Factory Service Maintenance Manual For Grove Crane. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG; ESP; POR

Quantity of Manuals: 6

Pages: 366; 360; 390; 370; 382; 374

Number: CTRL560-04 (march 2018); CTRL345-12 (november 2016)

Bookmarks: Yes

Searchable: Yes

Model

Grove Crane

RT9130E-2

Contents

-INTRODUCTION

Description

List Of Specifications

General Maintenance

Wire Rope

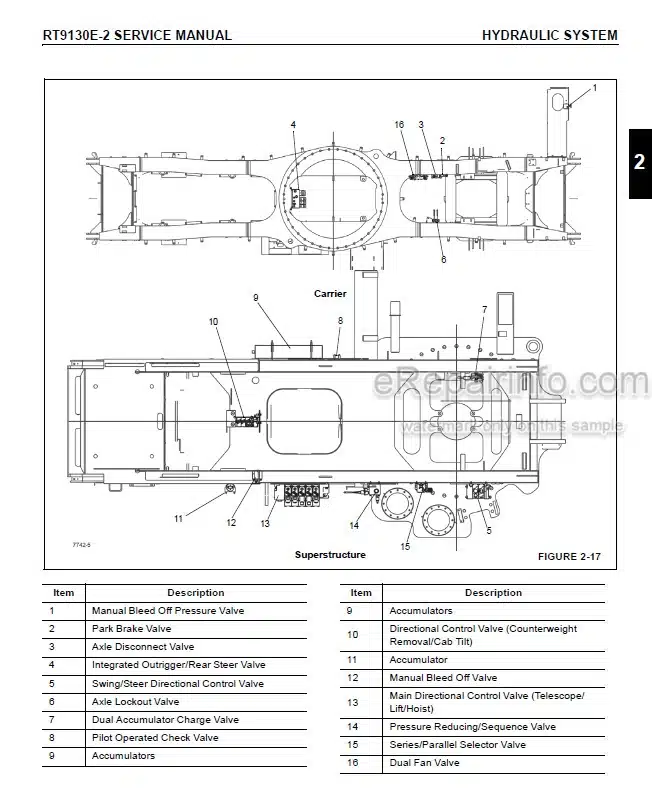

-HYDRAULIC SYSTEM

Description

Hydraulic Oil Recommendations

Draining and Flushing

Removing Air from the Hydraulic System

Parts Replacement

Directional Control Valves

Supply Pressure And Return Circuit

Maintenance

Oil Cooler

Hydraulic Pumps

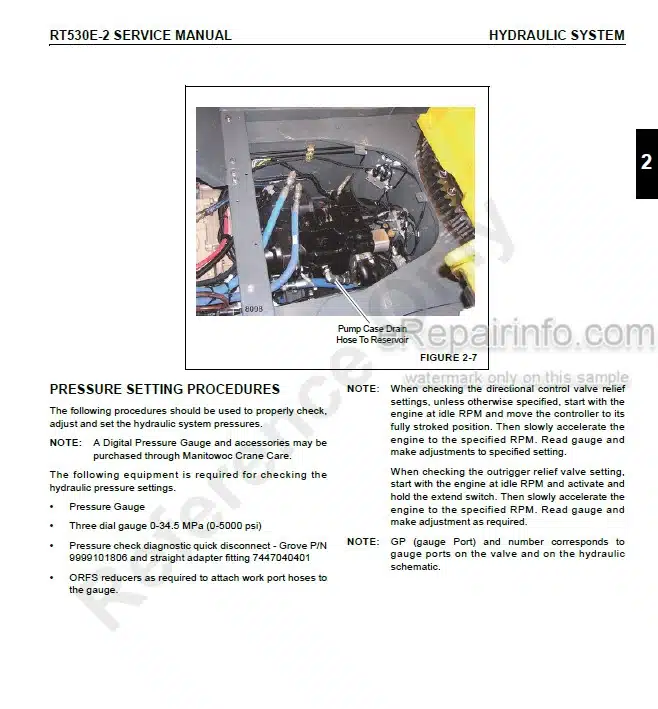

Pressure Setting Procedures

Valves

Directional Control Valves

Swing Series Parallel Selector Valve

Pressure Reducing Sequence Valve With Solenoid Controls Manifold

Steering Control Valve-Dual Displacement

Charge Air Cooler (CAC) Motor control Valve

Hydraulic Remote Control Valve

Swing Power Brake Valve

Double Pilot Operated Check Valve

Tandem Brake Valve w/ Treadle Pedal

Dual Accumulator Charge Valve

Service Brake Hydraulic Accumulator

Load Sense Hydraulic Accumulator

Holding Valves

Shuttle Valve

Solenoid Valves

Cross Axle Differential Lock Valve

Check Valves

Outrigger/Rear Steer/Outrigger Box Pin Removal Valve

Outrigger Control Manifold

Pilot Operated Check Valve

Pressure Bleed-Off Valve

Axle Oscillation Lockout Valve

Relief Valve

Telescope Cylinder Charge Valve Manifold (If Equipped)

Cylinders

Lift Cylinder

Dual Rod Telescope Cylinder

Upper Telescope Cylinder

Axle Oscillation Lockout Cylinder

Steer Cylinder

Outrigger Extension Cylinder

Outrigger Jack Cylinder

Tilt Cylinder

Power Pin Cylinder

Park Brake Cylinder

-ELECTRICAL SYSTEM

Description

Maintenance

Tools For Troubleshooting

Optional Equipment

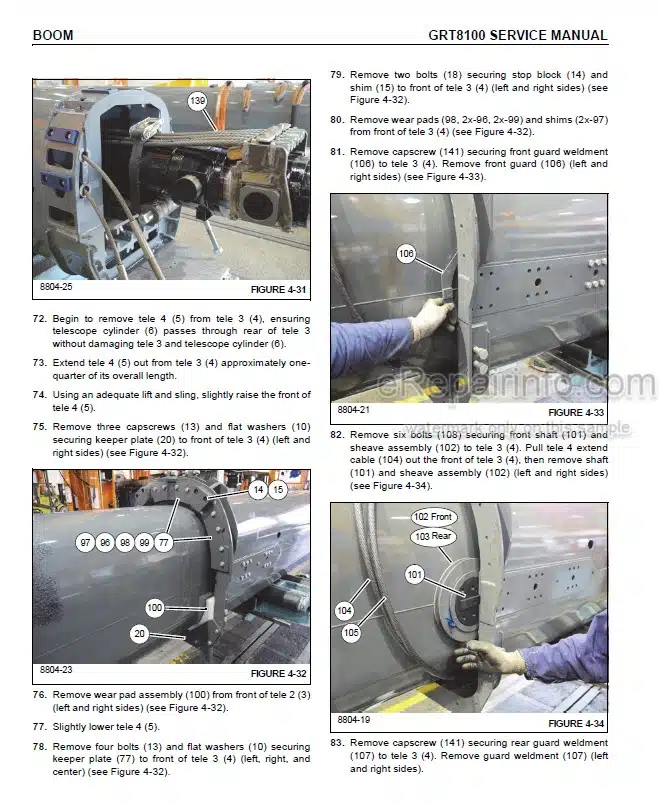

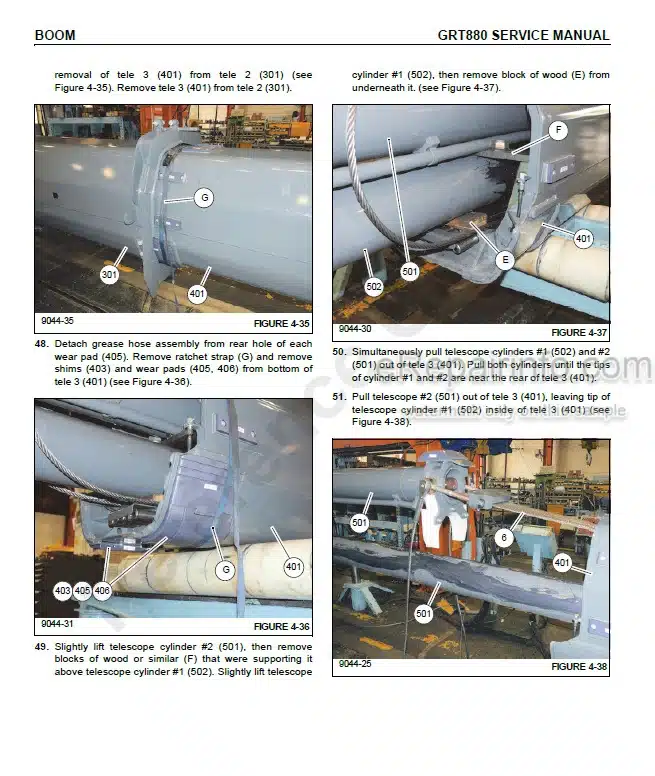

-BOOM

Description

Theory of Operation

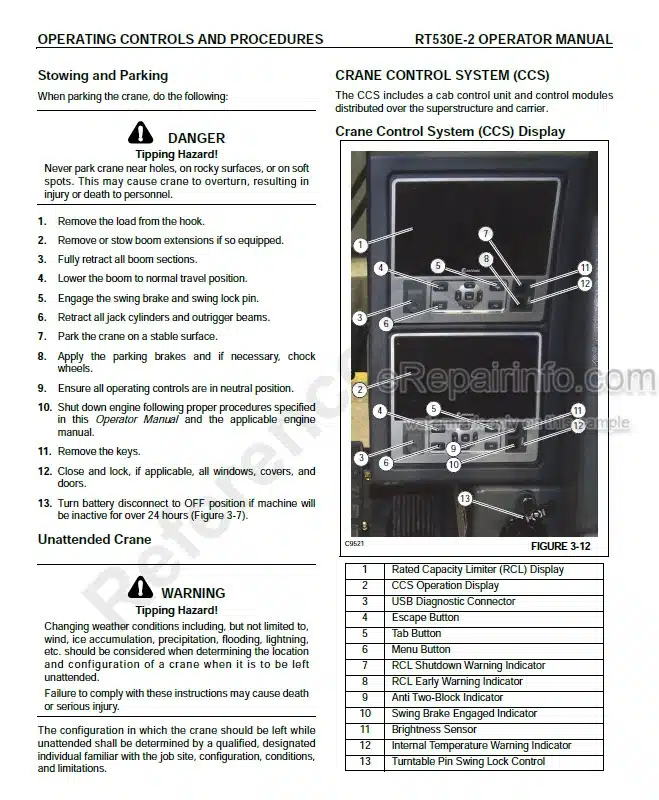

Rated Capacity Limiter (RCL) System (with Boom Control System)

Boom Maintenance

Boom Extension and Retraction Cables

Telescope Circuit

Hose Reel

Lift Circuit

Boom Removal System

Bi-Fold Swingaway Boom Extension

Hookblock

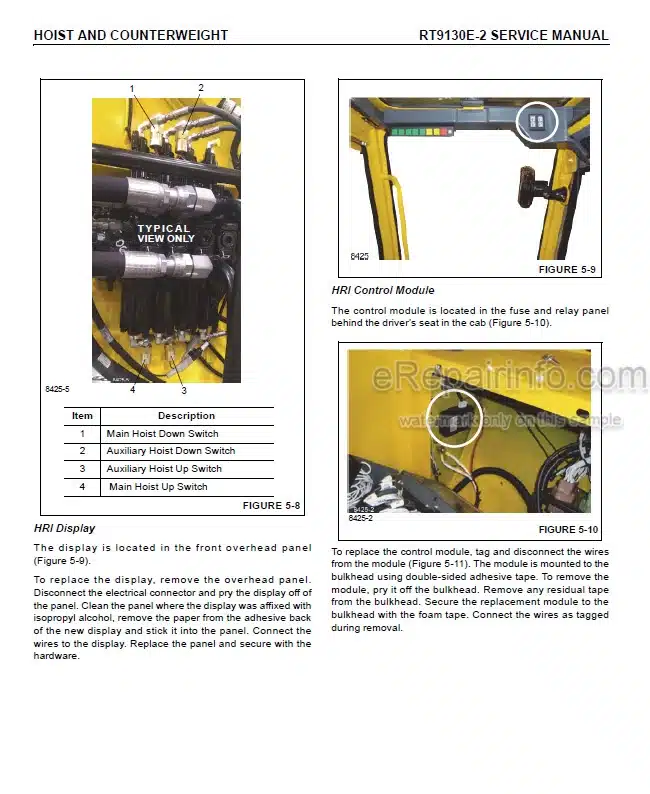

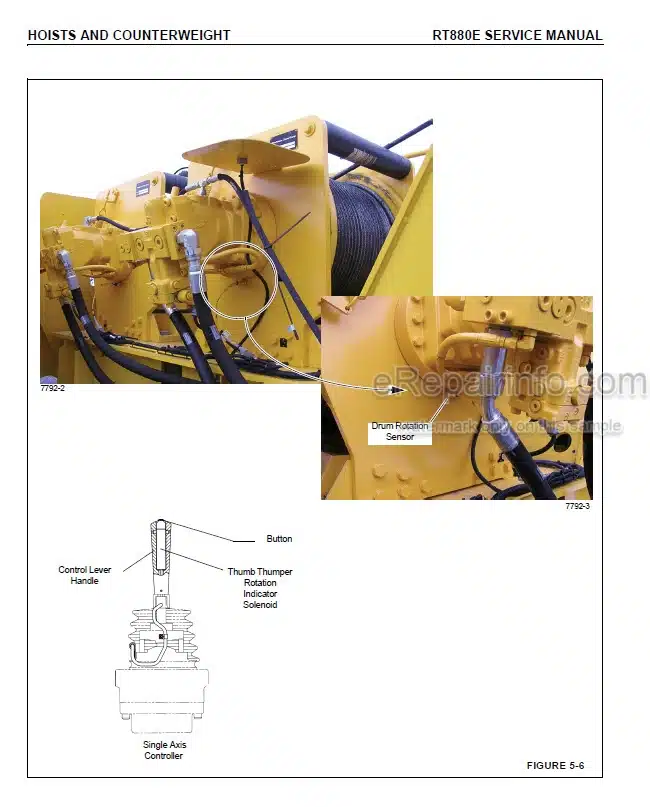

-HOIST AND COUNTERWEIGHT

Description

Theory Of Operation

Maintenance

Hoist to Boom Alignment

Motor And Brake

Idler Drum and Cable Follower

Minimum Layer Indicator

Hoist Drum Rotation Indicator System

Counterweight Removal and Installation

-SWING SYSTEM

Description

Theory of Operation

Maintenance

Swing Box Assemblies

Swing Bearing

Swivels

Swing Lock Pin

360° Swing Lock Control—Positive Lock Type (Optional)

-POWER TRAIN

Description

Maintenance

Electronic Control System

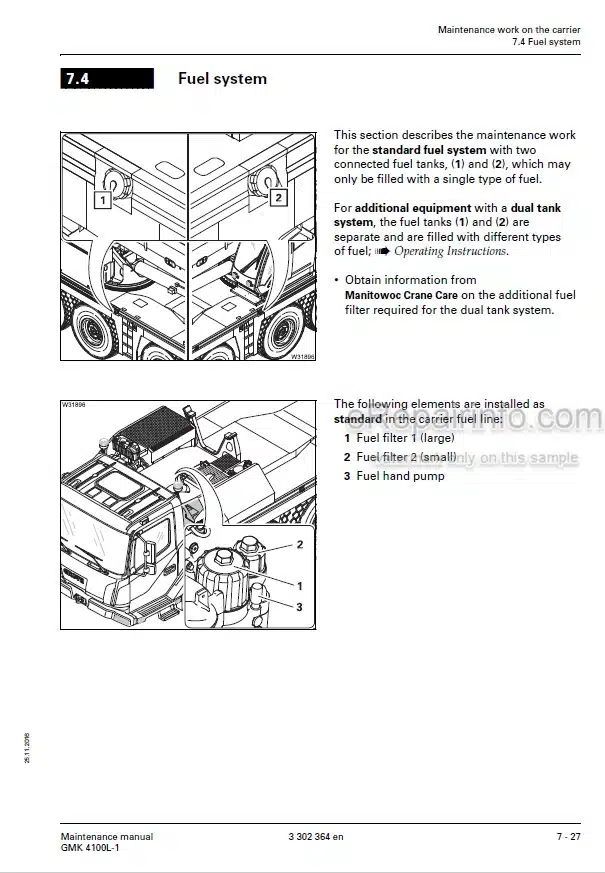

Fuel System

Air Intake and Exhaust System

Exhaust

Water Cooling System

Drive Train

Torque Converter

Transmission

-UNDERCARRIAGE

Axles

Maintenance

Wheels and Tires

Steering Systems

Brake System

Outrigger Circuit

-LUBRICATION

Lubricants and Lubrication Intervals

Surface Protection for Cylinder Rods

Wire Rope Lubrication

Lubrication Points

Carwell Rust Inhibitor

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.