Factory Technical Manual For John Deere Harvester. Manual Contains Illustrations, Instructions, Diagrams For Systems Diagnosis, Theory Of Operation, Performance Testing, Tests And Adjustments, Operational Check, Unit Locations, Diagnostic Codes, Schematics And A Lot Of Other Useful Information For Service And Repair.

Format: PDF

Language: English

Pages: 229

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

John Deere Cameco Harvester

CH3500

Contents

-SAFETY RECOMMENDATIONS

Safety and You

Operation Safety

Service Safety

Safety in Your Service Area

Safety when Cleaning or Storing

Safety Nevers

Seat Safety Shut-off

Tilting the Cab

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Protect Bystanders

Use Handles and Steps

Prevent Machine Runaway

Avoid Exhaust Fumes

Keep Riders Off Machine

Use Seat Belts

Handle Fuel Safely—Avoid Fires

Safely Service Accumulator

Safely Service Cooling System

Prepare For Emergencies

Wear Protective Clothing

Protect Against Noise

Use Safety Lights and Devices

Use Cylinder Safety Stops

Practice Safe Maintenance

Avoid High Pressure Fluids

Use Caution on Hillsides

Stopping and Parking

Service Tires Safely

Transport Harvester Safely

Avoid Electrical Power Lines

Keep Hands Away From Knives,

Avoid Contact with Moving Parts

Dispose of Waste Properly

Fire Prevention

Safety Recommendations

Harvester Safety

-GENERAL INFORMATION

Introduction

Diagnostic Sections

Troubleshooting Tools

Troubleshooting

Visually Inspect Hydraulic System

Hydraulic System Testing Precautions

Visually Inspect Electrical System

Electrical System Safety Precautions

Battery Specifications

Oil Storage and Filling

Oil Filtration

Hydraulic Components

Aeration and Cavitation

Troubleshooting Tips

Lines

Fluid Storage

Pumps

Motors

Cylinders

Valves

Miscellaneous Symbols

Methods of Operation

Electric Circuit Symbols

Quick Field Test

Hydrostatic Pump Charge Pressure Check

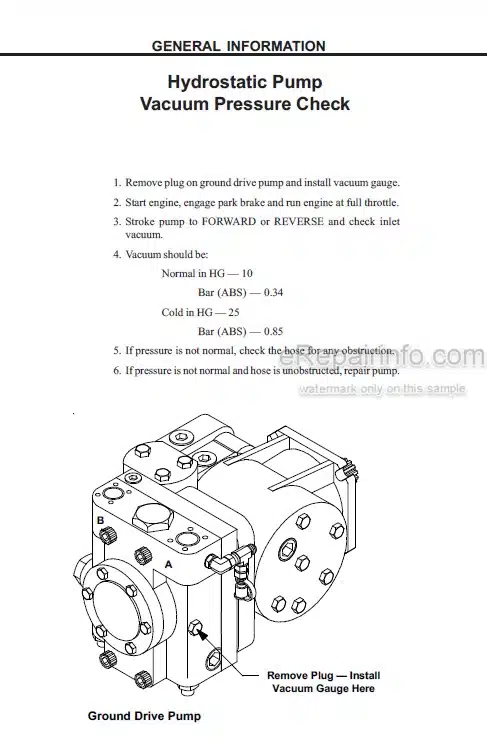

Hydrostatic Pump Vacuum Pressure Check

-ENGINE

Cooling System — Theory of Operation

Test Cooling System

Check Radiator Cap

Check Coolant Level and Condition

Check Radiator Outside Air Flow

Check Radiator Internal Core

Check Radiator For Bubbles

Engine Will Not Crank

Engine Hard to Start or Will Not Start

Engine Misfiring or Runs Irregularly

Lack of Engine Power

Engine Overheats

Cooling Fan

-OPERATOR’S STATION

Operator’s Station Theory of Operation

Air Pressurizing Circuit Theory of Operation

Air Conditioning Circuit Theory of Operation

A/C and Heater Air Flow Operation

Refrigerant Cautions

R134A Component Oil Charge

R134A Refrigerant Recover, Recycling and Charging System Installation Procedure

Recover R134A System

Evacuate R134A System

Air Conditioning System Test

Charge R134A System

Air Conditioning and Heating

Theory of Operation

Safety Precautions

Specifications

Air Pressurizer Blower Does Not Operate

Recirculate Blower Motor Does Not Operate

The Air Condition Does Not Operate

The Temperature Selector Does Not Operate Correctly

-ELECTRICAL SYSTEM

Visually Inspect Electrical System

Safety Precautions

ALTERNATOR AND BATTERY

Theory of Operation

Cleaning Battery Posts

Jumping the Battery

Charging The Batteries

Precautions For Alternators

Hydraulic Oil Temperature Sender

Fuel Sending Unit

Hydraulic Filter Pressure Switch

Air Filter Restriction Switch

Battery Visual Inspection

Battery Hydrometer Test

Battery Load Test

Ignition Switch Check

Diode Check

Switch Check

Multifunction Handle Check

Right Crop Divider Switch Check

Check Relay

Relay Check

Starter Solenoid Check

Fuse Check

Head Lights, Warning, Field and Work Light Switches Check

Turn Signal Switch Check

Elevator On/Off Switch

Elevator On/Off Switch

Left Engine Compartment Door Switch Check

Air Cleaner Restriction Indicator

Hydraulic Filter Restriction Indicator

Hydraulic Float Level Check

Lighting System – Road Lights Theory of Operation

Lighting System – Hazard and Turn Signal Lights Theory of Operation

Lighting System – Field Lights Theory of Operation

Lighting System – Work Lights Theory of Operation

Power Starting & Charging Circuits Electrical Schematic

Basecutter Electrical Schematic

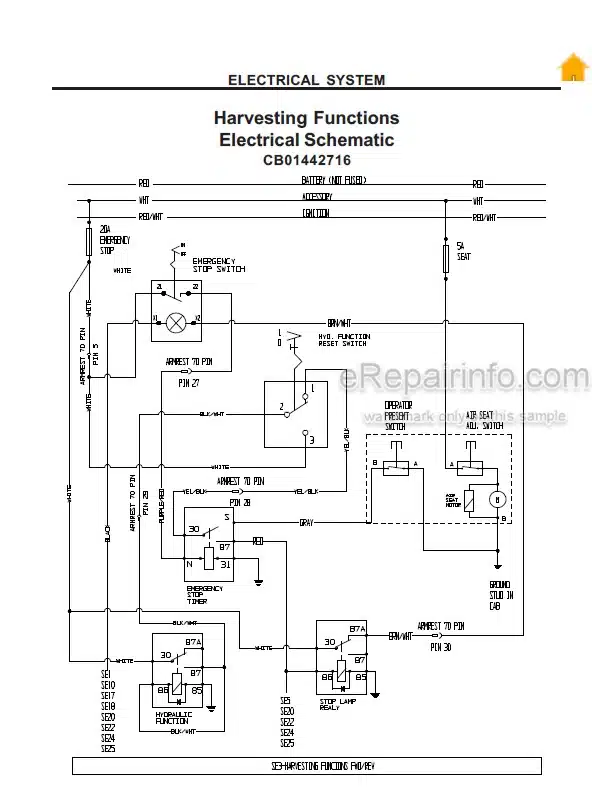

Harvesting Functions Electrical Schematic

Right Crop Divider Electrical Schematic

Elevator Forward/Reverse Electrical Schematic

Elevator Up/Down Electrical Schematic

Tachometer & Gauges Electrical Schematic Positrac (Wheel) Electrical Schematic

Speedometer Electrical Schematic

Radio, Dome & ACC Electrical Schematic

Heating & A/C Electrical Schematic

Park Brake Electrical Schematic

Road Lights Electrical Schematic

Work Lights Electrical Schematic

Turn Signal, Warning & Hazard Lights Electrical Schematic

Wipers & Washers Electrical Schematic

Transmission (Wheel) Electrical Schematic

Transmission (Track) Electrical Schematic

Topper Electrical Schematic

Sideknife Electrical Schematic

Throttle Electrical Schematic

Primary Extractor Electrical Schematic

Elevator Swing Electrical Schematic

Topper Left/Right Electrical Schematic

Basecutter Electrical Schematic

Horn Electrical Schematic

Hydraulic Oil Temperature Gauge Electrical Schematic

Engine Control Electrical Schematic

Left Crop Divider Up/Down Electrical Schematic

Secondary Hood Electrical Schematic

Camera Electrical Schematic

Crop Divider Tilt Electrical Schematic

Basecutter Tilt Electrical Schematic

Knockdown Electrical Schematic

-HYDROSTATIC SYSTEM

Transmission Theory of Operation

Hydrostatic Transmission Pump Theory of Operation

High Pressure Relief Valve

Charge Relief Valve

Pump Control Operation—Neutral

Pump Control Operation—Initial Movement

Flow / Pressure Specifications

Hydrostatic Transmission Control Operation

Track

Wheel

-HYDRAULIC SYSTEM

Hydraulic System Theory of Operation

Right Side Triple Pump

Left Side Triple Pump

Main Relief Test Procedure

Electrical Control over Hydraulic Pilot Operation Lines

Main Relief

Crossover Relief Settings

6 Bank Direction Control Valve

Primary Hood Motor Specification:

Main Relief

Load Check

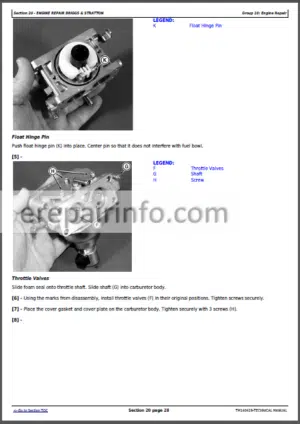

Throttling Valves

Check Valves

Cab Tilt Circuit

Topper Collector & Side Knives Hydraulic Schematic

Chopper & Basecutter Hydraulic Schematic

Front Feed Rollers Hydraulic Schematic

Ground Drive (Track) Hydraulic Schematic

Ground Drive (Wheel) Hydraulic Schematic

Rear Feed Roller Hydraulic Schematic

Crop Divider & Knockdown Roller Hydraulic Schematic

Cylinder Hydraulic Schematic

Rotary Screen & Elevator Hydraulic Schematic

Cooling System Hydraulic Schematic

-STEERING SYSTEM

Front Suspension And Steering

Steering Pivot Assembly

Steering Circuit Specifications

Steering Test Procedure

Troubleshooting

Slow Steering, Hard Steering, Or Loss Of Power Assist

Wander—The Tendency To Deviate From Operator Directed Course

Drift—The Tendency To Deviate From Non-Operator Directed Course

Slip—When A Slow Movement Of Steering Wheel Fails To Cause Any Movement Of Steered Wheels

Temporary Hard Steering Or Hang-Up (A Momentary Increase In Steering Wheel Torque During Steering Reversal Or Initial Input)

Erratic Steering

Spongy Or Soft Steering

Freewheeling—Steering Wheel Turns Freely With No Feeling Of Pressure And No Action On Steered Wheels

-BRAKE SYSTEM

Park Brake Electrical Theory Of Operation

Park Brake Cannot Be Cancelled

Park Brake Does Not Engage

Topper System

Topper Theory of Operation

Topper Electrical Theory of Operation

Topper/ Collectors/Side Knife Hydraulic

Theory of Operation

Topper Specifications:

Topper Lift Electrical Theory of Operation

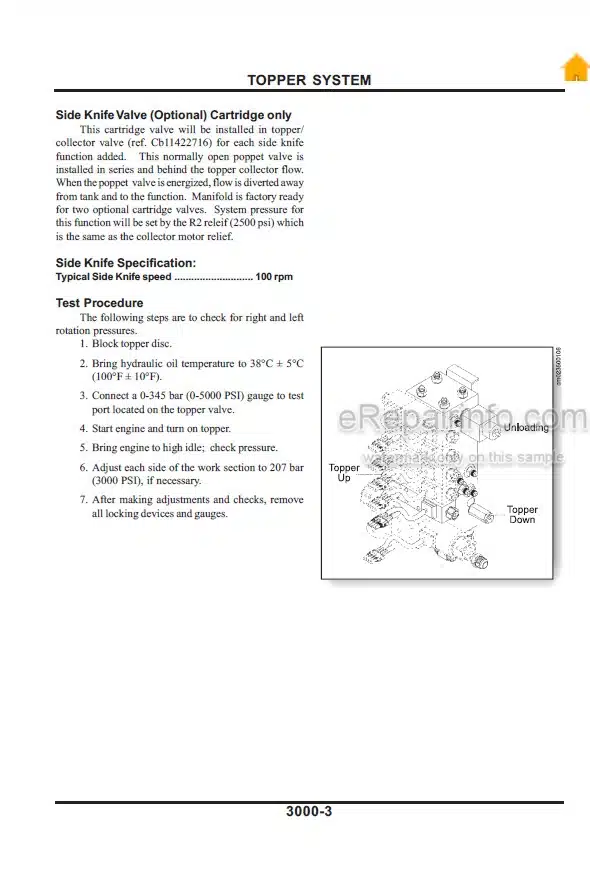

Side Knife Valve (Optional) Cartridge only

Side Knife Specification:

Test Procedure

All Topper Functions Do Not Operate — Whole Shredder

All Topper Functions Do Not Operate

Topper Collectors Do Not Operate, But Serving Disk Does

Topper Lift Does Not Operate

Crop Divider System

Crop Divider Theory of Operation

Crop Divider Electrical Theory of Operation

Crop Divider Hydraulic Theory of Operation

Crop Divider Specifications

Crop Divider Control Operation

Test Procedure

Twin Crop Dividers Showing Slow or No Operation

Crop Divider Lift Does Not Operate Properly

Right Crop Divider Does Not Lift Properly

Left Crop Divider Does Not Lift Properly

Crop Divider Tilt Does Not Work

Crop Divider & Knockdown & Fin Roller Show Slow or No Operation

-SIDE KNIVES

Side Knife Theory of Operation

Side Knife Electrical Theory of Operation

Side Knife Hydraulic Theory of Operation

Side Knife Specifications

Side Knife Control Operation

Test Procedure

Side Knives Do Not Operate

-FEED ROLLER SYSTEM

Feed Roller System-Theory Of Operation

-BASECUTTER SYSTEM

Basecutter System Theory Of Operation

-CHOPPER SYSTEM

Chopper Hydraulic System Operation

Chopper Electrical Theory of Operation

Chopper/Basecutter Specifications

Chopper Specifications

Set Chopper Shaft Timing (Pinch)

Chopper Forward/Reverse Does Not Operate

Chopper and Basecutter Do Not Operate

-VARIABLE PRIMARY EXTRACTOR

Primary Extractor Theory of Operation

Primary Extractor Theory of Operation

Hydraulic System Operation

Primary Extractor Hood Rotation Theory of Operation

Specifications

Control Operation

Primary Extractor Showing Slow or No Operation

Primary Extractor Showing Slow or No Operation

Primary Extractor Hood Does Not Rotate

Primary Extractor Hood Does Not Rotate

When Elevator Swing Pedal is Pressed

Primary Extractor Hood Does Not Rotate Correctly

-ELEVATOR SYSTEM

Elevator Swing

Electrical Theory of Operation

Elevator System Up/Down Electrical Theory of Operation

Elevator Forward/Reverse Electrical Theory of Operation

Secondary Extractor Electrical Theory of Operation

Secondary Extractor Hood Rotation Electrical Theory Of Operation

Bin Flap Electrical Theory of Operation

Elevator Circuit Hydraulic Theory of Operation

Rotary Screen and Elevator Auxiliary Function System

Elevator Does Not Raise

Elevator Does Not Lower

Secondary Hood Does Not Rotate

Secondary Extractor Fan Does Not Operate

Secondary Extractor Shows Slow or No Operation

Bin Flap Does Not Operate

Elevator Swing Does Not Operate

Elevator Drive Shows Slow or No Operation

Elevator Lowers But Does Not Raise

Elevator Raises But Does Not Lower

Secondary Hood Rotation Does Not Operate Bin Flap Does Not Operate

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.