Repair Manual For Versatile 756 836 856 876 936 956 976 Tractors. Illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-up.

Format: PDF

Language: English

Pages: 600

Bookmarks: Yes

Searchable: Yes

Number: 40075691

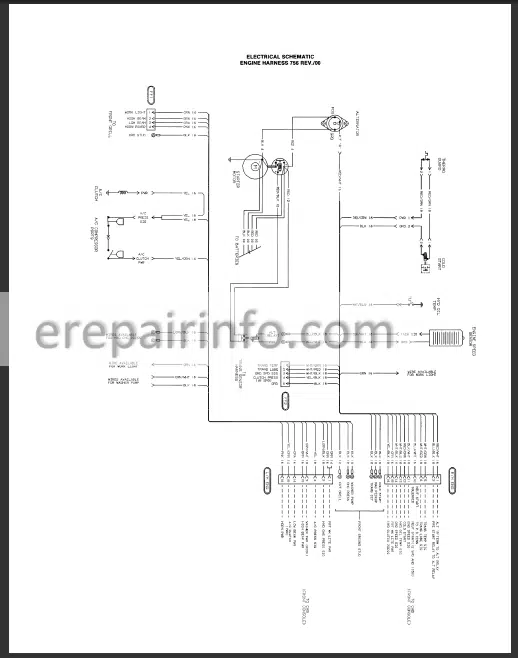

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Ford New Holland 756, 836, 856, 876, 936, 956, 976

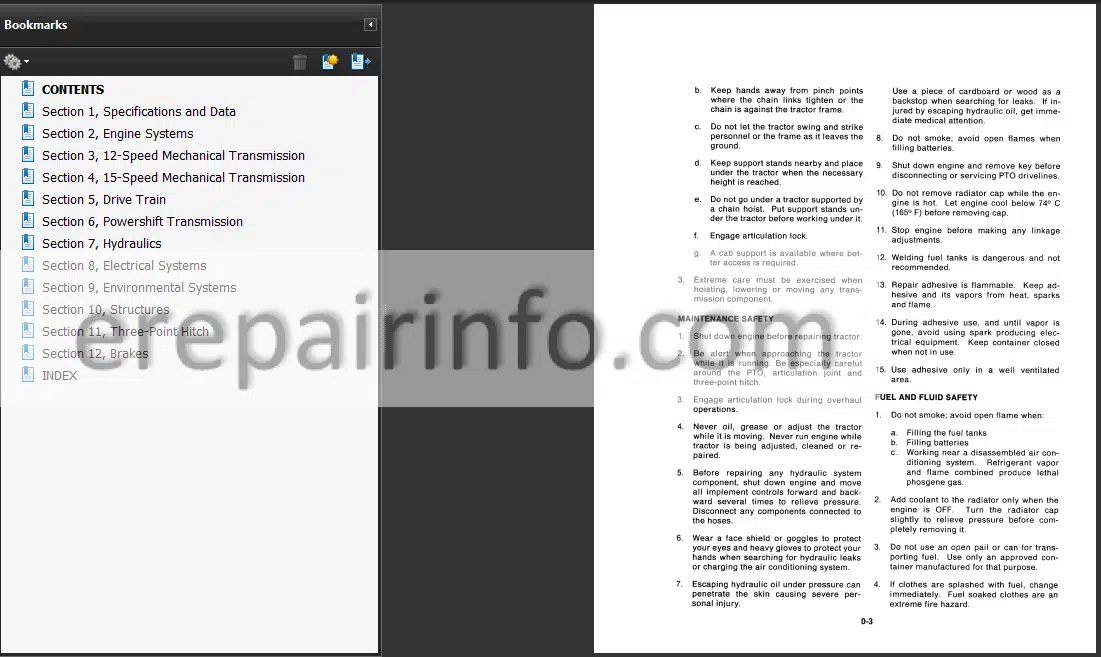

Contents

- – Specifications And Data

Introduction

Specifications

Accessories

Air Cleaner

Axles

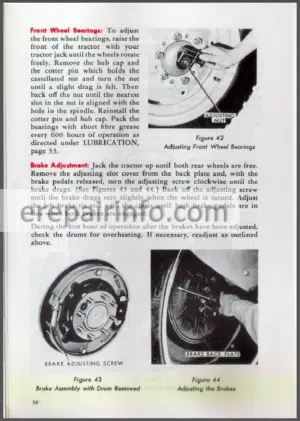

Brakes

Cab

Capacities

Cooling System

Dimensions

Drawbar

Electrical System

Engines

Frame

Hydraulic System

Steering

ThreePoint Hitch

Tires

Transmissions

Towing And Transport

Towing

Transporting

Hoists And Jacks

Jacks

Hoists

Fuel, Fluids And Lubricants

Fuels

Fluids

Coolant

Hydraulic Oil

Transmission Fluid

Brake Fluid

Lubricants

Engine OIl

Differentials

Pto Dropbox

Grease

Lubrication

Storage

General

Tractor Storage

Storing Batteries

Removal From Storage

Engine Startup After Storage - – Engine Systems

Introduction

Specifications And DATa

Engine Replacement

Special Tools And Equipment

Engine Mounts Replacement

Special Tools And Equipment

Replacement

Fuel System

Inspection Procedures

Throttle Linkage Adjustment

Purging Fuel Lines And Hoses

Priming The Fuel System

Fuel Tank Replacement

Fuel Gauge Sender Replacement

Cold Start

Inspection Procedures

Ether Cylinder Replacement

Cooling System

Inspection Procedures

Level/Temperature Senders

Coolant Hose Replacement

Radiator Replacement

Surge Tank Replacement

Removal

Installation

Flushing The Cooling System

Air Intake And Exhaust Systems

Inspection Procedures

Precleaner

Aspirator System

Air Cleaner Replacement

Muffler Replacement

Exhaust Pipe Replacement

Lubrication System

Inspection Procedures

Engine Oil And Filter Change - – Speed Mechanical Transmission

Specifications

How The System Works

Transmission Servicing

Special Tools And Equipment

Removal

Side Cover Replacement

Shift Arm And Seal Replacement

Shift Fork, Shaft And Seal Replacement

Input Shaft Bearing Replacement

Rear Output Bearing Seal Replacement

Front Output Bearing Seal Replacement

Transmission Lubrication Pump Replacement

Transmission Overhaul

Preparation

Input Shaft

Bottom Countershaft

Top Countershaft

Output Shaft

Reverse Idler Shaft

Inspection

Bearings

Gears

Output Shaft

Reverse Idler Shaft

Top Countershaft

Bottom Countershaft

Input Shaft

Final Assembly

Installation

Lubrication Pump Overhaul

Disassembly

Assembly

Shift Linkages

Shift Control Disassembly

Inspection

Shift Control Assembly

Adjustments

Range Shift Linkage

Gear Shift Linkage - – Speed Mechanical Transmission

How The System Works

Transmission Servicing

Transmission Removal

Special Tools And Equipment

Gear Shift Control Housing Replacement

Shift Shaft And Fork Adjustment

Lower Shift Fork Rail Adjustment

Transmission Lubrication Pump Replacement

Transmission Overhaul

Removal Of Lines, Hoses And Fittings

Removal Of Hydraulic Control Valves

Removal Of Master And Pto C Lutch

Removal Of Master Clutch

Removal Of Pto Clutch

Shift Shafts And Forks Removal

First Countershaft Removal

Third Countershaft Removal

Output Shaft Removal

Second Countershaft Removal

Reverse Idler Gear Assembly Removal

Reverse Idler Gear Assembly

Output Shaft

Second Countershaft

Third Countershaft

First Countershaft

Bearings Installation

Gear Shift Shaft And Fork Installation

Range Shaft Shaft And Fork Installation

Clutches

Description And Operation

Master Clutch And Input Shaft

Master Clutch Housing

Pto Clutch

Clutch Control Valves

Pressure Regulator Valves

Master Clutch Modulator Valve

Pto Clutch Modulator Valve

Pto Clutch Housing

Pto Manifold C A P

Troubleshooting

Troubleshooting The Master Clutch

Troubleshooting The Pto Clutch

Servicing

Master Clutch Facing Plates Removal And Installation

Installation

Pto Clutch Removal And Installation

Overhaul

Master Clutch Overhaul

Preparation For Disassembly

Disassembly

Preparation For Master Clutch Assembly

Master Clutch Assembly

Pto Clutch Overhaul

Preparation For Assembly

Final Assembly

Transmission Lubrication Pump Overhaul

Shift Linkages

Shift Control Disassembly

Inspection

Shift Control Assembly

Adjustments

Range Shift Linkage

Regulator Valve

Modulator Valve

Pto Valve

Hydraulic Transmission Brake - – Drive Train

Description And Operation

General

Description And Operation

Description

Operation

Troubleshooting

Clutch Removal

General

Preparation

Yoke Removal

Replacement Of Output Shaft

Replacement Of Clutch Brake

Replacement Of Clutch Release Bearing

Replacement Of Pressure Plate

Replacement Of Clutch Plates

Replacement Of Intermediate Plate

Drive Pins

Replacement Of Clutch Pilot Bearing

Clutch Overhaul

General

Free Seized SelfAdjusting Ring

Clutch Disassembly

Clutch Installation

Transmission Brake And Clutch Free

Pedal Adjustment

General

Transmission Brake Adjustment

Free Pedal And Release Travel Adjustment

Axle Assemblies

Description And Operation

Axles And Planetary Gears

Differential Carrier

Controlled Traction Differentials

Remove And Disassemble Clutch Pack

Assemble And Install Clutch Pack

Install Differential And Clutch Pack

Assembly In Carrier

Adjust Differential Bearing Preload

Electric Shift System

Electrical Operation

Mechanical Operation

Planet Carrier And Axle S Ha Ft

General

Removal

Inspection

Removal Of Planet Gears

Installation Of Planet Gears

Installation Of Planet Carrier

Wheel Bearings

Removal

Installation

Differential Carrier

Removal

Differential Conversion

Disassembly

Inspection

Assembly

Installation

Drivelines

Troubleshooting

Servicing

Cross Bearing Replacement

Driveshaft Repair

Steady Bearing Replacement - – Powershift Transmission

- – Hydraulics

Steering Circuit

Implement Circuit

Torque Values

Testing

Required Equipment

Steering Circuit

Implement Circuit

Steering Pump Tests

Inlet Pressure Test

Outlet Flow And Pressure Test

Relief Valve Test

Steering Valve Test

Steering Cylinder Leak Test

Implement Pump Tests

Pressure Test

Outlet Flow Test

Low Pressure StandBy Adjustment

High Pressure StandBy Test

Case Drain Test

Implement Valve Tests

Pressure Compensator Test

Flow Control Test

Valve Kickout Pressure Test

Troubleshooting

Steering Circuit

Implement Circuit

Overhaul

Hydraulic System ChargeUp

Steering Pump

Steering Valve

Steering Cylinders

Bleeding

Implement Pump

Implement Valve

Control Linkages

Filters

Oil Cooler

Hydraulic Reservoir

Removal

Installation - – Electrical Systems

Cab Main Harness

Powershift Controllers

Powershift Directional Control Levers

Specifications

Batteries

Alternator

Starter

Circuit Breakers/Fuses

Lighting Circuits

Instrumentation

Voltmeter Values

Oil Pressure Gauge Values

Coolant Temperature Gauge Values - – Environmental Systems

Introduction

Specifications And Data

Torque Values

Special Tools And Equipment

Environmental Systems

How The System Works

Air Conditioning System Tests

System Performance Test

Connecting The Gauges

Testing

System Leak Testing

Discharging The System

Compressor

Compressor Removal

Compressor Overhaul

Special Tools And Equipment

Inspection And Repair

Compressor Installation

Compressor Oil Check

Condenser

Repair

Installation

Evaporator/Heater Core

Repair

Expansion Valve Replacement

Receiver/Dryer Replacement

Air Conditioning Hoses And Lines

Evacuating The System

Charging The System

Heater Hose Replacement

Heater Valve Replacement - – Structures

Lubrication

Cab

Cab Mount Replacement

Special Tools And Equipment

Cab Window And Seal Replacement

Cab Insulation Panel Replacement

Replacement

Cab Roof Assembly

Cab Roof Removal

Cab Roof Repair

Special Tools And Equipment

Repair

Headliner Removal

Headliner Installation

Cab Roof Installation

Operator’S Seat

Seat Cushion Replacement

Lower Seat Assembly Repair

Frames

General

Frame Pivot Pin Bushing Replacement

Replacement

Steering Cylinder Replacement

Hood And Grill Removal - – ThreePoint HItch

Hydraulic Components

ThreePoint Hitch Hydraulic Circuit

ThreePoint Hitch Valve

Flow Control

Shuttle Valves

ThreePoint Hitch Solenoids

Electrical Components

Operator Controls

Controller

Feedback Potentiometer

Feedback Potentiometer Adjustment

ThreePoint Hitch Adjustments

Category Conversion

Swayblocks

Quick Hitch Installation

Lift Link Adjustment

Electrical System

Lowering Flow Control Adjustment

Hydraulic System Adjustments

Lift Pressure Adjustment

Raise Rate Flow Adjustment

Troubleshooting And Testing

Electrical System Testing

Special Tools And Equipment

Terminology

Electrical Test Procedures

Hydraulic Testing

Special Tools And Equipment

Test Gauge Installation

Hydraulic Test Procedure

Test Variables

Valve Leakage Test

Overhaul

Special Tools And Equipment

Electrical Harness Replacement

Hydraulic Disassembly And Assembly

Mounting Brackets Removal (With Pto)

Mounting Brackets Removal

(Without P To )

Final Disassembly - – Brakes

Minor Repairs

Replacing Friction Pads

Removal And Installation Of Brake Caliper

Removal And Installation Of Brake Master Cylinder

Removal And Installation Of Brake Disc

Bleeding Of Brake System

Overhaul

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.