Factory Technical Manual For John Deere Cotton Picker. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1492

Number: TM1613 (september 2001)

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

John Deere Cotton Picker

9935

Contents

-GENERAL

Safety

General Specifications

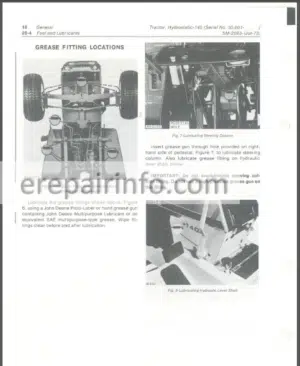

Fuels and Lubricants

Welding Repair

-ENGINE REPAIR

Remove and Install Engine

Cooling System Repair

-FUEL AND AIR REPAIR

Diesel Fuel System

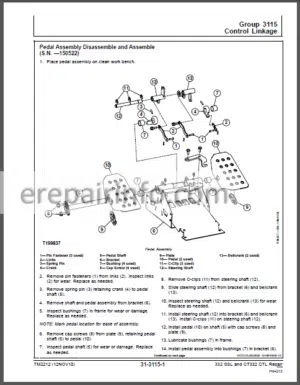

Control Linkage

-ELECTRICAL REPAIR

Charging Circuit

Starting Circuit

Monitor and Gauges

Accessory Circuit

Connector Repair

-POWER TRAIN REPAIR

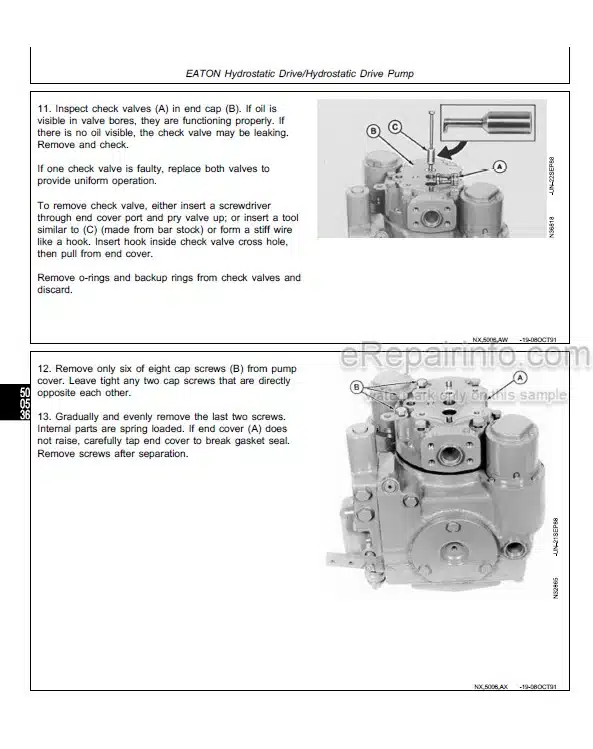

Hydrostatic Drive Components—Remove and Install

Hydrostatic Drive

Components—Repair

Transmission

Final Drive

Control Linkage

-STEERING AND BRAKES REPAIR

Remove and Install Steering

Components

Steering Column Repair

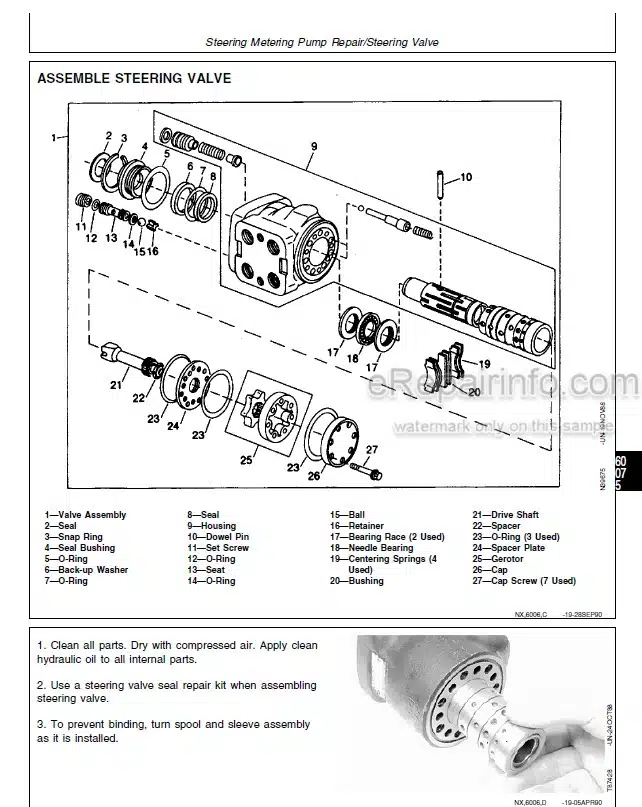

Steering Metering Pump Repair

Steering Cylinder Repair

Drake Repair

-HYDRAULIC SYSTEM REPAIR

Hydraulic Pump

Solenoid Control Valve Repair

Basket Lift Cylinder Repair

Picking Unit Lift Cylinder Repair

Vane Dump Control Cylinder Repair

Steering Cylinder

Compactor Hydraulic Motor Repair

Height Control Valve Repair

-GUIDE AXLE AND WHEEL HUB REPAIR

Axle and Wheel Hub Repair

-OPERATOR S STATION REPAIR

Air Conditioning System Repair

Heating System

Seat Repair

Cab Repair

-PICKING UNIT REPAIR—IN-LINE UNITS

Remove and Install

Grid Bar and Pressure Plate

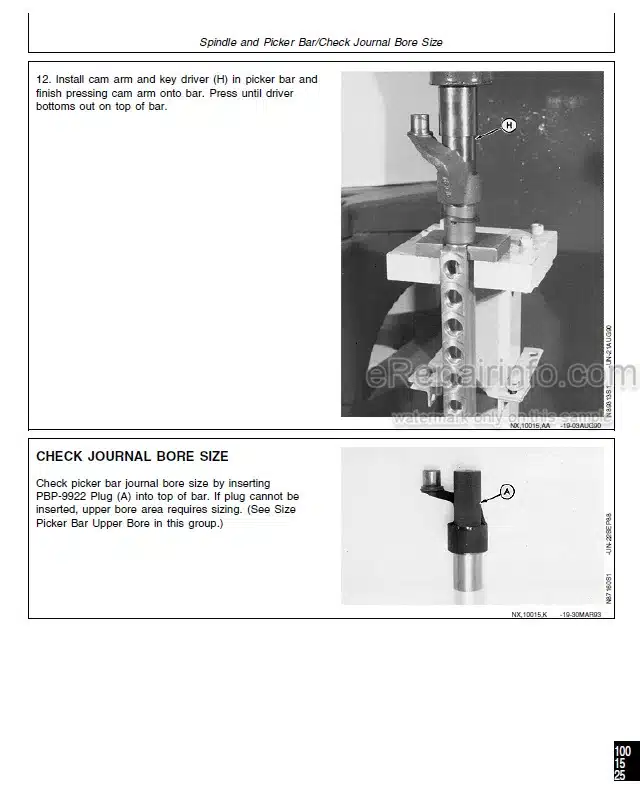

Spindle and Picker Bar

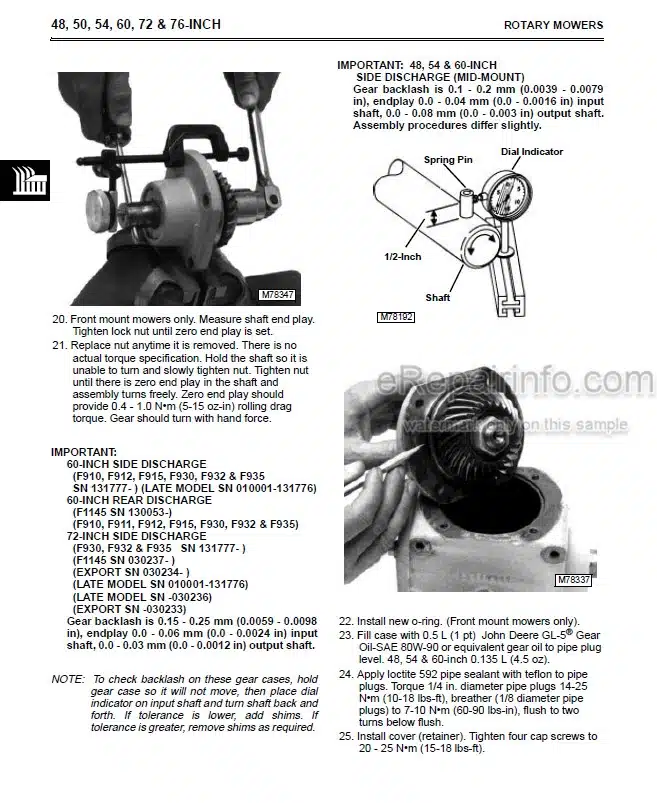

Drums, Drive Shafts, and Gear

Idler Gear

Doffer Columns

Moistener Column

Gear Cases and Countershafts

Cabinet and Cam Track Alignment

-PICKING UNIT REPAIR—PRO 12 UNITS

Picking Unit—Remove and Install

Grid Bar and Pressure Plate

Spindle and Picker Bar

Drums, Drive Shafts, and Gear

Idler Gear

Doffer Columns

Moistener Column

Gear Cases and Countershaft

Cabinet and Cam Track Alignment

-LUBRICATION SYSTEM REPAIR

Lubrication System Pump Repair

Solenoid Control Valve Repair

Transfer Pump Repair

-SOLUTION SYSTEM REPAIR

Water System Components

-AIR SYSTEM REPAIR

Cotton Fan Repair

-OPERATIONAL CHECKOUT PROCEDURE

Machine Operational Checkout

Diagnostic/Testing Procedures

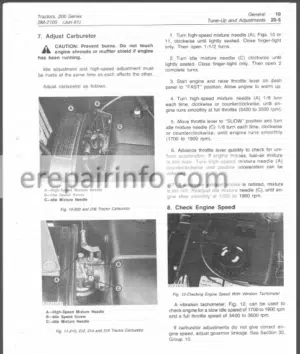

Tune-Up and Adjustments

-ENGINE OPERATION AND TESTS

System Operational Checks

Diagnostic Information

Engine System Operation and Tests

Theory of Operation

-FUEL/AIR OPERATION AND TESTS

System Operational Checks

Diagnostic Information

System Tests

System Adjustments

Theory of Operation

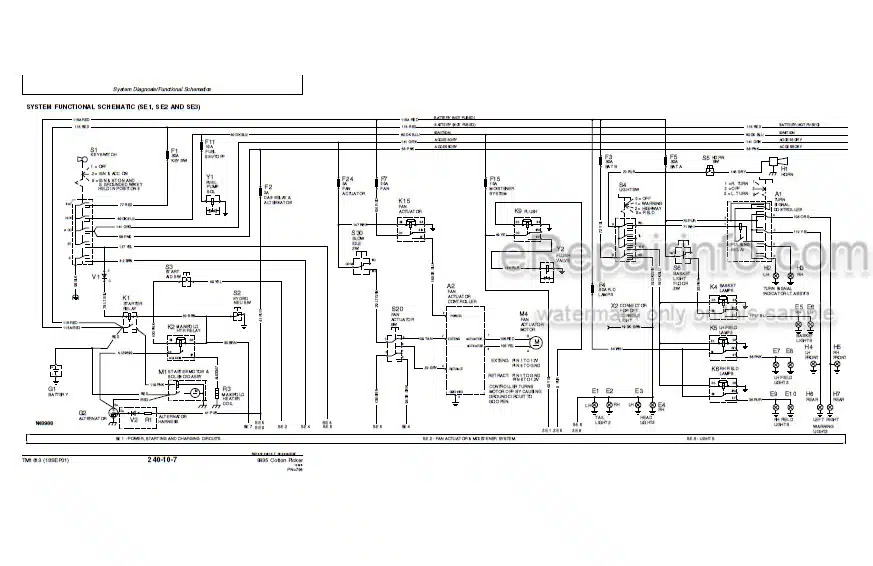

-ELECTRICAL OPERATION AND TESTS

System Information

System Diagnosis

Sub-System Diagnostics

Power Circuit

Start Circuit

Charging Circuit

Lighting System Circuit

Horn Circuit

Monitor System Circuit

Gauges Circuit

Tachometer Circuit (P.I.N. —2000)

Tachometer Circuit (P.I.N. 2001— )

Windshield Wiper Circuit

Dome and Console Light Circuit

Lighter Circuit

Radio Circuit (P.I.N. 2001— )

Cab Blower and Air Conditioning Circuit

Auxiliary Plug Circuit

Basket Electro-Hydraulic Controls Circuit

Units Electro-Hydraulic Controls Circuit

Fan Actuator Circuit

Destroke, Tether and Lube Circuit

-POWER TRAIN OPERATION AND TESTS

System Operational Checks

System Diagnostic Checks

System Tests

System Adjustments

Theory of Operation

-STEERING AND BRAKES OPERATIONS AND TESTS

System Operational Checks

System Diagnostics

System Tests

System Adjustments

Theory of Operation

-HYDRAULIC SYSTEM OPERATION AND TESTS

Operational Checks

Hydraulic System Diagnosis

Hydraulic Pump Diagnostics

Solenoid Control Valve Diagnostics

Hydraulic Cylinder Diagnostics

Height Sensing System Diagnostics

Hydraulic System Tests

Hydraulic System Adjustments

Theory of Operation

Hydraulic Pump Operation

Solenoid Control Valve Operation

Hydraulic Cylinder Operation

Hydraulic Motor Operation

Height Control Operation

-OPERATOR S STATION OPERATION AND TESTS

Operator’s Station Operational Checks

Operator’s Station Diagnostics

Air Conditioning System Tests

Operator’s Station Tests

Operator’s Station Theory of Operation

-IN-LINE PICKING UNIT OPERATION AND TESTS

Picking Unit Diagnostics

Picking Unit Adjustments

Picking Unit Theory of Operation

-PRO-12 PICKING UNITS OPERATION AND TESTS

Diagnostics

PRO-12 Picking Units Adjustments

Picking Unit Theory of Operation

-PICKING UNIT LUBRICATION SYSTEM OPERATION AND TESTS

Lubrication System Operational Checks

Lubrication System Diagnostics

Lubrication System Tests

Lubrication System Theory of Operation

-SOLUTION SYSTEM OPERATION AND TEST

Solution System Operational Checks

Solution System Diagnostics

Solution System Adjustments

Solution System Theory of Operation

-AIR SYSTEM OPERATION AND TEST

Air System Operational Checks

Air System Diagnostics

Air System Adjustments

Air System Theory of Operation

-DEALER FABRICATED SPECIAL TOOLS

Fabricated Tools

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.