Factory Service Repair Manuals set For Hitachi ZX 170W-3 190W-3 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 605

Searchable: Yes

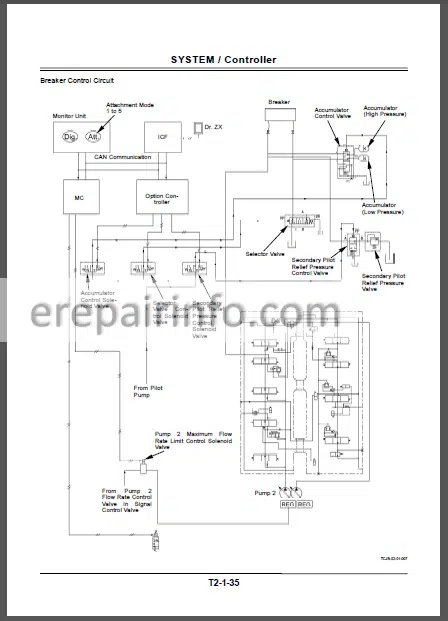

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi ZX170W-3, 190w-3

Contents

1.Operational Principle

2.Troubleshooting

3.Workshop Manual

INTRODUCTION

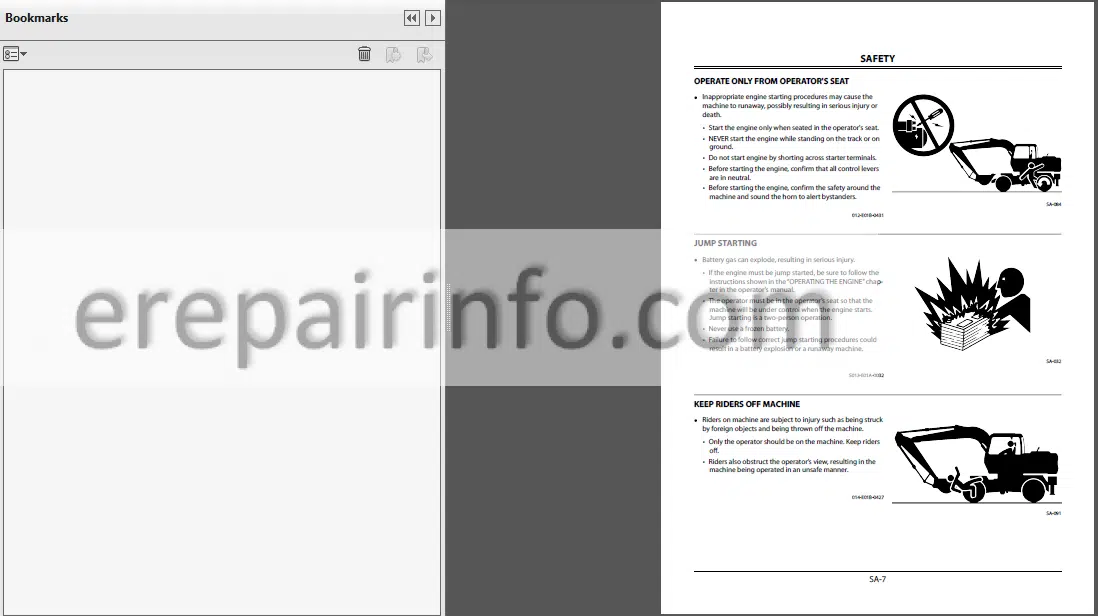

SAFETY

-GENERAL INFORMATION

–PRECAUTIONS FOR DISASSEMBLING AND ASSEMBLING

Precautions for Disassembling and Assembling

Maintenance Standard Terminology

–TIGHTENING

Tightening Torque Specifications

Torque Chart

Piping Joint

Periodic Replacement of Parts

–PAINTING

Painting

–BLEEDING AIR FROM HYDRAULIC OIL TANK

Bleeding Air from Hydraulic Oil tank

-UPPERSTRUCTURE

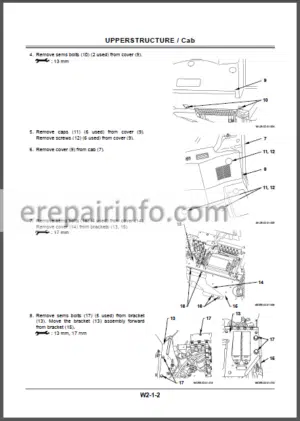

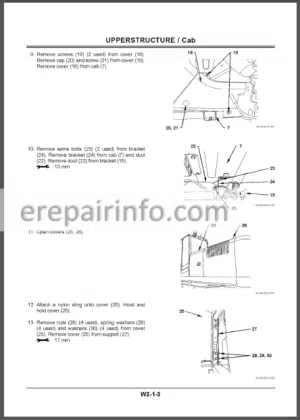

–CAB

Removal and Installation of Cab

Dimensions of Cab Glass

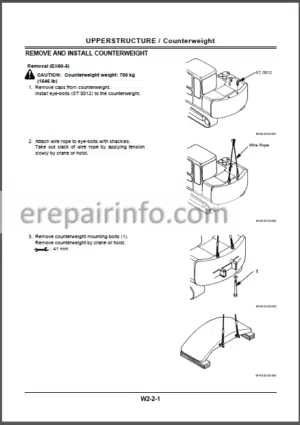

–COUNTERWEIGHT

Removal and Installation of Counterweight

–MAIN FRAME

Removal and Installation of Main Frame

–PUMP DEVICE

Removal and Installation of

Pump Device

Disassembly of Pump Device

Assembly of Pump Device

Disassembly of Regulator

Assembly of Regulator

Structure of Pilot Pump

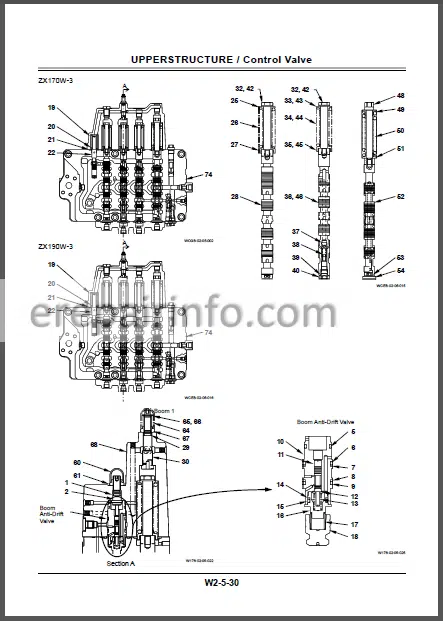

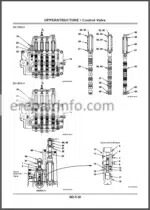

-CONTROL VALVE

Removal and Installation of Control Valve

Disassembly of Control Valve 4-Spool Side

Disassembly of Control Valve 5-Spool Side

Assembly and Disassembly of 4-Spool Side and 5-Spool Side

Assembly of Control Valve 4-Spool Side

Assemble of Control Valve 5-Spool Side

Removal and Installation of Positioning Control Valve>

Disassembly of Positioning Control Valve>

Assembly of Positioning Control Valve>

–SWING DEVICE

Removal and Installation of

Swing Device

Disassembly of Swing Device

Assembly of Swing Device

Disassembly of Swing Motor

Assembly of Swing Motor

Structure of Swing Dampener Valve

Maintenance Standard

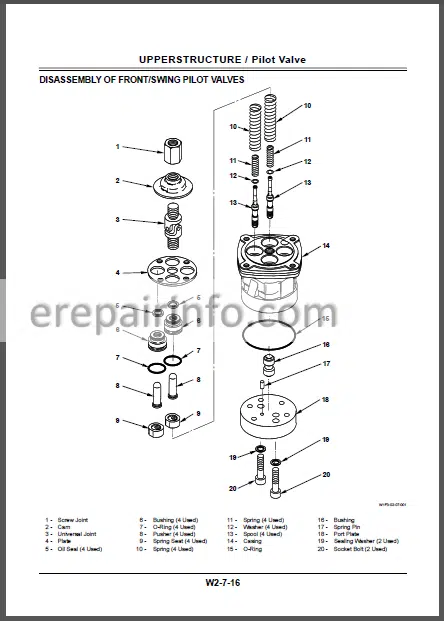

–PILOT VALVE

Removal and Installation of Pilot Valve

Removal and Installation of

Travel Pilot Valve

Disassembly of Front/Swing

Pilot Valves

Assembly of Front/Swing Pilot Valves

Disassembly of Travel and Auxiliary/Positioning Pilot Valves

Assembly of Travel and

Auxiliary/Positioning Pilot valves

–ELECTRIC LEVER

Removal and Installation of Electric Lever

Disassembly of Electric Lever

Assembly of Electric Lever

–SIGNAL CONTROL VALVE

Removal and Installation of Signal

Control Valve

Structure of Signal Control Valve

–SHOCKLESS VALVE

Removal and Installation

Shockless Valve

Structure of Swing Shockless Valve

Structure of Travel Shockless Valve

–SOLENOID VALVE

Removal and Installation of 3-Spool Solenoid Valve Unit

Structure of 3-Spool Solenoid Valve Unit

Disassembly and Assembly of 3-Spool Solenoid Valve Unit

Removal and Installation of Solenoid Valve Unit (For Electric Lever Operation)

Structure of Solenoid Valve Unit (For Electric Lever Operation)

–PILOT SHUT-OFF SOLENOID VALVE

Removal and Installation of Pilot

Shut-Off Solenoid Valve

Structure of Pilot Shut-Off Solenoid Valve

–STEERING VALVE

Removal and Installation of Steering Valve

–BRAKE VALVE

Removal and Installation of Brake Valve

Disassembly of Brake Valve

Assembly of Brake Valve

–ACCUMULATOR CHARGE VALVE

Removal and Installation of Accumulator Charge Valve

Structure of Accumulator Charge Valve

-UNDERCARRIAGE

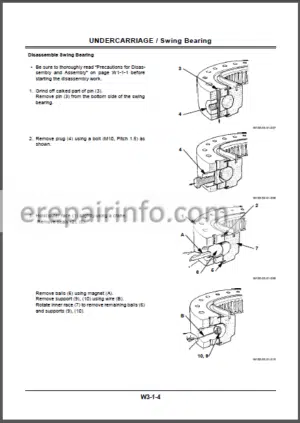

–SWING BEARING

Removal and Installation of Swing Bearing

Disassembly of Swing Bearing

Assembly of Swing Bearing

–TRAVEL MOTOR

Removal and Installation of Travel Motor

Disassembly of Travel Motor

Assembly of Travel Motor

Disassembly of Brake Valve

Assembly of Brake Valve

–CENTER JOINT

Removal and Installation of Center Joint

Disassembly of Center Joint

Assembly of Center Joint

–TRANSMISSION

Removal and Installation of Transmission

Disassembly of Transmission

Assembly of Transmission

–AXLE

Removal and Installation of Axle

Disassembly of Front Axle

Assembly of Front Axle

Disassembly of Rear Axle

Assembly of Rear Axle

Disassembly of Differential

Assembly of Differential

Disasembly of Steering Cylinder

Assembly of Steering Cylinder

–AXLE LOCK CYLINDER

Removal and Installation of Axle Lock Cylinder

Disassembly and Assembly of Axle Lock Cylinder

–OPERATE CHECK VALVE

Removal and Installation of Operate Check Valve (for Axle Lock Cylinder)

Structure of Operate Check Valve (For Axle Lock Cylinder)

–SOLENOID VALVE

Removal and Installation of Outrigger/BladeSolenoid Valve Unit

Structure of Solenoid Valve Unit

–TRANSMISSION CHANGEOVER SOLENOID VALVE

Removal and Installation of Transmission Changeover Solenoid Valve

–PROPELLER SHAFT

Removal and Installation of Propeller Shaft

-FRONT ATTACHMENT

–FRONT ATTACHMENT

Hydraulic Circuit Pressure

Release Procedure

Removal and Installation of

Front Attachment (Monoblock Boom) Removal and Installation of Front Attachment (2-Piece Boom)

Maintenance Standard

Standard Dimensions for Arm and Bucket Connection

Standard Dimensions for Arm and Boom Connection

–CYLINDER

Hydraulic Circuit Pressure

Release Procedure

Removal and Installation of Cylinder

Disassembly of Boom, Ami and Bucket Cylinders

Assembly of Boom, Arm and Bucket Cylinders

Disassembly of Positioning Cylinder

Assembly of Positioning Cylinder

Disassembly of Outrigger and Blade Cylinders

Assembly of Outrigger and Blade Cylinder

Maintenance Standard

–HOSE RUPTURE VALVE

Hydraulic Circuit Pressure Release Procedure

Removal and Installation of Hose

Rupture Valve for Arm CylinderW4-3-2

Removal and Installation of Hose Rupture Valve for Positioning Cylinder

Removal and Installation of Hose Rupture Valve for Boom Cylinder

Structure of Hose Rupture Valve for Ami Cylinder

Structure of Hose Rupture Valve for Positioning Cylinder

Structure of Hose Rupture Valve for Boom Cylinder

–OPERATE CHECK VALVE

Remove and Install Operate Check

Valve (for Blade and Outrigger)

Structure of Operate Check Valve

–HOSE RUPTURE VALVE

Hydraulic Circuit Pressure Release Procedure

Removal and Installation of Hose Rupture Valve for Arm Cylinder

Removal and Installation of Hose Rupture Valve for Positioning Cylinder

Removal and Installation of Hose Rupture Valve for Boom Cylinder

Structure of Hose Rupture Valve for Ami Cylinder

Structure of Hose Rupture Valve for Positioning Cylinder

Structure of Hose Rupture Valve for Boom Cylinder

–OPERATE CHECK VALVE

Remove and Install Operate Check Valve (for Blade and Outrigger)

Structure of Operate Check Valve

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.