Factory Service And Maintenance Manual For JLG Boom Lift. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 152

Issue: october 2001

Searchable: Yes

Wiring Diagrams: Yes

Model

JLG Boom Lift

40H

40H+6

Contents

-INTRODUCTION – MAINTENANCE SAFETY PRECAUTIONS

General

Hydraulic System Safety

Maintenance

Effectivity Changes

List Of Illustrations

List Of Tables

-SPECIFICATIONS

Capacities

Component Data

Performance Data

Torque Requirements

Lubrication

Pressure Settings

Cylinder Specifications

Boom Tape

Major Components Weights

Critical Stability Weights

Serial Number Location (See Figure 1-4)

-PROCEDURES

General

Servicing And Maintenance Guidelines

Lubrication Information

Cylinders – Theory Of Operation

Valves – Theory Of Operation

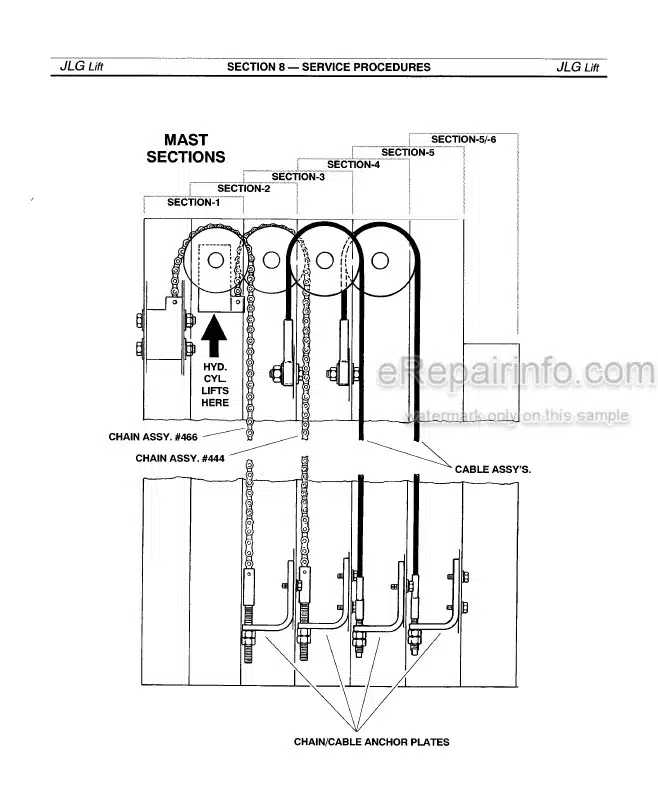

Boom Chains (See Figure 2-1)

Wear Pads

Cylinder Checking Procedure

Cylinder Repair

Cylinder Removal And Installation

Boom Maintenance

Tilt Alarm Switch

Horizontal High Speed Cutout Switch Adjustment Procedure

Governor Checks And Addco Adjustment, Ford

Throttle Checks And Precision Governor Adjustments, Addco (See Figure 2-6)

Electric Governor And Adjustments – Ford Engines

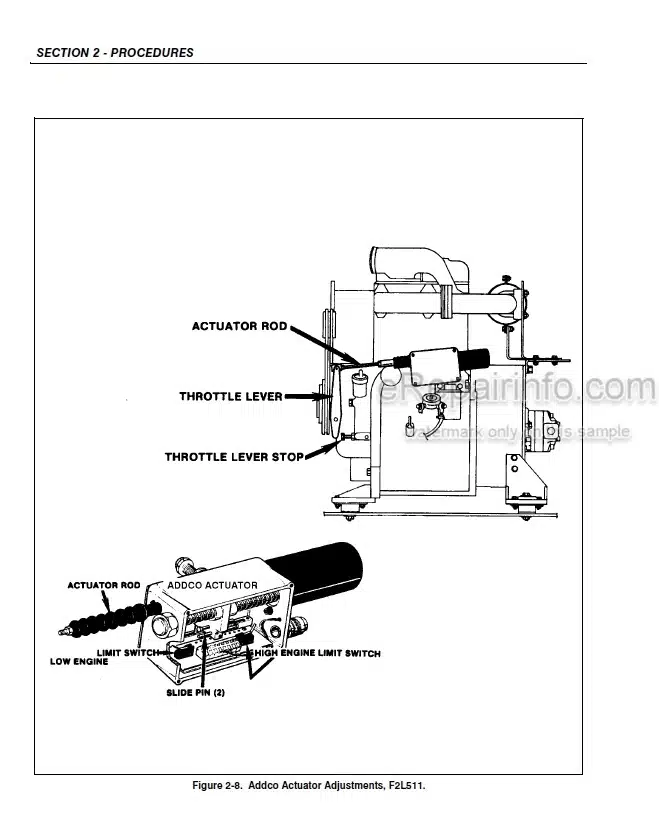

Throttle Checks And Adjustments – Deutz F2I511 Engine (See Figure 2-8)

Throttle Checks And Adjustments Wisconsin Engine (See Figure 2-9)

Throttle Checks And Adjustments – Deutz F3I912 Engine (See Figure 2-10)

Throttle Checks And Adjustments – Deutz Engine F3I1011 (See Figure 2-11)

Pressure Setting Procedures

Racine Proportional Air Gap Adjustment

Swing Bearing

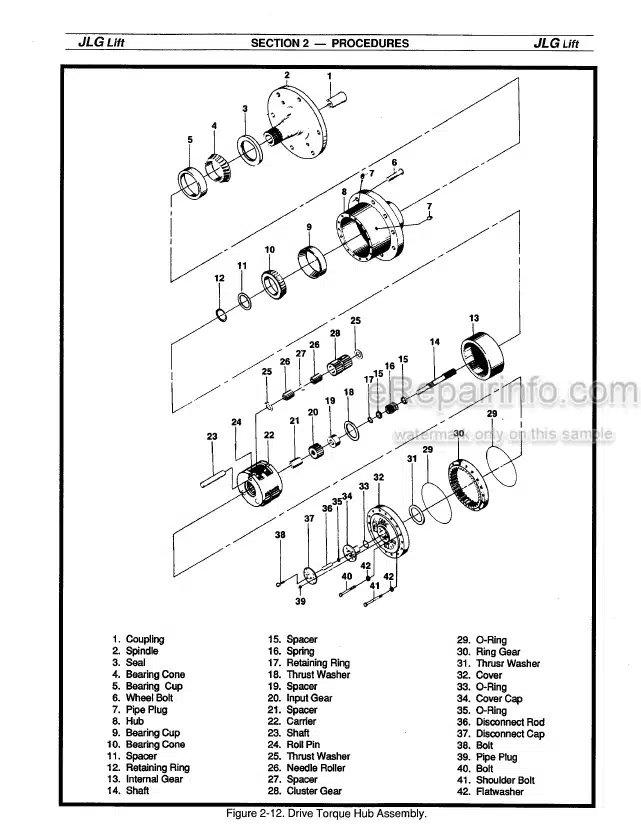

Torque Hub, 2w/d (See Figure 2-36)

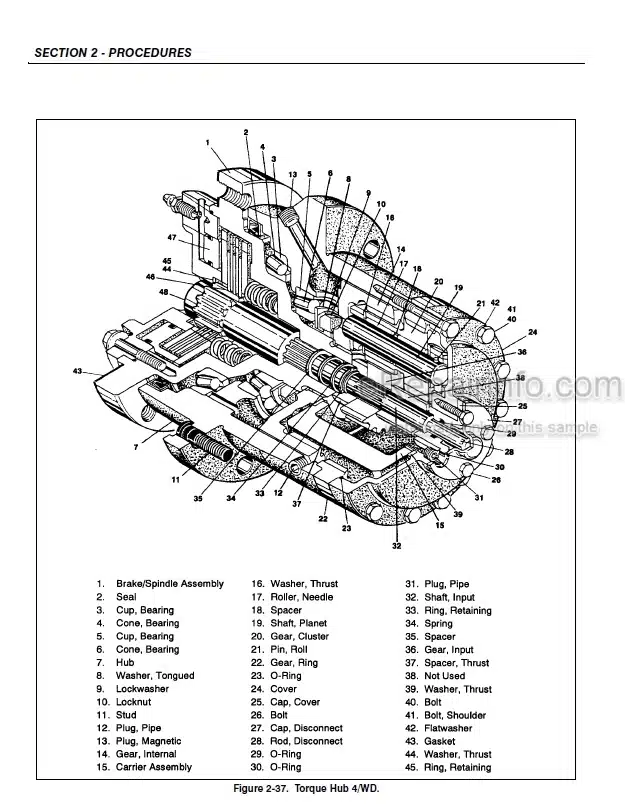

Torque Hub 4wd (See Figure 2-37)

Swing Drive Brake, Mico (Machines Built Prior To May 1992) (See Figure 2-39)

Drive Brake, Mico (Machines Built Prior To May 1992)(See Figure 2-40)

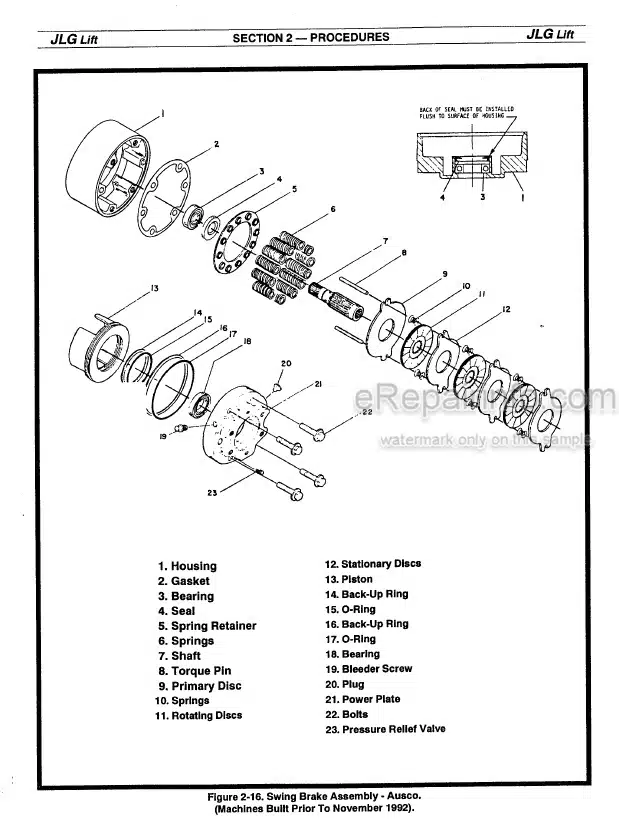

Swing Drive Brake, Ausco (Machines Built Prior To May 1992) (See Figure 2-41)

Drive Brake, Ausco (Machines Built Prior To May 1992) (See Figure 2-43)

Drive Brake, Mico (Machines Built From May 1992 To S/n 33476) (See Figure 2-44)

Swing Brake, Mico (Machines Built From May 1992 To S/n 33476) (See Figure 2-45)

Drive Brake, Mico (Machines Built From S/n 33476 To Present) (See Figure 2-46)

Swing Brake, Mico (Machines Built From S/n 33476 To Present) (See Figure 2-46)

Controllers

Oscillating Axle Bleeding Procedure

Oscillating Axle Lockout Test

Basket Rotator Brake (See Figure 2-48)

Free Wheeling Option

Spark Arrestor Mufflers

Footswitch Adjustment

Hydraulic Pump W/hayes Pump Drive Coupling Lubrication

Dual Fuel System

Preventive Maintenance And Inspection Schedule

Capacity Indicator

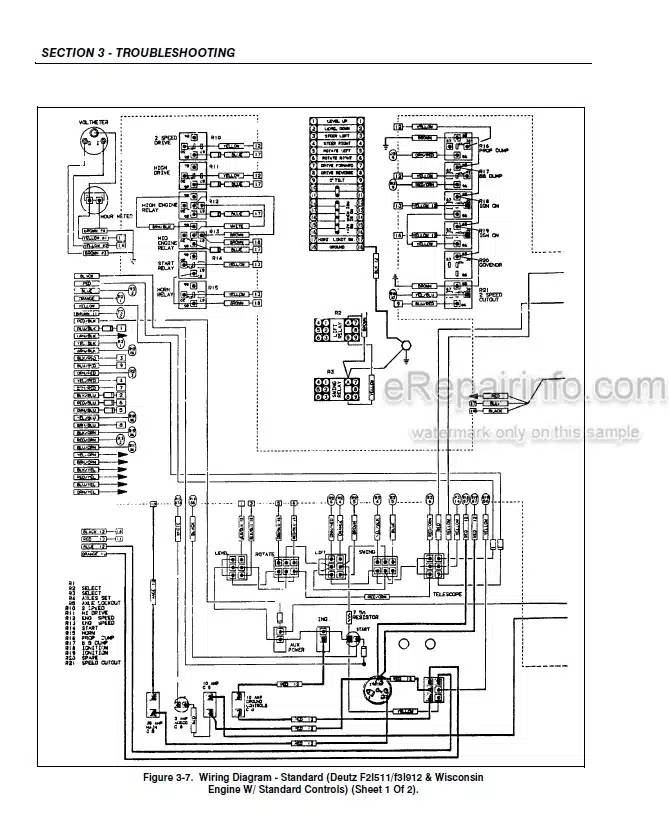

-TROUBLESHOOTING

General

Troubleshooting Information

Hydraulic Circuit Checks

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.