Factory Shop Manual For Komatsu Wheel Loader. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 749

Number: SEBM005908 (august 2005)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Avance Wheel Laoder

WA250-3

Serial No. 50001 and up

Contents

-SAFETY

Safety Notice

-FOREWORD

General

How To Read The Shop Manual

Hoisting Instructions

Method Of Disassembling, Connecting Push-Pull Type Coupler

Coating Materials

Standard Tightening Torque

Electric Wire Code

Conversion Table

Units

-GENERAL

General Assembly Drawing

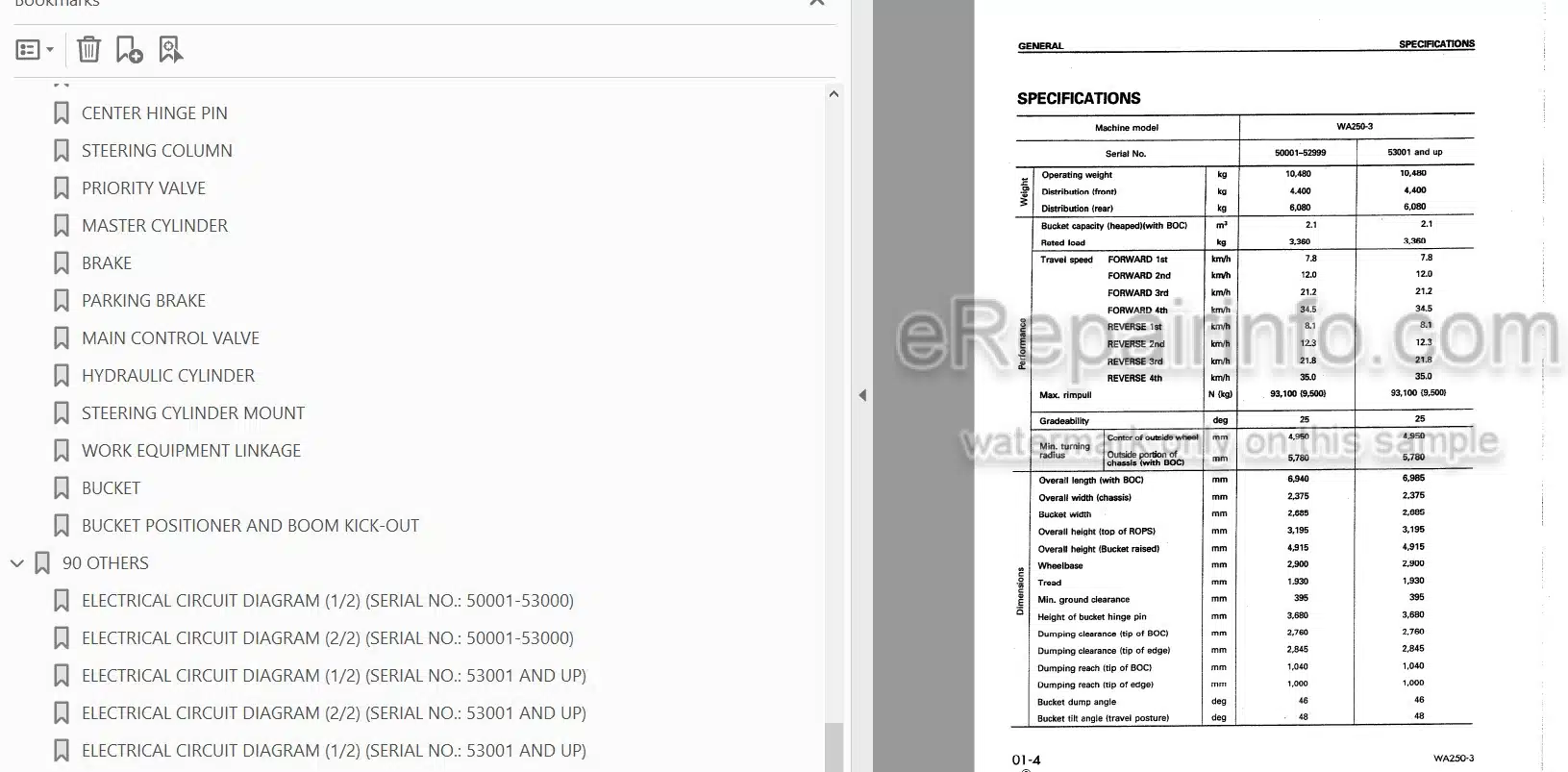

Specifications

Weight Table

List Of Lubricant And Water

-STRUCTURE AND FUNCTION

Power Train

Path Of Power Transmission

Torque Converter, Transmission Piping

Torque Converter, Transmission Hydraulic System

Torque Converter, Transmission Hydraulic Circuit Diagram

Torque Converter

Torque Converter Oil Filter

Transmission

Transmission Control Valve

Drive Shaft

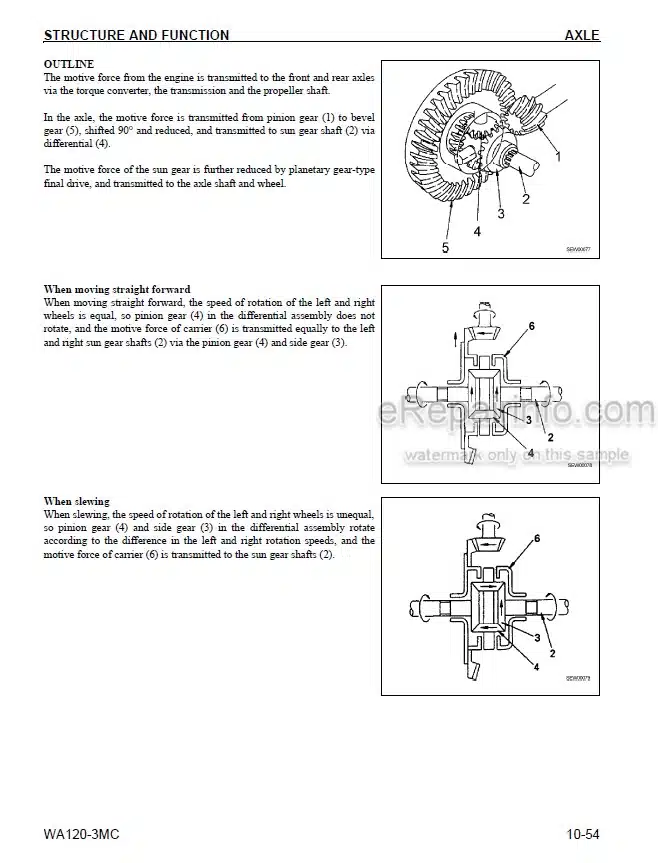

Axle

Final Drive

Axle Mount

Center Hinge Pin

Steering Piping

Steering Column

Priority Valve

Steering Valve (Orbit-Roll)

2-Way Restrictor Valve

Brake Piping

Power Master Cylinder

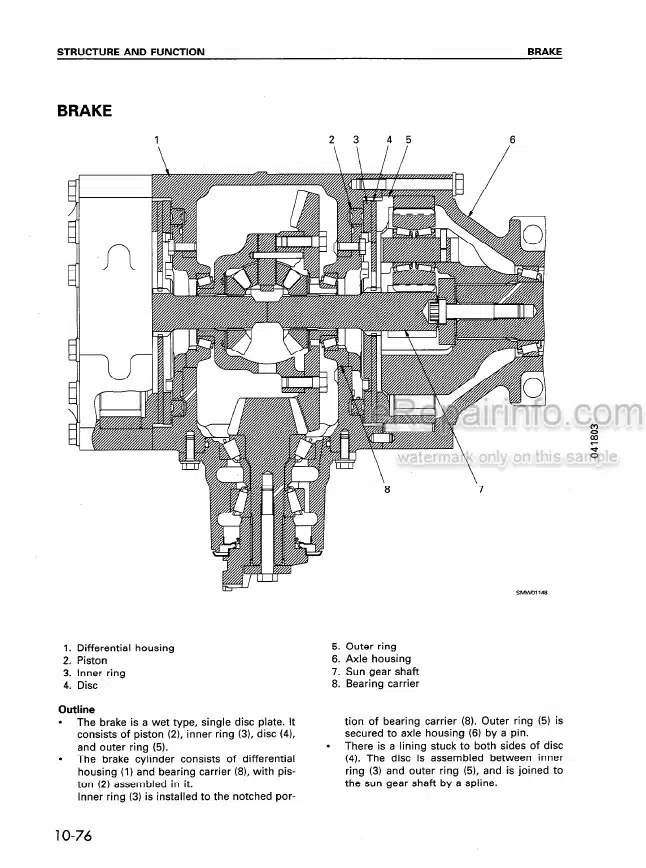

Brake

Parking Brake Control

Hydraulic Piping

Steering, Hydraulic Pump Hydraulic System Diagram

Steering, Hydraulic Pump Hydraulic Circuit Diagram

Work Equipment Control Lever Linkage

Hydraulic Tank

Main Control Valve

Work Equipment Linkage

Bucket

Bucket Positioner And Boom Kickout

Cab

Machine Monitor System

Main Monitor

Maintenance Monitor Display Function

Sensors And Switches

Engine Starting Circuit

Engine Stop Circuit

Preheating Circuit

Starting Aid

Electrical Transmission Control

Combination Switch

Transmission Cut-Off Function

Parking Brake Neutralizer Relay Function

Kick-Down Switch

Kick-Down Electric Circuit Diagram

Transmission Auto Shift Control System (If Equipped)

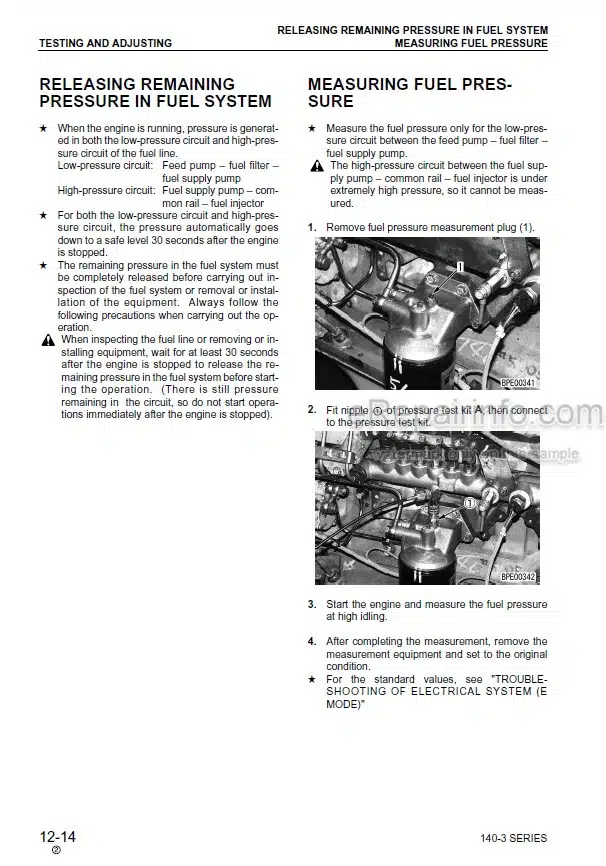

-TESTING AND ADJUSTING

Standard Value Table For Engine

Standard Value Table For Chassis

Standard Value Table For Electrical Parts

Tools For Testing, Adjusting, And Troubleshooting

Adjusting Valve Clearance

Measuring Compression Pressure

Testing And Adjusting Fuel Injection Timing

Measuring Exhaust Color

Measuring Blow-By Pressure

Testing And Adjusting Fan Belt Tension

Measuring Engine Speed

Method For Adjusting Engine Stop Motor Cable

Adjusting Engine Stop Solenoid

Measuring Engine Oil Pressure

Measuring Intake Air Pressure (Boost Pressure)

Measuring Exhaust Gas Temperature

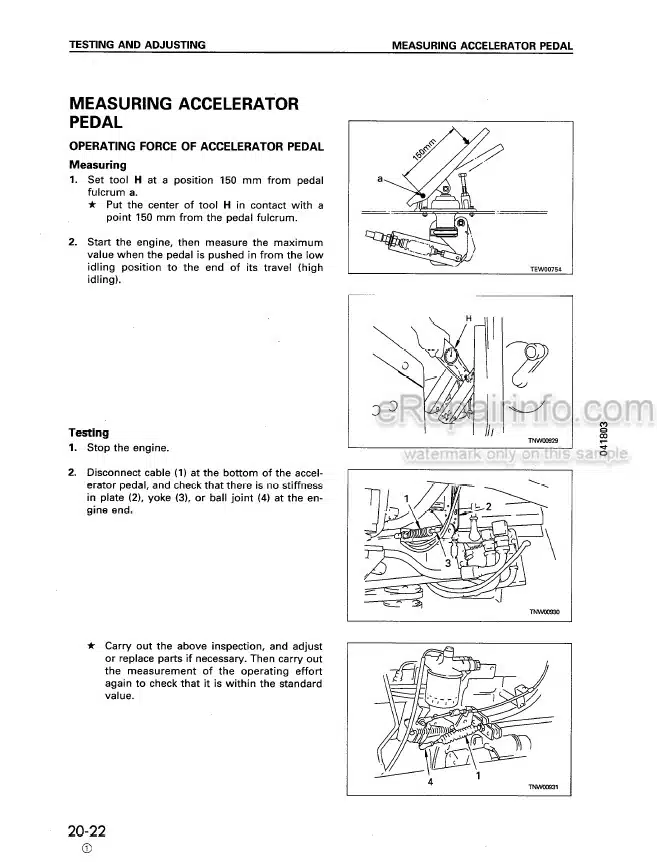

Measuring Accelerator Pedal

Measuring Shift Lever

Measuring Stall Speed

Measuring Torque Converter, Transmission Oil Pressure

Method Of Operating Emergency Manual Spool

Testing And Adjusting Steering Wheel

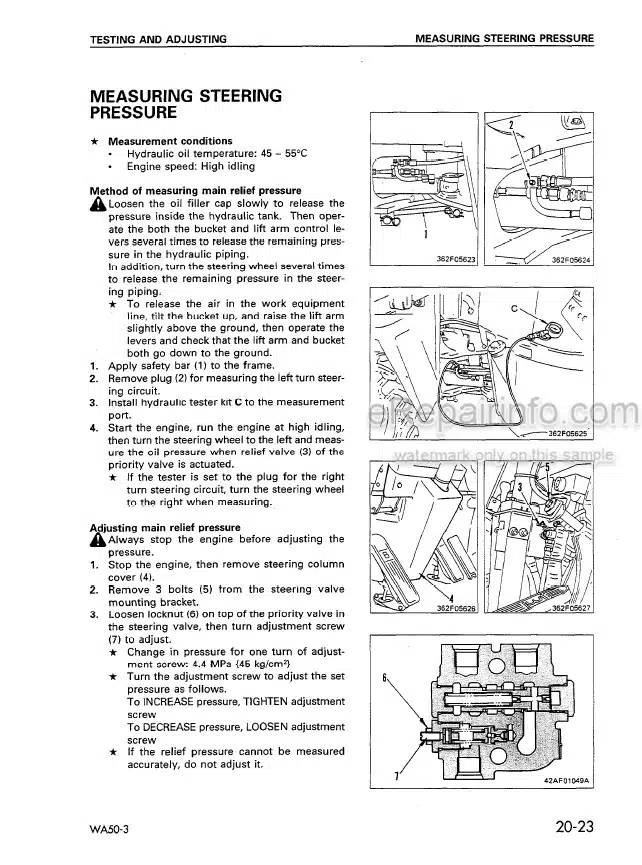

Measuring Steering Oil Pressure

Measuring Brake Pedal

Testing And Adjusting Brake Pedal Linkage

Measuring Brake Performance

Measuring Brake Oil Pressure

Measuring Wear Of Brake Disc

Bleeding Air From Brake System

Measuring Parking Brake Performance

Testing And Adjusting Parking Brake Linkage

Testing Parking Brake Piston Stroke

Measuring Wear Of Parking Brake Disc

Measuring And Adjusting Work Equipment Control Lever

Measuring Stroke Of Work Equipment Valve Spool

Measuring Work Equipment Hydraulic Pressure

Measuring Work Equipment

Testing And Adjusting Bucket Positioner

Testing And Adjusting Boom Kick-Out

Adjusting Main Monitor (Speedometer Module)

Checking For Abnormality In Fuel Level Sensor

Troubleshooting

-DISASSEMBLY AND ASSEMBLY

Method Of Using Manual

Precautions When Carrying Out Operation

Special Tool List

Starting Motor

Alternator

Engine Oil Cooler

Fuel Injection Pump

Water Pump

Turbocharger

Nozzle Holder

Thermostat

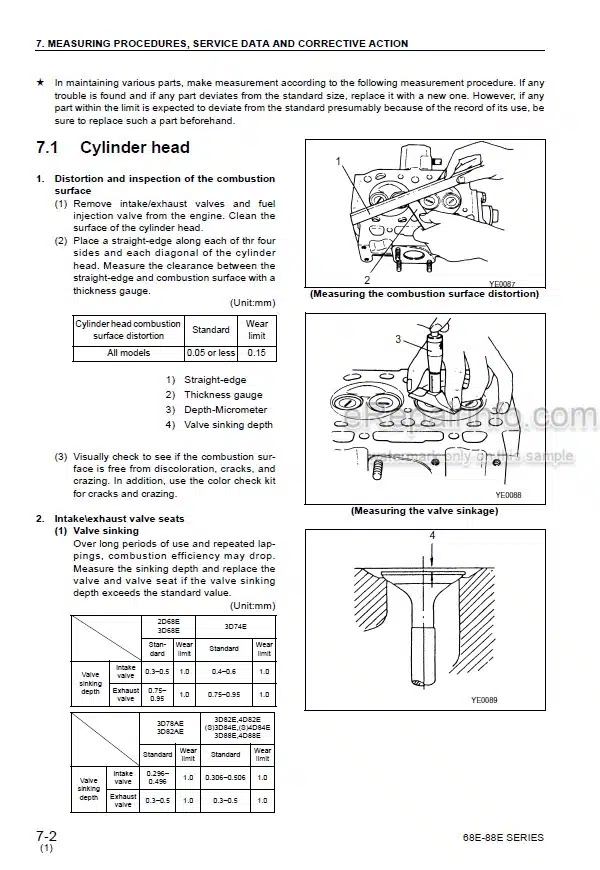

Cylinder Head

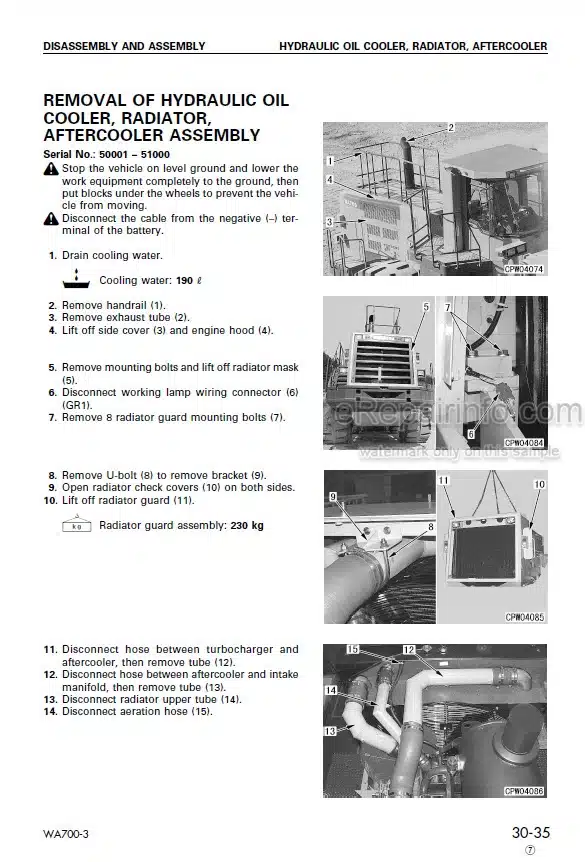

Radiator

Radiator, Hydraulic Cooler

Engine

Torque Converter Charging Pump

Torque Converter, Transmission

Torque Converter

Torque Converter

Transmission

Clutch Pack

Parking Brake

Transmission Control Valve

Transmission Solenoid Valve

Accumulator Valve

Drive Shaft

Front Axle

Rear Axle

Differential

Axle Housing

Center Hinge Pin

Steering Valve

Priority Valve

Steering Cylinder

Power Master Cylinder

Parking Brake Disc

Hydraulic Tank

Hydraulic Filter

Work Equipment, Steering Pump

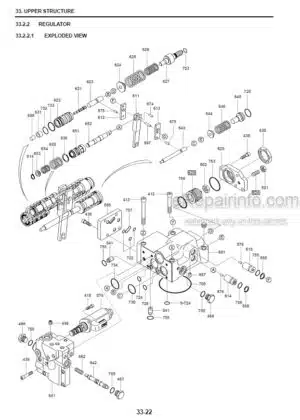

Main Control Valve

Bucket Cylinder

Boom Cylinder

Hydraulic Cylinder

Work Equipment

Counterweight

Fuel Tank

Cab

Main Monitor

Maintenance Monitor

Air Conditioner Unit

Air Conditioner Condenser

Dry Receiver

Air Conditioner Compressor

-MAINTENANCE STANDARD

Transmission, Engine Mount

Torque Converter

Transmission

Transmission Control Valve

Accumulator Valve

Drive Shaft

Differential

Final Drive

Axle Mount

Center Hinge Pin

Steering Column

Priority Valve

Master Cylinder

Brake

Parking Brake

Main Control Valve

Hydraulic Cylinder

Steering Cylinder Mount

Work Equipment Linkage

-OTHERS

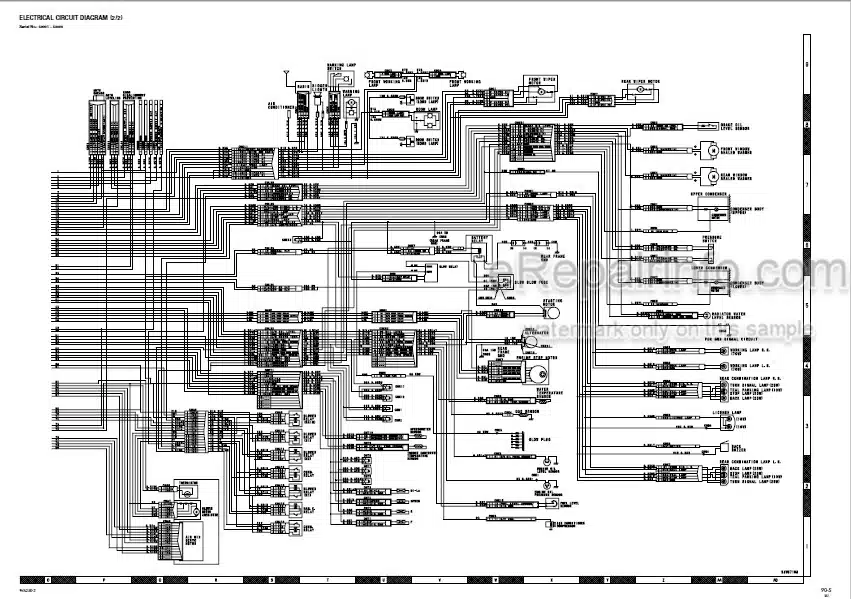

Electrical Circuit Diagram (1/2) (Serial No.: 50001-53000)

Electrical Circuit Diagram (2/2) (Serial No.: 50001-53000)

Electrical Circuit Diagram (1/2) (Serial No.: 53001 And Up)

Electrical Circuit Diagram (2/2) (Serial No.: 53001 And Up)

Electrical Circuit Diagram (1/2) (Serial No.: 53001 And Up)

Electrical Circuit Diagram (2/2) (Serial No.: 53001 And Up)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.