Factory Service And Maintenance Manual For JLG Boom Lift. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 462; 460

Issue: december 2010; december 2010

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

JLG Boom Lift

400S

460SJ

Contents

INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS

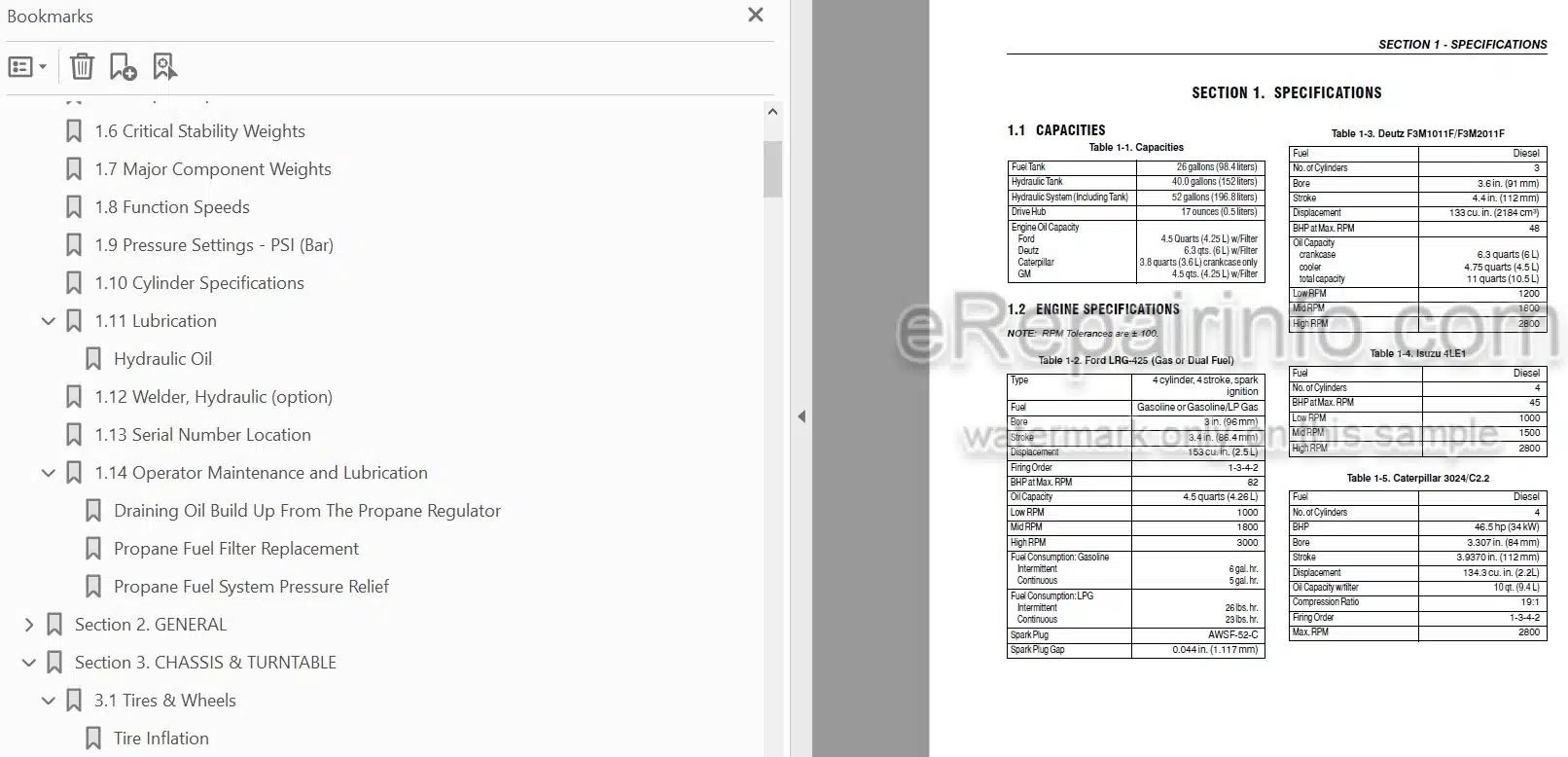

-SPECIFICATIONS

Capacities

Engine Specifications

Tires

Specifications and Performance Data

Torque Requirements

Critical Stability Weights

Major Component Weights

Function Speeds

Pressure Settings – PSI (Bar)

Cylinder Specifications

Lubrication

Welder. Hydraulic (option)

Serial Number Location

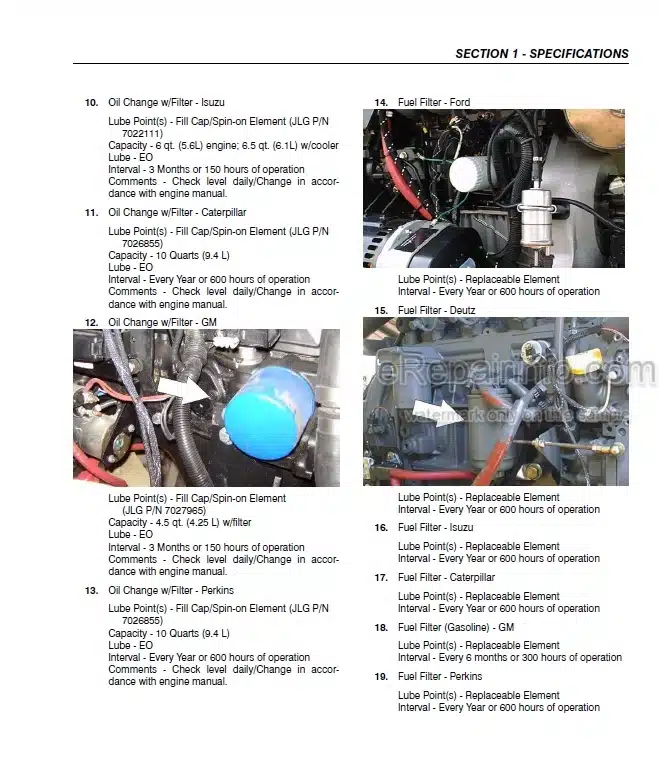

Operator Maintenance and Lubrication

-GENERAL

Machine Preparation, Inspection, and Maintenance

Service and Guidelines

Lubrication and Information

Cylinder Drift Test

Pins and Composite Bearing Repair Guidelines

Welding on JLG Equipment

-CHASSIS & TURNTABLE

Tires & Wheels

Drive Hub Part No. 2780243 (2wd Rear) Part No. 2780244 (4wd Rear)

Drive Hub Part No. 2780246 (4wd steer axle Prior to S/N 0300076633)

Torque Hub – 4WD (Machines built after S/N 0300076633)

Re-Aligning Torque Hub Input Coupling

Drive Brake

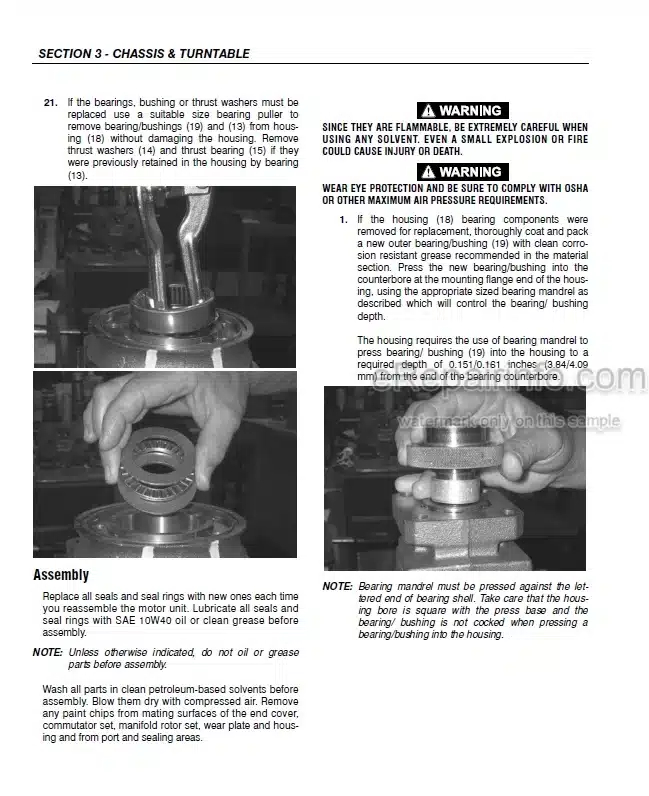

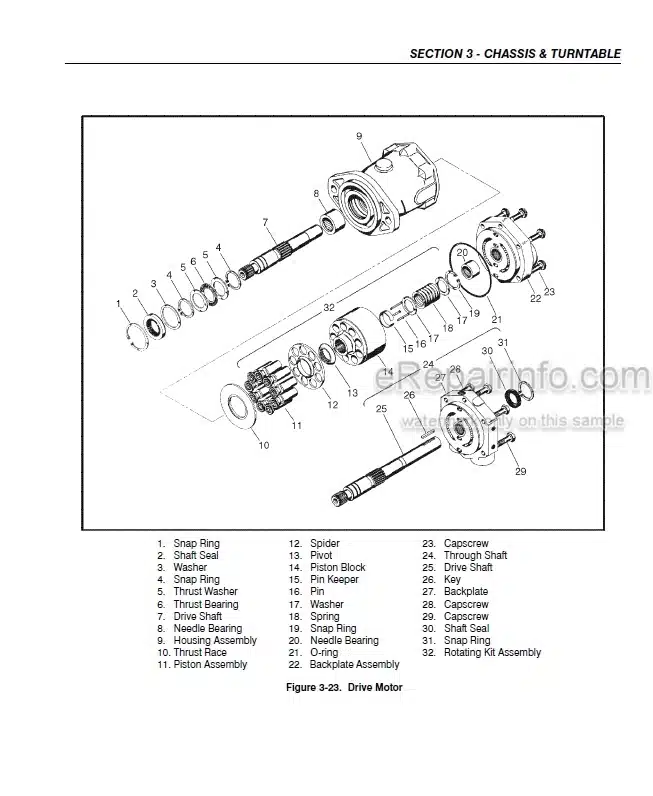

Drive Motor

Adjustment Procedure For Lockout Valve

Toe-In Adjustment

2WD Hub

Oscillating Axle Bleeding Procedure

Oscillating Axle Lockout Test

Swing Bearing

Swing Brake (Prior to S/N 64802)

Swing Brake S/N 64802 to Present

Swing Drive Torque Hub

Semi-Track

Generator

Ford EFI Engine

Throttle Checks and Adjustments – Deutz Engine (Prior to S/N 61718)

Tilt Alarm Switch (Prior to S/N 61718)

Hydraulic Welder (225-4)

Troubleshooting of the Sky Welder

Deutz EMR 2 (S/N 77682 to Present)

GM Engine General Maintenance

GM Engine Dual Fuel System

GM Engine Fuel System Repair

GM Engine LPG Fuel System Diagnosis

Perkins Engine General Maintenance

Engine Radiator Fill Procedure – Perkins & Caterpillar

DGC Diagnostic Support And Trouble Code Definitions

Diagnostic Trouble Code Fault Descriptions

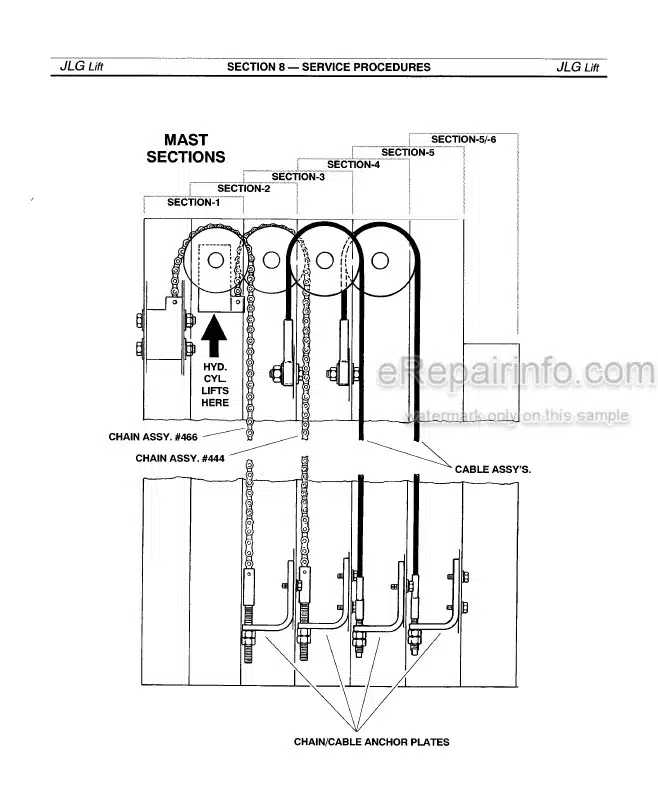

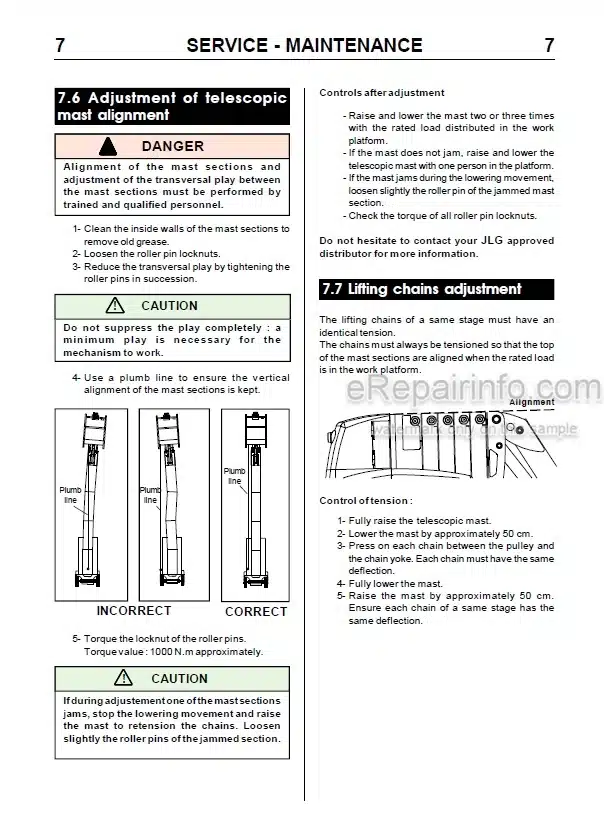

-BOOM & PLATFORM

Boom

Articulating Jib

Limit Switch Adjustments

Drive Card Setup Procedures

Helac Rotary Actuator

-HYDRAULICS

Cylinders – Theory of Operation

Cylinder Repair

Valves – Theory of Operation

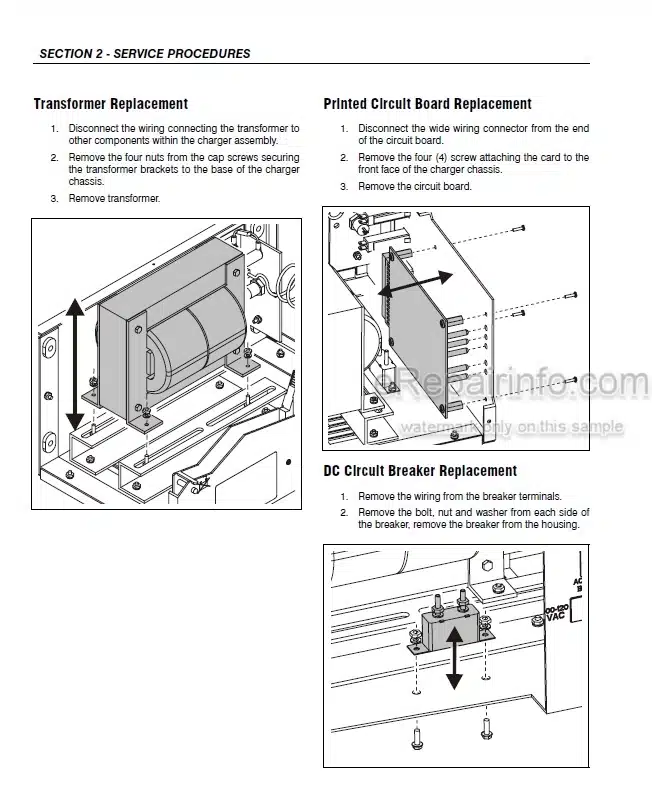

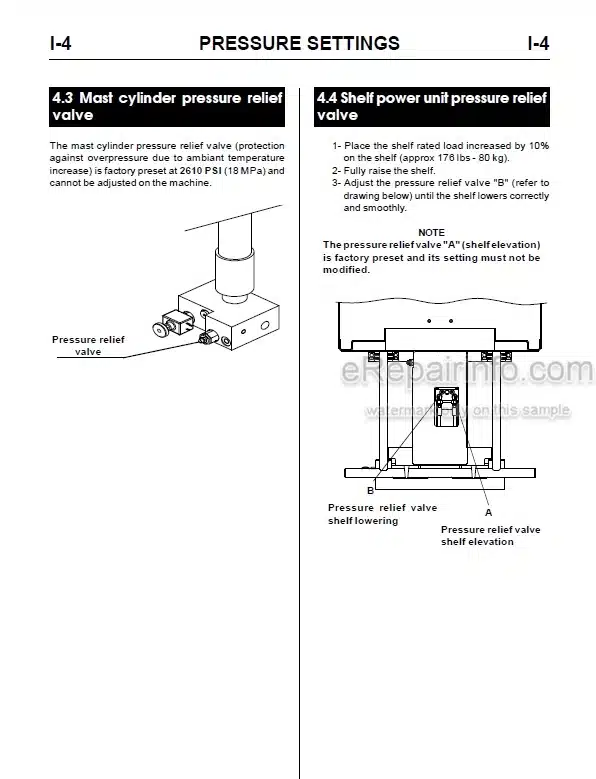

Pressure Setting Procedures

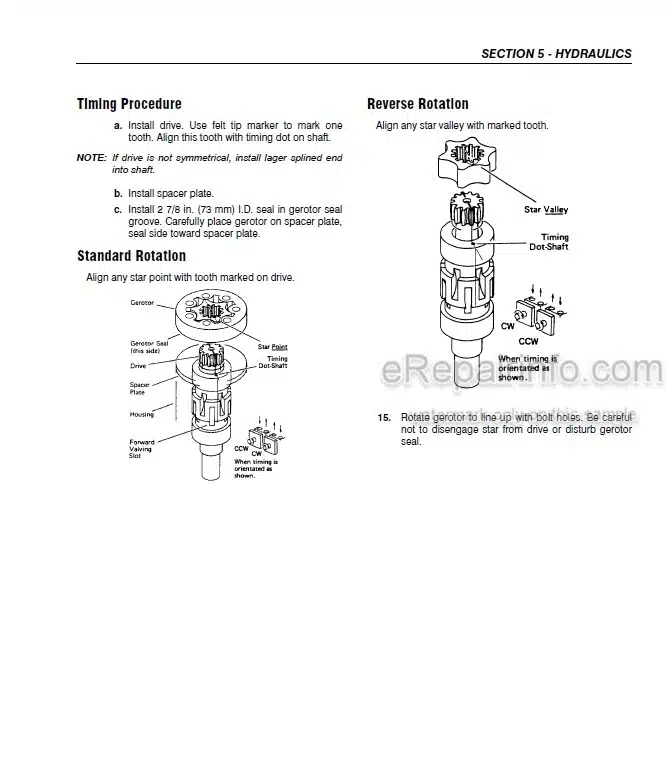

Hydraulic Motor Repair (H Series Char-lynn)

Hydraulic Pump “Neutral” Or Null Adjustment

Non-feedback, Proportional Electrical Control – NFPE

Hydraulic Component Start-Up Procedures and Recommendations

-JLG CONTROL SYSTEM FS/N 61718 TO PRESENT)

Introduction

To Connect the JLG Control System Analyzer

Using the Analyzer

Changing the Access Level of the Hand Held Analyzer

Adjusting Parameters Using the Hand Held Analyzer

Machine Setup

Level Vehicle Description

Machine Personality Settings

System Test

Analyzer Diagnostics Menu Structure

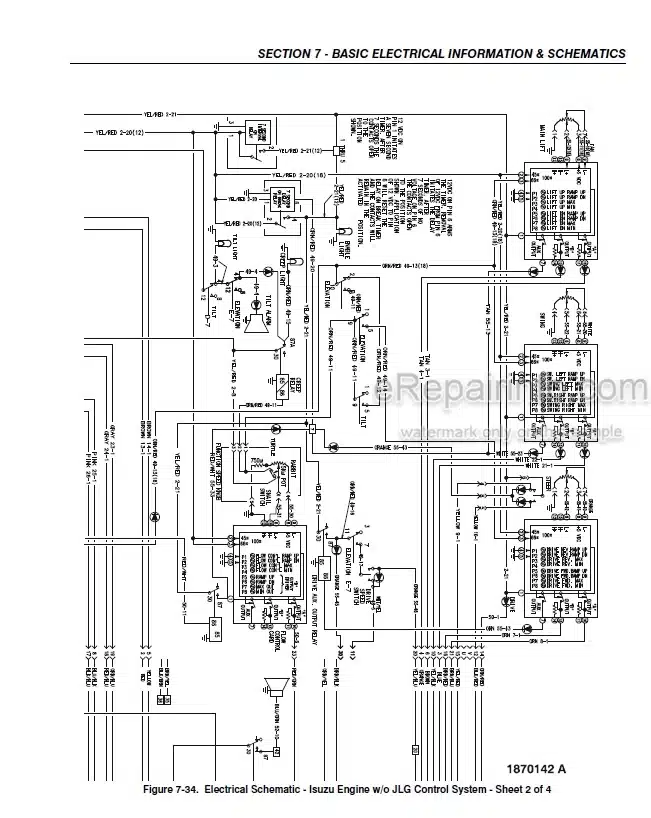

-BASIC ELECTRICAL INFORMATION & SCHEMATICS

General

Multimeter Basics

Checking Switches

Applying Silicone Dielectric Compound to Electrical Connections

AMP Connector

Deutsch Connectors

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.