Factory Service Technical Manuals (Operational Principle, Troubleshooting) For Hitachi ZX 70-3 70LC-3 70LCN-3 75US-3 85US-3 Excavators. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 638

Bookmarks: Yes

Searchable: Yes

Number: TO1P1-E-00

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Hitachi ZX 70-3, 70LC-3, 70LCN-3, 75US-3, 85US-3

Contents

1.Technical Manual(Operational Principle)

2.Technical Manual(Trobleshooting)

1.Technical Manual(Operational Principle)

-GENERAL

–SPECIFICATIONS

Specifications (Standard)

Working Ranges (Standard)

Specifications (EU)

Working Ranges (EU)

–COMPONENT LAYOUT

Mam Component Layout

Electrical System (Overview)

Electrical System (Monitor Switches)

Electrical System (Controllers Relays)

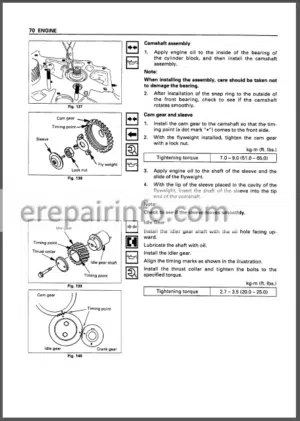

Engine

Electrical System (Pump Device)

Electrical System (Battery)

Control Valve

Pump Device

Swing Device

Travel Device

–COMPONENT SPECIFICATIONS

Engine

Engine Accessories

Hydraulic Component

Filter

Electrical Component

-SYSTEM

–CONTROLLER

Outline

CAN: Controller Area Network (Network Provided for Machine)

MC: Main Controller

ICF: Information Controller

Monitor Unit

–CONTROL SYSTEM

Outline

Engine Control

Pump Control

Valve Control

Other Control

–HYDRAULIC SYSTEM

Outline

Pilot Circuit

Main Circuit

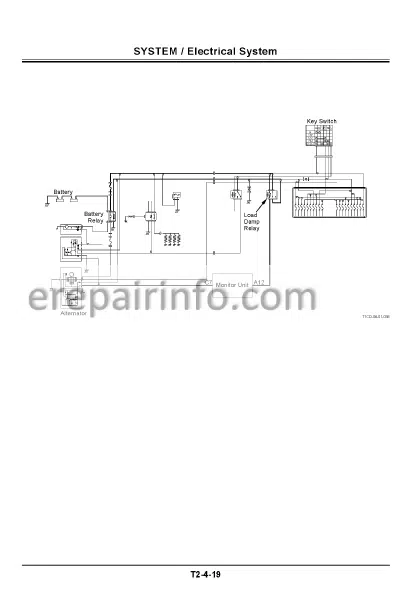

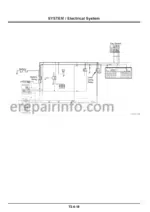

–ELECTRICAL SYSTEM

Outline

Main Circuit

Electric Power Circuit (Key Switch: OFF)

Accessory Circuit

Preheating Circuit

Starting Circuit (Key Switch: START)

Charging Circuit (Key Switch: ON)

Serge Voltage Prevention Circuit

Pilot Shut-Off Circuit (Key Switch: ON)

Security Lock Circuit

EGR (Exhaust Gas Recirculation) Control

Engine Stop Circuit (Key Switch OFF)

Security Horn Circuit

Working Light Circuit

Wiper / Washer Circuit

-COMPONENT OPERATION

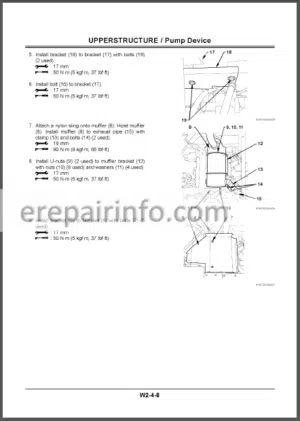

–PUMP DEVICE

Outline

Main Pumps 1 2 and 3

Regulator of Main Pumps 1 and 2

Regulator of Main Pump 3

Pilot Pump

N Sensor (Engine Speed Sensor)

–SWING DEVICE

Outline

Swing Motor

Swing Parking Brake

Make-Up Valve

Relief Valve

Swing Reduction Gear

–CONTROL VALVE

Outline

Hydraulic Circuit

Flow Combiner Valve

Mam Relief Pressure Selection

Boom Anti-Dnft Valve

Main Relief Valve

Overload Relief Valve

–PILOT VALVE

Outline

Operation

Shockless Function (Only for Travel Pilot Valve)

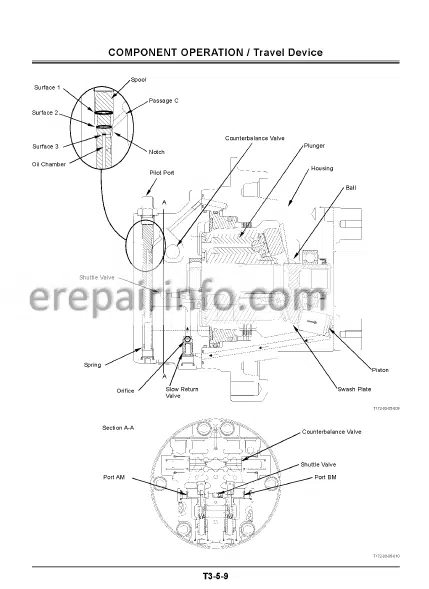

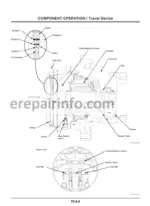

–TRAVEL DEVICE

Outline

Travel Motor

Parking Brake

Travel Brake Valve

Travel Reduction Gear

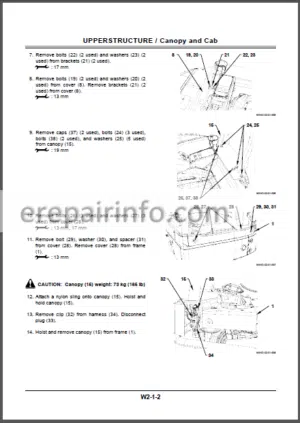

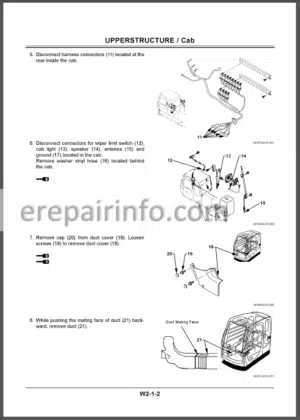

–OTHERS (UPPERSTRUCTURE)

Pilot Shut-Off Solenoid Valve

Shockless Valve

2-Spool Solenoid Valve Unit

EC Motor

Pilot Relief Valve

Engine Fan Clutch

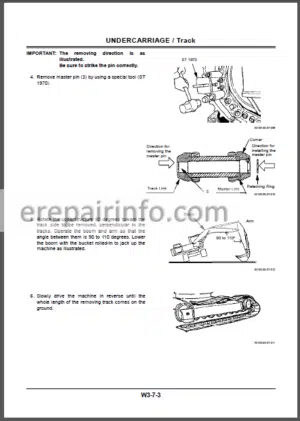

–OTHERS (UNDERCARRIAGE)

Swing Bearing

Center Joint

Track Adjuster

2.Technical Manual(Troubleshooting)

-OPERATIONAL PERFORMANCE TEST

–INTRODUCTION

Operational Performance Tests

Preparation for Performance Tests

–STANDARD

Operational Performance Standard Table

Mam Pump 1, 2 P-Q Diagram (ZX70-3)

Main Pump 1, 2 P-Q Diagram (ZX75US-3)

Mam Pump 3 P-Q Diagram

Sensor Activating Range

–ENGINE TEST

Engine Speed

Engine Compression Pressure

Valve Clearance

Nozzle Check

Injection Timing

Lubricant Consumption

–EXCAVATOR TEST

Travel Speed

Track Revolution Speed

Mistrack Check

Travel Parking Leakage

Swing Speed

Swing Function Drift Check

Swing Motor Leakage

Maximum Swingable Slant Angle

Swing Bearing Play

Hydraulic Cylinder Cycle Time

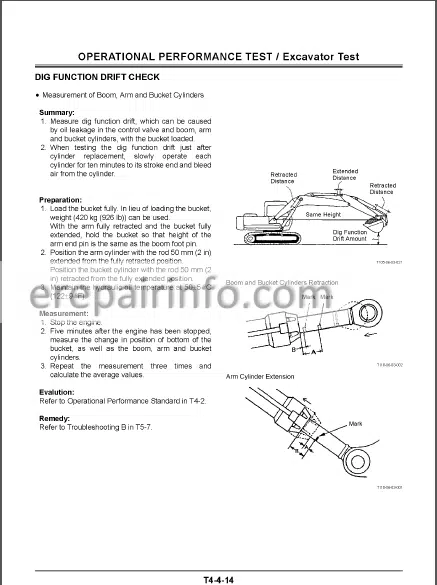

Dig Function Drift Check

Control Lever Operating Force Control Lever Stroke

Combined Operation of Boom Raise / Swing Function Check

–COMPONENT TEST

Primary Pilot Pressure

Secondary Pilot Pressure

Solenoid Valve Set Pressure

Mam Pump Delivery Pressure

Main Relief Set Pressure

Overload Relief Valve Set Pressure

Main Pump 1 and 2 Flow Rate

Main Pump 3 Flow Rate

Swing Motor Drainage

Travel Motor Drainage

–ADJUSTMENT

Engine Speed Adjustment and Engine Learning

Guveiriui Level and Fuel Cut Lever Positions

-TROUBLESHOOTING

–DIAGNOSING PROCEDURE

Introduction

Diagnosing Procedure

–MONITOR UNIT

Outline

Howto Use Screens

Screen Display When an Alarm is Issued

Contents of Alarms

Time Setting

Maintenance Setting

Mail (Optional)

Password Change (Optional)

Back Monitor Setting

Language Setting

Monitoring

Service Menu (Built-In Diagnosing System) Operation

Troubleshooting

Monitoring

Controller Version

Keyless Hour Meter

List of Monitor Unit Sotting Function

–DR ZX

Outline

Monitoring List

MC Setup

All Parameter Initialize

ICF Setup

Dr ZX Operation Procedure

–ICF

Outline

List of Daily Report Data

List of Frequency Distribution Data

List of Total Operating Hours

How to Download and Upload Data of ICF

Various Setup of ICF and Satellite Communication Terminal by Using Dr ZX

List of Fault Code

Satellite Communication System

–COMPONENT LAYOUT

Main Component Layout

Electrical System (Overview)

Electrical System (Monitor, Switches)

Electrical System (Controllers, Relays)

Engine

Electrical System (Pump Device)

Electrical System (Battery)

Control Valve

Pump Device

Swing Device

Travel Device

Components in Control Valve

–TROUBLESHOOTING A

Troubleshooting A Procedure

MC Fault Code List

ECF Fault Code List

ICF Fault Code List

Satellite Terminal Fault Code List

Monitor Unit Fault Code List

MC Fault Codes 11000 to 11002

MC Fault Code 11003

MC Fault Code 11004

CAN Harness Check

MC Fault Code 11100

MC Fault Code 11101

MC Fault Cede 11304

MC Fault Code 11307

MC Fault Code 11401

MC Fault Code 11405

MC Fault Codes 11910 to 11920

MC Fault Code 11901

ICF Fault Codes 14000 to 14003

Information C/U: Initialize

Control Data: Initialize

Enter Model and Serial No

ICF Fault Codes 14006, 14008

Satellite Terminal Fault Codes 14100 to 14106

Monitor Unit Fault Code 13303

Monitor Unit Fault Code 13304

Monitor Unit Fault Codes 13306 and 13308

Monitor Unit Fault Code 13310

Monitor Unit Fault Code 13311 Pilot Shut-Off Lever Alarm

–TROUBLESHOOTING B

Troubleshooting B Procedure

Relationship between Machine Trouble Symptoms and Related Parts

Correlation between Trouble Symptoms and Part Failures

Engine System Troubleshooting

All Actuator System Troubleshooting

Front Attachment System Troubleshooting

Swing System Troubleshooting

Travel System Troubleshooting

Blade System Troubleshooting

Other System Troubleshooting

Exchange Inspection

Emergency Boom Lowering Procedure

–ELECTRICAL SYSTEM INSPECTION

Precautions for Inspection and Maintenance

Instructions for Disconnecting Connectors

Fuse Inspection

Fusible Link Inspection

Battery Voltage Check

How to Check Alternator

Continuity Check

Voltage and Current Measurement

Check by False Signal

Test Harness

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.