Factory Service Manual For Gehl, Mustang And Manitou Articulated Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 654

Number: 50940441 (november 2019)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Gehl, Mustang And Manitou Articulated Loader

Gehl 650

Gehl 750

Gehl T750

Mustang 608

Mustang 708

Mustang 708T

Manitou MLA-6

Manitou MLA-7

Manitou MLA-T516

Contents

-INTRODUCTION

Safety Symbol and Signal Words

Contents and Use of this Manual Machine Orientation

Proper Machine Use

Model/Serial Numbers

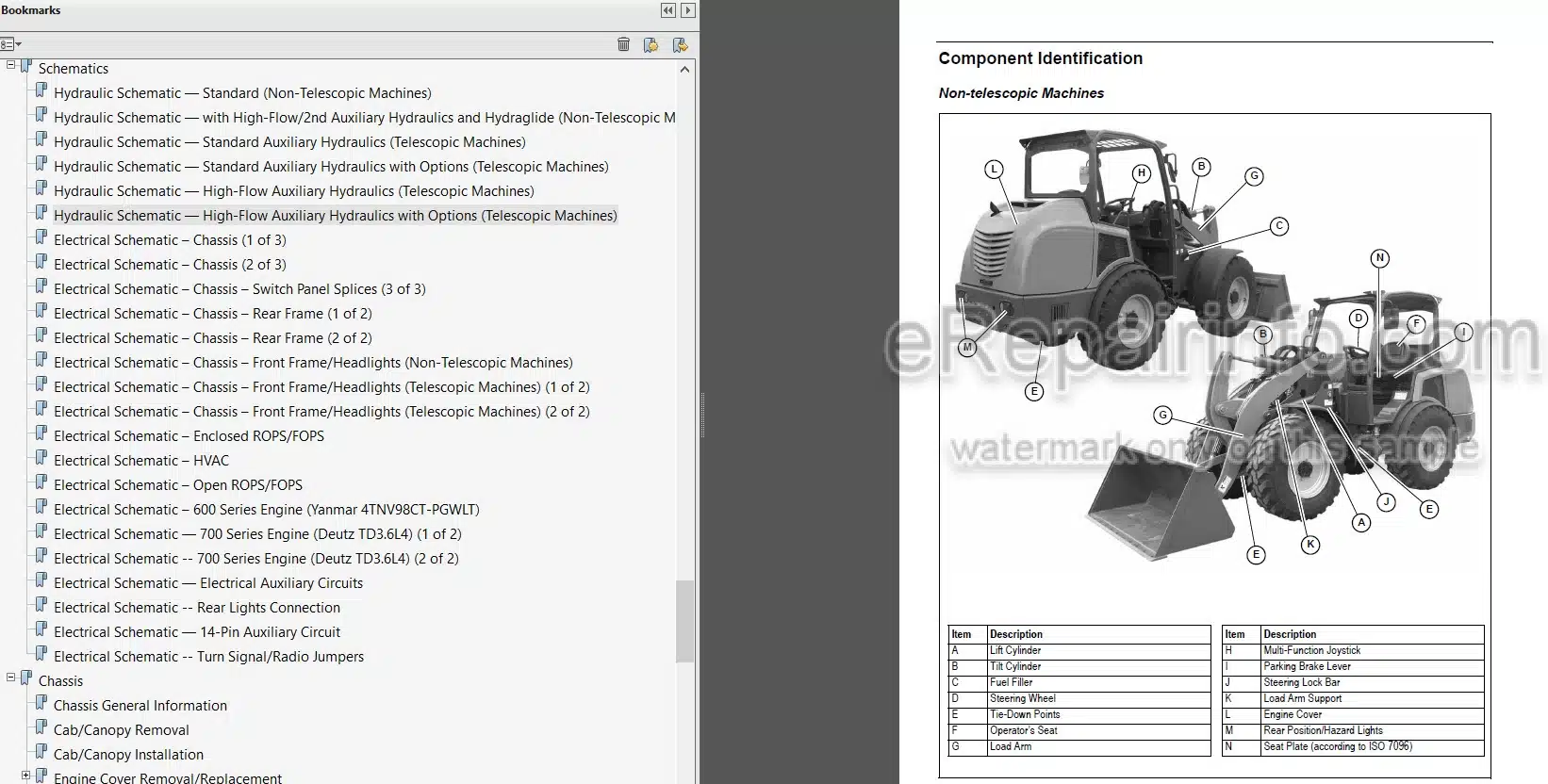

Component Identification

Fields of Application

Using Attachments

Fire Extinguisher

Manufacturer Information

Indicator and Operation Symbols

-SAFETY

Safety Symbol and Signal Words

Mandatory Safety Shutdown Procedure

Before Starting

During Operation

Provision for Stability/Avoiding Rollover and Tipover Accidents

Telescopic Machines

Articulated Loader Stability

Applications with Load-Handling Devices

Parking the Machine

Electrical Energy

Maintenance and Service Safety Practices

Battery Hazards

Fire Hazards

Additional Safety Equipment

Crystalline Silica Exposure

Transporting the Machine

Raising the Machine with a Crane

Loading and Transporting the Machine

Safety Decals

ANSI-Style and Common Safety Decal Locations

ISO-Style Safety Decal Locations

-INDICATORS AND CONTROLS

Multi-Function Display

Control Keypad

Switch Panel

Telescopic Machines Load/Level Indicators (Telescopic Machines)

Ignition Switch

Operator’s Seat/Armrest

Multi-Function Joystick

Parking Brake

Control Lever (Option)

Throttle Controls

Travel Controls

High/Low Travel Speed Selection

Constant Speed (Option)

Differential Lock

Engine Off Load Arm Lower

Hydraulics Transport Lock-out

Attachment Mounting

Auxiliary Hydraulic System

Hydraglide Button (Option)

Cooling Fan Rotation Reversing Button

Cab Heat and Air Conditioning (HVAC)

Work Lights Button

Load Arm Lights Button (Telescopic Machines Only)

Beacon (Option)

Windshield Wiper/Washer and Defrost

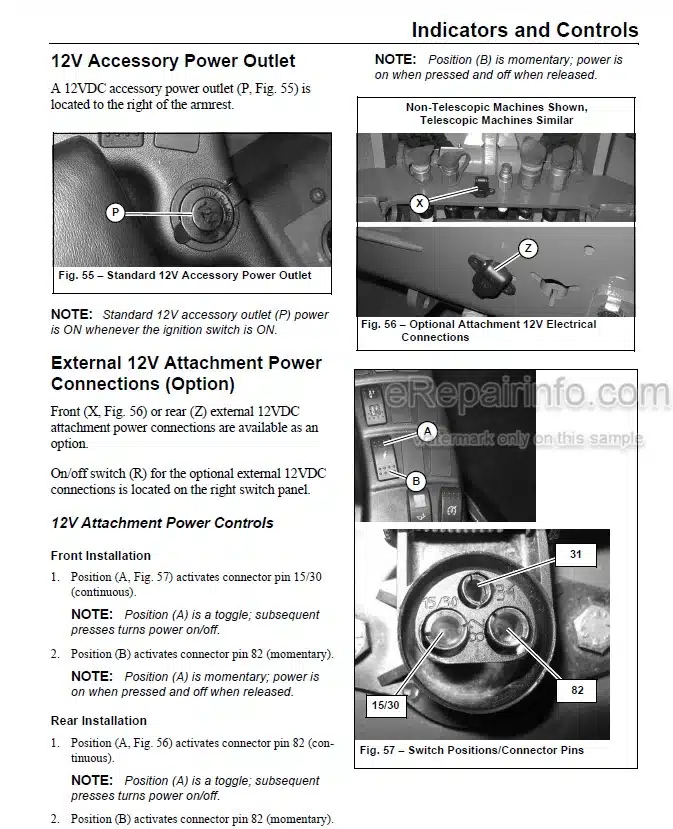

12V Accessory Power Outlet

External 12V Attachment Power Connections (Option)

Battery Disconnect Switch

-OPERATION

Operational Checks

Before Operation

Seat Belt

Dome Light

Starting the Engine

Engine Warm Up

Run-In Period

Stopping the Engine

Engine Stalling

Safety Interlock System (Hydraloc1)

Travel Drive Operation

Constant Speed Operation (Option)

Special Considerations for Telescopic Machines

Load Arm Operation

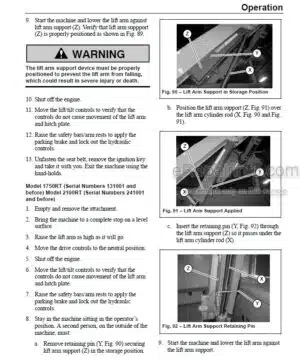

Load Arm Raise/Tilt Support (Non-Telescopic Machines Only)

Self-Leveling and Return-To Dig

Hydraglide Ride Control System (Option)

Hydraulics Transport Lock-Out Operation

Connecting/Disconnecting Attachments

Powering Attachments with Hydraulic Function

14-Pin Connector (Option)

Working with Buckets

Working with Pallet Forks

Diesel Particulate Filter (DPF) Regeneration Procedures

After Operation

Jump-Starting

Raising the Machine using a Crane

Towing

Loading and Transporting the Machine on a Transport Vehicle

-MAINTENANCE

Maintenance Schedule

Maintenance Interval

General Lubrication

Telescopic Load Arm Maintenance (Telescopic Machines Only)

LLMI Calibration (EU Telescopic Machines Only)

Engine Maintenance

DPF Service

Fuel System Maintenance

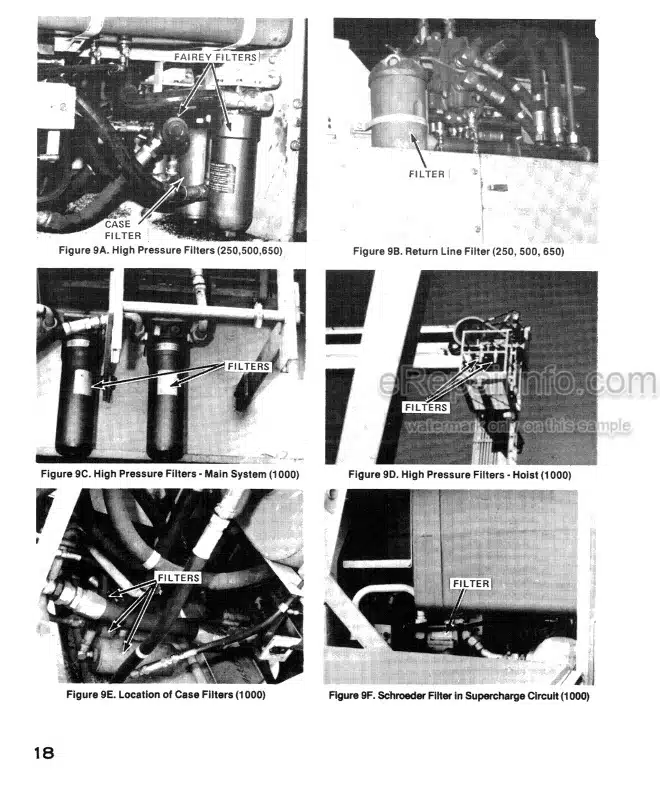

Hydraulic System Maintenance

Hydraulic Hose Maintenance

Planetary Axles

Brake Fluid Reservoir

Parking Brake Adjustment/Service

Wheels and Tires

Travel Motor Lubrication

Electrical System

HVAC/Air Conditioning Maintenance

Windshield Washer Reservoir

Long-Term Storage

Final Shutdown / Decommissioning

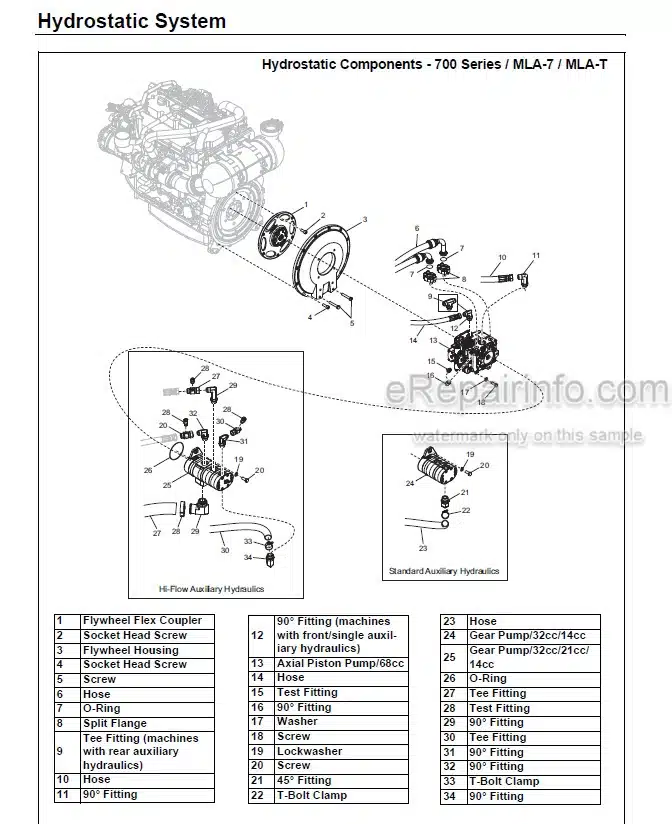

-HYDROSTATIC SYSTEM

Hydrostatic System General Information

Charge Pressure Test and Adjustment

Hydrostatic Pump Pressure Relief Valves

600 Series IMLA-6 Hydrostatic Pump Removal

Splined Coupler Removal/Installation

600 Series / MLA-6 Hydrostatic Pump Installation

700 Series IMLA-71MLA-T Hydrostatic Pump Removal

Splined Coupler Removal/Installation

700 Series I MLA-71 MLA-T Hydrostatic Pump Installation

Hydrostatic Pump Drive Coupling Removal and Installation

-DRIVE SYSTEM

Drive System General Information

Pump and Drive Motor Error Codes

Hydraulic Drive Motor

600 Series / MLA-6 Hydraulic Motor Removal

600 Series / MLA-6 Hydraulic Motor Installation

700 Series / MLA-7 / MLA-T Hydraulic Motor Removal

700 Series / MLA-71 MLA-T Hydraulic Motor Installation

Brake/Inching Pedal Calibration

Bleeding the Brake System

Brake/lnching Pedal Electrical

Throttle Pedal Electrical

Hand Throttle Electrical

Transmission Control Unit (TCU)/ Drive Controller

-HYDRAULIC SYSTEM

Hydraulic System General Information

General Hydraulic Service Notes

Hydraulic System Diagrams

Main Pressure Test and Adjustment

Control Valve

Non-Telescopic Machines Tilt/ Lift Cylinder Tests

Telescopic Machines Lift/Tilt Functional Description

Telescopic Machines TiIt/Lift/ Extension Cylinder Tests

Hydraulic Cylinder Disassembly/ Assembly

Hydraulic Solenoid Valves and Tests

Hydraglide

Solenoid Valve Disassembly/ Reassembly

Steering

Hydraulic System Troubleshooting

-HYDRAULIC SCHEMATICS

Hydraulic Shematic

-ELECTRICAL CONTROL SYSTEM

Electrical Control System General Information

Control Modules

CAN System Service/Computer Connection

Operation/Controller Area Network (CAN) Functional Organization

Accessories and Options Functional Detail

CAN/Control System Troubleshooting

-ELECTRICAL SYSTEM

Power Distribution

Start/Glow Relay Solenoid Test

Control Modules

J1939 Data Connector

Easy Manager

-WIRE HARNESS DIAGRAMS

Wire Harness Diagram

-SHEMATIC

Hydraulic Schematic

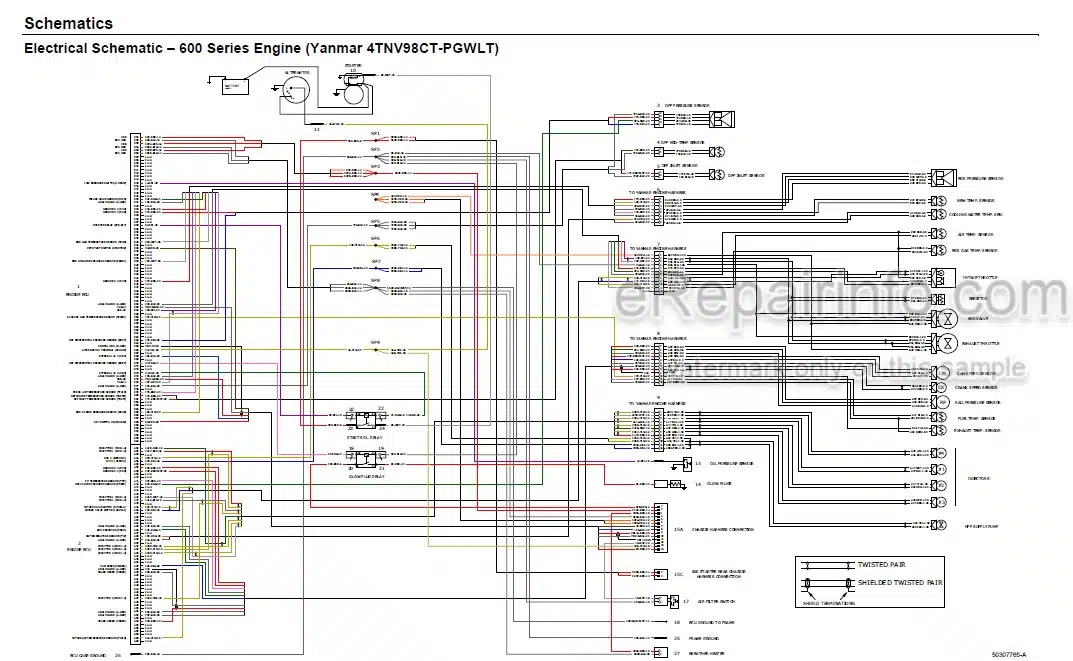

Electrical Schematic

-CHASSIS

Chassis General Information

Cab/Canopy Removal

Cab/Canopy Installation

Engine Cover Removal/Replacement

Articulation Joint

-TELESCOPIC LOAD ARM

Telescopic Load Arm Component Identification

Tilt Cylinder Removal/Installation

Inner Load Arm Hydraulic Tube and Hose Removal/Installation

Load Arm Slide Pad Service

Hose Support Removal

Hose Support Installation

Extension Indicator Potentiometer (Domestic Telescopic Machines)

-HVAC SYSTEM

Air Conditioning Refrigerant Recovery

Air Conditioning System Charging

700 Series I MLA-71 MLA-T Air Conditioning Compressor Removal

700 Series / MLA-7 / MLA-T Air Conditioning Compressor Installation

-600 SERIES IMLA-6 ENGINE

600 Series / MLA-6 Engine Removal

600 Series / MLA-6 Engine Installation

-700 SERIES / MLA-71 MLA-T ENGINE

700 Series / MLA-7 / MLA-T Engine Removal

700 Series / MLA-7 / MLA-T Engine Installation

-ENGINE COOLING SYSTEM

Engine Cooling System General Information

600 Series / MLA-6 Radiator Removal

600 Series / MLA-6 Radiator Installation

700 Series / MLA-7 / MLA-T Radiator Removal

700 Series / MLA-7 / MLA-T Radiator Installation

-TROUBLESHOOTING

Engine Troubleshooting

Indicator Lamp Troubleshooting

Seal and Hose Troubleshooting

Hydraulic System Troubleshooting

Hydrostatic Travel Drive System Troubleshooting

Electrical Troubleshooting

Error Codes

-SPECIFICATIONS

Fluids/Lubricants Types and Capacities

Payloads/Capacities

Dimensions

Weights

Coolant Compound Table

Wheels/Tires

Engine

Hydraulic System

Sound Power/Pressure Levels (Non-Telescopic Machines)

Sound Power/Pressure Levels (Telescopic Machines)

Vibration Levels

Common Materials and Densities

INDEX

TORQUE SPECIFICATIONS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.