Factory Service Repair Manuals Set For Hitachi EX750-5, EX800H-5 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Bookmarks: Yes

Searchable: Yes

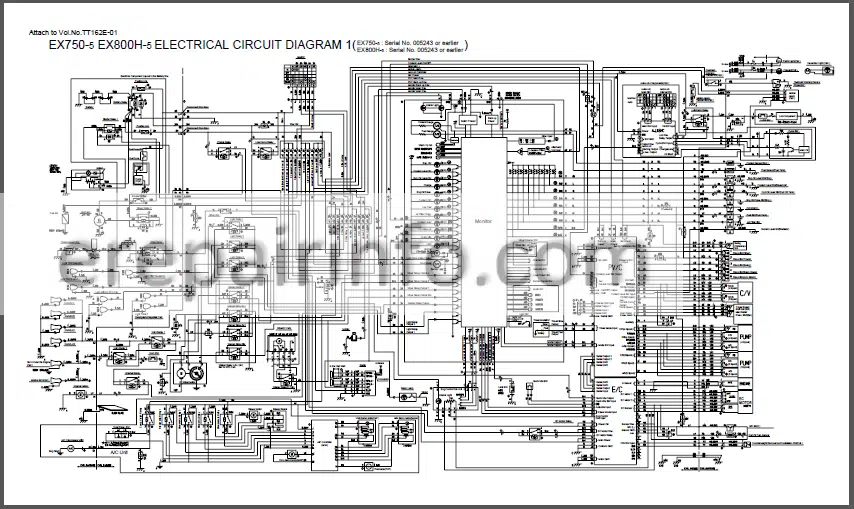

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi EX750-45, EX800H-5

Contents

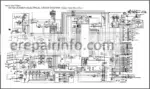

1.Circuit shematics

2.Parts Catalog(Basic)

3.Parts Catalog(Equipment Components)

4.Technical Manual(OperationalPrinciple)

5.Technical Manual(Troubleshooting)

6.Workshop Manual

1.Technical Manual(OperationalPrinciple)

INTRODUCTION

-GENERAL

–SPECIFICATION

Specifications

Working Ranges/Transporting Dimensions

–COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Components

Filters

Electrical Components

–COMPONENT LAYOUT

Main Components

Electrical System (1)

Electrical System (2)

Electrical System (3)

Control Valve

Other Components

-SYSTEM

–CONTROL SYSTEM

Outline

Engine Control

Pump Control

Valve Control

Other Control

–HYDRAULIC SYSTEM

Outline

Main Circuit

Pilot Circuit

–ELECTRICAL SYSTEM

Outline

Power Circuit

Bulb Check Circuit

Engine Start Circuit

Charging Circuit

Accessory Circuit

Surge Voltage Prevention Circuit

Engine Stop Circuit

-COMPONENT OPERATION

–PUMP DEVICE

Outline

Main Pump

Regulator

Pilot Pump

N Sensor (Engine Speed Sensor)

P Sensor (Pump Delivery Pressure Sensor)

A Sensor (Pump Displacement Angle Sensor)

–SWING DEVICE

Outline

Swing Motor

Valve Unit

Swing Parking Brake

Swing Reduction Gear

–CONTROL VALVE

Outline

Hydraulic Circuit

Flow Combiner Valve

Center Bypass Valve

Pump Control Valve

Main Relief Valve

Overload Relief Valve

Make-Up Valve

Holding Valve

Arm Regenerative Valve

–PILOT VALVE

Outline

Operation

–TRAVEL DEVICE

Outline

Travel Reduction Gear

Travel Motor

Travel Brake Valve

Travel Motor Displacement

Angle Shift

Parking Brake

–OTHERS (UPPERSTRUCTURE)

Pilot Shut-Off Valve

Shockless Valve

Solenoid Valve

Accumulator

–OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Track Adjuster

2.Technical Manual(Troubleshooting)

INTRODUCTION

SAFETY

-OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Operational Performance Tests

Preparation for Performance Test

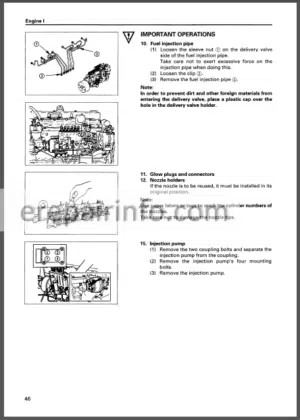

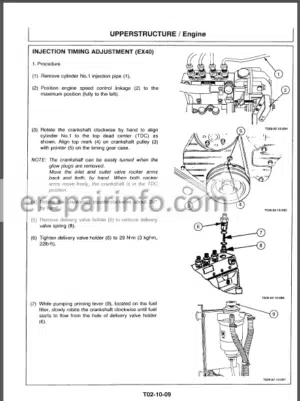

–ENGINE TEST

Engine Speed

Injector and Valve Clearance

Adjustment

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Parking Function Check

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

Dig Function Drift Check

Control Lever Operating Force

Control Lever Stroke

Boom Raise I Swing Combined Operation Check

–COMPONENT TEST

Primary Pilot Pressure

Secondary Pilot pressure

Swing Preference Circuit Shift Control Pressure (MA Pressure)

Main Relief Pressure Shift Control

Pressure (SA Pressure)

Travel Mode Shift Control Pressure (SB Pressure)

Main Relief Pressure

Overload Relief Valve Set Pressure

Main Pump Flow Test

Swing Motor Drainage

Travel Motor Drainage

–STANDARD

Operational Performance Standard Table

-TROUBLESHOOTING

–DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

Dr EX

Dr EX Start Up Procedure

Clearing the Self-Diagnosing Function

Retrial “A”

Retrial “B”

Fault code List

Monitoring Function

–COMPONENT LAYOUT

Main Components

Electrical System Component (1)

Electrical System Component (2)

Electrical System Component (3)

Control Valve

Others

–TROUBLESHOOTING A

Troubleshooting A Procedure

Fault Code List

Fault Codes 01, 02, 03, 04, 06 (EC Failure)

Fault Code 05 (Communication Failure between PVC and EC)

Fault Code 09, 10 (EC Sensor Failure)

Fault Code 11, 12 (Engine Control Dial Failure)

Fault Code 13 (N Sensor Failure)

Fault Code 14, 15 (Overheat Switch L Failure, Hydraulic Oil Temperature Sensor Failure)

Fault Codes 17, 18, 19, 21,22 (PVC Failure)

Fault Code 20 (Communication Failure between EC and PVC)

Fault Code 23, 24 (Pump Control Failure)

Fault Code 25, 26, 33, 34 (DP Sensor Failure)

Fault Code 27, 28, 35, 36 (P Sensor Failure)

Fault Code 29, 30, 37, 38 (A Sensor Failure)

Sensor Operating Range List

–TROUBLESHOOTING B

Troubleshooting B Procedure

Correlation between Part Failure and Abnormalities that Machine may Show

Correlation between Troubles and

Part Failures

Engine System Troubleshooting

Total Actuator System Troubleshooting

Front Attachment System Troubleshooting

Swing System Troubleshooting

Travel System Troubleshooting

Troubleshooting for Other Functions

Engine Speed Adjustment

EC Sensor Installation and Voltage Adjustment

–TROUBLESHOOTING C

Troubleshooting C Procedure

Malfunction of Coolant Temperature Gauge

Malfunction of Fuel Gauge

Malfunction of Indicator Bulb Check System

Malfunction of Level Check Switch

Malfunction of Engine Oil Level Indicator

Malfunction of Coolant Level Indicator

Malfunction of Hydraulic Oil Level Indicator

Malfunction of Alternator Indicator

Malfunction of Engine Oil Pressure Indicator

Malfunction of Overheat Indicator

Malfunction of Fuel Level Indicator

Malfunction of Air Filter Restriction Indicator

Malfunction of Hour Meter

Malfunction of Buzzer

Malfunction of Work Light Indicator

Malfunction of Quick Idle Indicator

–ELECTRICAL SYSTEM INSPECTION

Precautions for Inspection and Maintenance

Instructions for Disconnecting Connectors

Fuse Continuity Test

Fusible Link Inspection and Replacement

Battery Voltage Check

How to Troubleshoot Alternator Malfunctions

Continuity Check

Voltage and Current Check

Relay Replacing Procedure

–HARNESS CHECK

Circuit Check

3.Workshop Manual

INTRODUCTION

SAFETY

-GENERAL IMFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

Maintenance Standard Terminology

–TIGHTENING

Tightening Torque Specification

Torque Chart

Piping Joint

-UPPERSTRUCTURE

–CAB

Remove and Install Cab

Dimensions of the Cab Glass

–COUNTERWEIGHT

Remove and Install Counterweight

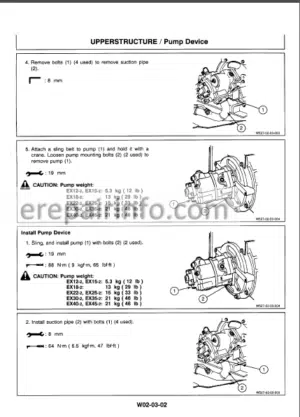

–PUMP DEVICE

Remove and InstallPump Device

Disassemble Pump Transmission

Assemble Pump Transmission

Remove and Install Main Pump

Disassemble Main Pump

Assemble Main Pump

Maintenance Standard

Disassemble Regulator

Assemble Regulator

Disassemble and Assemble Pilot Pump

–CONTROL VALVE

Remove and Install Control Valve

Disassemble Control Valve 1

Assemble Control Valve 1

Disassemble Control Valve 2

Assemble Control Valve 2

Disassemble Control Valve 3

Assemble Control Valve 3

Disassemble Control Valve 4

Assemble Control Valve 4

Disassemble Control Valve 5

Assemble Control Valve 5

–SWING DEVICE

Remove and Install Swing Device

Disassemble Swing Reduction Gears

Assemble Swing Reduction Gears

Disassemble Swing Motor

Assemble Swing Motor

Disassemble and Assemble Swing Parking Brake Release Valve

Maintenance Standard

–PILOT VALVE

Remove and Install Right Pilot Valve

Remove and Install Left Pilot Valve

Remove and Install Travel Pilot Valve

Disassemble Right and Left Pilot Valve

Assemble Right and Left Pilot Valve

Disassemble Travel Pilot Valve

Assemble Travel Pilot Valve

–PILOT SHUT-OFF VALVE

Remove and Install Pilot Shut-off Valve

Disassemble Pilot Shut-off Valve

Assemble Pilot Shut-off Valve

–SHOCKLESS VALVE

Remove and Install Front Attachment Shockless Valve

Disassemble and Assemble Shockless Valve (Front Attachment)

Remove and Install Travel Shockless Valve

Disassemble and Assemble Travel Shockless Valve

–SOLENOID VALVE

Remove and Install Two-Spool Solenoid Valve

Disassemble and Assemble Two-Spool Solenoid Valve

-UNDERCARRIAGE

–SWING BEARING

Remove and Install

Swing Bearing

Disassemble Swing Bearing

Assemble Swing Bearing

–TRAVEL DEVICE

Remove and Install

Travel Device

Disassemble Travel Device

Assemble Travel Device

Disassemble Travel Motor

Assemble Travel Motor

Disassemble Brake Valve

Assemble Brake Valve

Maintenance Standard

–CENTER JOINT

Remove and Install Center Joint

Disassemble Center Joint

Assemble Center Joint

Maintenance Standard

–TRACK ADJUSTER

Remove and Install Track Adjuster

Disassemble Track Adjuster

Assemble Track Adjuster

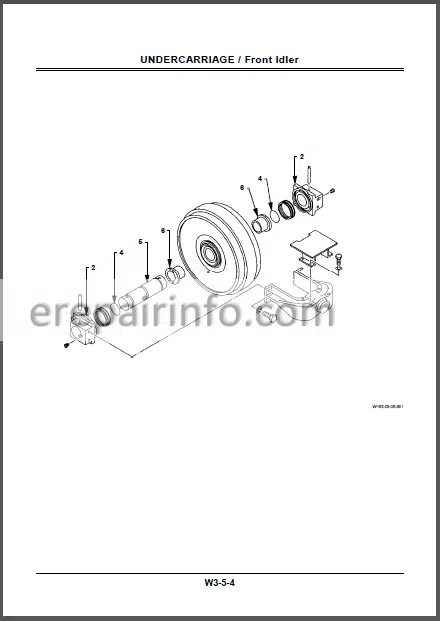

–FRONT IDLER

Remove and Install Front Idler

Disassemble Front Idler

Assemble Front Idler

Maintenance Standard

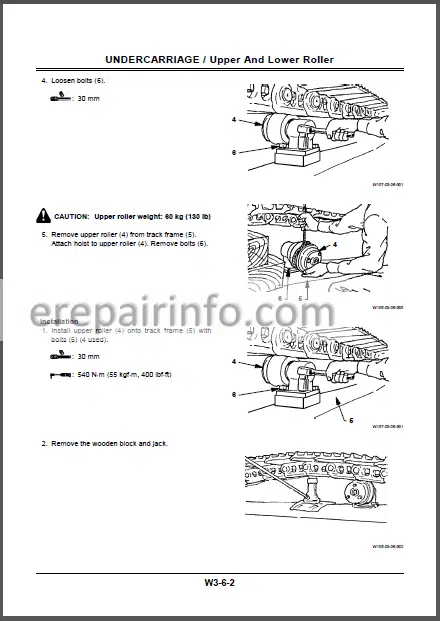

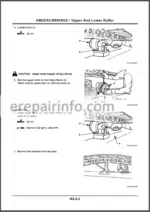

–UPPER AND LOWER ROLLER

Remove and Install Upper Roller

Remove and Install Lower Roller

Disassemble Lower Roller

Assemble Lower Roller

Disassemble Lower Roller

Assemble Lower Roller

Maintenance Standard

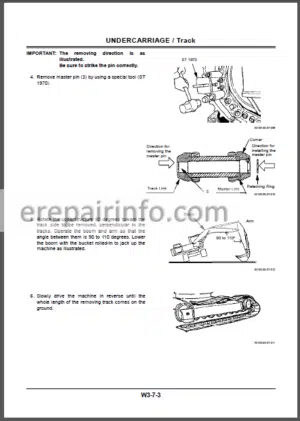

–TRACK

Remove and Install Track

Maintenance Standard

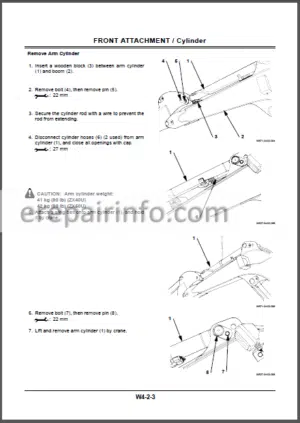

-FRONT ATTACHMENT

–FRONT ATTACHMENT

Remove and Install Front Attachment Cylinder and Preparation

Maintenance Standards

Air Bleeding Procedure

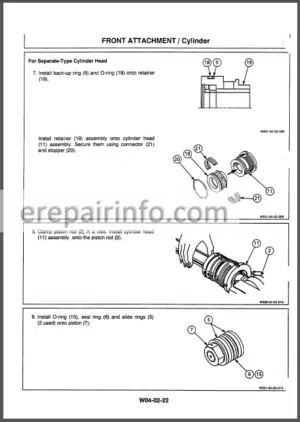

–CYLINDER

Disassemble Cylinder

Assemble Cylinder

Maintenance Standard

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.