Factory Workshop Manual For Kohler Engine. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 116

Issued: june 2012

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

Kohler Engine

KDW702

KDW1003

KDW1404

Contents

-MANUFACTURER AND ENGINE IDENTIFICATION

The Identification Plate Shown In The Figure Can Be Found Directly On The Engine

Approval Data

Name Plate For EPA Rules Applied On Rocker-Arm Cap

Compilation Example

-GENERAL REMARKS AND SAFETY INFORMATION

California Emission Control Warranty Statement

Your Warranty Rights And Obligations

Explanation Of The Safety Pictograms That Can Be Found On The Engine Or In The Operation And Maintenance Handbook

Indications Regarding The Points On The Engine Where The Safety Pictograms Are Placed

Limited 3 Year Kohler Diesel Engine Warranty

General Service Manual Notes

Glossary And Terminology

Safety Regulations

General Safety During Operating Phases

Safety And Environmental Impact

Troubleshooting

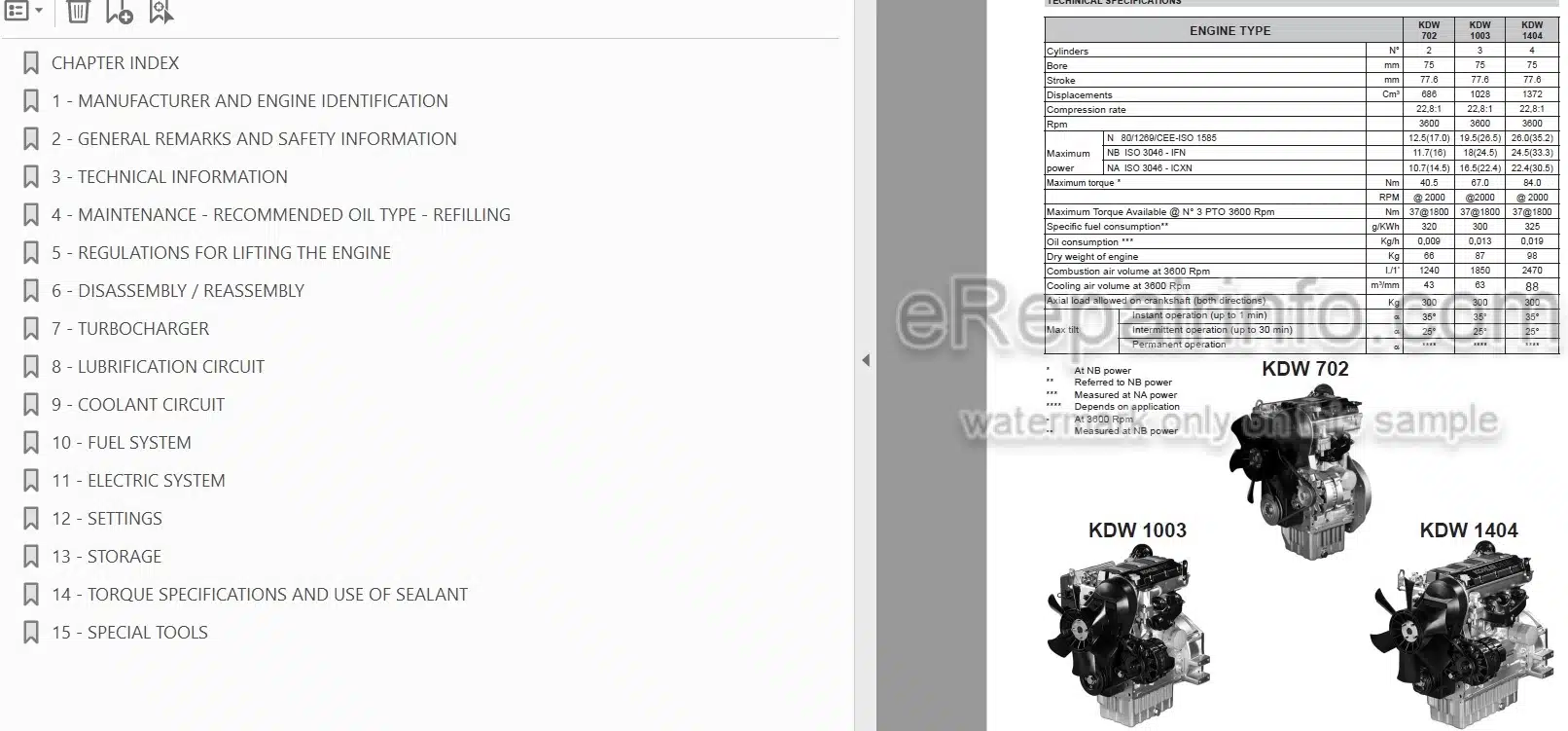

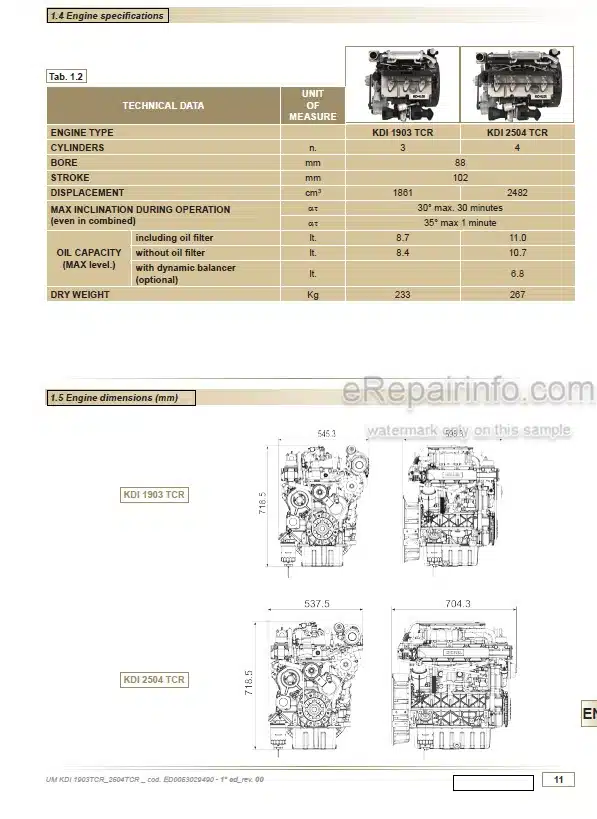

-TECHNICAL INFORMATION

Trouble Shooting

Technical Specifications

Performance Diagrams

Overall Dimension

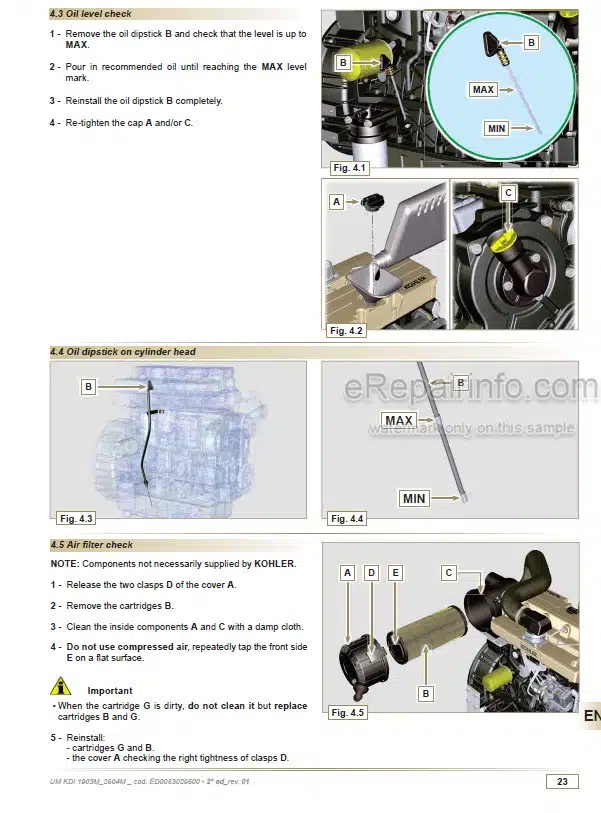

-MAINTENANCE – RECOMMENDED OIL TYPE – REFILLING

Routine Engine Maintenance

Ordinary Maintenance

Extraordinary Maintenance

Lubricant

Prescribed Lubricant

Coolant

Fuel Recommendations

REGULATIONS FOR LIFTING THE ENGINE

-DISASSEMBLY/REASSEMBLY

Recommendations For Disassembling And Assembling

Recommendations For Overhauls And Tuning

Dry Type Air Filter

Air Restriction Switch

Oil Bath Air Cleaner (On Request)

Air Filter Support

Intake Manifold – Remote Air Filter

EGR Circuit (Components)

EGR Circuit

Vacuum Pump And Vacuum Pump Flange

Exhaust Manifold

Exhaust Manifold – Engines With EGR

Cooling Fan

Alternator/Cooling Fan Belt Drive

Fuel Tank (Optional)

Flywheel

Return Pulley

Driving Pulley

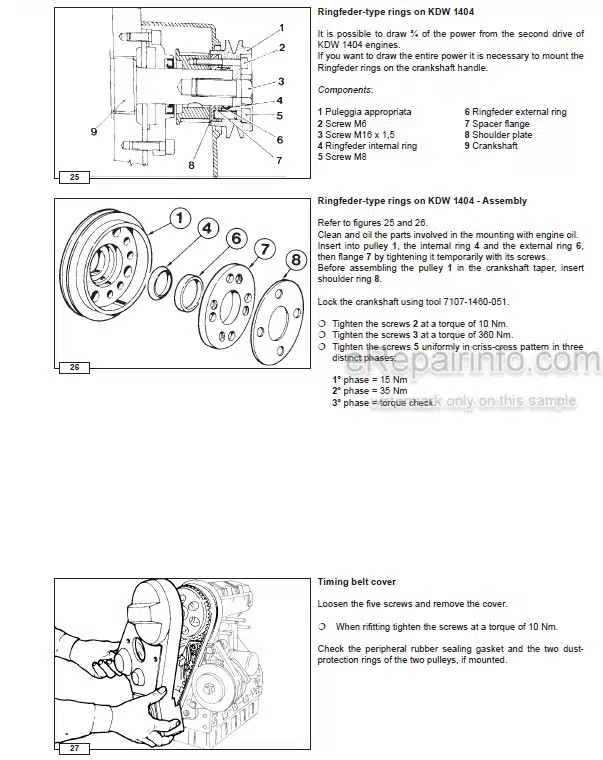

Ringfeder-Type Rings On Kdw 1404

Ringfeder-Type Rings On Kdw 1404 – Assembly

Timing Belt Cover

Timing Belt / Timing Pulley Arrangement

Timing Belt Removal

Tightening Pulley

Crankshaft Timing Pulley

Camshaft Timing Pulley

Camshaft Timing

Valve Timing Check

Valve Timing – Angles

Speed Governor

Speed Governor Components

Governor Springs

Speed Governor

Oil Pump

Rocker Arm Cover

Rocker Arm Cover Gasket

Crankcase Vacuum Regulator Valve

Crankcase Breather

Valve / Rocker Arm Clearance

Injection Pump Control Rod

Fuel Rail

Pump/Injector Unit

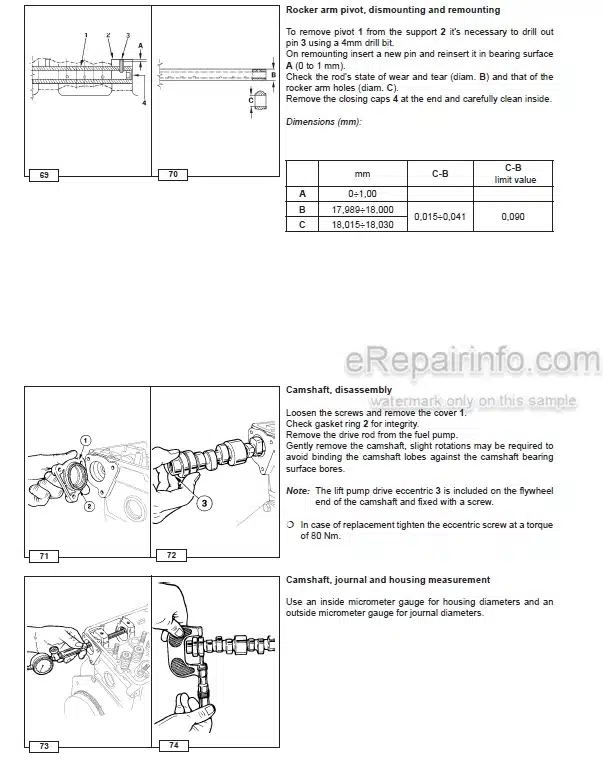

Rocker Arm Pivot, Dismounting And Remounting

Camshaft

Camshaft Journals And Housings – Dimensions (Mm)

Camshaft Lobe Measurement

Intake / Exhaust / Injection Camshaft Lobe Height

Cylinder Head, Removal

Valves

Valve Stem Sealing Rings – Reassembly

Valve Springs

Valve, Specifications

Valve Guides And Valve Guide Housings

Valve Guide Insertion

Valve Seats And Housings – Dimensions

Valve Recess And Seat Sealing Width

Pre-Combustion Chamber

Pre-Combustion Chamber Ring Nut Removal

Pre-Combustion Chamber, Removal

Pre-Combustion Chamber, Installation

Oil Pan, Removal

Piston

Stop Pin Rings, Dismounting And Remounting

Piston, Disassembly And Inspection

Piston, Class

Piston, Weight

Piston Rings – End Gaps (Mm)

Piston Ring, Clearance Between Grooves (Mm)

Piston Ring, Mounting Order

Piston, Assembly

Piston Clearance

Head Gasket

Cylinder Head Assembly

Cylinder Head Tightening Procedure KDW 1003

Cylinder Head Tightening Procedure KDW 1404

Connecting Rod

Big End Bearing

Connecting Rod, Weight

Connecting Rod With Bearings And Pin

Connecting Rod Alignment

Cylinders

Cylinder, Class

Cylinder Roughness

Central Main Bearing Caps

Rear And Forward Main Bearing Caps

Check The Clearances Between The Bearings And The Journal

Piston Coolant Nozzles

Shoulder Half Rings

Crankshaft Axial Clearance

Shoulder Half Rings, Oversized Elements

Crankshaft Front And Back Oil Seal Rings

Crankshaft, Lubrication Lines

Crankshaft, Check Journals And Crank

Journal And Connecting Rod Pins Diameters

Main Bearings And Connecting Rod Big Ends Diameters

Clearances Between The Bearings And Corresponding Pins

Hydraulic Pump Drive

Third Drive, Components

-TURBOCHARGER

Turbo Charger

Turbocharger Components

Turbocharger Pressure Testing

-LUBRIFICATION CIRCUIT

Lubrication Circuit

Internal Oil Filter And Oil Sump Return Pipe

Oil Pump

Oil Pump, Clearance Between Rotors

Oil Pressure Regulating Valve

Oil Filter Cartridge

Oil Pressure Check

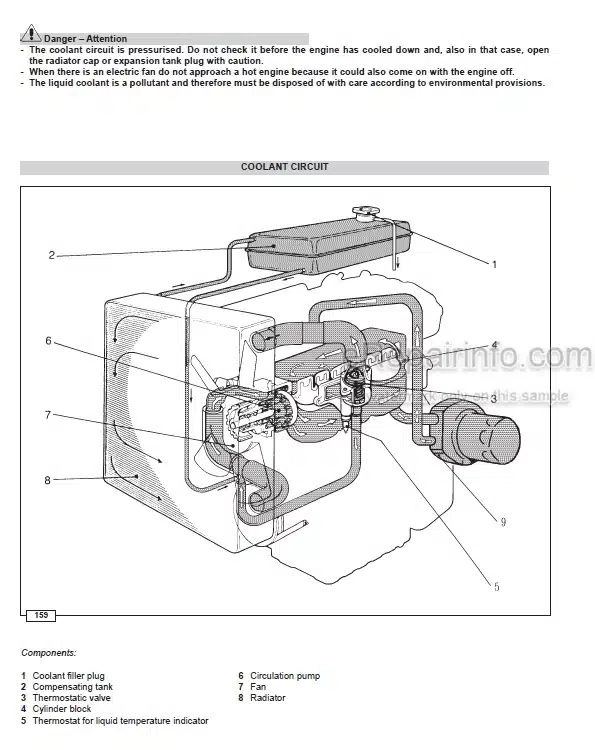

-COOLANT CIRCUIT

Coolant Circuit

Radiator And Compensation, Check And Seal Tank Cap

Coolant Circulation Pump, Components

Thermostatic Valve

-FUEL SYSTEM

Fuel Feeding / Injection Circuit

Fuel Filter Detached From The Tank (On Request)

Fuel Lift Pump

Fuel Pump Drive Rod Projection

Pump/Injector Unit

Pump/Injector Unit, Components

Plunger Barrel Ring Nut Assembly/Disassembly

Injection Pump Assembly/Disassembly

Plunger Injection Pump Reassembly

Pumping Element (Old-Type Injection Pump)

Pumping Element

Pump/Injector Unit See No. 6590285 Control Data

Injector, Setting (Old Type)

Setting Of Injector According To Current Pump/Injector Unit

Injector, Nozzle Projection

Injector, Spark Arrester

Injection Advance Control And Regulation

Injection Advance For Currently Used Pump/Injector Unit

Static Injection Advance Tuning

Injection Advance References On Timing Belt Protector

TDC (Top Dead Center) References

Tester And Special Coupling For Injection Advance Control (Old-Type Injection Pump)

Static Injection Advance Regulation

Preliminary Steps To Pump/Injector Unit Delivery Balancing Test

Closing The Oil Hole

Test Head B Assembly

Instrument Connection

Injection Pumps Delivery Balancing

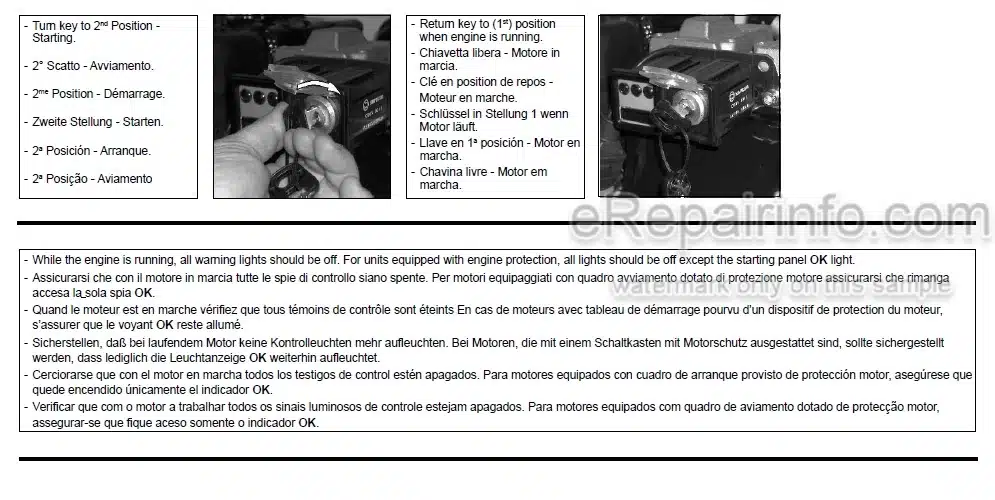

Electric Control Panel With Automatic Engine Stop (Upon Request)

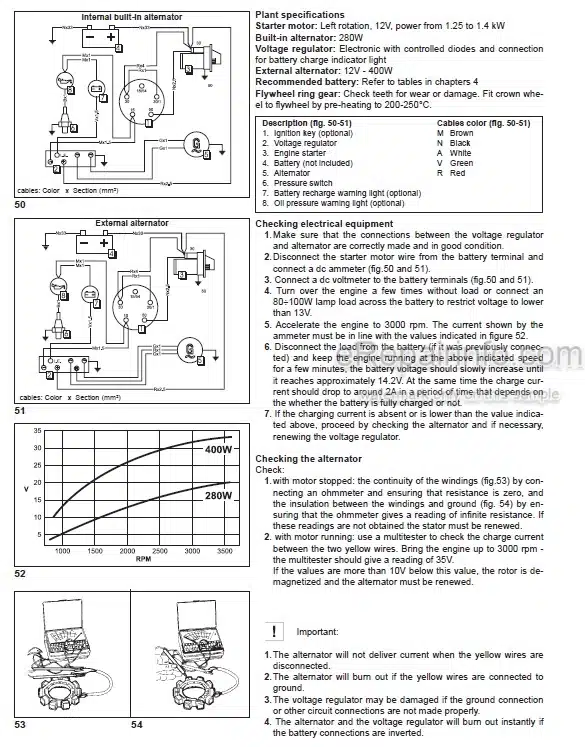

-ELECTRIC SYSTEM

Alternator, 14V 33A

Alternator, 14V 33A – Performance Curve

Electric Starting Layout (12V) With Alternator 14V 33A

Alternator 14V 45A – 65A

Alternator, 14V 45A – Performance Curve

Alternator, 14V 65A – Performance Curve

Electric Starting Layout 12V 33A – 45A – 65A

Flywheel Alternator

Alternator Battery Charger Curve 12V 30A

Electric Starting Layout (12V) With Flywheel Alternator

Voltage Regulator Connections

Starter Motor – Bosch Dw 12V 1,1 Kw

Starter Motor, Bosch Dw 12V 1,1 Kw – Performance Curve

Starter Motor, Bosch 12V 1,6 Kw

Starter Motor, Bosch Dw 12V 1,6 Kw – Performance Curve

Pre-Heating Glow Plug

Pre-Heating Plug Control Unit With Coolant Temperature Sensor

Temperature Sensor For Control Unit

Oil Pressure Switch (Fig 215)

Pre-Heating Water Temperature Thermistor And Water Temperature Indicator Thermal Contact

-SETTINGS

Speed Settings

Setting The Idle Minimum (Standard)

Setting The Idle Maximum (Standard)

Pump Injection Delivery Standard Setting Without Dynamometric Brake

Injection Pump Flow Limiter And Engine Torque Gearing Device

Pump/Injector Unit Timing With Speed Governor

Pump/Injector Unit Delivery Setting With Braked Engine

EGR Calibration

-STORAGE

Engine Storage

Protective Treatment

Preparing The Engine For Operation After Protective Treatment

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.