Factory Operators Manual For Gehl Compact Track Loader. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 180

Issue: february 2013

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Gehl Compact Track Loader

RT175

Serial Numbers 10720 and Before

RT210

Serial Numbers 21040 and Before

Contents

DELIVERY CHECKLISTS

-INTRODUCTION

Safety Symbol

Contents and Use of this Manual

Safety Symbol and Signal Words

Machine Orientation

Proper Machine Use

Service and Registration

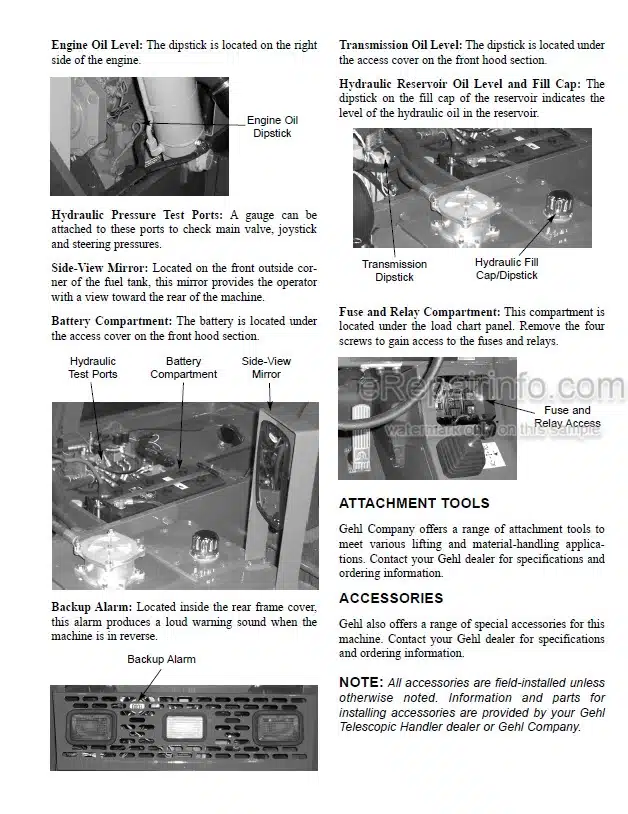

Component Identification

Fields of Application

Using Attachments

Vibration Information

Fire Extinguisher

Manufacturer Information

Indicator and Operation Symbols

-SAFETY

Safety Symbol and Signal Words

Mandatory Safety Shutdown Procedure

Before Starting

During Operation

Applications with Load-Handling Devices

Parking the Machine

Electrical Energy

Maintenance and Service Safety Practices

Battery Hazards

Fire Hazards

Additional Safety Equipment

Crystalline Silica Exposure

Transporting the Machine

Lifting the Machine with a Crane

Loading and Transporting the Machine

Safety Decals

ANSI-Style Safety Decals

ISO-Style Safety Decals

-SPECIFICATIONS

Fluids/Lubricants Types and Capacities

Dimensions

Payloads/Capacities

Weights

Track Drive

Coolant Compound Table

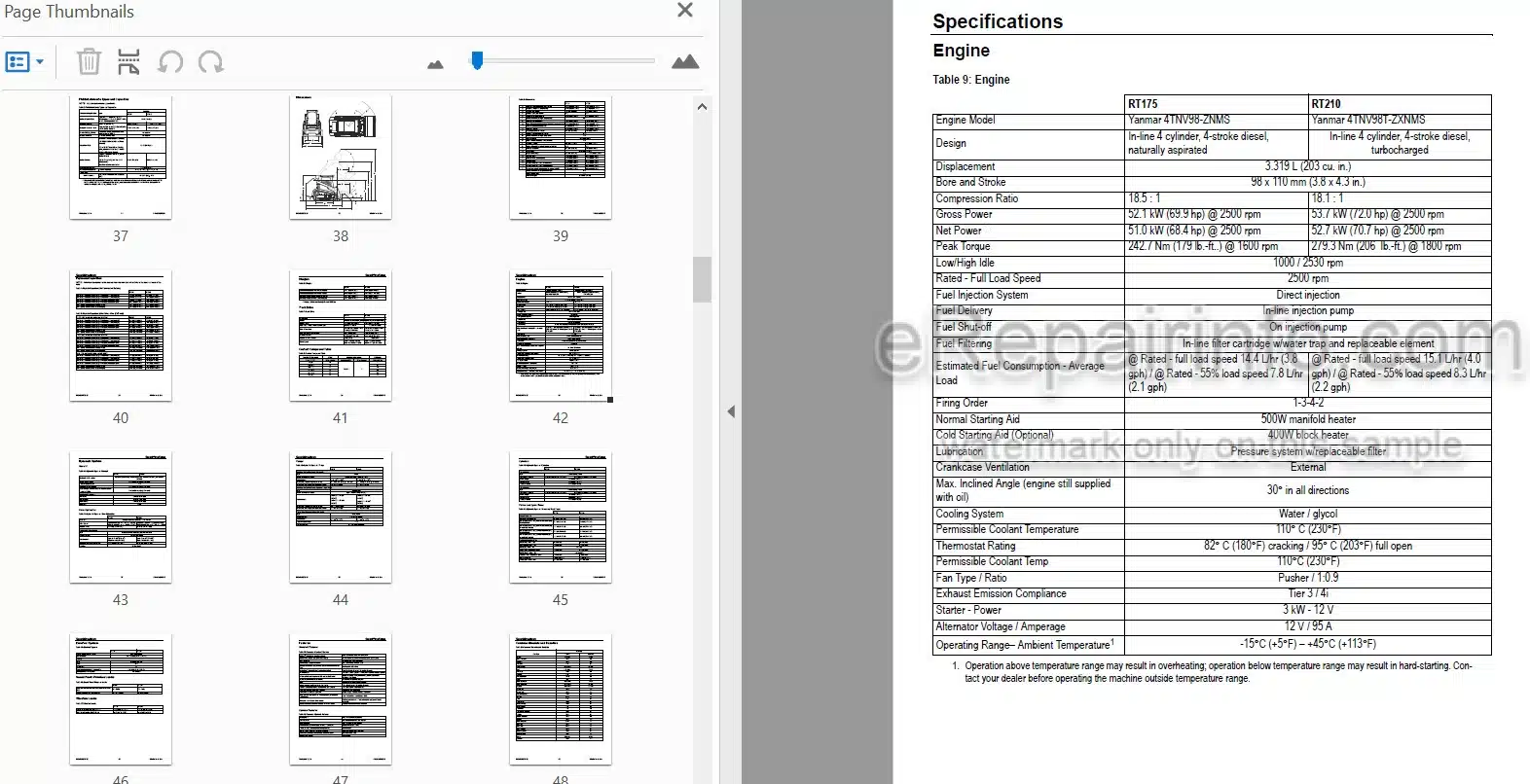

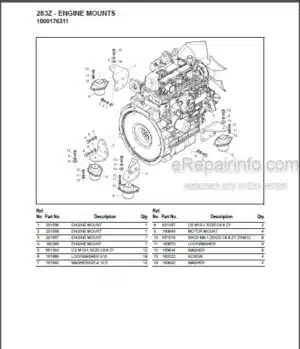

Engine

Hydraulic System

Electrical System

Sound Power/Pressure Levels

Vibration Levels

Features

Standard Features

Optional Features

Common Materials and Densities

-CONTROLS

Multi-Function Display

Switches/Indicators

Multi-Function Display Screens

Control Joysticks

Parking Brake/Work Hydraulics Lock-out

Cab Heat and Air Conditioning (Option)

Operator’s Seat

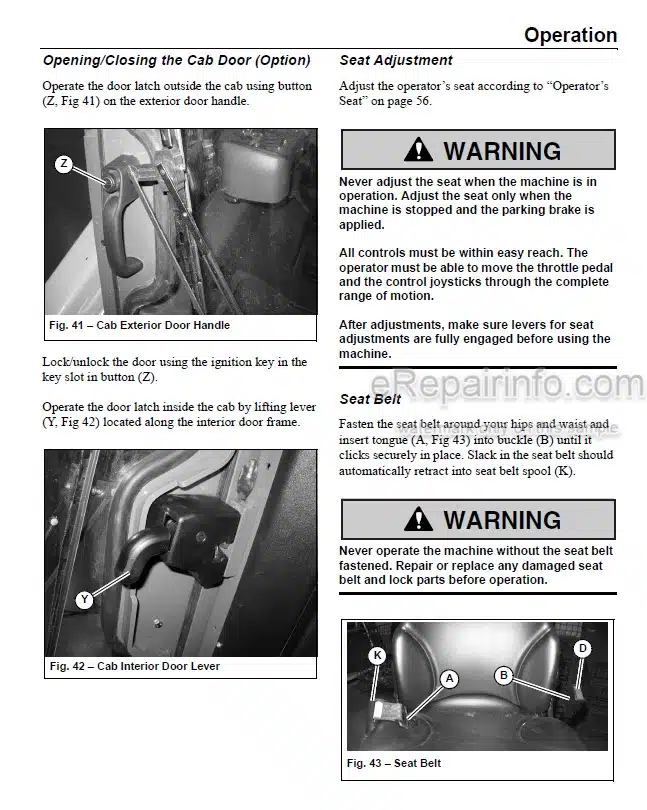

Seat Belt

Throttle Controls

Travel Controls

Travel Speed Range Selection

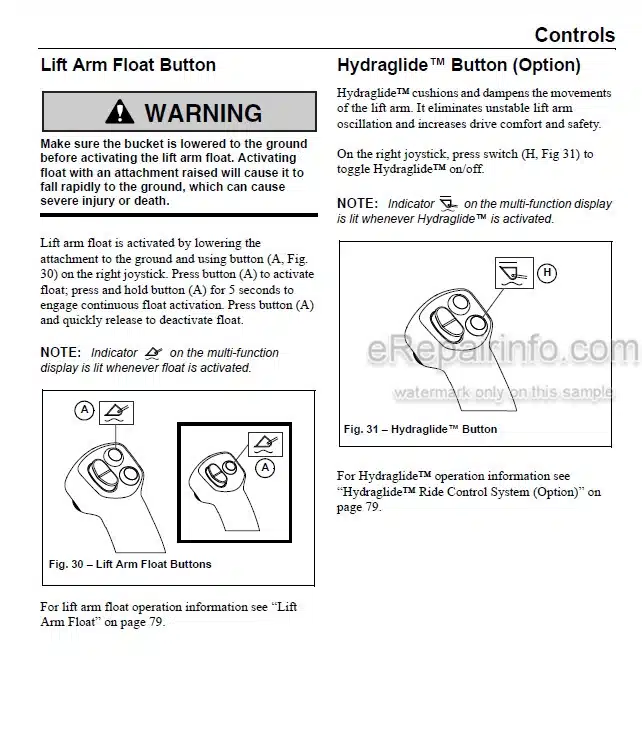

Lift Arm Float Button

Hydraglide Button (Option)

Work Lights

Battery Disconnect Switch (Option)

Windshield Wipers/Washer

-OPERATION

Operational Checks

Before Operation

Starting the Engine

Warm Up

Run-In Period

Stopping the Engine

After Operation

Jump-Starting

Travel Drive Operation

Lift Arm Operation

Self-Leveling

Lift Arm Float

Hydraglide Ride Control System (Option)

Hydraulics Control Lock

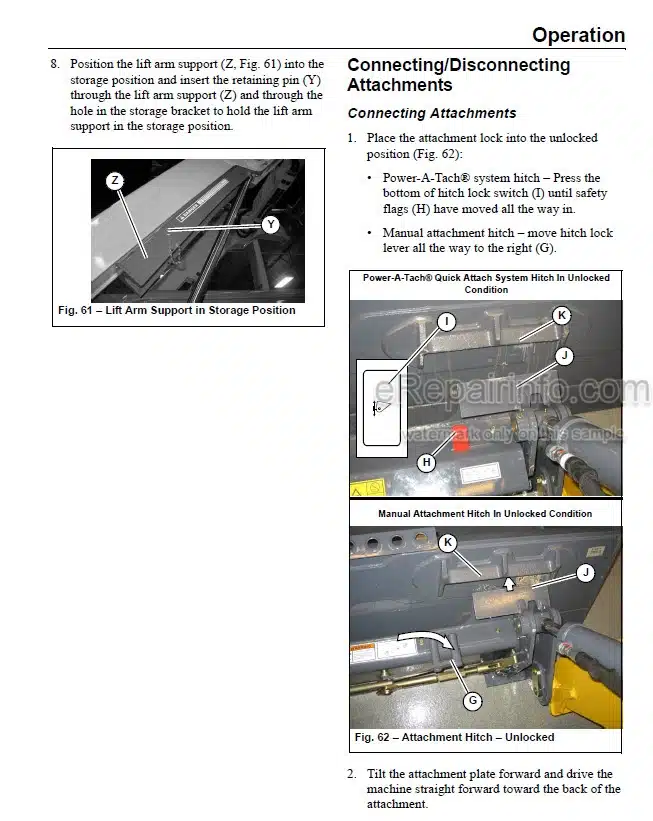

Lift Arm Support

Connecting/Disconnecting Attachments

Powering Attachments with Hydraulic Function

Working with Buckets

Working with Pallet Forks

Lifting the Machine using a Crane

Loading and Transporting the Machine on a Transport Vehicle

Storage Box

-MAINTENANCE

Maintenance Schedule

Maintenance Interval

Engine Maintenance

Fuel System Maintenance

Hydraulic System Maintenance

Hydraulic Hose Maintenance

Travel Motor Maintenance

Track Maintenance

General Lubrication

Tilting ROPS/FOPS

Electrical System

Long-Term Storage

Air Conditioning Maintenance

Windshield Washer Reservoir

Final Shutdown / Decommissioning

Maintenance Log

-TROUBLESHOOTING

Engine Troubleshooting

Indicator Lamp Troubleshooting

Seal and Hose Troubleshooting

Hydraulic System Troubleshooting

Hydrostatic Travel Drive System Troubleshooting

Electrical Troubleshooting

Miscellaneous Troubleshooting

Error Codes

-SCHEMATICS

Engine/Starting and Charging

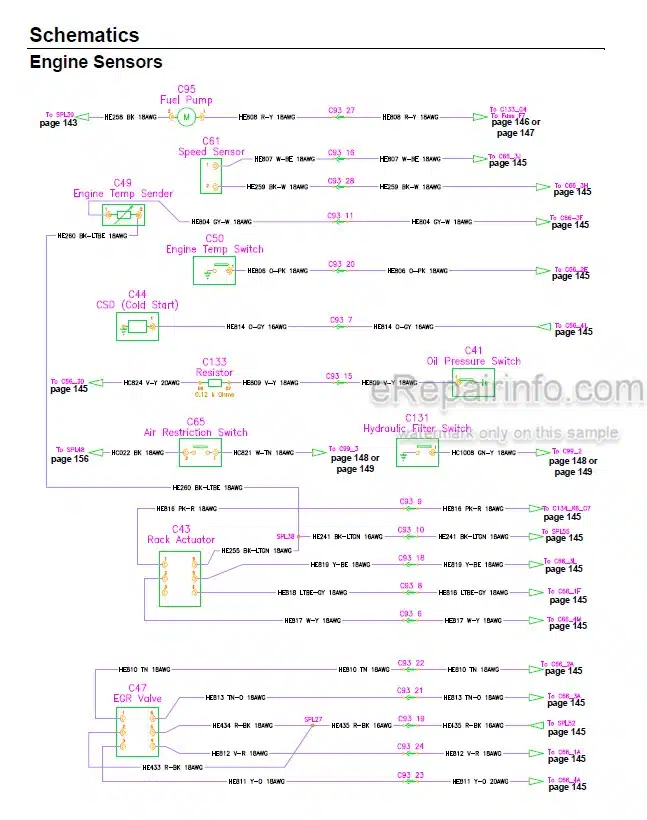

Engine Sensors

Engine ECU

Power Distribution (Later Machines)

Power Distribution (Early Machines)

I/O Controller (Later Machines)

I/O Controller (Early Machines)

Solenoid Control – A (Later Machines)

Solenoid Control – A (Early Machines)

Solenoid Control – B

Operator/Drive Controls

High-Flow/Self-Level/Power-A-Tach Ouick Attach System (Later Machines)

High-Flow/Self-Level/Power-A-Tach Ouick Attach System (Early Machines)

HVAC

Track Tension/Lighting Control

Wipers/Washer Pumps

Work Lights

Auxiliary Power/Dome Light/Radio

Operator CAN Interface

Grounds

Hydraulic Schematic

INDEX

EC DECLARATION OF CONFORMITY

TORQUE SPECIFICATIONS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.