Factory Operation And Maintenance Manual For Doosan Excavator. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: ENG

Pages: 492

Number: 950106-01108AEU (november 2017)

Bookmarks: Yes

Searchable: Yes

Model

Doosan Excavator

DX225LC-5

SN 1001 And Up

Contents

-FOREWORD

Intended Use

Engine and Emission Control System Maintenance

Machine Capacity

Attachments

Product Identification Number (PIN)

Engine Identification

Your Machine Serial Numbers

Safety Messages

EC Declaration of Conformity

-SAFETY

Safety Decals

General

Transportation

Operation

Maintenance

Environment and Circumstances

-OPERATING CONTROLS

Component Locations

Operator’s Area

Operational Controls and Panels

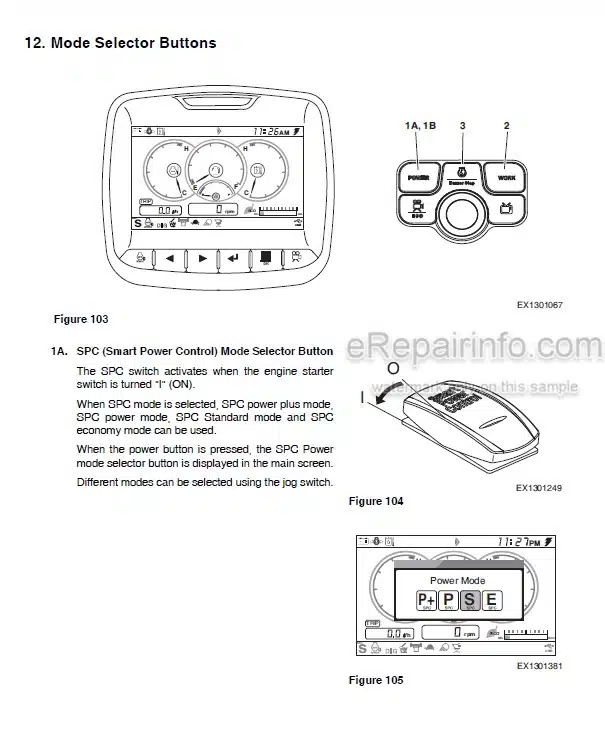

Display Monitor

User Menu

Heater and Air Conditioner Control Panel

Stereo

Miscellaneous Electrical Devices

Seat Adjustment

Engine Emergency Stop Switch

Emergency Exit Glass Breaking Tool

Miscellaneous Convenience Devices

Miscellaneous Access Covers and Doors

Air Gun and Compressor (Optional)

-OPERATION

To Operate a New Excavator

Starting and Stopping Engine

Safety Lever

Travel

Operating Instructions

Operating Precautions

Parking Excavator

Towing Procedure

Attachments

Hydraulic Attachments (Optional)

Lifting Objects

Lifting Objects with Quick Coupler

Operation Under Abnormal Conditions

Long Term Storage

-INSPECTION, MAINTENANCE AND ADJUSTMENT

Maintenance Information

Machine Setup Position for Maintenance

Maintenance Handling Access

Handling Oil, Fuel, DEF (AdBlue), Coolant

Electrical System Maintenance

Recommend Fuel, Coolant, and Lubricant

Fluid Capacities

Table of Recommended Lubricants

Maintenance Intervals

10 Hour / Daily Service

50 Hour / Weekly Service

250 Hour / Monthly Service

500 Hour / 3 Month Service

1.000 Hour/6 Month Service

2.000 Hour / Yearly Service

4.000 Hour / Biennial Service

4,500 Hour / Biennial Service

12.000 Hour / 6 Year Service

Air-conditioning System

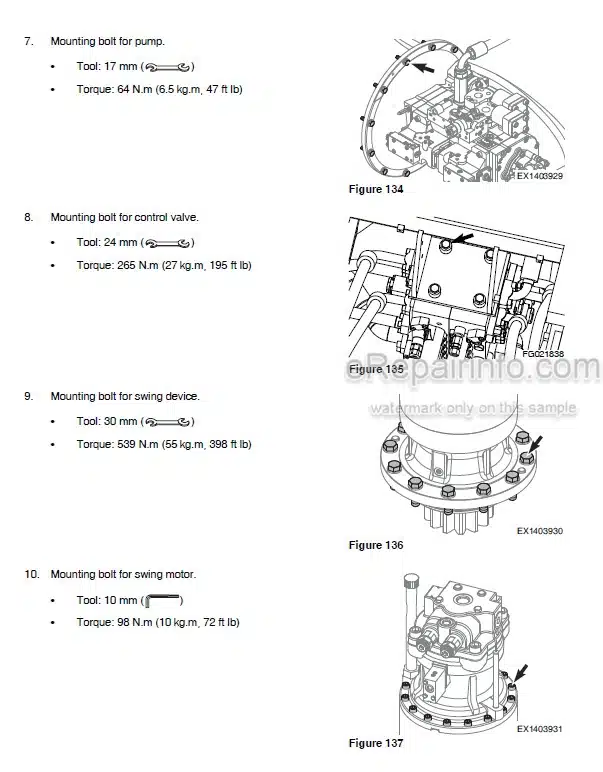

Bolt and Nut Inspection

Bucket

Electrical System

Engine Cooling System

Fuel Transfer Pump (Optional)

Handling of Accumulator

Track Tension

Venting and Priming Hydraulic System

Maintenance in Special Conditions

-TRANSPORTATION

Loading and Unloading

Lifting Machine

-TROUBLESHOOTING

Electrical System

Engine

Lubrication System

Hydraulic System

Air Compressor (Optional)

Swing System

Travel System

Cooling Fan

-SPECIFICATION

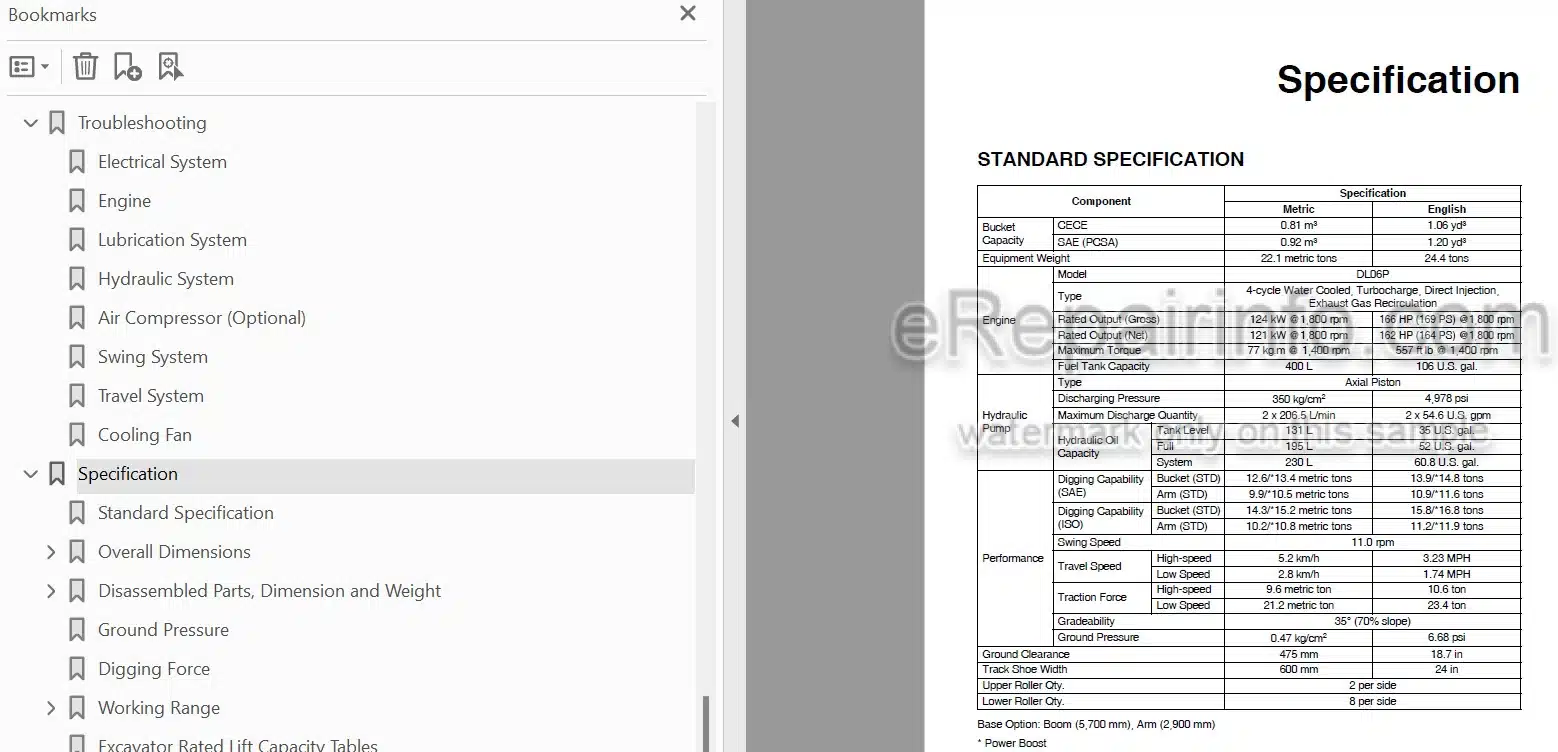

Standard Specification

Overall Dimensions

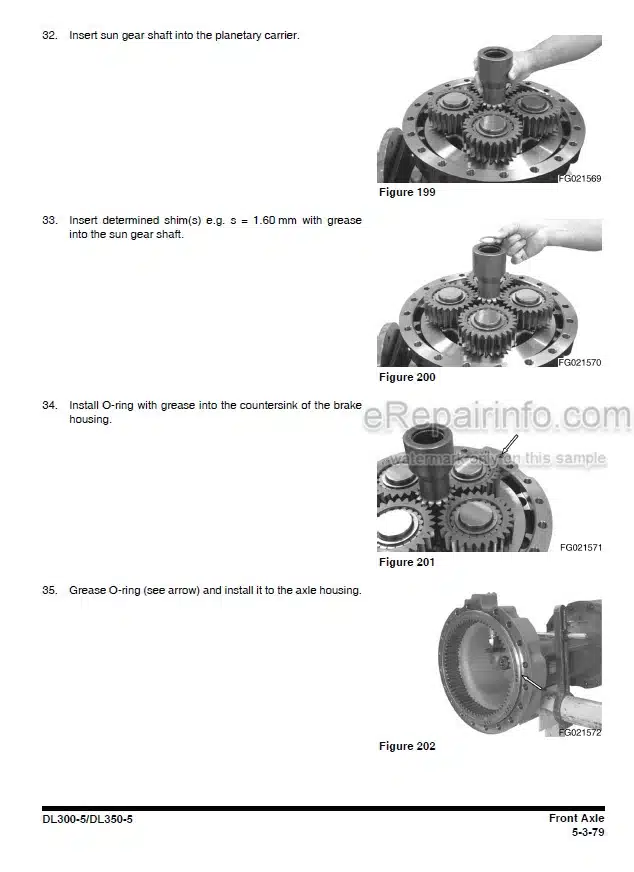

Disassembled Parts, Dimension And Weight

Ground Pressure

Digging Force

Working Range

Excavator Rated Lift Capacity Tables

Approximate Weight Of Workload Materials

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.