Factory Troubleshooting And Repair Manual For Cummins Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 693

Number: 3810298-00 (june 1986)

Bookmarks: Yes

Model

Cummins Engine

Big Cam III

Big Cam IV

NT855

Contents

-INTRODUCTION

About The Manual

How to Use The Manual

Symbols

Illustrations

Definition Of Terms

General Repair Instructions

General Cleaning Instructions

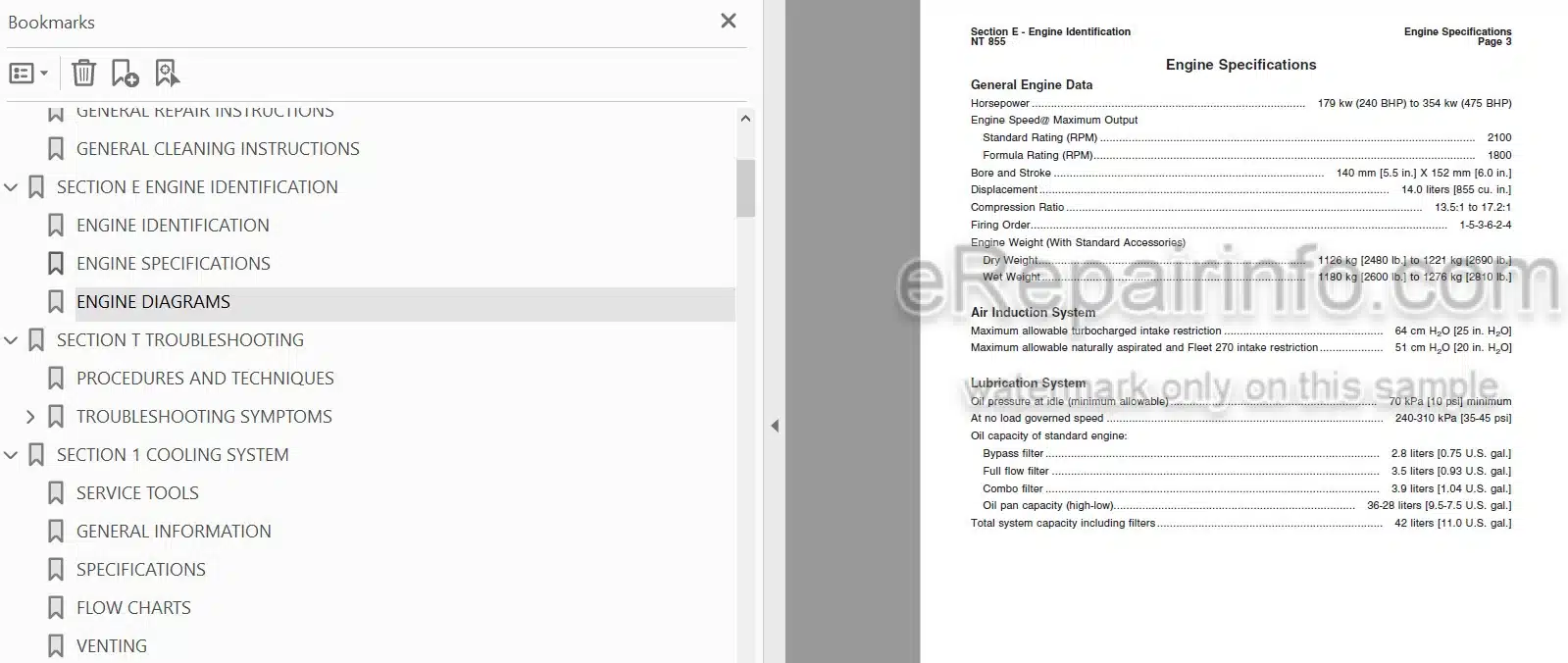

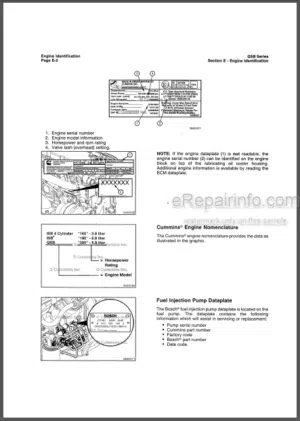

-ENGINE IDENTIFICATION

Engine Identification

Engine Specifications

Engine Diagrams

-TROUBLESHOOTING

Procedures And Techniques

Troubleshooting Symptoms

-COOLING SYSTEM

Service Tools

General Information

Specifications

Flow Charts

Venting

Cooling System, Maintenance

Cooling System, Drain

Cooling System, Fill

Coolant Filter-Replace

Diesel Coolant Additives (Dca4)

Cooling System, Clean

Cooling System – Test For Air Or Combustion Gases

Cooling System-Pressure Test

Hoses-Check

Coolant Temperature Gauge-Check

Radiator Pressure Cap-Check

Radiator Fins-Inspect

Shutter Operation-Check

Fan Shroud Spacer & Pulley-Inspect

Water Pump Belt-Replace

Fan Drive Belts-Replace

On-Off Fan Clutch-Check

Fan Clutch, Air Engaged Type

Fan Clutch, Air Disengaged Type

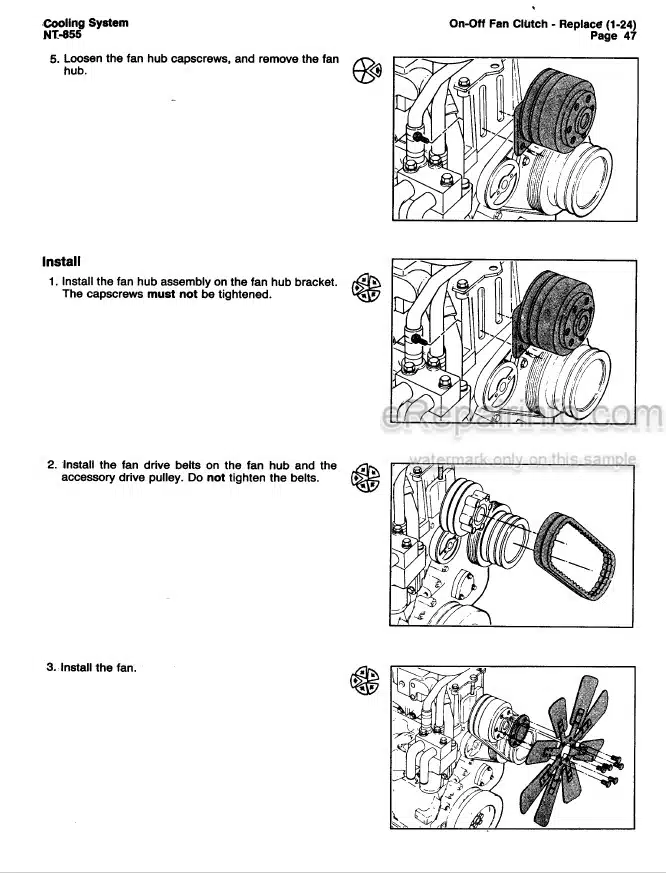

On-Off Fan Clutch-Replace

Fan Clutch Viscous Type

Fan Hub-Replace

Idler Pulley Assembly, Water Pump (Big Cam Iv And New Big Cam Iv) -Replace

Water Pump- Replace

Thermostat (Big Cam Iii) – Test “Thermostat In Chassis”

Thermostat (Big Cam Iii) – Replace

Thermostat (Big Cam Iii) – Test “Thermostat Removed”

Thermostat Seal (Big Cam Iii) – Replace

Thermostat, Radiator (Big Cam Iv) – Check

Thermostat, Bypass (Big Cam Iv) – Check

Thermostat Housing (Big Cam Iv) – Replace

Thermostat (Big Cam Iv) – Replace

Thermostat Seal, Bypass (Big Cam Iv) – Replace

Thermostat Seal, Radiator (Big Cam Iv) – Replace

Thermostat Housing Check Valve O-Rings (Big Cam Iv) – Replace

Thermostat Housing Check Valve Assembly (Big Cam Iv) – Replace

Radiator Check Valve Leakage (Big Cam Iv Only) – Check

Aftercooler Filter Screen (Big Cam Iv Only) – Clean

Water Manifold Sealing Ring Balance Orifices (Big Cam Iv Only) – Replace

Radiator Baffle Leakage (Big Cam Iv Only) – Check

Radiator (Two-Pass, Vertical-Flow) – Check

Radiator (Horizontal-Flow) – Check

Radiator (Three-Pass, Vertical-Flow) – Check

Head Gasket, Cylinder Liner, Crevice Seal Or Cylinder Block – Inspect For Coolant Leaks

-LUBRICATING OIL SYSTEM

Service Tools

General Information

Demand Flow And Cooling Lubricating System – Operation

Specifications

Flow Diagrams

Internal Engine Damage – Check

Oil Leaks (External) – Check

Oil Pressure Gauge – Check

Oil Temperature Gauge – Check

Oil Pan, Drain

Oil Pan. Fill

Oil Filters (Full Flow And Bypass) – Replace

Crankcase Breather And Tube – Replace

Dipstick Tube And Housing – Replace

Dipstick – Calibrate

Oil Transfer Tube – Replace

Oil Pan – Replace

Oil Cooler Bypass Valve – Check

Oil Filter Head – Replace

Oil Cooler Assembly – Replace

Oil Cooler Core – Replace

Oil Cooler Core – Pressure Test

Main Oil Pressure Regulator – Replace

Lubricating Oil Pump Signal Line Orifice – Clean “In Chassis”

Lubricating Oil Pump Signal Line Orifice – Clean “Pump Removed”

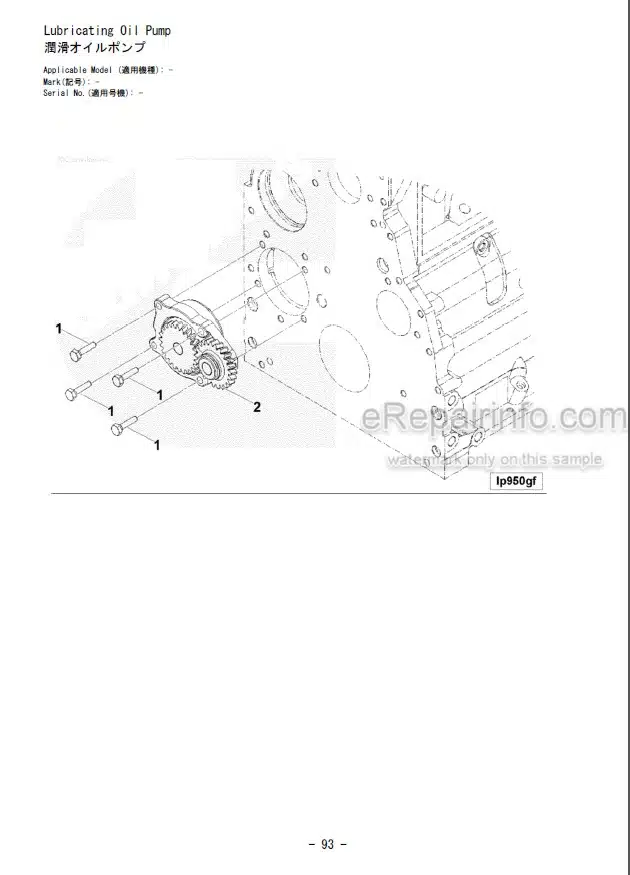

Lubricating Oil Pump – Replace

High Oil Pressure Relief Valve – Check

High Oil Pressure Relief Valve Replace

-COMBUSTION AIR SYSTEM

General Information

Specifications

Flow Diagrams

Service Tools

Turbocharger Turbine Seal Leaks Check

Compressor Seal Leakage – Check

Correct Turbocharger Installed – Check

Intake Air Restriction – Check

Exhaust Restriction – Check

Air Leaks – Check

Turbocharger Blade Damage – Check

Turbocharger Axial And Radial Clearance – Check

Turbocharger – Replace

Series Turbocharger – Replace

Exhaust Manifold – Replace

Aftercooler – Replace

Aftercooler – Pressure Test

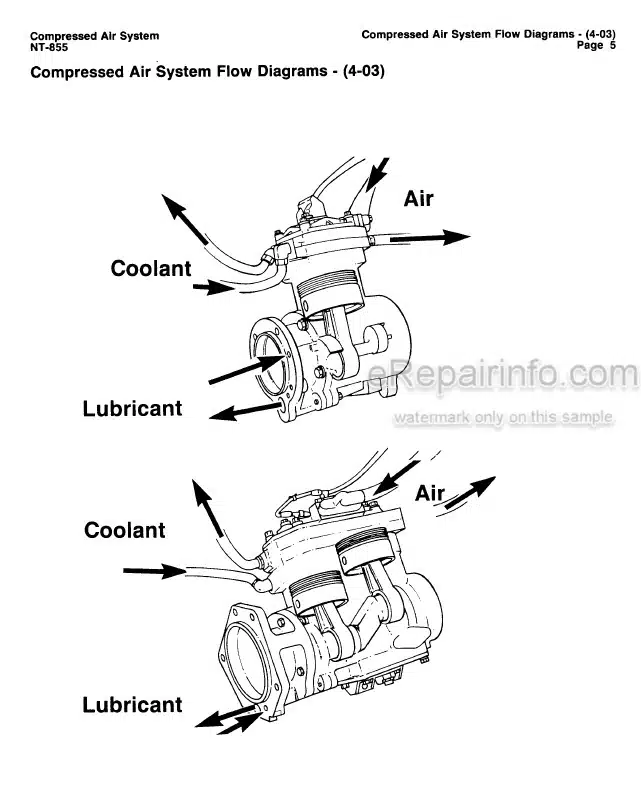

-COMPRESSED AIR SYSTEM

General Information

Specifications

Flow Diagrams

Service Tools

Carbon Buildup, Air Compressor Check

Gasket Leaks, Air Compressor – Check

Air Governor And Compressor Unloader Valve – Check

Air Governor-Check

Lubricating Oil Usage. Air Compressor – Check

Unloader Valve -Check

Air Compressor, Cylinder Head – Replace

Air Compressor, Replace

-FUEL SYSTEM

General Information

Specifications

Flow Diagrams

Service Tools

Fuel Pump Adjust

Injectors – Replace

Fuel Pump – Replace

Fuel System Maintenance

Variable Speed (Vs) Governor Leaking Fuel

Fuel Shut-Off Valve

Fuel Pump – Flow Check, Prime And Rotation

Air Leaks

Cylinder Misfire

Engine Oil Dilution By Fuel Oil

Fuel Line Restriction

Fuel Consumption Check

Low Power Check

Throttle Response Time By Road Test

Engine Stall Speed And Time Check

Driveability – Low Power Check List

Fuel Consumption – Check List

-ELECTRICAL SYSTEM

General Information

Specifications

Service Tools

Batteries – Check

Battery Terminal Connections – Check

Starting Circuit-Check

Alternator Belt – Adjust

Alternator – Output Test

Alternator – Replace

Starting Motor – Replace

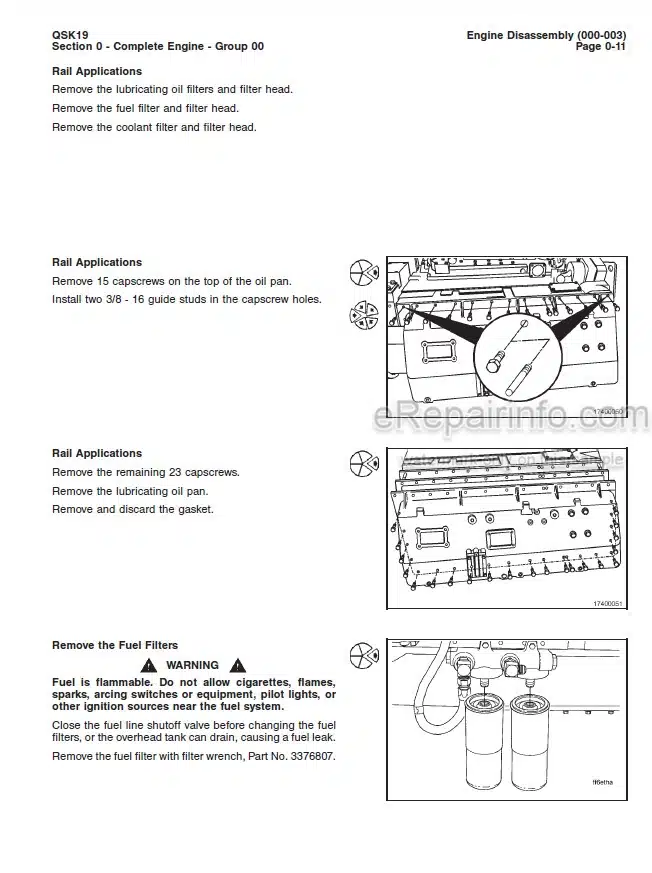

-BASE ENGINE COMPONENTS

Service Tools

General Information

Rocker Housing Covers – Replace

Engine Lifting Brackets – Replace

Crossheads, Valves And Injectors Adjust

Jacobs Engine Brake – Adjust

Jacobs Engine Brake – Check

Jacobs Engine Brake – Replace

Push Rods – Replace

Rocker Levers/Rocker Lever Housing – Replace

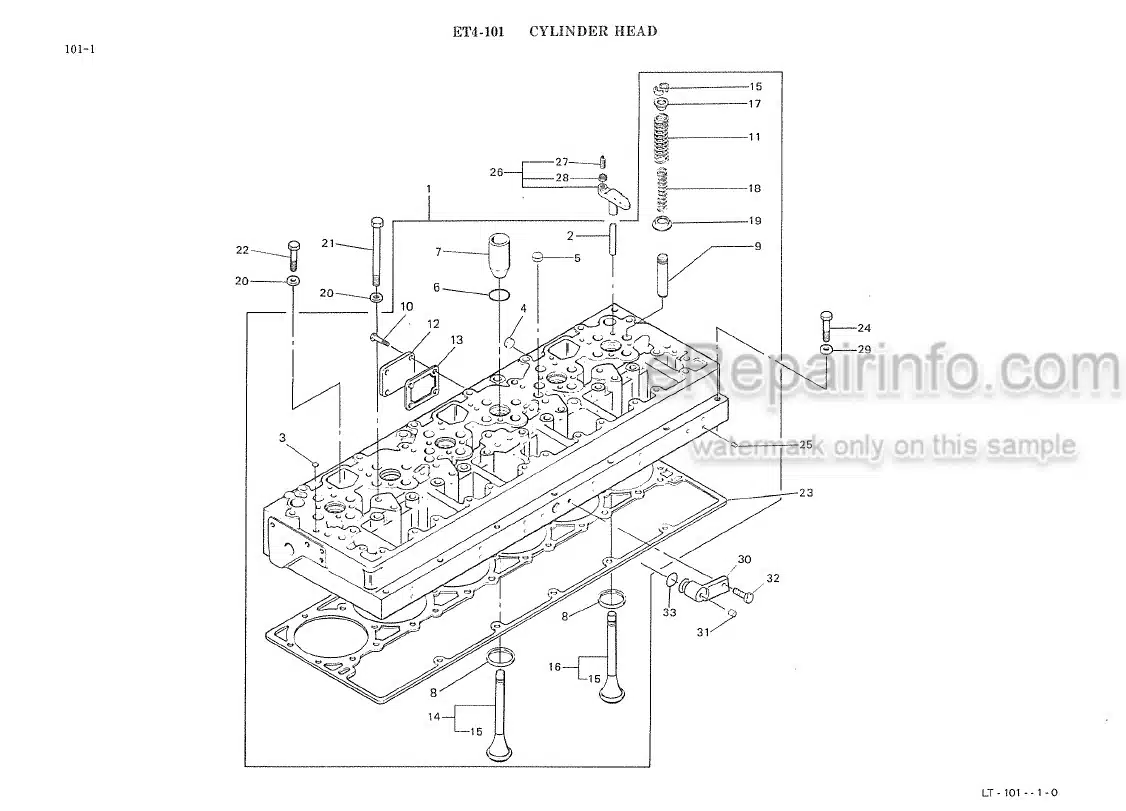

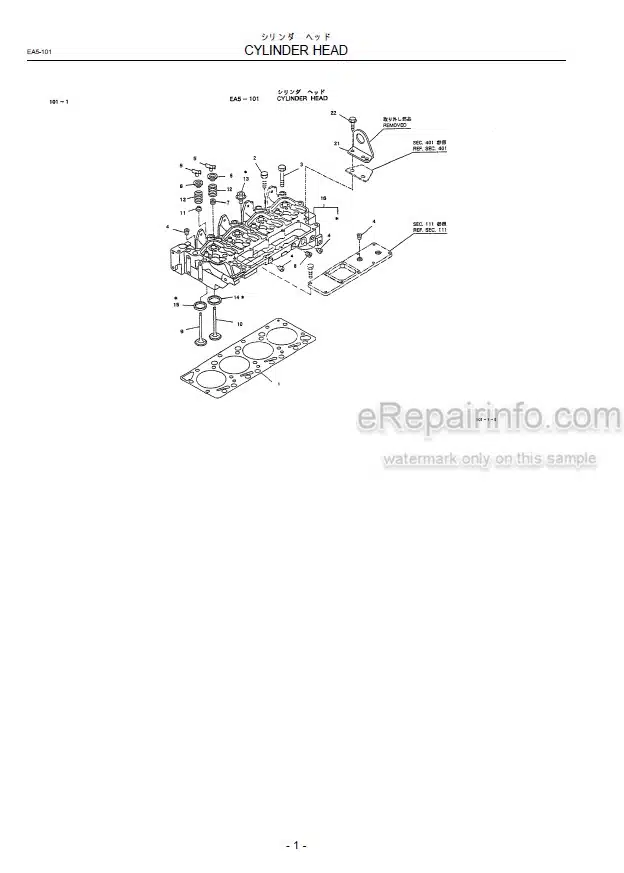

Cylinder Head Gasket(S) – Replace

Cylinder Heads – Replace

Cylinder Head – Pressure Test

Cam Followers (Fixed Injection Timing) – Replace

Mechanical Variable Timing (MVT) System

Cam Followers (MVT Injection Timing) – Replace

Injection Timing (General Information)

Injection Timing (Fixed)

Injection Timing (MVT)

Piston Cooling Nozzles – Replace

Main And Thrust Bearings – Replace

Connecting Rod Bearings – Replace

Pistons And Rings – Replace

Connecting Rods – Replace

Cylinders Liners Replace

Accessory Drive Pulley – Replace

Wear Sleeve, Accessory Drive Pulley – Replace

Seal. Accessory Drive – Replace

Accessory Drive – Replace

Vibration Damper – Check

Crankshaft Pulley – Replace

Seal, Front Crankshaft – Replace

Camshaft Bearing Support – Replace

Front Engine Support Bracket – Replace

Gear Cover – Replace

Crankshaft Gear – Replace

Camshaft – Replace

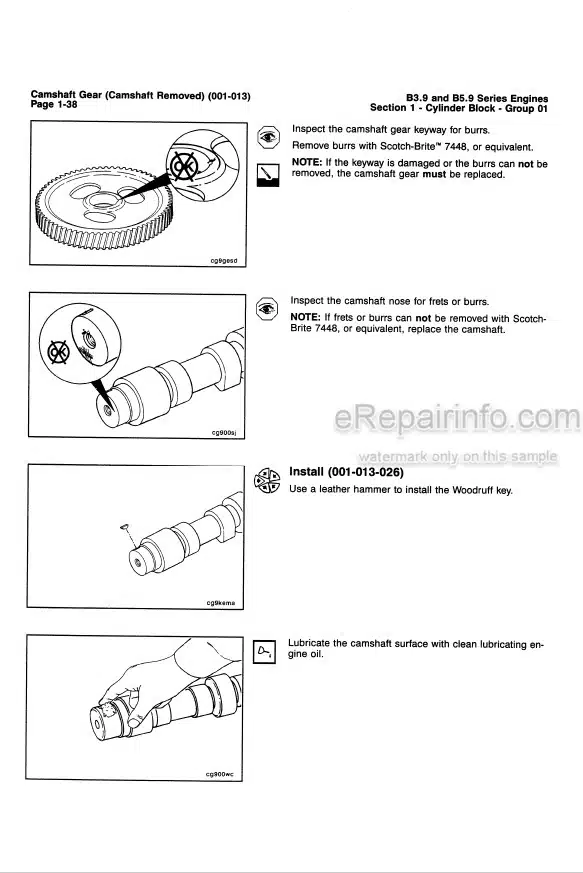

Camshaft Gear – Replace

Camshaft Bushing – Replace

Flywheel – Replace

Seal. Rear Cranshaft – Replace

Flywheel Housing – Replace

Flywheel Housing Redowel To Cylinder Block

Pipe Plugs And Cup Plugs – Replace

-ENGINE TESTING (“IN CHASSIS”)

Service Tools

General Engine Test Specifications And Procedures

Chassis Dynamometer Operation

Engine Run-In Procedure (Chassis Dynamometer)

Engine Run-In Procedure “In-Chassis” (On And Off-Highway Vehicles)

-ENGINE REMOVE AND INSTALL

General Information

Service Tools

Engine Remove

Engine Mounts – Inspect

Engine – Install

-ENGINE COMPONENT SPECIFICATIONS

General Information

Conversion Factors

Pipe Plug Torque Values

Capscrew Markings And Torque Values

Decimal And Metric Equivalents

Cooling System Torque Values

Lubricating Oil System Torque Values

Combustion Air System Torque Values

Compressed Air System Torque Values

Fuel System Torque Values

Electrical System Torque Values

Base Engine Components Torque Values

ALPHABETICAL INDEX

ADDITIONAL SERVICE LITERATURE

ACCESSORY COMPONENT MANUFACTURERS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.