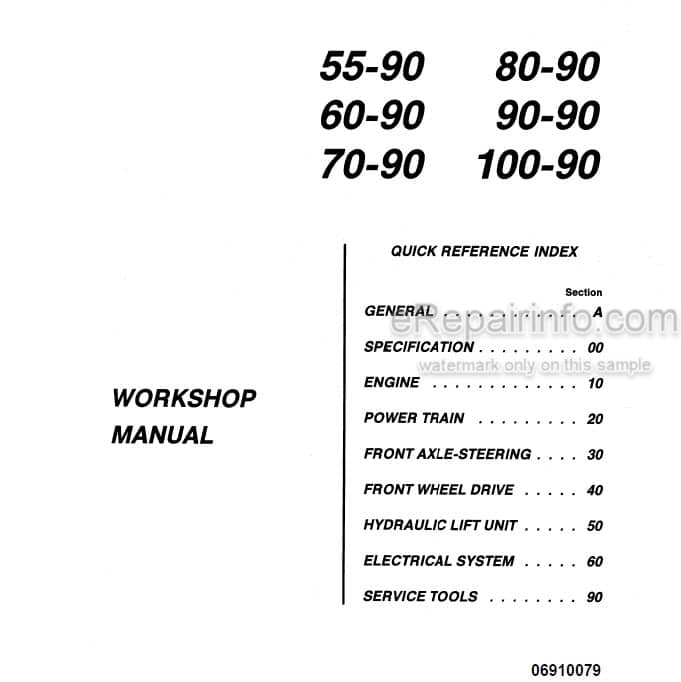

Factory Workshop And Supplement Manual For Fiat 55-90, 60-90, 70-90, 80-90, 90-90, 100-90, 60-94, 65-94, 72-94, 82-94, 88-94, 60-93, 65-93, 72-93, 82-93, 88-93 Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 3 (1 pdf)

Pages: 586

Number: 06910079; 603.54.241.02; 603.54.241.01

Bookmarks: Yes

Wiring Diagrams: Yes

Model

Fiat Tractor

55-90

60-90

70-90

80-90

90-90

100-90

60-94

65-94

72-94

82-94

88-94

60-93

65-93

72-93

82-93

88-93

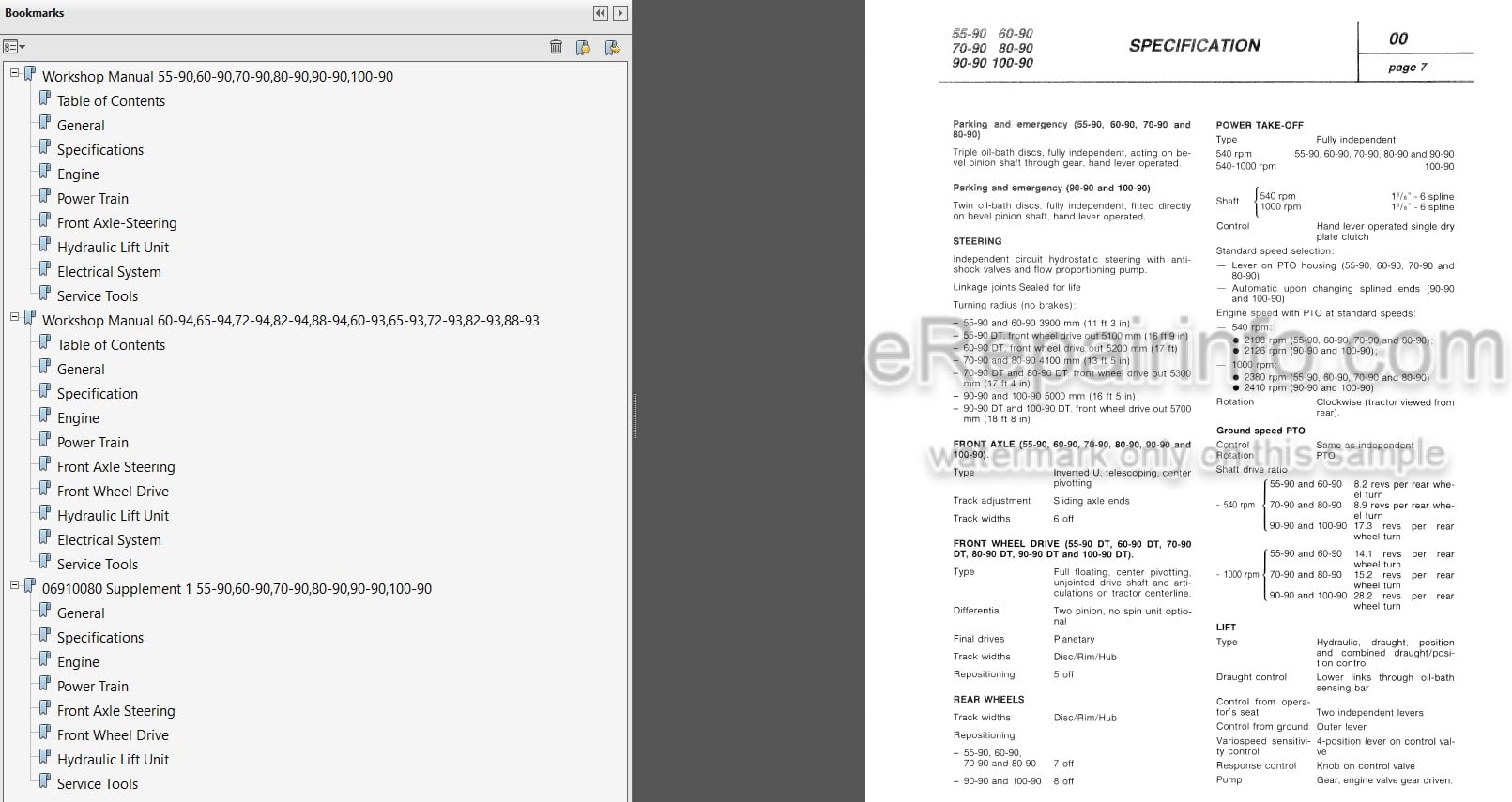

Contents

- WORKSHOP MANUAL FOR FIAT 55-90,60-90,70-90,80-90,90-90,100-90

- WORKSHOP MANUAL FOR FIAT 60-94,65-94,72-94,82-94,88-94,60-93,65-93,72-93,82-93,88-93

- SUPPLEMENT 1 FOR WORKSHOP MANUAL FOR FIAT 55-90,60-90,70-90,80-90,90-90,100-90

WORKSHOP MANUAL FOR FIAT 55-90,60-90,70-90,80-90,90-90,100-90

-GENERAL

General Instructions

Safety Precautions

-SPECIFICATION

Identification Data – Weights

Engine

Power Train – Brakes – Steering -Front Axle – Front Wheel Drive – Rear Wheels – Power Take-Off

Hydraulic Lift – Towing Attachments -Ballasting – Body

Electrical System – Lighting – Instruments And Accessories – Tyre Sizes Main Dimensions

Power Train Schematics

Capacities

-ENGINE: SPECIFICATION AND DATA

Engine Block – Cylinder Head

Crank Gear

Valve Gear

Lubrification System

Cooling System

Fuel System

Torque Data

Fastener Inspection

Engine Section 55-90 And 60-90

Engine Section 70-90 And 80-90

Engine Section 90-90

Engine Section 100-90

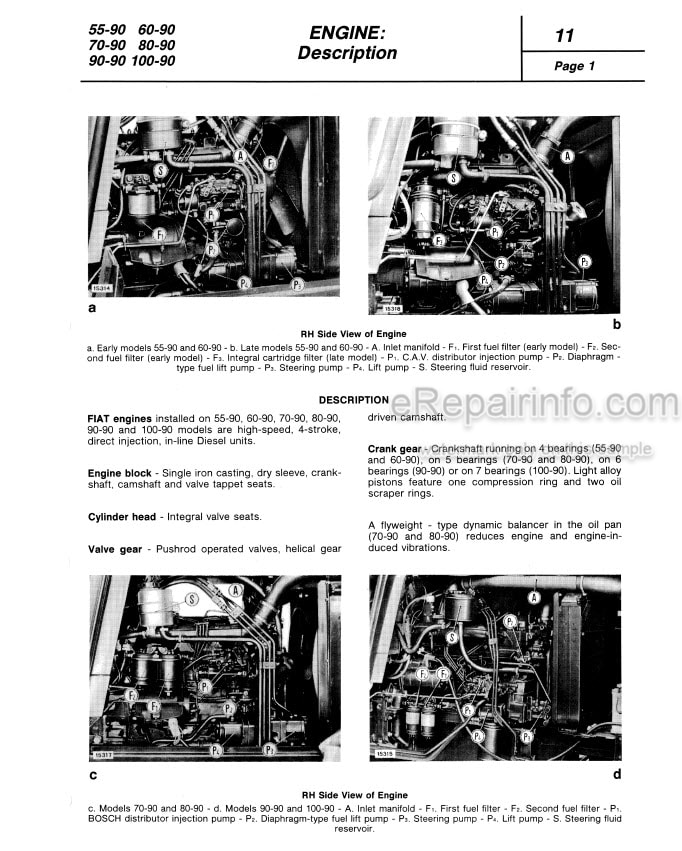

-ENGINE: DESCRIPTION REMOVAL – INSTALLATION

Description

Performance Data

Compression Test

Removal-Installation- Performance Data

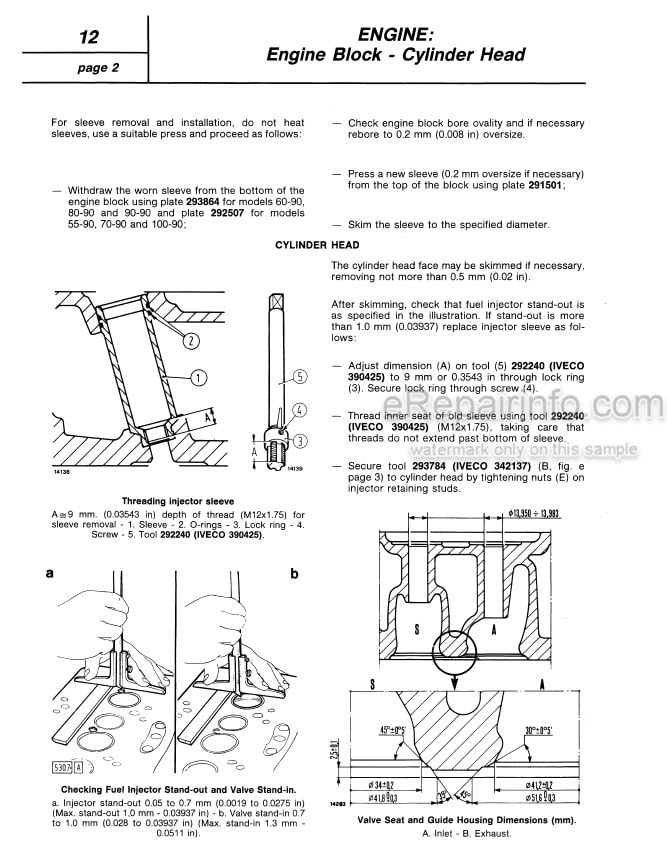

-ENGINE: ENGINE BLOCK – CYLINDER HEAD

Cylinder Sleeves

Cylinder Head

-ENGINE: VALVE GEAR

Camshaft – Valves, Guides And Springs

Tappets, Pushrods And Rockers

Valve Timing Gear Train

-ENGINE: CRANKGEAR

Crankshaft

Main And Big End Bearings And Caps Pistons And Rings

Connecting Rods

Flywheel

Dynamic Balancer (70-90 And 80-90)

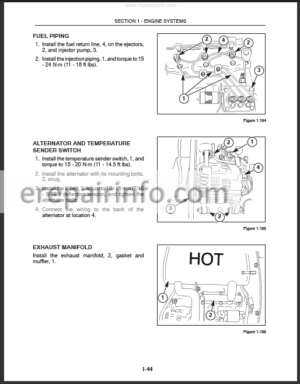

-ENGINE: FUEL SYSTEM

Air Cleaner – Fuel Tank – Fuel Filters

Fuel System Bleeding

Injection Pump Removal, Installation And Timing-Bosch Pump-Cav Pump

-ENGINE: LUBRICATION SYSTEM

Lubrication System Diagram 55-90 And 60-90

Lubrication System Diagram 70-90 And 80-90

Lubrication System Diagram 90-90 Lubrication System Diagram 100-90 Oil Pump – Oil Filter – Low Oil Pressure Indicator System

-ENGINE: COOLING SYSTEM

Cooling System Diagram

Description – Water Pump

Radiator – Belt Tension Adjustment Water Temperature Gauge – Thermostat

-POWER TRAIN: SPECIFICATION AND DATA

Clutches

Transmission And Splitter

Creeper

Reverser

Bevel Drive And Differential

Brakes

Final Drives

Power Take-Off

Torque Dat

Longitudinal Section Through Power Train 55-90, 60-90, 70-90, 80-90

Longitudinal Section Through Power Train 90-90 And 100-90

Cross Section Through Power Train 55-90 And 60-90

Cross Section Through Power Train 70-90 And 80-90

Cross Section Through Power Train 90-90

Cross Section Through Power Train 100-90

-POWER TRAIN: REMOVAL AND INSTALLATION

Platform Removal And Installation Platform Removal And Installation Together With Fiat Cab

Fiat Cab Removal Without Platform

-POWER TRAIN: CLUTCH

Clutch Removal And Installation

Early Model Valeo 11/11 Clutch Overhaul

Early Model Valeo 11/11 Clutch Adjustment

Late Model Valeo 11/11 Clutch Overhaul

Late Model Valeo 11/11” Clutch Adjustment

Valeo 12*712” Clutch Overhaul

Valeo 12’712” Clutch Adjustment

Luk Or O.M.G. Clutch Overhaul

Luk Or O.M.G. Clutch Adjustment

Clutch Control Adjustment

-POWER TRAIN: Transmission and splitter

Removal And Installation

Disassembly (55-90. 60-90, 70-90 And 80-90)

Longitudinal And Cross Sections Through Transmission And Splitter (55-90, 60-90, 70-90 And 80-90) Inspection – Assembly (55-90, 60-90,70-90 And 80-90) Disassembly (90-90 And 100-90) 11-12

Longitudinal And Cross Sections Through Transmission And Splitter (90-90 And 100-90) Inspection – Assembly (90-90 And 100-90)

Driven Shaft Adjustment (90-90 And 100-90)

Drive Shaft Adjustment (90-90 And 100-90)

Sections Through Linkage – Plan View Of Transmission And Splitter

Clutch/Splitter Shaft Seal Replacement (55-90. 60-90, 70-90 And 80-90)

-POWER TRAIN: CREEPER AND REVERSER

Creeper: Description – Overhaul (55-90, 60-90, 70-90 And 80-90)

Mechanical Reverser: Description -Overhaul (90-90 And 100-90)

Mechanical Reverser: Description -Overhaul (55-90, 60-90, 70-90 And 80-90)

-POWER TRAIN: BEVEL DRIVE AND DIFFERENTIAL

Removal – Installation – Disassembly – Assembly Of Bevel Drive And Differential

Bevel Pinion Shaft Removal And Installation

Bevel Drive Adjustment (55-90, 60-90, 70-90 And 80-90)

Bevel Drive Adjustment (90-90 And 100-90)

Differential Pinion And Side Gear Backlash Adjustment

Longitudinal And Cross Sections Through Bevel Drive And Differential (55-90. 60-90. 70-90, 80-90)

Longitudinal And Cross Sections Through Bevel Drive And Differential (90-90 And 100-90)

Differential lock installation and adjustment

-POWER TRAIN: BRAKES

Operation

Brake Unit Master Cylinder Assembly And Disassembly

Brake Pedal Adjustment

Brake Circuit Bleeding

Master Cylinder Bench Test

Parking Brake Lever Adjustment Transmission Brake – Removal And Installation (55-90, 60-90, 70-90, 80-90)

Transmission Brake – Removal And Installation (90-90 And 100-90)

-POWER TRAIN: FINAL DRIVES

Removal

Disassembly

Assembly And Installation

-POWER TRAIN: POWER TAKE-OFF

Removal And Installation

Disassembly And Assembly (55-90, 60-90. 70-90, 80-90)

Disassembly And Assembly (90-90, 100-90)

Longitudinal Section Through Pto

-FRONT AXLE-STEERING: SPECIFICATION AND DATA

Front Axle

Power Steering Torque Data

-FRONT AXLE-STEERING: POWER STEERING

Removal And Installation – Steering Knuckle Overhaul

Axle Checks

-FRONT AXLE-STEERING: FRONT AXLE

Power Steering Overhaul

Hydraulic Cylinder Overhaul

Steering Pump And Reservoir Overhaul – Hydraulic System Bleeding

Rotary Valve Wear Check

Return To Neutral Check

Seal Check

Relief Valve Calibration

Cylinder Safety Valve Adjustment

Power Steering Control Valve Overhaul

Trouble Shooting Chart

Operation – Diagrams

Steering Column Disassembly

-FRONT WHEEL DRIVE – SPECIFICATION AND DATA

Front Axle Axle Drive Drive Shafts Torque Data

-Front Wheel Drive: Live Front Axle

Removal – Final Drive, Wheel Hub And Steering Knuckle Overhaul

King Pin Bearing Adjustment

Wheel Bearing Adjustment

Bevel Drive And Differential Overhaul

Bevel Drive Adjustment

No Spin Differential

-FRONT WHEEL DRIVE: DRIVE SHAFTS – AXLE DRIVE

Drive Shaft Removal And Installation – Axle Drive Disassembly/Assembly

Front Wheel Drive Sections

-HYDRAULIC LIFT UNIT: SPECIFICATION AND DATA

Lift

Lift Pump

Implement Attachment

Remote Control Valves

Auxiliary Cylinder

Trailer Brake Valve Trouble Shooting Chart

Lift Trouble Shooting Chart

Torque Data

-HYDRAULIC LIFT UNIT: LIFT

Description

Removal – Disassembly

Inspection

Assembly And Installation

Position Control Adjustment

Maximum Lift Arm Travel Adjustment On Bench

Draught Control Adjustment

Lift Control Lever Adjustment

Variospeed Lever Adjustment

Response Link Adjustment

Lift-O-Matic Adjustment

Maximum Lift Arm Travel Adjustment With Lift Installed On Tractor

Valve Checks

Operation

Hydraulic Lift System Schematics

Auxiliary Cylinder

-HYDRAULIC LIFT UNIT: LIFT PUMP

Overhaul

Output Test

-HYDRAULIC LIFT UNIT: IMPLEMENT ATTACHMENT

Three Point Linkage – Right-Hand Lifting Rod

Draught Control Device

-HYDRAULIC LIFT UNIT: REMOTE CONTROL VALVES

Description And Operation

Hydraulic System Diagrams

Disassembly And Assembly

On -Bench Relief Valve Adjustment

Spool Return Test

Remote Control Valve Leakage Test

Control Lever Adjustment

Trailer Brake Remote Control Valve

Description

Hydraulic System Diagrams

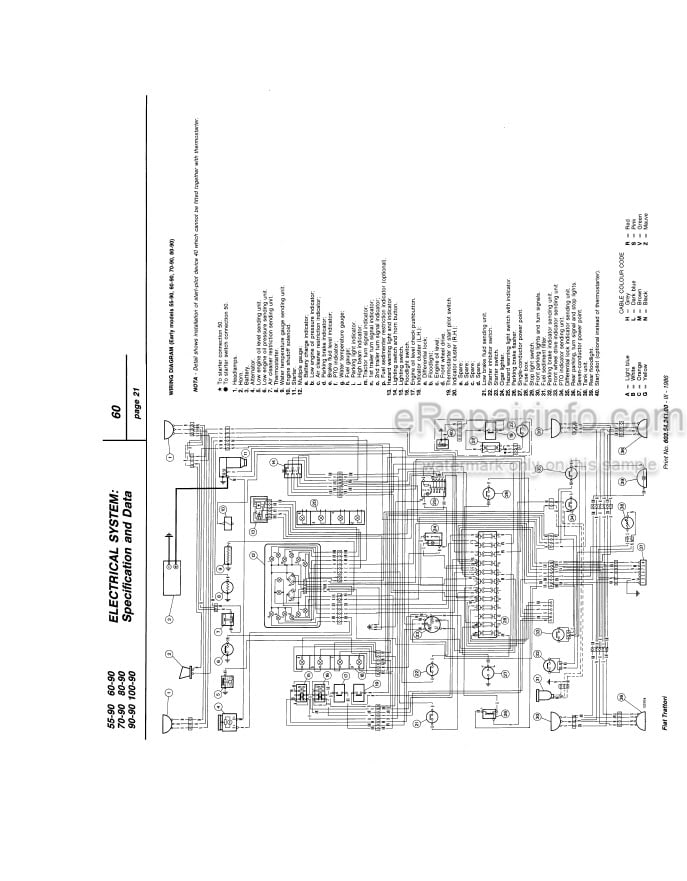

-ELECTRICAL SYSTEM: SPECIFICATION AND DATA

Charging System

Marelli Starter (55-90. 60-90)

Lucas Starter (55-90. 60-90)

Bosch Starter (55-90. 60-90)

Marelli Starter (70-90. 80-90)

Bosch Starter (70-90. 80-90)

Marelli Starter (90-90. 100-90)

Bosch Starter (90-90. 100-90)

Battery

Fuses

Lighting – Signals – Accessories

Switches

Controls And Instruments

Wiring Diagram (55-90. 60-90. 70-90 And 80-90)

Wiring Diagram (90-90 And 100-90)

-SERVICE TOOLS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.