Factory Operators Manual For Kobelco Hydraulic Excavator. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 116

Number: S2YN1004E-01 (issued 2004)

Bookmarks: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Kobelco Hydraulic Excavator

SK200

Applicable YN06501~

SK200LC

Applicable YQ01101~

Contents

-SAFETY OPERATION

Directions for Safety

Safety Precautions

Safety Precautions for Preventive Maintenance

Outline of Safety Devices

-OPERATING EQUIPMENT

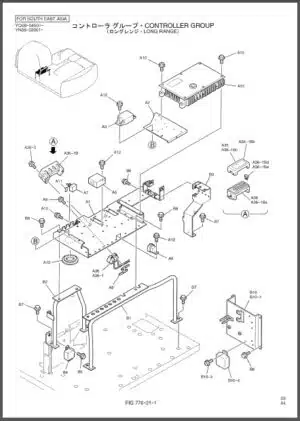

Designation of Components

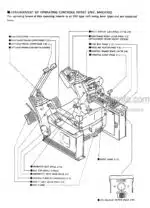

Arrangement of Operating Controls

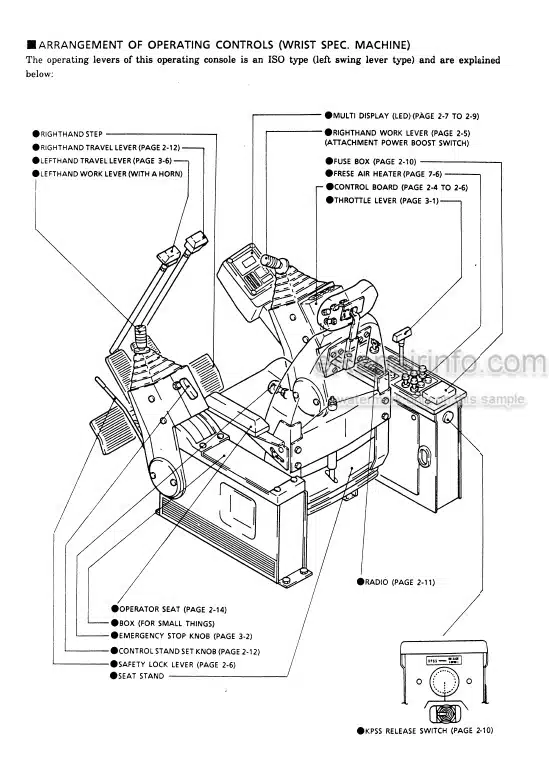

Arrangement of Operating Controls (Wrist Spec Machine)

Operating Controls for Operation

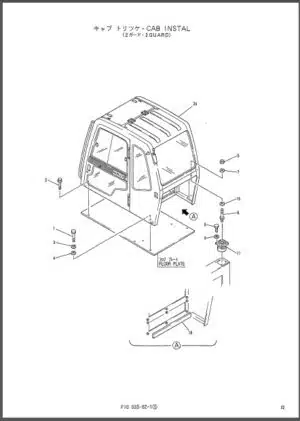

Cab

Outline of ITCS

-OPERATION

Inspection before Startup and Work

Starting and Stopping the Engine

Handling a New Vehicle

Operating Procedure

Standard of Selecting the Work Mode Select Switch (KPSS)

Manipulating the Auto Accel

Operating Methods for Improving Efficiency in Operation

Symptoms Peculiar to Hydraulic Excavators

Prohibition on Machine operation to Machine

-MAINTENANCE

Introduction

Regular Maintenance Items and Intervals

Replacement table of Oils, Greases and Filter Elements

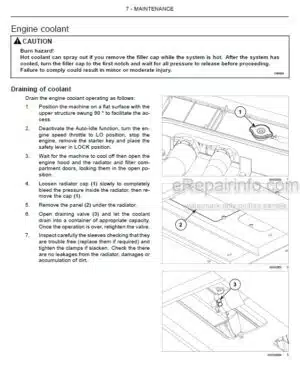

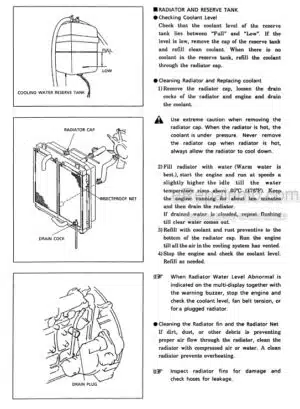

Procedure of Maintenance the Engine

Procedure for the Maintenance of Hydraulic Unit

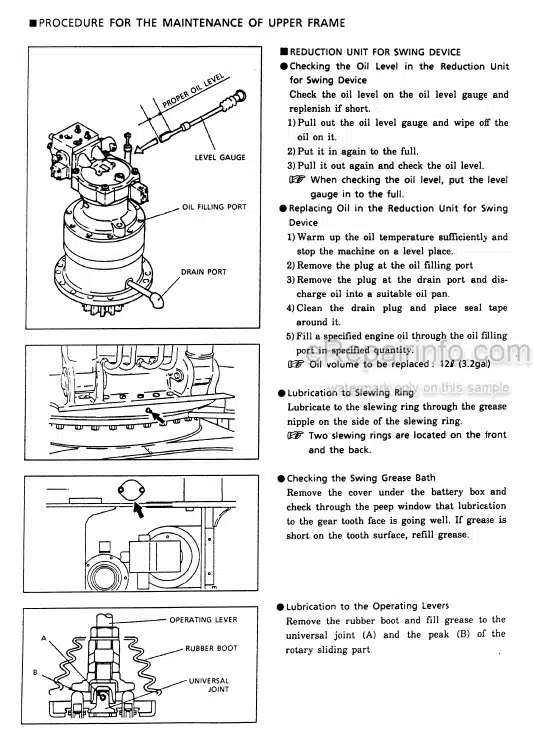

Procedure for the Maintenance of Upper Frame

Procedure for the Maintenance of Lower Frame

Procedure for the Maintenance of Attachments

Attaching, Detaching and Turning Over the Bucket

Replacing the Tooth Point

Inspection and Maintenance of Electrical Equipment

Tightening Torque of Capscrews and Nuts

Periodical Inspection of Important Preventive Maintenance Parts

Storage of Machine Introduction

Regular Maintenance Items and Intervals

Replacement table of Oils, Greases and Filter Elements

Procedure of Maintenance the Engine

Procedure for the Maintenance of Hydraulic Unit

Procedure for the Maintenance of Upper Frame

Procedure for the Maintenance of Lower Frame

Procedure for the Maintenance of Attachments

Attaching, Detaching and Turning Over the Bucket

Replacing the Tooth Point

Inspection and Maintenance of Electrical Equipment

Tightening Torque of Capscrews and Nuts

Periodical Inspection of Important Preventive Maintenance Parts

Storage of Machine

TRANSPORTATION

-REFERENCE DOCUMENTS

General Dimension

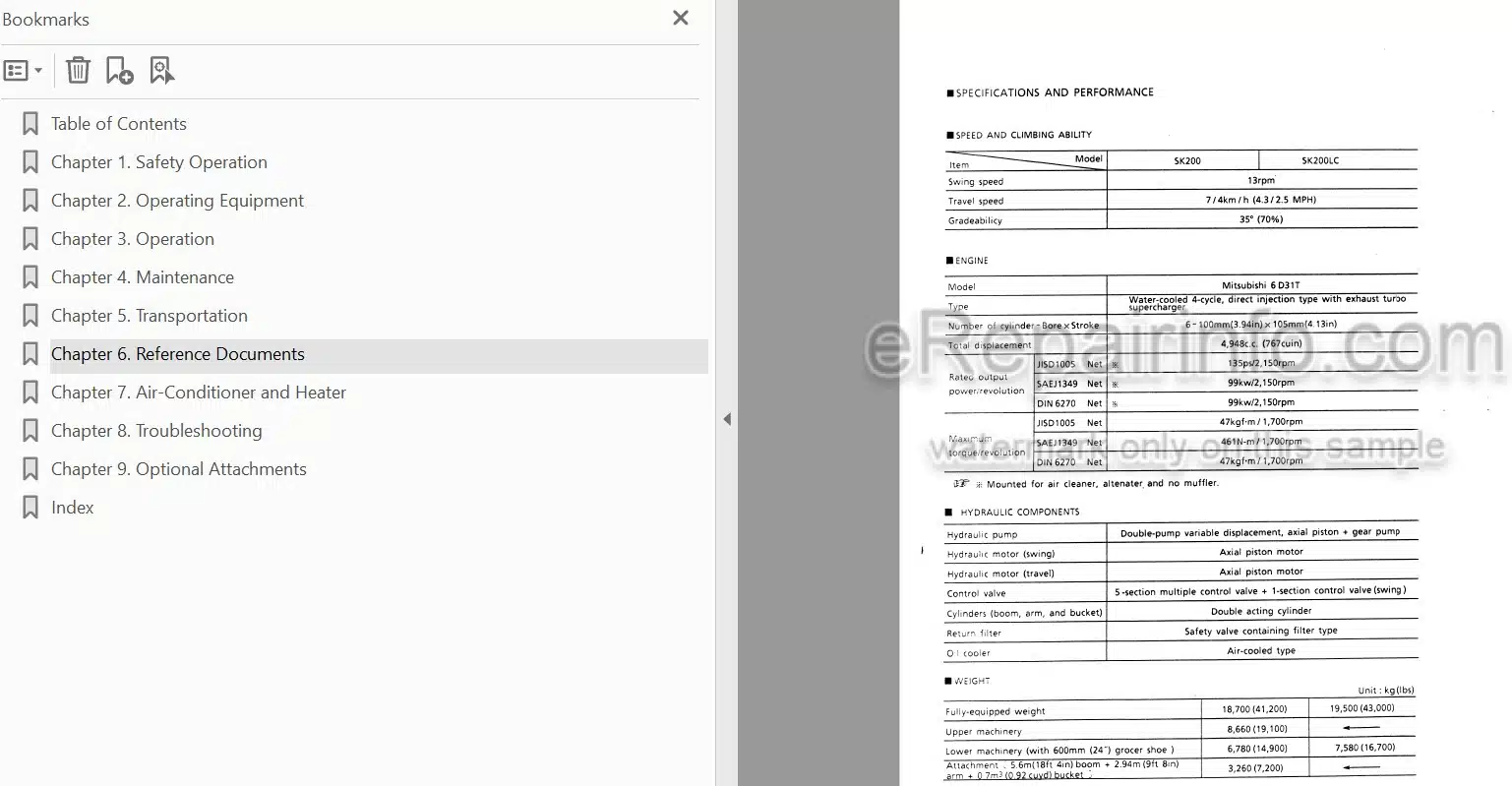

Specifications and Performance

Types of Attachments and Combinations

Working Ranges of Attachments

Weight of Components

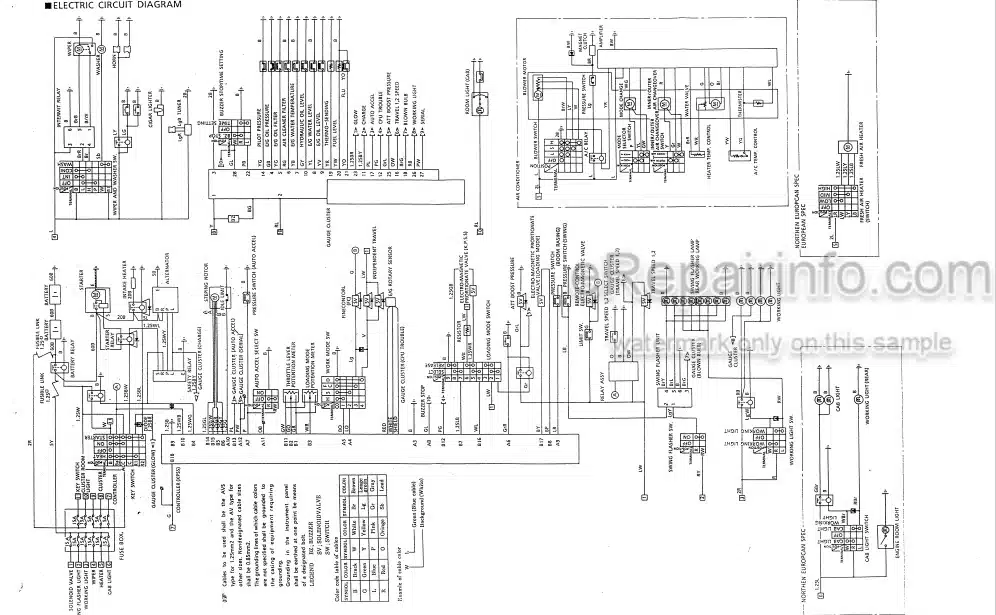

Electric Circuit Diagram

Hydraulic Circuit Diagram (Long lever type)

Hydraulic Circuit Diagram

-AIR-CONDITIONER AND HEATER

Designation Of Components

Operation

Inspection And Maintenance

Designation Of Section (Fresh Air Heater)

Designation Of Section (Inner Air Heater)

TROUBLESHOOTING

-OPTIONAL ATTACHMENTS

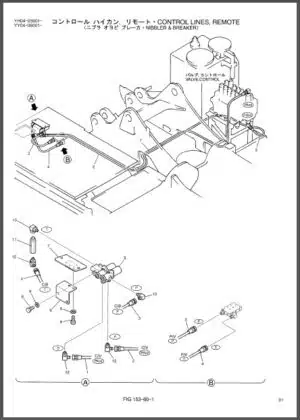

Cautions on the use of Hydraulic Breaker

Regular Inspection and Maintenance List

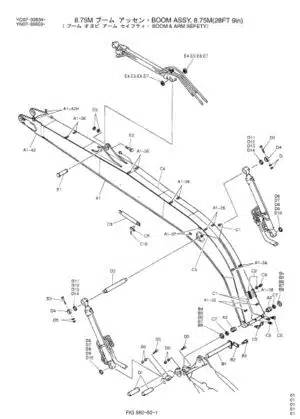

Handling the Long Range Attachment

General Dimension

Working Ranges of Attachments

INDEX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.