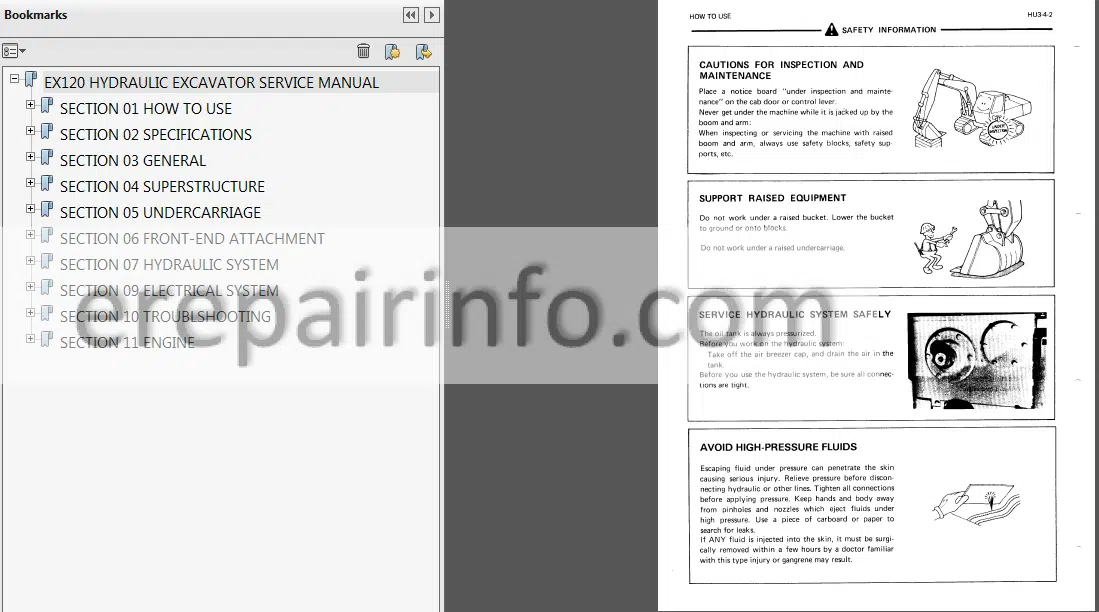

Factory Service Repair Manual For Hitachi EX120 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 984

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi EX120

Contents

- -HOW TO USE

–SECTION & GROUP CONTENTS

–INTRODUCTION

Introduction

Care of the Handling

Symbols

–FEATURES OF THIS MANUAL

Construction

Tab

Page

Contents

–SAFETY INFORMATIONS - -SPECIFICATION

–GENERAL SPECIFICATIONS

Dimensions

Weights and Ground Pressurers

Capability

Backhoe Attachments

Other Attachments

Working Ranges

Lifting Capacities

–COMPONENTS SPECIFICATIONS

Engine

Main Pump

Pilot Pump

Control Valve

Swing Motor

Travel Motor

Center Joint

Pilot Valve (for Travel)

Pilot Valve (for Swing, Boom, Arm, Bucket)

Control Neutralizer Valve

Sockless Valve

Accumulator

Hydraulic Tank

Suction Filter

Full-Flow Filter

Air Breezer

Bypass Check Valve

Pilot Filter

Oil Cooler

Restriction Valve

Solenoid Valve

Mode Selection Cylinder Boom Cylinder

Arm Cylinder

Bucket Cylinder

–TORQUE REFERENCE

–OTHERS

Maintenance Intervals

–CONVERSION TABLE - -GENERAL

–INTRODUCTION

–CONSTRUCTION

–HYDRAULIC SYSTEM

Hydraulic System

Main Hydraulic Circuit

Pilot Hydraulic Circuit - -ELECTRIC SYSTEM

Main Circuit

Control System

Monitor System

–MAINTENANCE

Removal & Installation

Maintenance

Name Plate - -SUPERSTRUCTURE

Main Frame & Counter-Weight

Engine

Hydraulic Oil Tank

Fuel Tank

Swing Device

Electric Parts

Cab Heater

Engine Control Lever

Main Piping

Oil Cooler Piping

Cover

Pump Device

Control Box

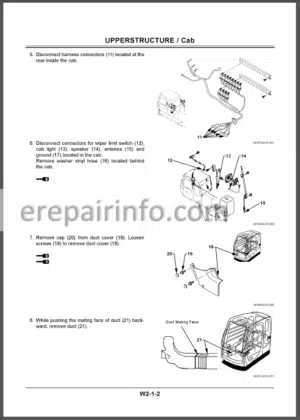

Cab Group

Pilot Piping

Control Lever

–HYDRAULIC PUMP DEVICE

O/P, Hydraulic Pump

D/A, Main Pump

–CONTROL VALVE

O/P, CV-22M Control Valve

D/A, CV-22M Control Valve

–SWING DEVICE

O/P, Swing Motor

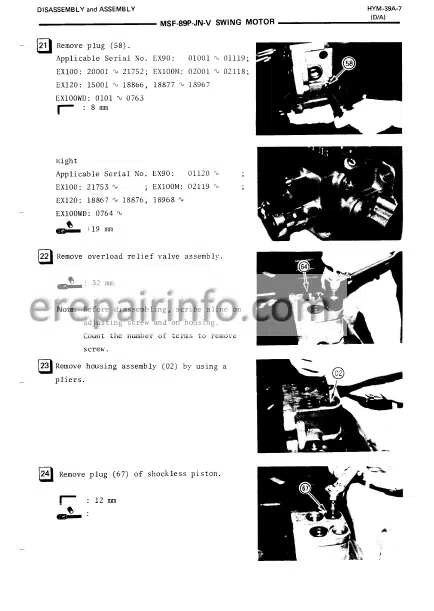

D/A, Swing Motor

D/A, Swing Reduction Device

–PILOT VALVE

O/P, Pilot Valve

D/A, HV Type Pilot Valve (Front-End Attachment)

D/A, HV Type Pilot Valve (Travel)

–CONTROL NEUTRALIZER VALVE

O/P, Control Neutralizer Valve

D/A, Disassembly & Assembly

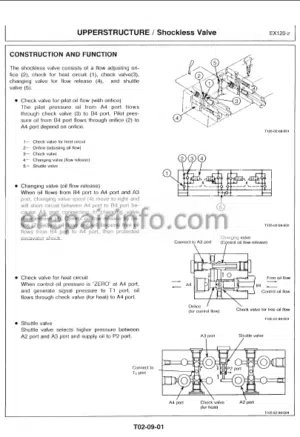

–SHOCKLESS VALVE

O/P, Shockless Valve

D/A, Shockless Valve

–ACCUMULATOR

O/P, Accumulator

–SOLENOID VALVE

O/P, Solenoid Valve

D/A, Solenoid Valve

–MODE SLECTION CYLINDER

D/A , Mode Selection Cylinder - -UNDERCARRIGE

–UNDERCARRIAGE

Track Frame

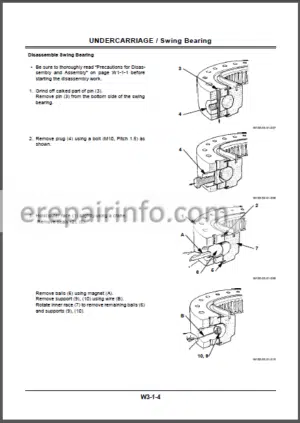

Swing Bearing

Travel Device & Piping

Front Idler

Adjuster

Upper Roller & Lower Roller

Track Link

Center Joint

–TRAVEL DEVICE

O/P, Travel Motor

D/A, Travel Motor

D/A, Travel Device

–CENTER JOINT

O/P, Center Joint

D/A, Center Joint - -FRONT-END ATTACHMENTS

–FRONT-END ATTACHMENT

Boom Assembly

Arm Assembly

Bucket Assembly

Front Pipings

–HYDRAULIC CYLINDER

Operational Principle

Disassembly & Assembly

–PIN & BUSHING

Specifications

–POINT & SIDE CUTTER

Maintenance

–OUTLINE

–MAIN HYDRAULIC CIRCUIT

Suction Circuit and Delivery Circuit

Return Circuit

Drain Circuit

–PILOT CIRCUIT

Suction Delivery and Return Circuit

Accumulator

Control neutralizer Valve

Pump Displacement Control Circuit

Relief Pressure Change Circuit

Switch Valve Circuit

Swing Parking Brake Circuit

Heat-Run Circuit

–SINGLE OPERATION

Boom Raise Circuit Operation

Boom Lower Circuit Operation

Arm Roll-In Circuit Operation

Arm Roll-Out Circuit Operation

Bucket Circuit Operation

Swing Circuit Operatrion

Swing Operation

Travel Circuit Operation

Travel Forward and Reverse Operation

–COMBINED OPERATION

Outline

Combined Swing and Boom Operation

Combined Swing and Arm Operation

Combined Swing and Bucket Operation

Combined Swing, Boom, Arm and Bucket Operation

Combined Swing and Travel Operatrion

Combined Boom and Travel Operation

Combined Arm and Travel Operation

Combined Bucket and Travel Operation

–EXTRA CONTROL CIRCUIT

Outline

Single Operation

Combined Extra and Arm Roll-In Operation

Combined Extra and Arm Roll-Out Operation - -ELECTRICAL SYSTEM

–SAFETY PRECAUTIONS

Safety Precautions

–SPECIFICATiONS

Battery

Starter

Safety Relay

Alternator

Regulator

Head Light

Wiper Motor

Speaker

Fuse

–CONSTRUCTION & FUNCTION

Construction of Electrical System

Monitor

Control (E-P Control) System

Engine Reverse Rotation Preventive Device

Function of Sensor and Relays

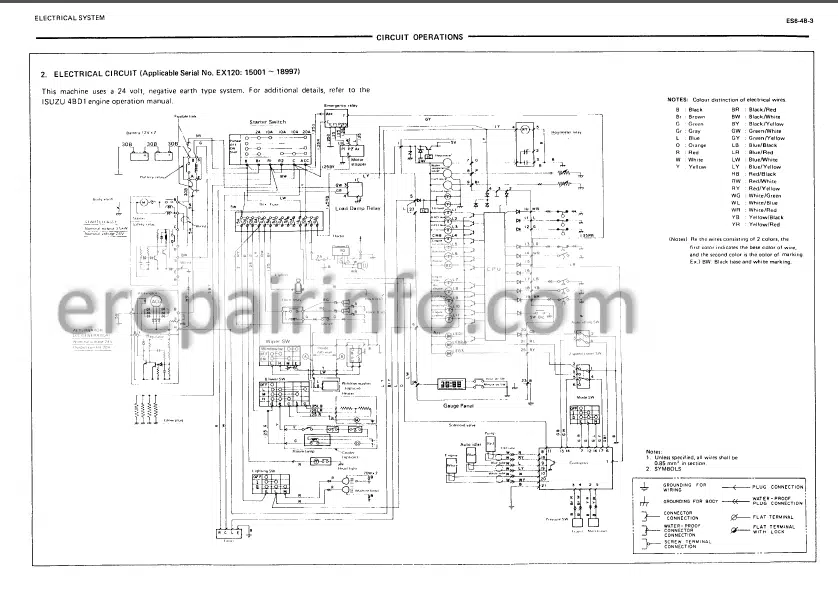

–CIRCUIT OPERATIONS

Characteristics of Electrical Circuit

Electrical Circuit

Battery Circuit

Preheat Circuit

Starting Circuit

Charging Circuit

Safety Circuit

Engine Emergency Stop Circuit

Accessory Circuit

Gauge Panel Circuit

Control Circuit

–MAINTENANCE

Replacing Panel Gauge Parts

Assembly & Adjustment of Auto-Idle Device - -TROUBLESHOOTING

–INTRODUCTION

General Information

Notes on Performance Measurement

–DIAGNOSE MALFUNCTIONS

Malfunctions Phenomena

Hydraulic System

Electric System

–EXCAVATOR PERFORMANCE TEST

Introduction

Engine Performance Measurement

Travel Performance Measurement

Swing Performance Measurement

Front-end Attachment

Control Lever Performance Measurement - -COMPONENTS PERFORMANCE STANDARD

Introduction

Pilot Relief Valve

Main Relief Valve

Overload Relief Valve

Swing Overload Relief Valve

Travel Crossover Relief Valve

Main Hydraulic Pump

–ELECTRICAL SYSTEM TEST

Common Circuit Test

Articles Necessary for Electric Circuit Test

Measurement Procedure

Measurement Standard - -ENGINE

–GENERAL INFORMATION

General Repair Instructions

Notes on the Format of Engine Section

Main Data & Specifications

Design Features & General Outline

Tightening Torque Specifications

Anglular Nut & Bolt Tightening Method

Major Parts Fixing Nuts & Bolts

Identifications

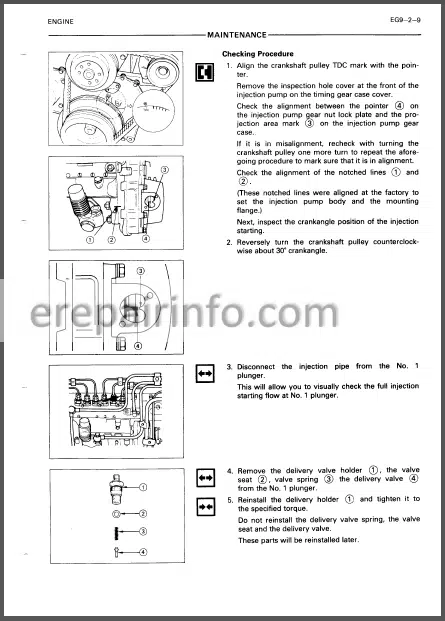

–MAINTENANCE

Lubricating System

Fuel System

Cooling System

Valve Clearance Adjustment

Injection Timing

Compression Pressure Measurement

Turbocharger Inspection

Engine Repair Kit

Recommended Lubricants

Engine Oil Viscosity Chart

–ENGINE DISASSEMBLY

External Parts

Major Components

Rocker Arm & Rocker Arm Shaft

Cylinder Head

Piston & Connecting Rod

–INSPECTION & REPAIR

Cylinder Head

Valve Guide

Valve Spring

Tappet

Push Rod

Rocker Arm Shaft & Rocker Arm

Idler Gear & Idler Gear Shaft

Cam Shaft

Cylinder Body & Liner

Piston & Piston Ring

Piston Pin

Connecting Rod

Crankshaft

Fly Wheel & Fly Wheel Housing

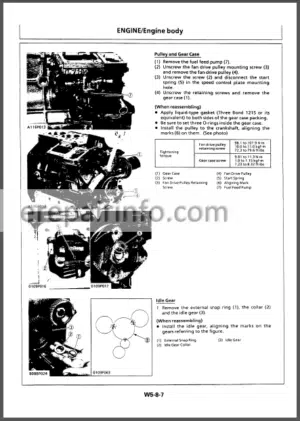

Timing Gear Case Cover

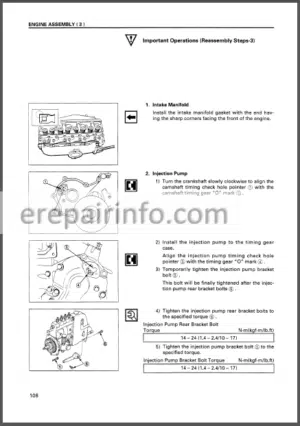

–ENGINE ASSEMBLY

Piston & Connecting Rod

Cylinder Head

Rocker Arm & Rocker Arm Shaft

Major Components

External Parts

Engine Tuning Operation

Engine Section View

–LUBRICATING SYSTEM

General Description

Oil Pump

Main Oil Pump

Oil Cooler - -COOLING SYSTEM

General Description

Water Pump

Thermostat

–FUEL SYSTEM

General Description

Fuel Filter

Injection Nozzle

–TURBO CHARGER

General Description

Identification

Roter Shaft Play Inspection

–ENGINE ELECTRICALS

Starter Motor

Alternator

–TROUBLESHOOTING

Hard Starting

Unstable Low Idling

Insufficient Power

Excessive Fuel Consumption

Overheating

White Exhaust Smoke

Darkish Exhaust Smoke

Not Rising Oil Pressure

Abnormal Engine Noise

–SPECIAL TOOL LIST

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.