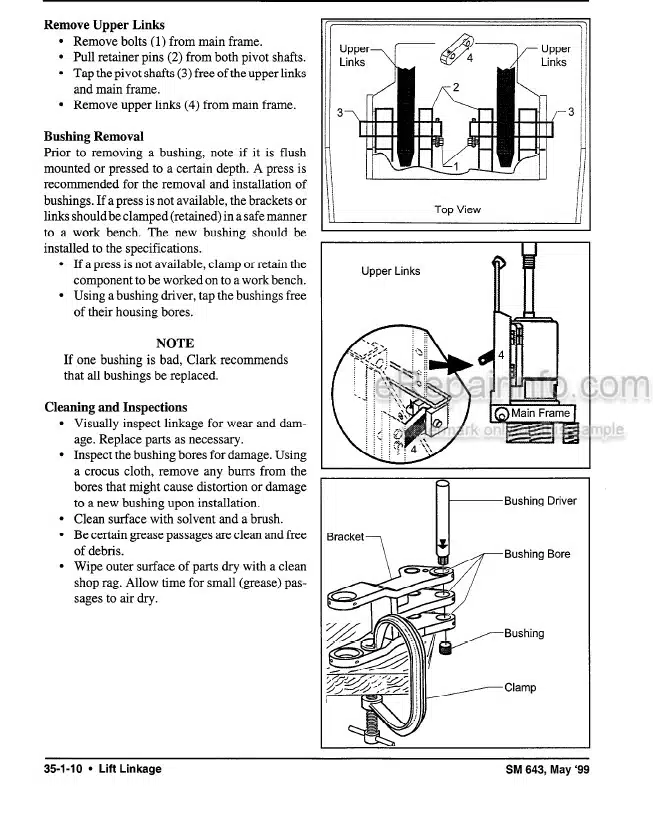

-LIFT LINKAGE & LOAD WHEELS OPERATIONAL CHECK

Pull Rod Adjustment Check

Bushing Identification

Lift Linkage Removal

Bushing Removal

Bushing Installation

Dual Load Wheels

Single Load Wheels

Lift Linkage Installation

Pallet Entry Skids

-BODY PARTS

Walkie Model Trucks

Rider Model Trucks

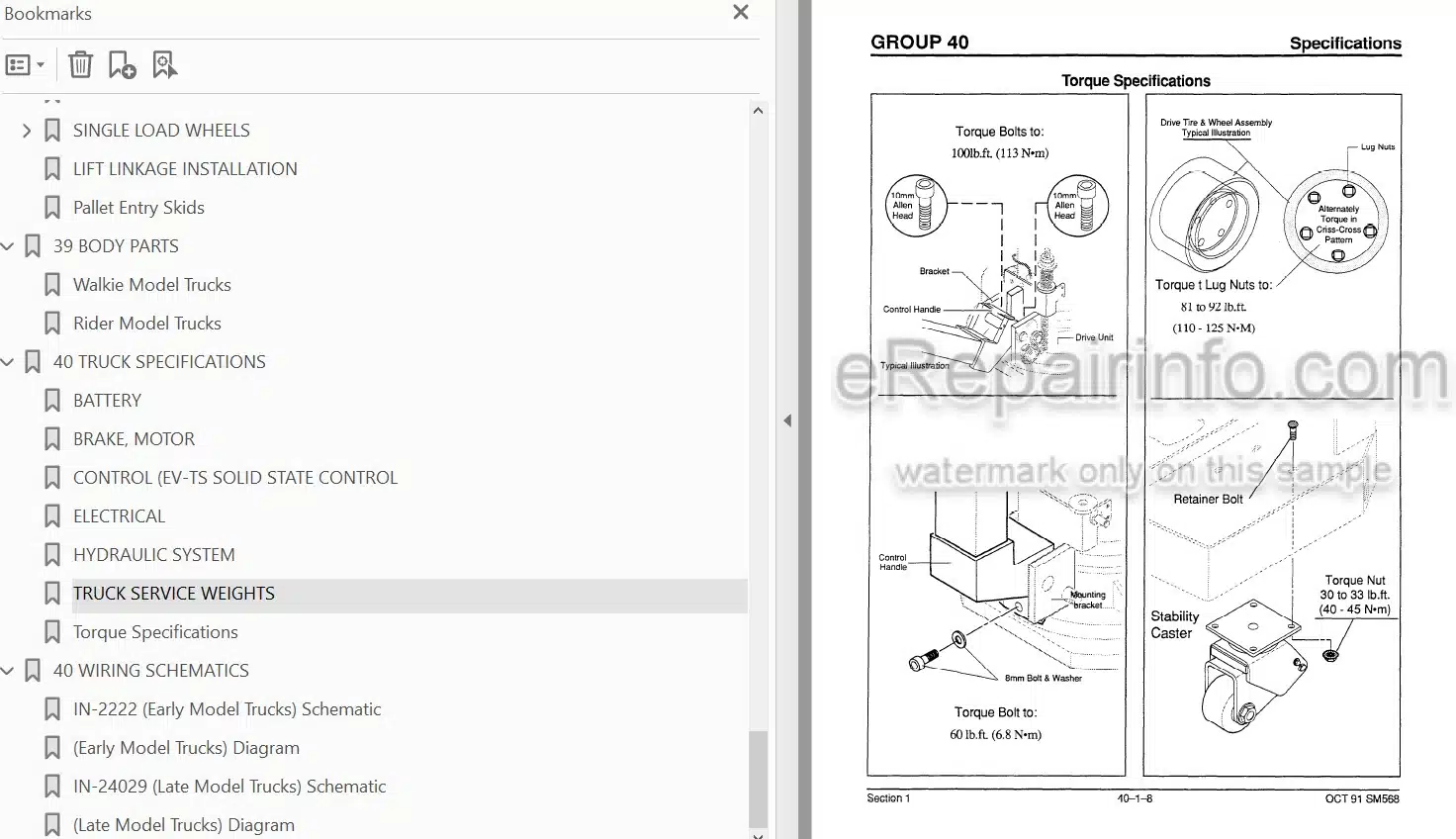

-TRUCK SPECIFICATIONS

Battery

Brake, Motor

Control (EV-TS Solid State Control)

Electrical

Hydraulic System

Truck Service Weights

Torque Specifications

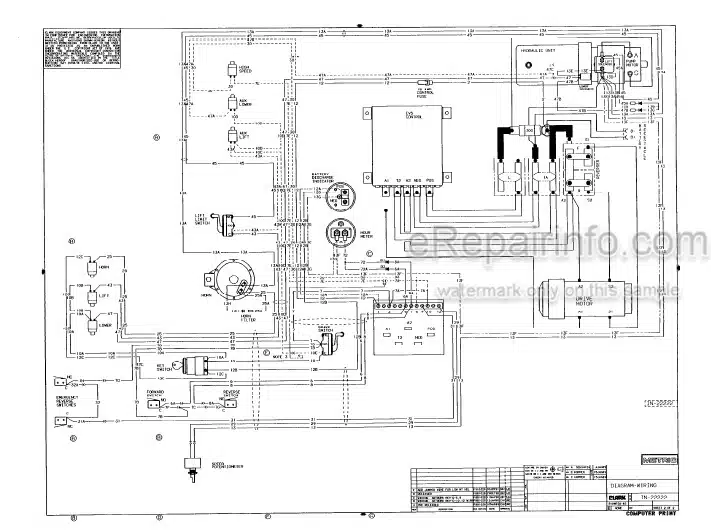

-WIRING SCHEMATICS

IN-2222 (Early Model Trucks) Schematic (Early Model Trucks) Diagram

IN-24029 (Late Model Trucks) Schematic (Late Model Trucks) Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.