Factory Component Technical Manual For John Deere Axle. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 462

Number: CTM43 (november 2006)

Bookmarks

Searchable

Model

John Deere Inboard Planetary Axle

1200 Series

1400 Series

1600 Series

Contents

-SAFETY

Recognize Safety Information

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Handle Chemical Products Safely

Avoid High-Pressure Fluids

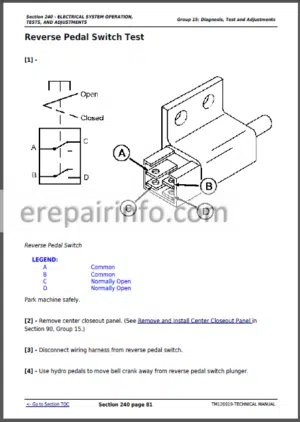

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Avoid Harmful Asbestos Dust

Avoid Heating Near Pressurized Fluid Lines

Remove Paint Before Welding or Heating

Use Proper Tools

Construct Dealer-Made Tools Safely

Dispose of Waste Properly

Live With Safety

-GENERAL

General Inboard Planetary Axle Specifications

Axle Identification

Serial Number Plate

Specification and Configuration Code Plate – 1200 Series

Specification and Configuration Code Plate – 1400 Series

Serial Number Plate—OEM Applications—1600 Series

General Repair Procedures

Sealants and Adhesives Cross-Reference Chart

Sealing Instructions

Transmission, Hydraulic, and Gear Case Oil

Service and Maintenance Schedule

Standard and Extreme Duty Axle—Oil Capacity (Approximate)

Super Wide Extreme Duty Axle—Oil Capacity (Approximate)

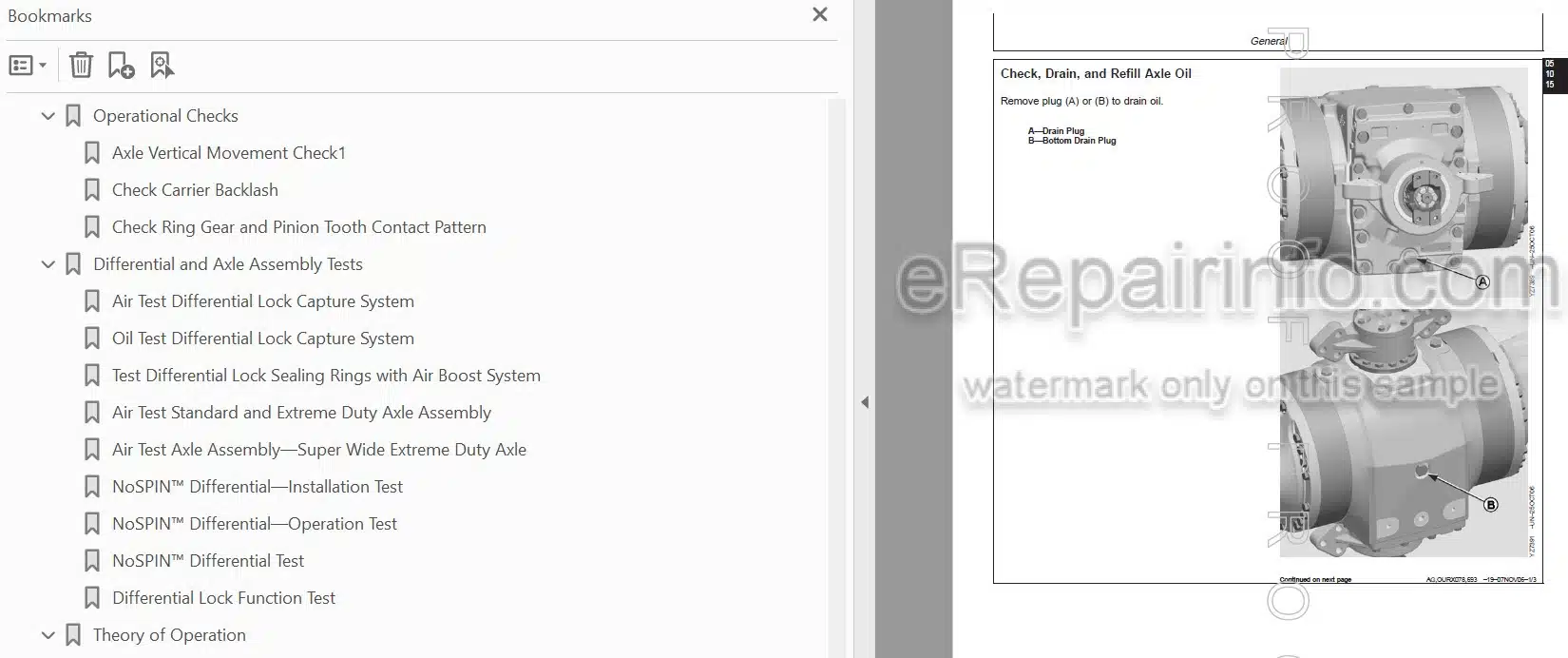

Check, Drain, and Refill Axle Oil—Standard and Extreme Duty Axles

Check, Drain, and Refill Axle Oil

Alternative and Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Grease

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values— Grade 180

Hydraulic Connections

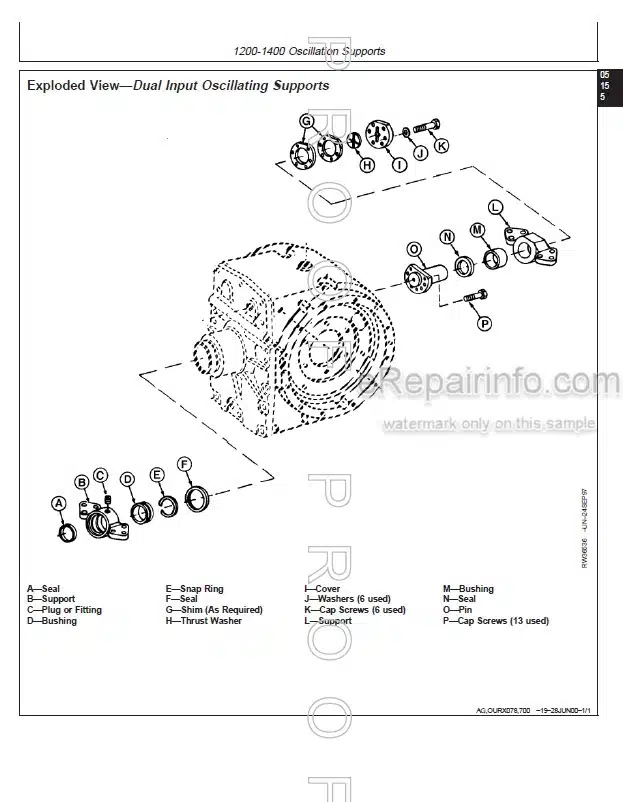

-1200-1400 OSCILLATION SUPPORTS

Essential or Recommended Tools

Other Material

Specifications

Cross-Sectional View—Input Housing/Cover

Exploded View—Dual Input Oscillating Supports

Remove Input Oscillating Support

Disassemble and Inspect Input Oscillating Support

Assemble Input Oscillating Support

Install Oscillating Support—Non-helical Input Spline Axles

Install Oscillating Support—Helical Input Spline Axles

Remove. Disassemble, and Assemble Oscillating Support from Opposite End of Input

-1600 OSCILLATION SUPPORTS

Essential or Recommended Tools

Other Material

Specifications

Cross-Sectional View—Input Quill—Oscillating

Remove Oscillating Support

Disassemble Oscillating Support

Assemble Oscillating Support

Install Oscillating Support

Remove and Install Pivot Pin

Remove, Disassemble, and Assemble Oscillating Support from Opposite End of Input

-AXLE ASSEMBLY END PLAY

Specifications

Adjust Axle Assembly End Play-In Vehicle

-1200-1400 NON-HELICAL INPUT SPLINE AXLE INPUT HOUSING

Essential or Recommended Tools

Other Material

Specifications

Remove and Install Input Housing

Cross-Sectional View—Input Housing/Cover

Exploded View—Input Housing/Cover

Disassemble and Assemble Input Housing

Determine Differential Drive Shaft Cone Point Shim Pack

Continue Assembly

Adjust Input Pinion Shaft End Play

-1400 HELICAL INPUT SPLINE, INPUT HOUSING

Essential or Recommended Tools

Other Material

Specifications

Remove and Install Input Housing

Cross-Sectional View—Input Housing/Cover

Exploded View—Input Housing/Cover

Disassemble and Assemble Input Housing

Determine Differential Drive Shaft Cone Point Shim Pack

Continue Assembly

Adjust Input Pinion Shaft End Play

-1600 INPUT HOUSING/CASE COVER

Essential or Recommended Tools

Other Material

Specifications

Install Axle in Repair Stand

Remove Input Housing/Cover

Cross-Sectional View—Input Housing/Cover

Exploded View—Input Housing/Cover

Disassemble Input Housing/Cover and Bevel Pinion Shaft

Assemble Input Housing/Cover and Bevel Pinion Shaft

Determine Differential Drive Shaft Cone Point Shim Pack

Continue Assembly of Input Housing/Cover

Install Input Housing/Cover

-DISCONNECT AND INPUT HOUSING/CASE COVER

Essential or Recommended Tools

Other Material

Specifications

Cross-Sectional View—Axle Disconnect and Input Housing/Case Cover

Cross-Sectional and Exploded Views—Axle Disconnect

Remove Disassemble and Assemble Axle Disconnect

Cross-Sectional and Exploded Views—Input Housing/Case Cover

Remove Input Housing/Case Cover

Disassemble Input Housing/Case Cover and Pinion Shaft

Assemble Input Housing/Case Cover and Pinion Shaft

Determine Differential Drive Shaft Cone Point Shim Pack

Continue Assembly

Adjust Pinion Shaft

Install Input Housing/Case Cover

Install Axle Disconnect

-1200-1400 DIFFERENTIAL HOUSINGS

Essential or Recommended Tools

Other Material

Specifications

Exploded View—Differential Lock Lines— Air Boost System

Exploded View—Differential Lock Lines— Suction Tube

Cross-Sectional View—Differential Assembly With Differential Lock

Remove Differential Housing Assembly

Disassemble, Inspect, and Assemble Differential Housing

Assemble and Test Differential Lock Quill

Remove and Install Rina Gear

Disassemble, Inspect, and Assemble Differential Pinions

Cross-Sectional View—Differential Assembly—NoSPIN

Exploded View—Differential Assembly—NoSPIN

Disassemble, Inspect, and Assemble NoSPIN Differential

Install Differential

Adjust Differential Bearing Preload

Adjust Differential Backlash

Install Differential Lock Lines

Install Housing/Cover

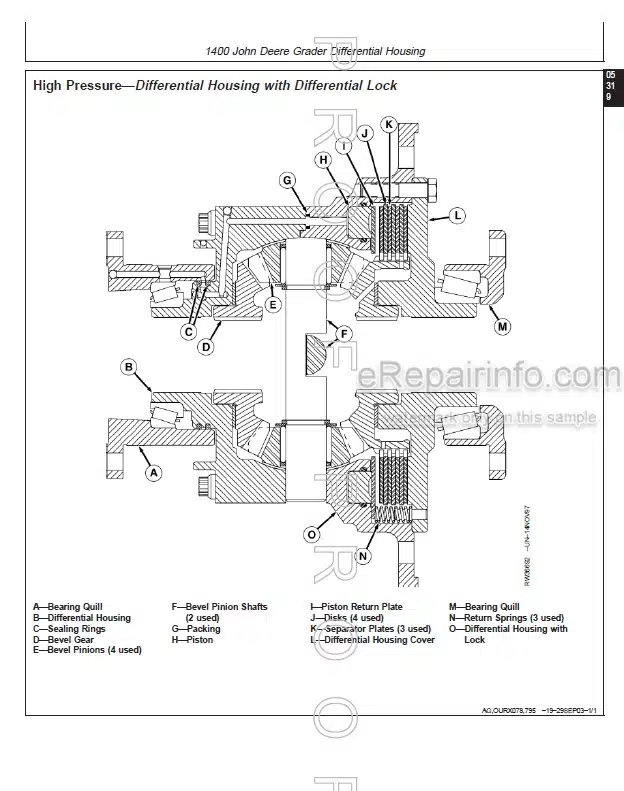

-1400 JOHN DEERE GRADER DIFFERENTIAL HOUSING

Essential or Recommended Tools

Other Material

Specifications

Remove Differential Lock Valve

Install Differential Case Assembly in Repair Stand

Remove Input Housing/Cover

High Pressure—Differential Housing with Differential Lock

Low Pressure—Differential Housing with Differential Lock

Remove Differential Housing

Disassemble, Assemble, and Test Differential Lock Quill

High Pressure—Disassemble Differential Housing

Low Pressure—Disassemble Differential Housing

Remove and Install Ring Gear

High Pressure— Assemble Differential Housing

Low Pressure—Assemble Differential Housing

Install Differential Housing

Adjust Differential Bearing Preload

Install Differential Lock Lines

Install Input Housing/Cover

Adjust Differential Backlash

Differential Lock Valve Exploded View – Solenoid Valve

Remove and Install Differential Lock Solenoid Valve

Differential Valve Group Exploded View

Install Differential Lock Valve

-1600 DIFFERENTIAL HOUSING

Essential or Recommended Tools

Other Material

Specifications

Install Axle in Repair Stand

Remove Differential Housing

Cross-Sectional View—Differential with Differential Lock

Cross-Sectional View—Standard Differential

Disassemble, Inspect, and Assemble Differential Housing

Install Differential Housing

Adjust Differential Preload

Adjust Differential Backlash

-1200-1400 STANDARD AND EXTREME DUTY AXLE FINAL DRIVE

Essential or Recommended Tools

Other Material

Specifications

Exploded View—Axle Shaft and Housing—Greased Outer Bearing

Exploded View—Axle Shaft and Housing—Greased Outer Bearing with Spacer

Exploded View—Axle Shaft and Housing— Oiled Outer Bearing Axles

Exploded View—Final Drive

Remove Axle Housing Assemblies

Remove Axle Housing

Disassemble, Inspect, and Assemble Axle Shaft

Disassemble and Assemble Axle Housing

Assemble Final Drive/Axle Housing Assembly

Cross-Sectional View—Planet Pinion Carrier and Axle Shaft

Cross-Sectional View—Final Drive Hub and Axle Shaft—1200 Series

Disassemble Planet Pinion Carrier

Inspect Planet Pinion Components

Assemble Planet Pinion Carrier

Assemble Axle Shaft and Housing

Adjust Axle Bearings

Install Axle Housing Assemblies

Torque Turn Tightening Procedure

Fill Axle Housing with Grease (Greased Outer Bearing Axles)

-1400 JOHN DEERE GRADER PLANETARY CARRIER

Essential or Recommended Tools

Other Material

Cross-Sectional View—Planet Pinion Carrier

Disassemble Planet Pinion Carrier

Inspect Planet Pinion Components

Assemble Planet Pinion Carrier

Inspect and Install Final Drive Rina Gear

-1400 JOHN DEERE EXTREME DUTY PLANETARY CARRIER

Specifications

Cross-Sectional View—Planet Pinion Carrier

Disassemble, Inspect, and Assemble Planet Pinion Carrier

-1400 SUPER WIDE EXTREME DUTY AXLE HOUSING, SHAFT, AND FINAL DRIVE

Essential or Recommended Tools

Other Material

Specifications

Exploded View—Axle Shaft and Housing

Exploded View—Final Drive

Remove and Disassemble Axle Housing Assemblies

Disassemble, Inspect, and Assemble Axle Shaft

Cross-Sectional View—Planet Pinion Carrier

Disassemble, Inspect, and Assemble Planet Pinion Carrier

Install Axle Face Seals

Install Axle Housing to Axle Shaft

Adjust Axle Bearings

Install Axle Housing Assemblies

-1600 FINAL DRIVE/PLANETARY CARRIER

Essential or Recommended Tools

Other Material

Specifications

Install Axle Assembly in Repair Stand

Remove Final Drive Assemblies

Install Final Drive Assemblies

Cross-Sectional View—Final Drive and Axle Assembly—Oiled Outer Axle Bearing

Exploded View—Axle Shaft and Housing—Oiled Outer Axle Bearing

Cross-Sectional View—Final Drive and Axle Assembly Greased Outer Axle Bearing

Exploded View—Axle Shaft and Housing Greased Outer Axle Bearing

Disassemble Final Drive

Exploded View—Final Drive Planetary Carrier

Disassemble Planet Pinion Carrier

Inspect Planet Pinion Components

Assemble Planet Pinion Carrier

Remove Axle Housing

Disassemble and Assemble Axle Housing

Disassemble, Inspect, and Assemble Axle Shaft

Install Axle Housing

Adjust Axle Bearings

-1200-1400 SINGLE DISK BRAKES

Essential or Recommended Tools

Specifications

Exploded View—Brake Components—Early Design—Three Dowel

Exploded View—Brake Components—Later Design

Exploded View—Brake Components—Later Design—Retained Backing Plate

Disassemble and Assemble Brakes

-1600 SINGLE DISK BRAKES

Specifications

Cross-Sectional View—Brake Components

Exploded View—Brake Components

Disassemble and Assemble Brakes

-1400 MULTIPLE DISK BRAKES

Essential or Recommended Tools

Specifications

Brake Inspection—Hydraulic Brakes

Cross-Sectional View—Brake Components—Multiple Disk Brakes

Exploded View—Brake Components—Multiple Disk Brakes

Remove and Install Brake Components from Differential Case

Brake Piston Packings—Vacuum Leakdown Test

-PARKING BRAKE

Essential or Recommended Tools

Specifications

Cross-Sectional View—Manual Park Brake

Remove, Assemble, and Adjust Park Brake— Manual

Cross-Sectional View—Spring Applied/Hydraulic Release Park Brake

Remove. Assemble, and Adjust Park Brake— SprinaApplied/Hvdraulic Release

-DRY DRUM BRAKE

Specifications

1400 Series Dry Drum Brake Axle

Remove Brake Drum

Inspect Brake Drum

Remove Brake Adjuster

Remove Camshaft and Air Chamber Bracket

Inspect Air Chamber Inner Bracket

Inspect Spider Assembly

Remove and Install Spider Assembly

Install Air Chamber Bracket and Camshaft

Install Brake Adjuster

Install Brake Drum

-TROUBLESHOOTING

Troubleshoot Axle and Differential

-BRAKE INSPECTION, ADJUSTMENTS, TESTS, AND BLEEDING

Adjust Park Brake—Spring Applied/Hydraulic Release

Park Brake Pressure Test

Adjust Park Brake—Manual

Brake Disk Inspection (External)

Annular Brake Piston Inspection

Leakdown Test—Brake Piston Packings

Bleed Hydraulic Brakes

-OPERATIONAL CHECKS

Axle Vertical Movement Check

Check Carrier Backlash

Check Ring Gear and Pinion Tooth Contact Pattern

-DIFFERENTIAL AND AXLE ASSEMBLY TESTS

Air Test Differential Lock Capture System

Oil Test Differential Lock Capture System

Test Differential Lock Sealing Rings with Air Boost System

Air Test Standard and Extreme Duty Axle Assembly

Air Test Axle Assembly—Super Wide Extreme Duty Axle

NoSPIN Differential—Installation Test

NoSPIN Differential—Operation Test

NoSPIN Differential Test

Differential Lock Function Test

-THEORY OF OPERATION

Axle Oscillation

Axle Disconnect Operation

Inboard Planetary Axle Operation

Differential Operation

Standard Differential Operation

Dif-Lok Differential Operation

NoSPIN Differential Operation

Capture System Operation

Air Boost System Operation

Pressurized Differential Case Operation

Standard and Extreme Duty Final Drive/Axle Operation (Oiled Outer Axle Bearing)

Standard and Extreme Duty Final Drive/Axle Operation (Greased Outer Axle Bearing)

Super Wide Extreme Duty Final Drive/Axle Operation

Service Brake Operation—Single Disk

Service Brake Operation—Multiple Disk

Park Brake Operation—Manual

Park Brake Operation—SAHR

Dry Drum Brake Operation

-DEALER FABRICATED TOOLS

Fabricated Tools

DF1055—Yoke Holding Tool

DF1057—Axle Adjusting Tool

DFRW7A—Differential Lifting Tool For 1400 Series

DFRW30—Axle Jacking Tool

DFRW102—Pinion Shaft Tool

DFRW143—Axle Housing and Inner Bearing Removal Tool

Speedi Sleeve Installation Tool

Quill Alignment Tool

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.