Factory Service Manual For Mustang Compact Track Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 316

Number: 50940649 (august 2020)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Gehl, Mustang And Manitou Compact Track Loader

Gehl RT185

Gehl RT215

Gehl RT255

Mustang 1850RT

Mustang 2150RT

Mustang 2550RT

Manitou 1850RT

Manitou 2150RT

Manitou 2550RT

Contents

-SAFETY

Safety Symbol and Signal Words

Mandatory Safety Shutdown Procedure

Before Starting

During Operation

Applications with Load-Handling Devices

Parking the Machine

Electrical Energy

Maintenance and Service Safety Practices

Battery Hazards

Fire Hazards

Additional Safety Equipment

Crystalline Silica Exposure

Transporting the Machine

Lifting the Machine with a Crane

Loading and Transporting the Machine

Safety Decals

ANSI-Style Safety Decals

ISO-Style Safety Decals

Lifting the Machine using a Crane

Loading and Transporting the Machine on a Transport Vehicle

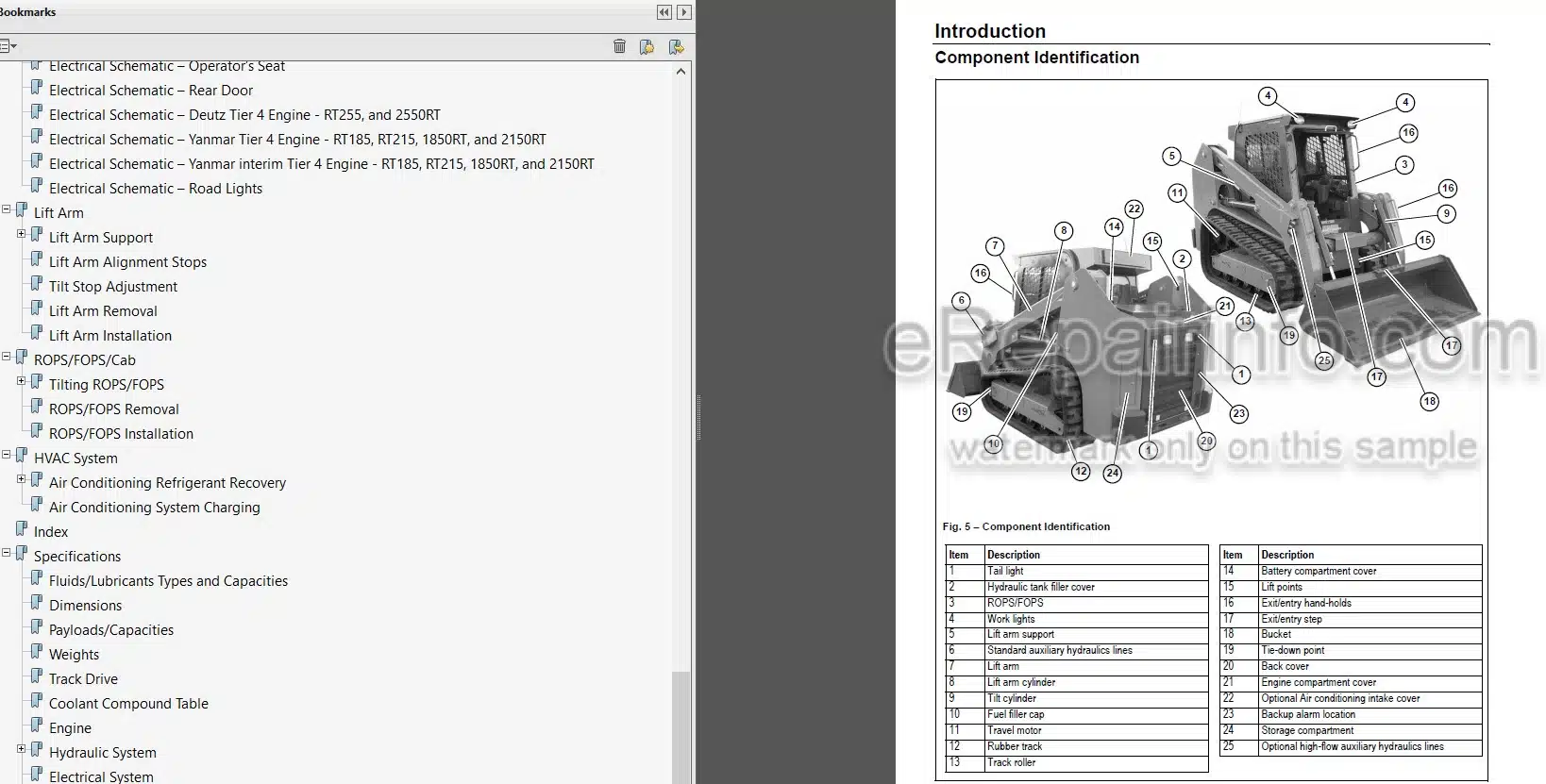

-INTRODUCTION

Contents and Use of this Manual

Machine Orientation

Component Identification

Machine Model and Serial Number Locations

ROPS/FOPS Certification Label

Indicator and Operation Symbols

Machine Controls and Operation

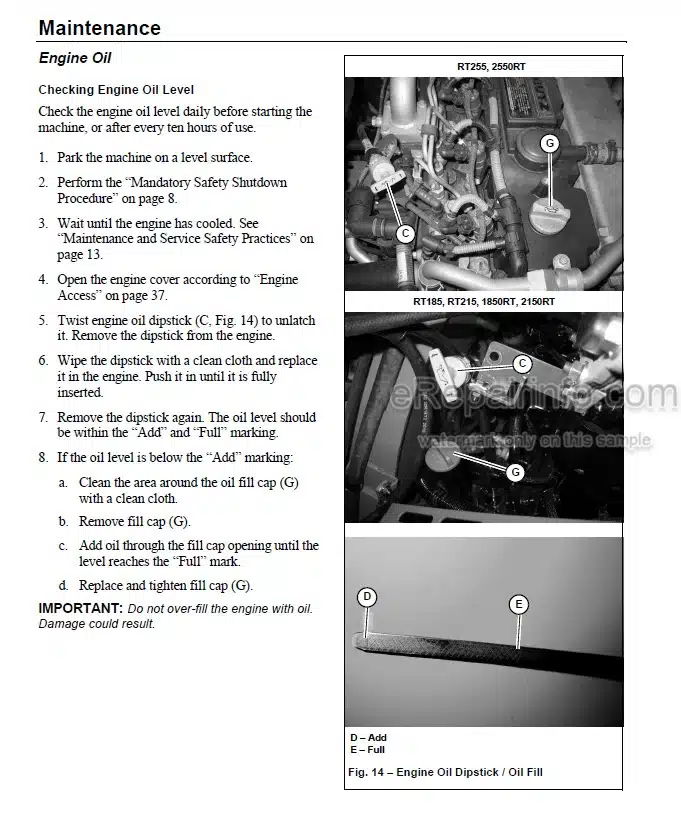

-MAINTENANCE

Maintenance Schedule

Engine Maintenance

DPF Service

Fuel System Maintenance

Hydraulic System Maintenance

Hydraulic Hose Maintenance

Travel Motor Maintenance

Track Maintenance

General Lubrication

Tilting ROPS/FOPS

Electrical System

Lighting

Long-Term Storage

Air Conditioning Maintenance

Windshield Washer Reservoir

Window Removal

Final Shutdown / Decommissioning

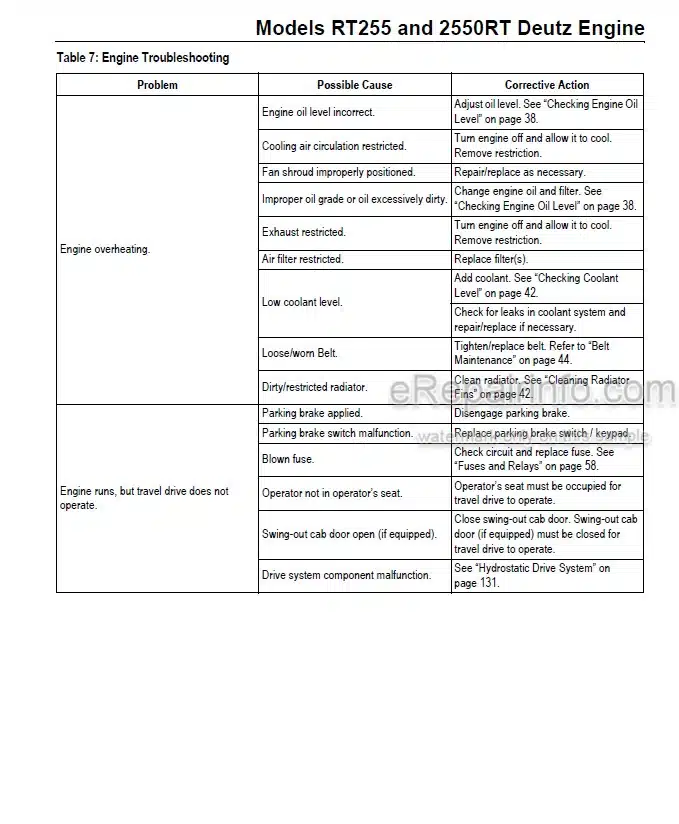

-MODELS RT255 AND 2550RT DEUTZ ENGINE

General Information

Engine Access

Engine Maintenance

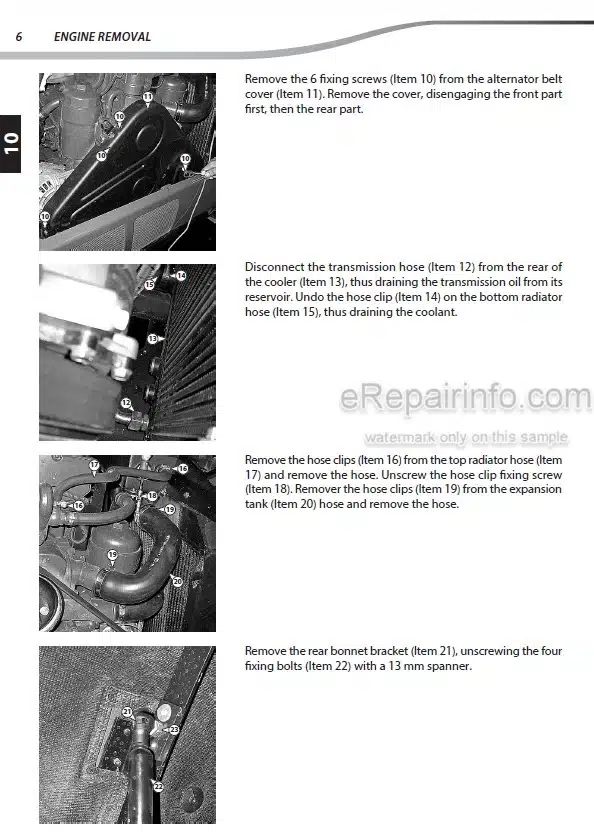

Deutz Engine Removal/Installation

Fuel System Maintenance

Engine Troubleshooting

-MODELS RT215, RT185, 2100RT, AND 1850RT YANMAR ENGINE

General Information

Engine Access

Engine Maintenance

Yanmar Engine Removal/Installation

Fuel System Maintenance

Engine Troubleshooting

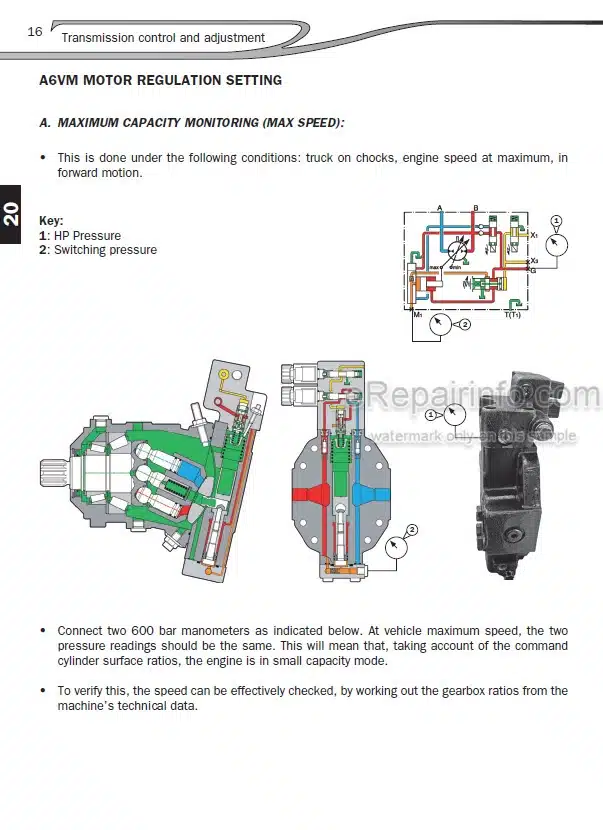

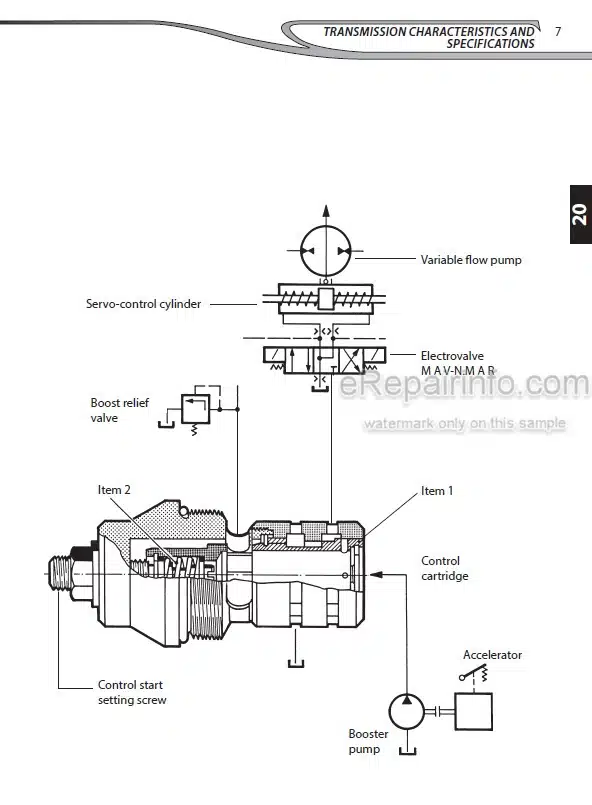

-HYDROSTATIC DRIVE SYSTEM

General Information

General Hydraulic Service Notes

Hydraulic Oil Analysis

Hydrostatic Drive Pump

Hydrostatic Pump Relief Valves

Travel Drive Troubleshooting

Neutral Centering Check/Adjustment

Straight Tracking Adjustment

Hydrostatic Pump Removal and Installation

Hydrostatic Pump Drive Coupling Removal and Installation

Travel Motors

Travel Drive High-Speed Troubleshooting

Tracks

Parking (SAHR) Brake Malfunctions

Hydrostatic Drive System Troubleshooting

-WORK HYDRAULICS

General Information

General Hydraulic Service Notes

Hydraulic Oil Analysis

Main Pressure Test and Adjustment

Hydraulic Gear Pump

Control Valve

Tilt/Lift Cylinder Service/Tests

Hydraulic Cylinder Disassembly/Assembly

Work Hydraulics Tests and Solenoid Valves

Hydraglide

Solenoid Valve Disassembly/ Reassembly

Work Hydraulics Troubleshooting

HYDRAULIC SCHEMATIC

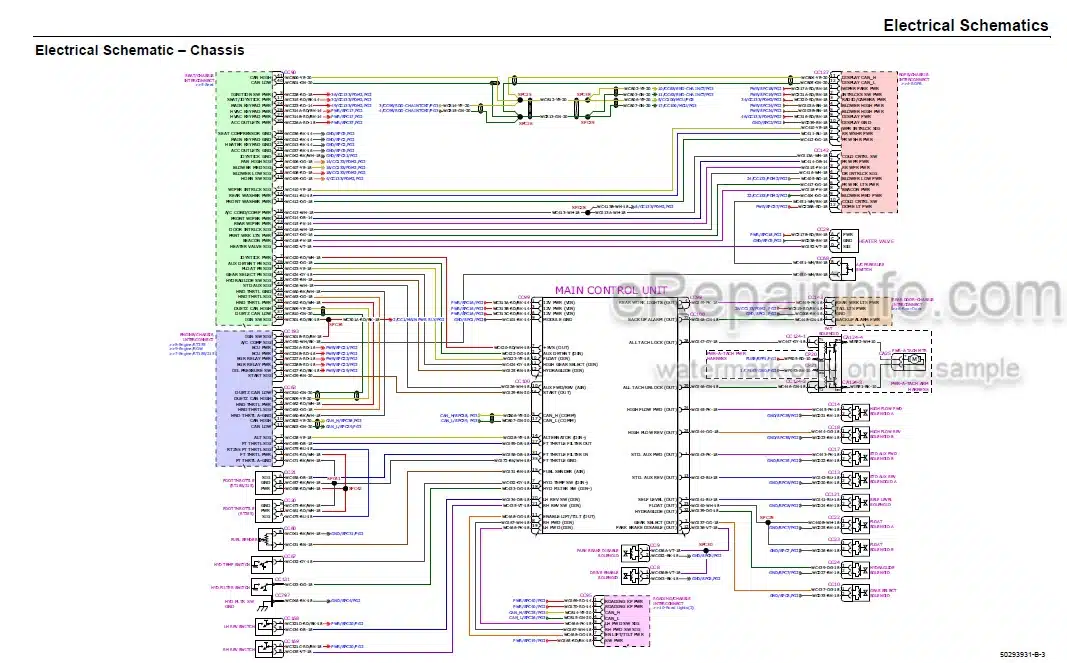

-ELECTRICAL CONTROL SYSTEM

Electrical Control System General Information

Control Modules

CAN System Service/Computer Connection

Operation/Controller Area Network (CAN) Functional Organization

Accessories and Options Functional Detail

CAN/Control System Troubleshooting

Indicator Lamp Troubleshooting

-ELECTRICAL SYSTEM

Battery

Power Distribution

Glow Relay Solenoid Test

Power-A-Tach Relay Solenoid Test

Control Modules

Lighting

-WIRE HARNESS DIAGRAMS

Chassis Wire Harness Diagram -RT255 and 2550RT

Chassis Wire Harness Diagram -RT185, RT215,1850RT, and 2150RT

Deutz Engine Wire Harness Diagram – RT255 and 2550RT

Yanmar interim Tier 4 Engine Wire Harness Diagram – RT185, RT215,1850RT, and 2150RT

Yanmar Tier 4 Engine Wire Harness Diagram – RT185, RT215,1850RT, and 2150RT

ROPS/FOPS (Cab) Wire Harness

Operator’s Seat Wire Harness Diagram)

Rear Door Wire Harness Diagram)

14-Pin Connector Wire Harness Diagram)

-ELECTRICAL SCHEMATICS

Electrical Schematic

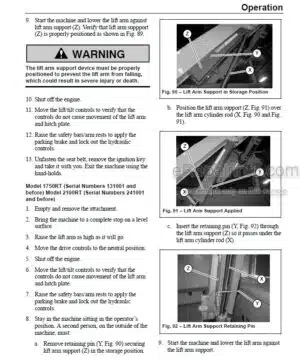

-LIFT ARM

Lift Arm Support

Lift Arm Alignment Stops

Tilt Stop Adjustment

Lift Arm Removal

Lift Arm Installation

-ROPS/FOPS/CAB

Tilting ROPS/FOPS

ROPS/FOPS Removal

ROPS/FOPS Installation

-HVAC SYSTEM

Air Conditioning Refrigerant Recovery

Air Conditioning System Charging

INDEX

-SPECIFICATIONS

Fluids/Lubricants Types and Capacities

Dimensions

Payloads/Capacities

Weights

Track Drive

Coolant Compound Table

Engine

Hydraulic System

Electrical System

Sound Power/Pressure Levels

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.