Factory Technical Manual For John Deere Garden Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 366

Number: TM1974 (march 2003)

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

John Deere Garden Tractor

GX355

Contents

-SAFETY

Recognize Safety Information

Understand Signal Words

Replace Safety Signs

Be Prepared for Emergencies

Use Care in Handling and Servicing Batteries

Use Care Around High-Pressure Fluid Lines

Use Safe Service Procedures

Service Tires Safely

Service Cooling System Safely

Handle Chemical Products Safely

Dispose of Waste Properly

Live with Safety

-SPECIFICATIONS AND INFORMATION

Metric Fastener Torque Values

Metric Fastener Torque Values -Grade

Inch Fastener Torque Values

Face Seal Fittings with Inch Stud Ends Torque

Face Seal Fittings with Metric Stud Ends

Torque

O-Ring Face Seal Fittings

O-Ring Boss Fittings

Diesel Fuel

Diesel Fuel Lubricity

Diesel Fuel Storage

Engine Oil

Engine Break-in Oil

Alternative Lubricants

Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Chassis Grease

Transaxle Oil

Engine Coolant

Operating in Warm Temperature Climates

Flush and Service Cooling System

Disposing of Coolant

Engine Coolant Drain Interval

Machine Product Identification Number

Engine Serial Number Location

Transmission Serial Number Location

-ENGINE

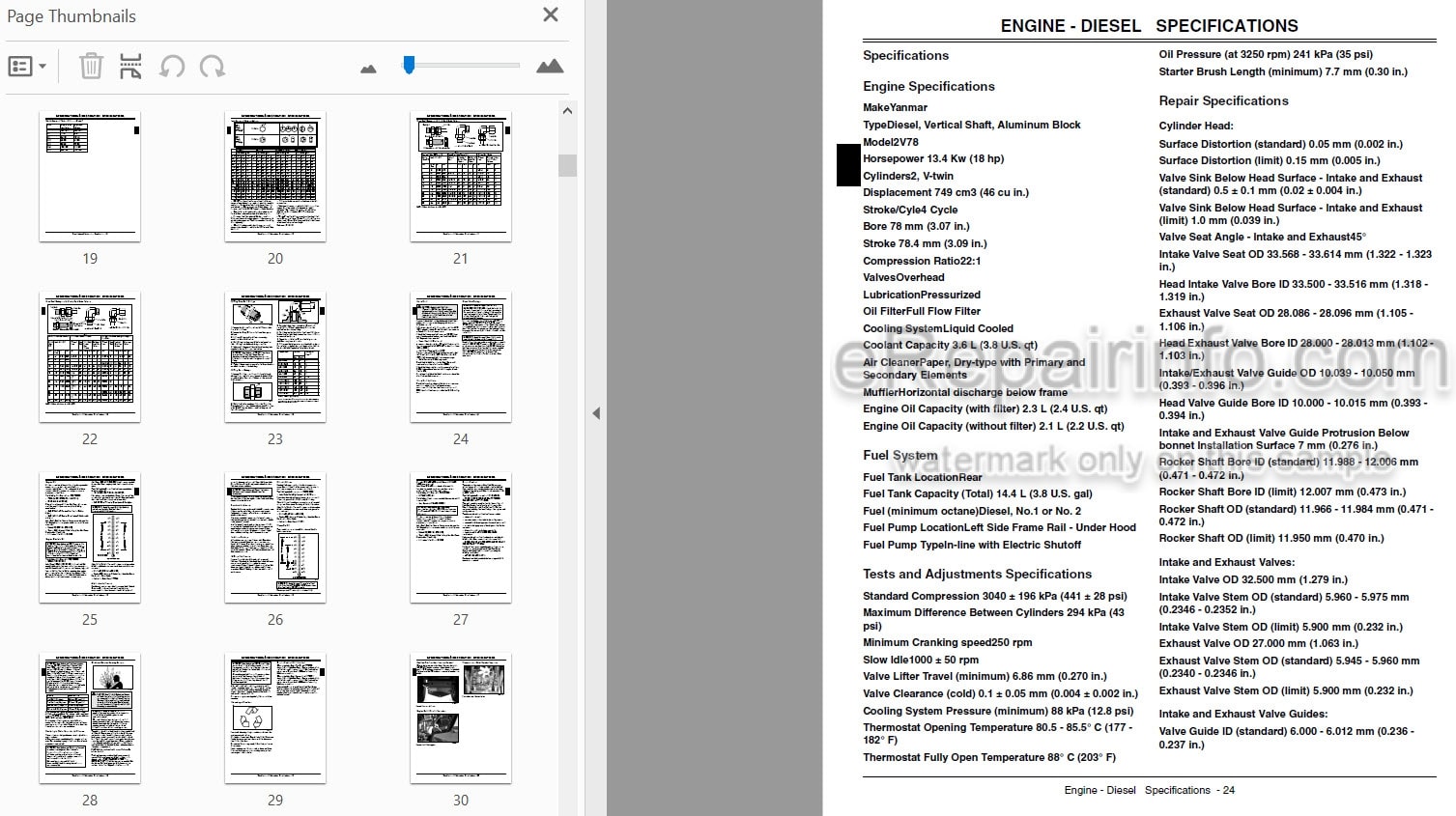

Engine Specifications

Fuel System

Tests and Adjustments Specifications

Repair Specifications

Torque Specifications (Aluminum Block)

Special Tools

Other Materials

Engine Components

Hood Switch

Lubrication System Operation

Cooling System Operation

Fuel / Air System Operation

Engine System

Oil Pressure Test

Cylinder Compression Test

Throttle Cable Adjustment

Slow Idle Speed Adjustment

Fast Idle Speed Adjustment

Torque Capsule Adjustment

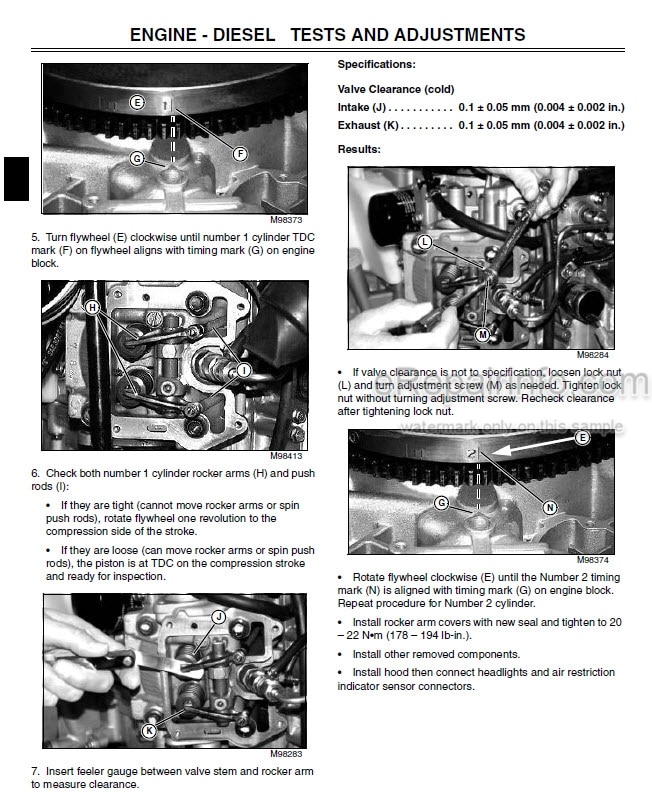

Valve Clearance Inspection and Adjustment

Fuel Injection Pump Timing Adjustment

Radiator Cap Pressure Test

Radiator Bubble Test

Cooling System Pressure Test

Thermostat Opening Test

Engine Removal and Installation

Engine Mounts and Isolators: Position and

Torques

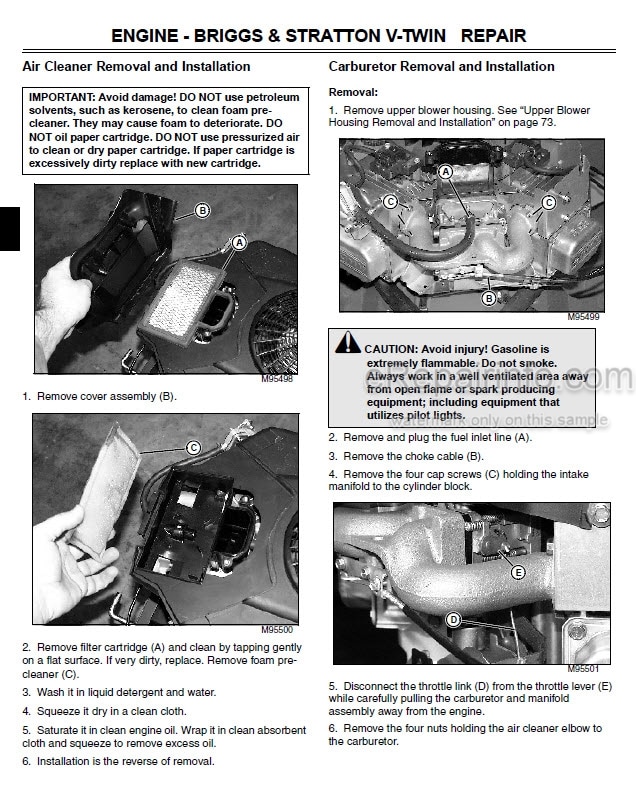

Air Filter Removal and Installation

Muffler Removal and Installation

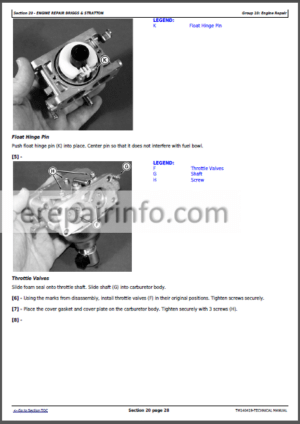

Intake Manifold Removal and Installation

Oil Pressure Sensor Removal and Installation

Thermostat Removal And Installation 45

Coolant Temperature Sensor Removal and Installation

Radiator Removal And Installation

Fuel Shut-Off Solenoid Removal and Installation

Fuel Hoses Removal And Installation

Fuel Pump Removal And Installation

Fuel Filter Removal And Installation

Fuel Injectors Removal and Installation

Fuel Injectors Tests

Injection Pump Assembly Removal and Installation

Governor Assembly Removal and Installation

Fan/Flywheel Removal And Installation

Rocker Arm Covers Removal and Installation

Rocker Arms Removal And Installation

Number 1 Cylinder Head Removal and Installation

Number 2 Cylinder Head Removal and Installation

Glow Plugs Removal and Installation

Cylinder Head and Valves Disassembly and Inspection

Cylinder Head and Valves Assembly

Crankcase Breather Removal And Installation

Crankcase Cover Removal and Installation

Water Pump Removal and Installation

Oil Pump Removal and Installation

Camshaft, Valve Lifters, and Injection Pump

Lifters Removal and Installation

Camshaft, Valve Lifters, and Injection Pump

Lifters Inspection

Piston and Connecting Rod Removal and Installation

Crankshaft Removal and Installation

Stator Removal And Installation

Starter Solenoid Removal and Installation

Starter Motor Removal and Installation

Starter Motor Disassembly and Assembly

-ELECTRICAL

Reading Electrical Schematics

Theory of Operation Information

Diagnostic Information

Wire Color Abbreviation Chart

Common Circuit Tests

Conductors for 12 Volt Circuits

General Specifications

Special or Required Tools

Schematic and Wiring Harness Legend

Component Location

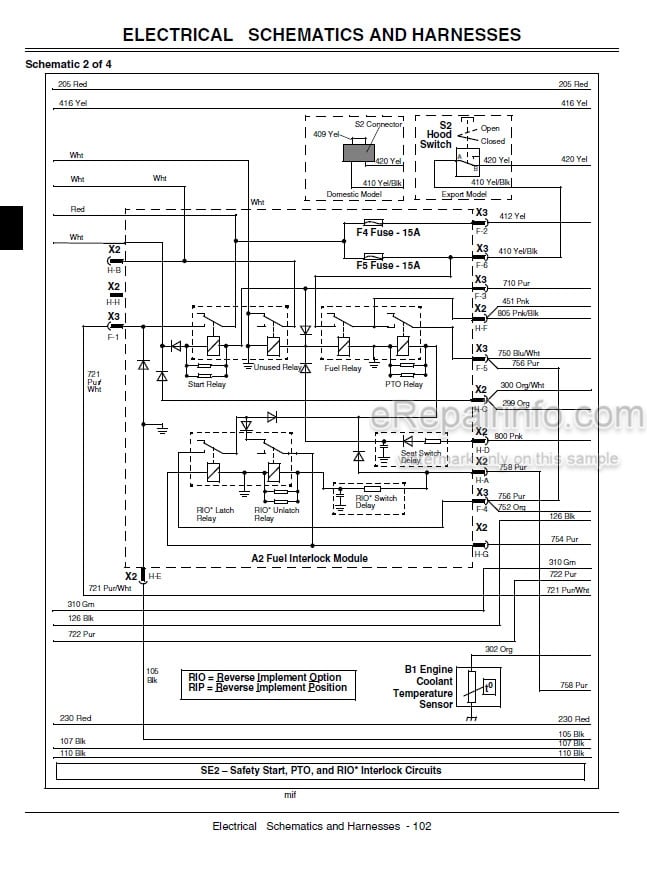

Main Electrical Schematic

Main Wiring Harness

Main Wiring Harness Color Codes

Additional Wiring Harnesses

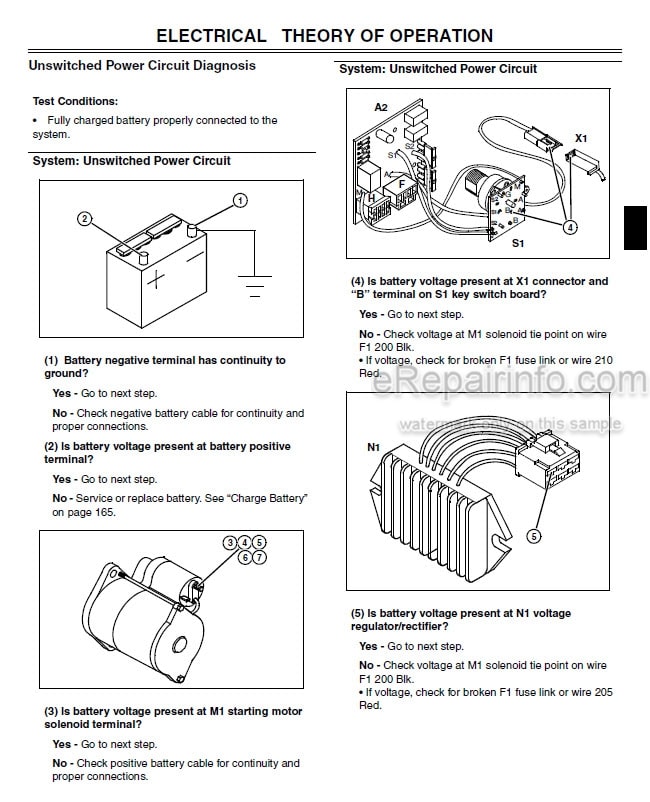

Unswitched Power Circuit Operation

Unswitched Power Circuit Schematic

Unswitched Power Circuit Diagnosis

Switched Power Circuit #1 Operation

Switched Power Circuit #1 Schematic

Switched Power Circuit #1 Diagnosis

Switched Power Circuit #2 Operation

Switched Power Circuit #2 Schematic

Switched Power Circuit #2 Diagnosis

Starting Circuit Operation

Starting Circuit Schematic

Starting Circuit Diagnosis1

Fuel Shut-Off & Fuel Pump Circuit Operation

Fuel Shut-Off & Fuel Pump Circuit Schematic

Fuel Shut-Off & Fuel Pump Circuit Diagnosis

Charging Circuit Operation

Charging Circuit Schematic

Charging Circuit Diagnosis

PTO Circuit Operation

PTO Circuit Schematic

PTO Circuit Diagnosis

RIO Circuit Operation

RIO Circuit Schematic

RIO Circuit Diagnosis

Coolant Temperature Sensor Circuit Operation

Coolant Temperature Sensor Circuit Schematic

Coolant Temperature Sensor Circuit Diagnosis

Air Restriction Indicator Circuit Operation

Air Restriction Indicator Circuit Schematic

Air Restriction Indicator Diagnosis

Oil Pressure & Low Fuel Sensor Circuit Operation

Oil Pressure & Low Fuel Sensor Circuit Schematic

Oil Pressure & Low Fuel Sensor Diagnosis

Headlight & Hour Meter Circuit Operation

Headlight & Hour Meter Circuit Schematic

Headlight & Hour Meter Circuit Diagnosis

Common Circuit Tests

Ground Circuit Test

Battery Test

Charge Battery

Battery Load Test

Regulated Voltage Test

Unregulated Voltage Test

Regulated Amperage Test

Starting Motor Solenoid Test

Starting Motor No-Load Amperage Draw and RPM Test

Starting Motor Loaded Amperage Draw Test

Hood Switch Connector Jumper Wire Test

Fuel Shut-Off Solenoid Test

Seat Switch Test

Brake Switch Test

PTO/RIO Switch Test

RIO Switch Test

PTO Clutch Test

PTO Clutch Adjustment

Headlight Switch Test

Engine Oil Pressure Sensor Test

Glow Plug Test

Low Fuel Level Sensor Test

Air Restriction Indicator Sensor Test

V1 and V2 Diodes Test

Hour Meter Test

Fuel Pump Tests

Key Switch Test

Coolant Temperature Switch Test

Starting Motor and Starting Motor Solenoid

PTO Clutch

Connector Body – Blade Terminals

METRIPACK, Connectors

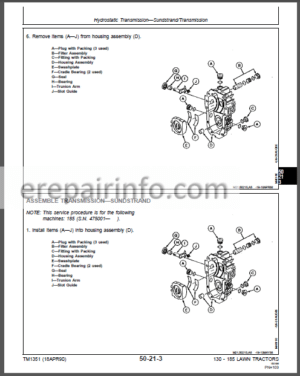

-POWER TRAIN

Hydrostatic Transaxle

Adjustment Specifications

Repair Specifications

Torque Specifications

Other Materials

Transaxle Case Halves

Charge Pump

Piston Pump

Motor

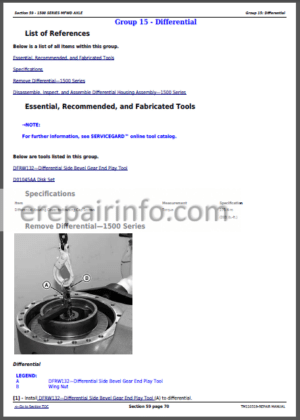

Reduction Gears, Differential, and Axles

Swash Plate and Neutral Centering Assembly

Transaxle Brake

Center Case Assembly

Belt Drive and Idlers

Brake Pedal and Linkage

Forward and Reverse Pedals and Linkage (Exploded View)

Controls and Linkage Operation

Foot Controls

Brake Linkage

Hydrostatic System Operation

Gear Power Flow

Machine Will Not Move Forward Or Reverse

Noisy Operation

Machine Creeps

Machine Moves In One Direction Only

Erratic Speed

Machine Does Not Achieve Full Ground Speed

Park Brake Does Not Hold Machine On Hill

Brake Switch Will Not Engage

Hydrostatic Transaxle Bleeding Procedure

Neutral Creep Adjustment

Forward and Reverse Pedal Height Adjustment

Brake Linkage Adjustment

Belt Tension Adjustment

Traction Drive Belt Removal and Installation

Traction Drive Belt Tensioner Assembly

Control Pedals and Linkage

Intermediate Shaft

Brake Pedal and Linkage

Brake Rod Removal and Installation

Transaxle Removal and Installation

Case Disassembly

Final Drive and Axle Removal

Brake Removal

Rotating Group Removal

Control Shaft Removal

Control Shaft Disassembly

Oil Filler Tube Removal

Shock Absorber Removal

Freewheeling Control Shaft Removal

Center Case Disassembly

Transaxle Assembly

Freewheeling Control Shaft Installation

Shock Absorber Installation

Oil Filler Tube Installation

Control Shaft Assembly

Control Shaft Installation

Rotating Group Assembly

Brake Installation

Charge Pump Installation

Final Drive and Axle Installation

Case Assembly

-HYDRAULICS

Tests and Adjustments Specifications

Repair Specifications

Special Tools

Special Materials

Hydraulic Lift System Components

Lift Lever and Linkage

Mower Deck Lift Linkage

Hydraulic Schematic

Hydraulic Lift System Operation

Noise From Transmission When Using Hydraulics

Excessive Attachment Drop With Control Valve

In Neutral

Hydraulic Lift Slow Or No Lift Capacity

Hydraulic Lift Will Not Work

Hydraulic Lift Oil Flow and Pressure Test

Hydraulic Lift Control Valve

Hydraulic Lift Cylinder Removal and Installation

Lift Lever Removal And Installation

Lift Linkage Inspection

Hydraulic In-Line Filter Removal and Installation

-STEERING

Tests and Adjustments Specifications

Torque Specifications

Special Tools

Other Materials

Steering System Components

Steering Valve and System Operation 280

Tilt Steering Operation

Hydraulic System Checks

Steers Hard or No Steering In Both Directions

Steers Hard or No Steering In One Direction

Steering Pulls In One Direction

Steering Wheel Tilt Assembly Will Not Move

Steering Wheel Creeps

Steering Shimmy Or Vibration

Noise During Turn

Slow Steering Responses

Steering System Oil Flow And Pressure Tests

Steering System Leakage Test

Steering Valve Leakage Test

Steering Cylinder Leakage Test

Toe-In Adjustment

Steering Tilt Assembly

Steering Valve and Column

Steering Cylinder

-BRAKES

Brake Pedal and Linkage

External Brake Linkage

Transaxle Brake Operation

Machine Will Not Move In Forward Or Reverse

Brakes Do Not Engage When Pedal Depressed

Parking Brake Does Not Hold Machine On Hill

Noisy Operation

Erratic Speed

Machine Does Not Achieve Full Ground Speed

Machine Will Not Move In Forward Direction Or Is Slow In Forward

Machine Is Slow In Reverse

Neutral Start Switch Does Not Engage When Pressing Brake Pedal

Engine Can Be Started Without Depressing Brake Pedal

Brake Linkage Test And Adjustment

Brake Assembly

-ATTACHMENTS

Mower Deck Adjustment Specifications

Mower Deck Repair Specifications

Special Tools

48 – Inch Convertible Mower Deck

54 – Inch Convertible Mower Deck

Mower Decks Troubleshooting Chart

Mower Drive Checks

PTO Clutch Diagnosis

Mower Level Side-to-Side

Mower Level Front-To-Rear

Electric PTO Clutch Adjustment

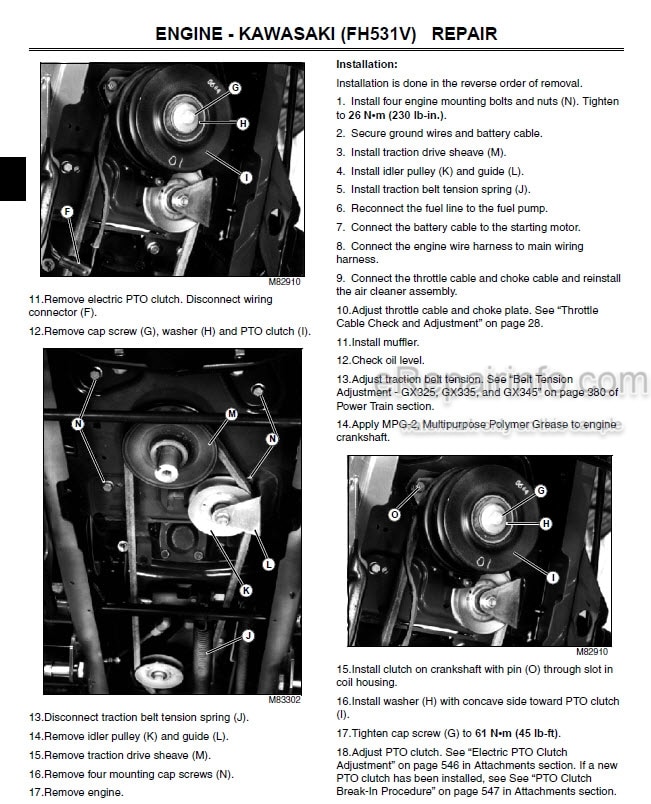

Electric PTO Clutch Removal and Installation

PTO Clutch Break-In Procedure

48-Inch Convertible Mower Deck Removal and Installation

48-Inch Mower Drive Belt

48-Inch Deck Mower Blades

48-Inch Deck Spindles

48-Inch Deck Jack Sheave

Idlers

54-Inch Mower Deck Removal and Installation

-MISCELLANEOUS

Torque Specifications

Front Axle

Steering Spindles

Front Wheels

Rear Wheels

Engine Hood

Control / Dash Panel

Fender Deck and Tunnel Cover

Fuel Tank

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.