Factory Workshop Manual For Fendt F390GTA F395GTA F395GHA Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Wiring Diagrams: Yes

Model

Fendt F 390 GTA, F 395 GTA, F395 GHA

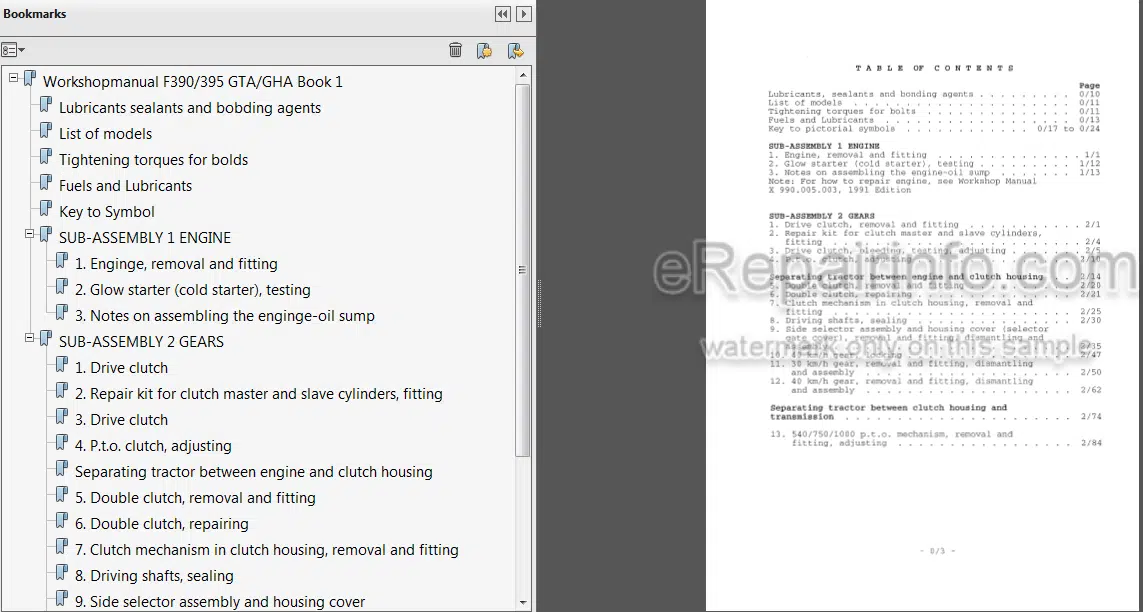

Contents

Lubricants, Sealants And Bonding Agents

List Of Models

Tightening Torques For Bolts

Fuels And Lubricants

Key To Pictorial Symbols

-Engine

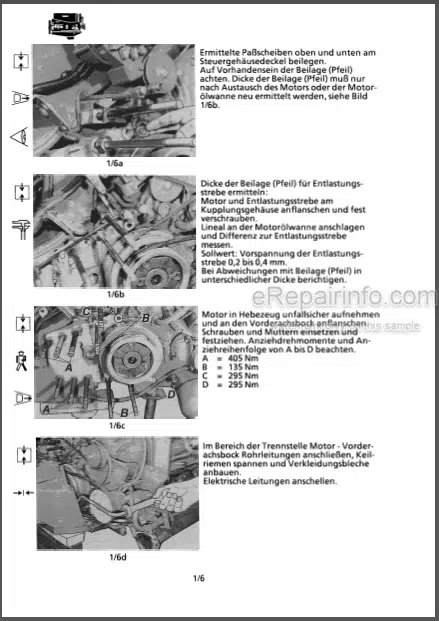

Engine, Removal And Fitting

Glow Starter (Cold Starter), Testing

Notes On Assembling The Engine-Oil Sump

– Gears

Drive Clutch, Removal And Fitting

Repair Kit For Clutch Master And Slave Cylinders, Fitting

Drive Clutch, Bleeding, Testing, Adjusting

PTO Clutch, Adjusting

Separating Tractor Between Engine And Clutch Housing

Double Clutch, Removal And Fitting

Double Clutch, Repairing

Clutch Mechanism In Clutch Housing, Removal And Fitting

Driving Shafts, Sealing

Side Selector Assembly And Housing Cover (Selector Gate Cover), Removal And Fitting, Dismantling And Assembly

Locking

Removal And Fitting, Dismantling

40 Km/H Gear,

30 Km/H Gear, And Assembly

40 Km/H Gear, And Assembly, Removal And Fitting, Dismantling

–Separating tractor between clutch housing and transmission

-540/750/1000 pto mechanism, removal and fitting, adjusting

Transmission, Dismantling And Assembly L/M/S Splitter

25/30/40 Km/H Overdrive

25/30 Km/H Overdrive

Super-Creeper Gear With L/M/S Splitter

–Separating Tractor Between Transmission And Rear Axle Housing

Pinion Shaft (Crown Gears) And Set Of Gearwheels Removal And Fitting

Front Wheel Drive

Shift Path Of 4-Wheel Drive Clutch, Testing

4-Wheel Drive Clutch Plates, Changing

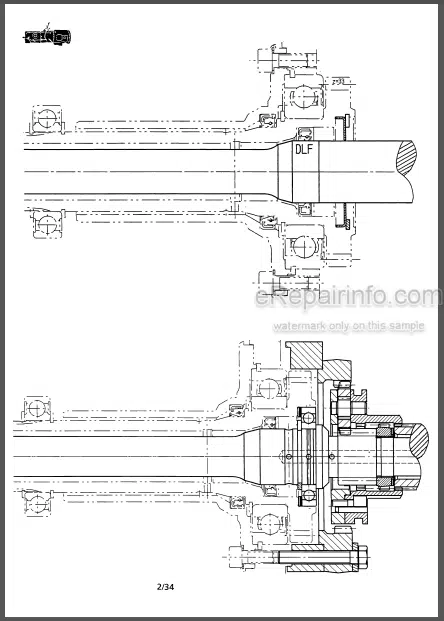

Front Wheel Drive, Removal And Fitting, Dismantling And Assembly

Hydraulics

Electrics/Electronics, See Page 5/42

Forward And Backward Offset Of Front Wheel Drive, Measuring

Cardan Shaft, Removal And Fitting, Dismantling And Assembly

Rear PTO, Removal And Fitting

Differential Gears, Dismantling And Assembly

Differential Lock, Adjusting

Hydraulics, See Page 2/333

Electrics, Electronics, See Page 5/42

Diff Lock Slave Cylinder, Dismantling And Assembly

Differential, Removal And Fitting

Brakes

Wear On Rear Solid-Disc Brakes, Testing

Rear Solid-Disc Brakes, Adjusting

Rear Solid-Disc Brakes, Dismantling And Assembly

Rear Wheel Brake Cylinders, Removal And Fitting, Sealing With Repair Kit

Fixed-Caliper Brakes (Cardan Shaft Brakes), Removal And Fitting, Using Repair Kit

Main Brake Cylinder And Extra Valve, Testing For Internal Leaks

Main Brake Cylinder, Removal And Fitting, Adjusting, Sealing With Repair Kit

Brakes, Bleeding

Handbrake (Parking Brake), Adjusting

Handbrake (Parking Brake), Removal And Fitting

Brake Hydraulics Faults Table

Front PTO, Removal And Fitting

Clutch Plates, Changing, Dismantling And Assembly

Hydraulics

Electrics, Electronics

Clutch On Engine Side, Changing

Comfort Controls, Hydraulics

Position Of Components And Pressure Measurements Hydraulic Circuit Diagram

Comfort Controls, Electrics/Electronics, See Page 5/42

-Front Axle

Swivel Joint Between Front Axle Bracket And Axle Mounting, Sealing

Complete Front Axle, Removal And Fitting

Hydraulics

Electrics/Electronics

-Steering

Hydraulic Geared Pump, Removal And Fitting

Steering Unit, Removal And Fitting, Sealing

Priority Valve, Removal And Fitting, Dismantling/Cleaning

Steering Pillar, Removal And Fitting,Dismantling And Assembly

Steering Cylinders, Removal And Fitting,Sealing

Toe-In, Testing/Adjusting

Steering-Stop, Adjusting

Hydrostatic Steering, Testing

Max Pressure, Testing

Circulating Pressure, Testing

Steering Unit And Cylinders, Testing For Internal Leaks

Position Of Pressure Relief Valve In The Steering Unit

Hydrostatic Steering, Faults Table

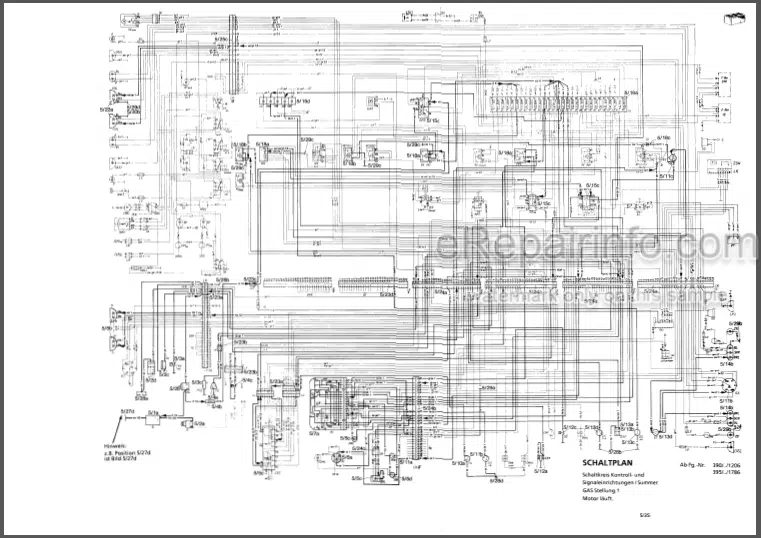

-Electrics

Lights And Signalling

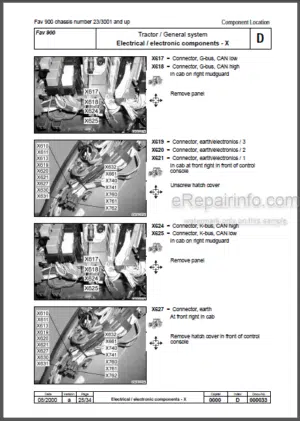

Position And Testing Of Electrical Components Position Of Line-Couplings

Position Of Earthing Points

Electrical Circuit Diagrams – Lighting, Signalling

Electronic Indicators And Comfort Controls Electrics And Electronics

Position And Testing Of Electrical And Electronic Components

Position Of Sensors

Electronic Control Box (E-Box) For Electronic Indicators, Encoding

Speed Indicator, Testing

Block Diagram – Electronic Indicators Block Diagrams – 4-Wheel Drive Comfort Controls And Diff Lock

Block Diagrams – Front PTO Comfort Controls Electrical Circuit Diagrams – Electronic Indicators And Comfort Controls

Faults Table – Electronic Indicators

Faults Code-Table – PTO Comfort Controls 4-Wheel Drive/Diff Lock

Faults Codes Table – Front PTO Comfort Controls

Functions – 4-Wheel Drive/Diff Locks Comfort Controls

Functions – Front PTO Comfort Controls

-Hydraulics

Hydraulic Geared Pump, Removal And Fitting, Dismantling And Assembly, Sealing

Hydraulic Oil Filter, Removal And Fitting

Control Valve For Lift-Controls Function Testing

Removal And Fitting

Magnets, Removal And Fitting

Pressure-Relief Valve In 1St And 2Nd Valve Units, Removal And Fitting, Cleaning

Additional Control Valves, Removal And Fitting Automatic Oil-Flow Connection, Testing, Removal And Fitting, Dismantling And Assembly

Position Of Non-Return Valve

Lifting Cylinders Of Electronically-Controlled Lifting-Gear Removal And Fitting, Dismantling And Assembly

Lifting Shaft Of Electronically-Controlled Lifting-Gear

Removal And Fitting, Sealing

Lifting-Gear, Removal And Fitting

Lifting-Gear, Adjusting And Testing

Hydraulic Circuit Diagrams

Sensor Pins, Removal And Fitting

Position And Testing Of Electrical And Electronic Epc Components, Pressureregulation And External Control

Epc Electrical Circuit Diagrams

Controls, Dismantling, Assembly, Testing

Electrical Circuit Diagram With Epc Test Values

Pressure Tests

Hydraulic Cylinders For Front Liftinggear, Removal And Fitting, Dismantling And Assembly

Faults Table – Electronically-Controlled Lifting-Gear And Working Hydraulics, Hydraulics

Faults Table – Electronically-Controlled Lifting-Gear, Electrics

Diagnostics – Electronically-Controlled Lifting-Gear, Fault-Code Indication

Shock-Load Stabiliser, Re-Coding

-Cab

Cab, Removal And Fitting

Cab Ventilation Fan, Removal And Fitting

Heater

Position Of Components

Power Supply, Testing

Testing Components When Fitted

Electric Circuit Diagram – Heater

Quantity Of Fuel, Measuring

Engine Fuse, Changing

Glow-Plug, Changing

Heater Unit, Removal And Fitting

Over-Heat Switch, Changing

Thermostat, Changing

Heating Unit, Dismantling And Assembly

Description Of Functions

Test Values For Control Unit, Cut-Off Relay And Rheostat

Technical Data

Cross-Section – D 3 L Heater

Faults Table

Operating The Time Switch

-Compressor

Compressor, Removal And Fitting, Sealing

Anti-Freeze Pump, Removal And Fitting, Sealing

Trailer Control Valve (For Single-Line System), Removal And Fitting, Sealing

Position, Testing And Adjustment Of Components

Compressor

Anti-Freeze Pump

Pressure Regulator

Pressure Gauge In Dashboard

Drainage Valve

Pressure Relief Valve

Trailer Control Valve (For Twin-Line System)

Trailer Control Valve (For Single-Line System)

Notes On Filling The Tyres

Testing The Compressor Unit – Summary

Function Diagram Of Compressor Unit

Faults Table

What you get

You will receive a PDF file with a high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.