Factory Operators Manual For Kobelco Hydraulic Excavator. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 243

Number: YM91Z00001D1-01NA (august 2001)

Bookmarks: Yes

Wiring Diagrams: Yes

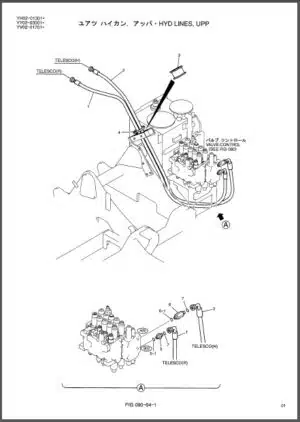

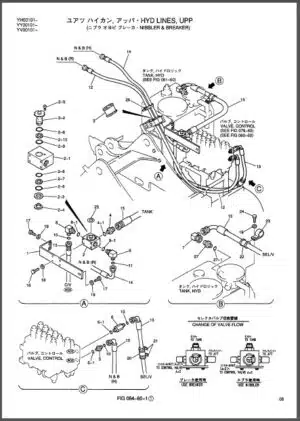

Hydraulic Diagrams: Yes

Model

Kobelco Hydraulic Excavator

SK160LC-VI

Applicable YM02U0101 –

ED190-VI

Applicable YL02U0101 –

Dynamic Acera

Contents

-SAFETY PRECAUTIONS

General Safety Information

Safety Precautions

Pre-Start Safety

Safety During Operation

Inspection & Maintenance Safety

Battery Safety

Warning Labels & Decals

Prohibited Machine Operation

End Of Work Shift Safety

Precautions For Transportation

Precautions For Towing The Machine

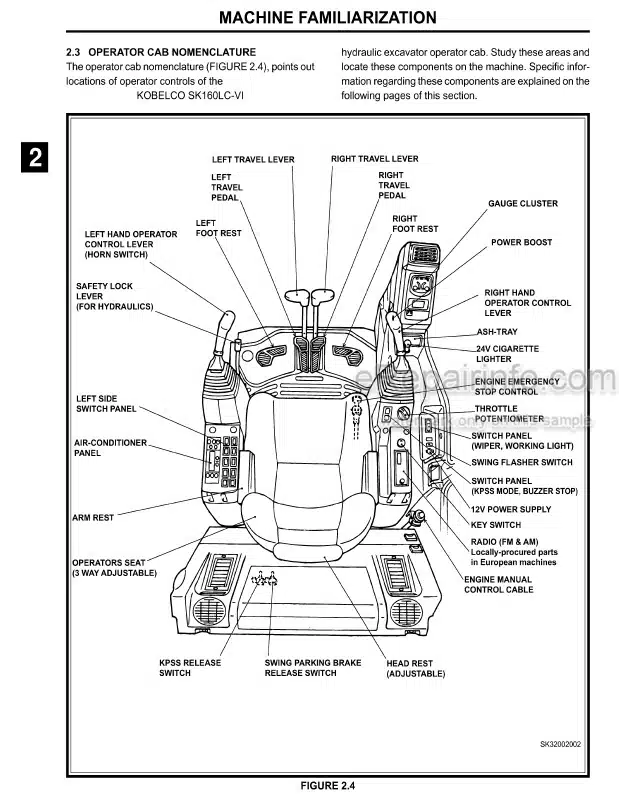

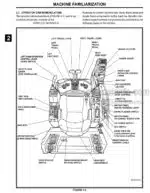

-MACHINE FAMILIARIZATION

Familiarization

General Machine Nomenclature

Operator Cab Nomenclature

Component & Controls Nomenclature

-BASIC MACHINE OPERATION

Pre-Start Check

Starting & Stopping Machine Engine With Temperature Above 0 C (32 F)

Starting & Stopping Machine Engine With Temperature Below 0 C (32 F)

Starting Machine Engine With Booster Cables

Machine Warm Up

Controls Decal

Basic Operation Of Hydraulic Controls

Practices To Improve Efficiency

Bucket Selection Guide

Use Of Optional Attachments

Recommendations For Longer Undercarriage Life

Flagman Hand Signals

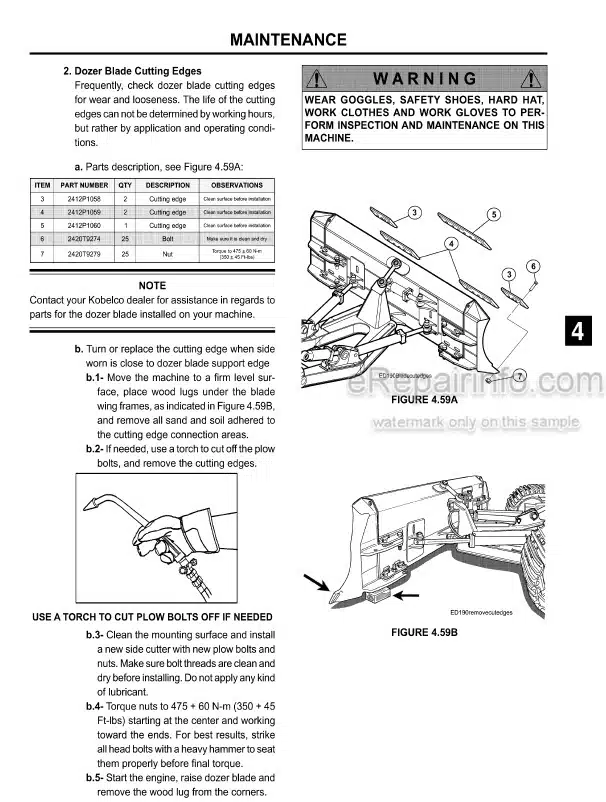

-MAINTENANCE

General Information

General Safety

Inspection & Maintenance Chart

Fluids & Filters

Pre-Start (Every 8 Hrs) Inspection & Maintenance

50 Hour (Weekly) & New Machine Break-In Inspection & Maintenance Procedures

120 Hour Inspection & Maintenance Procedures

250 Hour (3-Month) Inspection & Maintenance Procedures

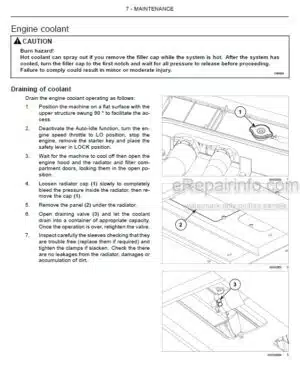

500 Hour (6-Month) Inspection & Maintenance Procedures

1000 Hour (12-Month) Inspection & Maintenance Procedures

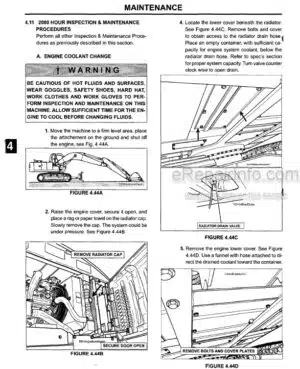

2000 Hour Inspection & Maintenance Procedures

Periodical Inspection Items

Dust Seals

Machine Storage

Prepare Machine

-TRANSPORTATION

Ground Transportation

Lifting Machine

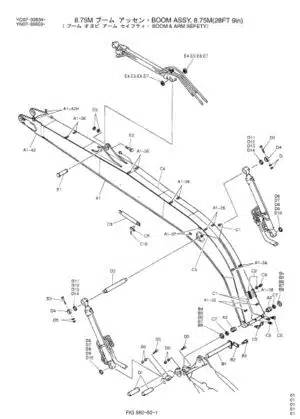

Attachment Shipping Dimensions

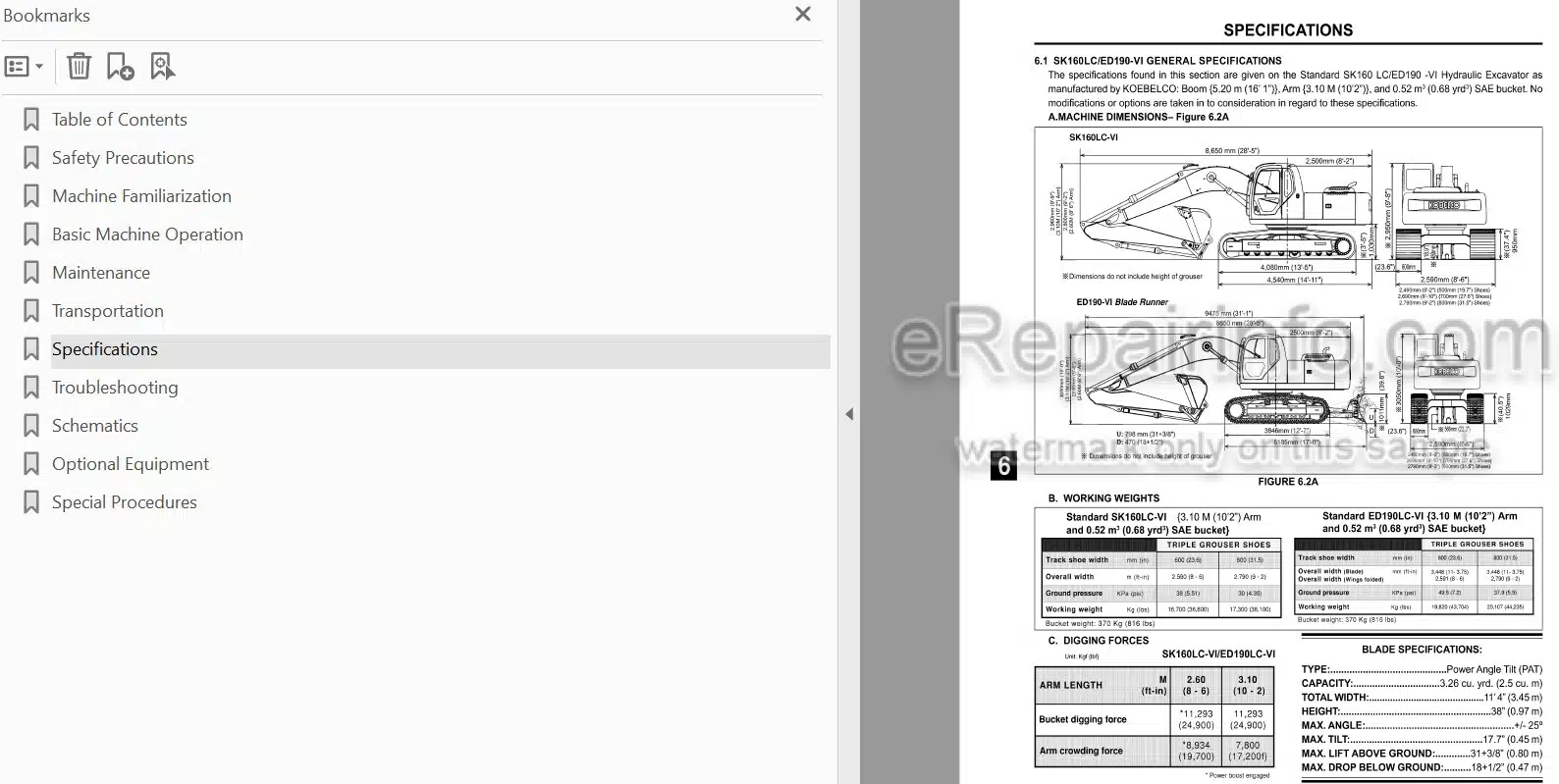

-SPECIFICATIONS

General Specifications

Lifting Capacities

Torque Specifications

Miscellaneous Information

-TROUBLESHOOTING

General Troubleshooting

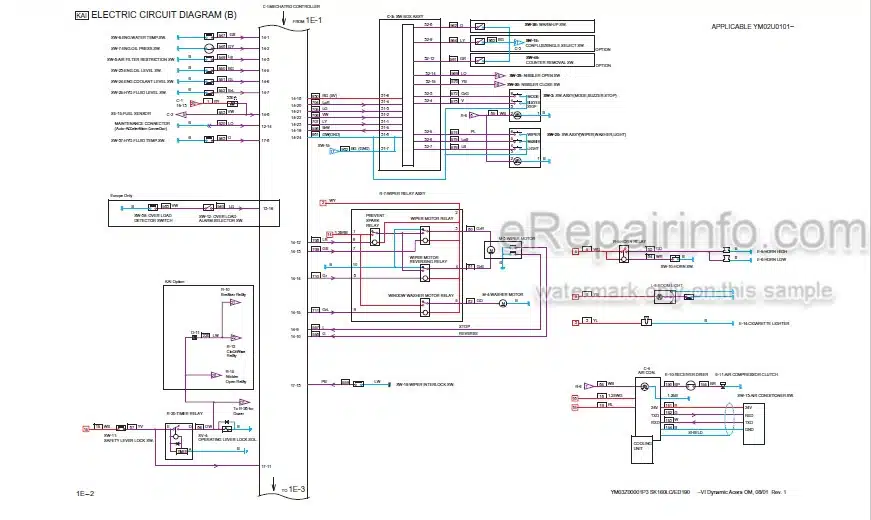

-SCHEMATICS

Electric Circuit Diagram

-OPTIONAL EQUIPMENT

Hydraulic Breaker

Nibbler/Breaker

Safety Precautions

Getting The Most Out Of Your Breaker

Maintenance For Nibbler/Breaker

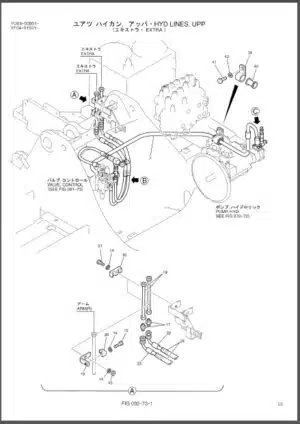

Extra (Grapple, Clamshell, Etc) And Extra & Breaker

Pattern Control Change

Installation Of Vandalism Guards

-SPECIAL PROCEDURES

General

Releasing Travel Motor Brakes

Lowering Attachment When Sudden Engine Failure Occurs

Releasing Swing Brake

Bleeding The Pilot System

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.