Factory Shop Manual For Komatsu Forklift Truck. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 586

Number: BEB17E1-06 (june 2018)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Forklift Truck

BX50 Series

FD20-17

FD25-17

FD30-17

FD20H-17

FD25H-17

FD30H-17

FD35A-17

SN 300001 And Up

Contents

-INDEX AND FOREWORD

Index

Foreword And General Information

-OUTLINE

Specifications

Outside View

Weight Table

Lubricant List

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Engine And Cooling System

Power Train

Steering System

Brake System

Undercarriage And Frame

Hydraulic System

Work Equipment

Electric Devices

-STANDARD VALUE TABLE

Standard Value Table

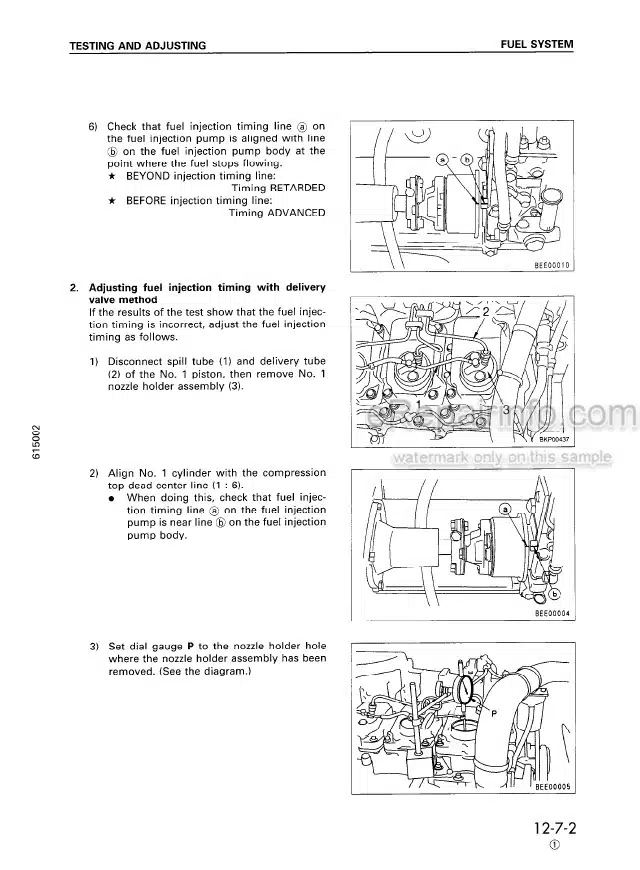

-TESTING AND ADJUSTING

Checking The Engine Speed

Hydraulic Piping Pressure Release Procedure

Replacement Of Engine Oil And Engine Oil Filter

Replacement Of Fuel Filter

Cleaning Of Radiator

Check Of Air Cleaner And Replacement Of Cleaner Element (2 Ton)

Tightening Torque Of Cylinder Head Mounting Bolts

Adjustment Of Valve Clearance

Testing Of Compression

Replacement Of Clutch Disc

Oil Replacement And Strainer Cleaning Of Torqflow Transmission

Oil Level Check And Oil Replacement Of Differential Case

Testing Power Train Oil Pressure

Initial Setting Of Power Steering Valve

Checking The Steering Oil Pressure

Testing And Adjusting The Work Equipment Oil Pressure

Check Of Hydraulic Tank

Adjustment Of Clutch And Brake Pedal (Clutch Model)

Adjustment Of Inching And Brake Pedal (Torqflow Model)

Adjustment Of Accelerator Pedal

Adjusting The Parking Brake Lever

Adjustment Of Cables Of The Forward And Backward Control Lever And The High And Low Speed Lever (Clutch Model)

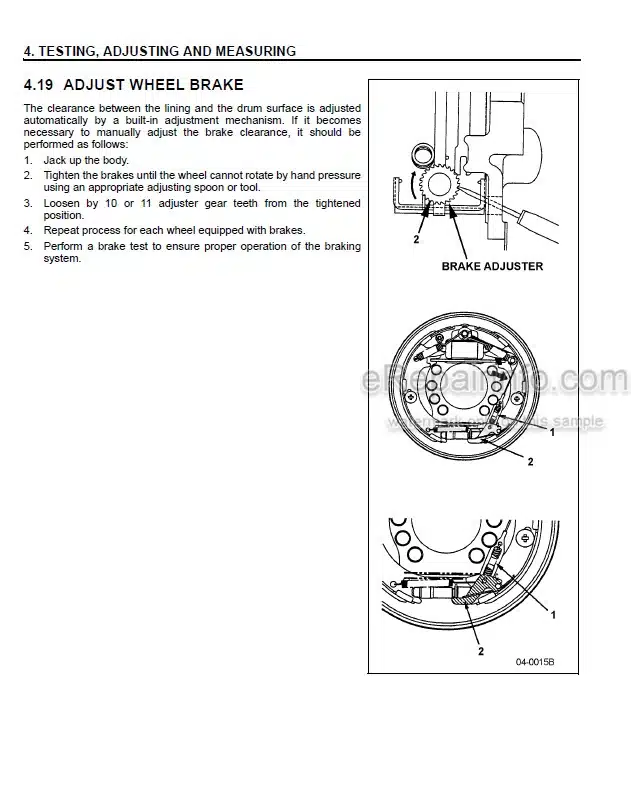

Wheel Brake

Bleeding Air

Measurement Of Cylinder Hydraulic Drift And Hydraulic Forward Drift

Adjustment Of Mast

Checking The Lift Chain

Check Of Drive Shaft For Looseness, Play And Damage

Check Of Diode

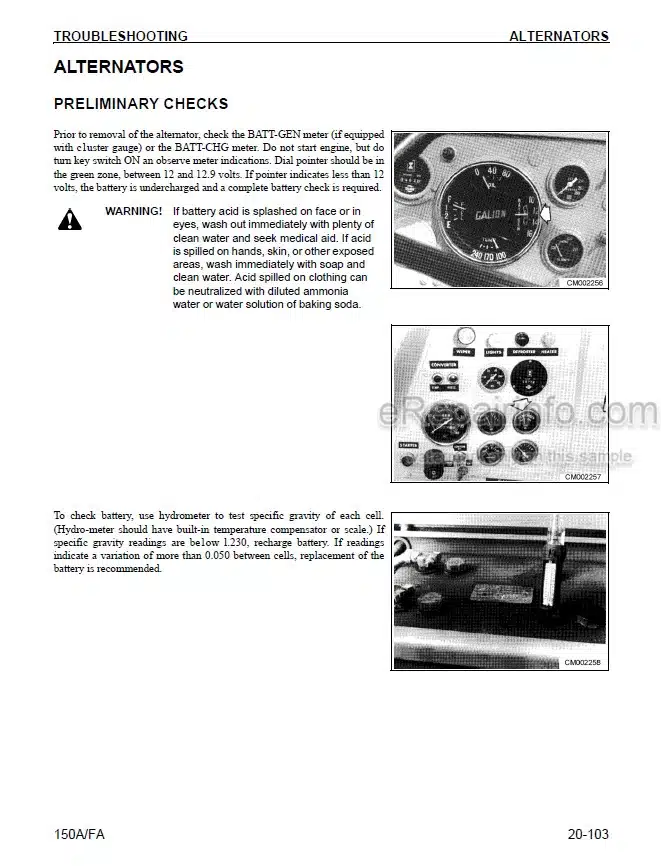

-TROUBLESHOOTING

General Information On Troubleshooting

Troubleshooting By Failure Code (ISO Controller System )

Troubleshooting By Failure Code (EPACS Controller System)

Troubleshooting Of Electrical System (E-Mode)

Troubleshooting Of Hydraulic And Mechanical System (H-Mode)

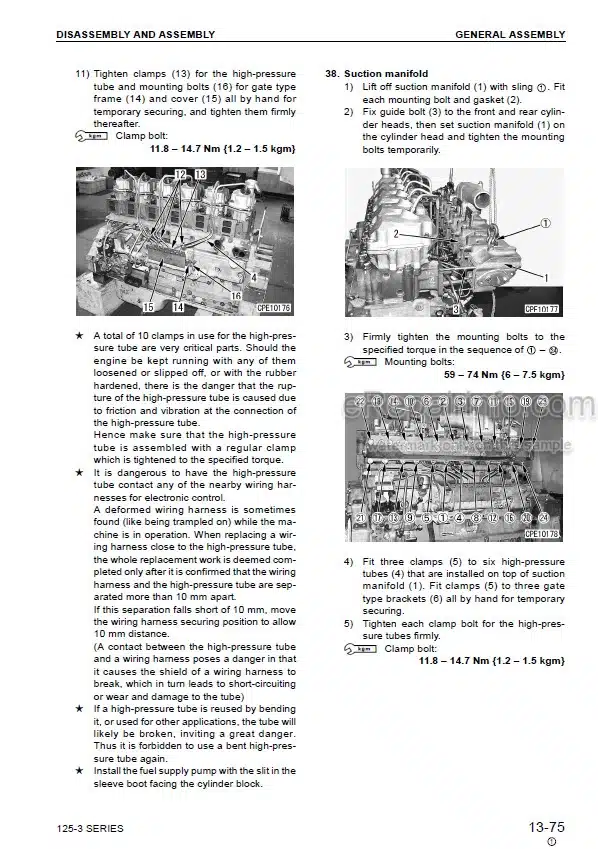

-DISASSEMBLY AND ASSEMBLY

General Information On Disassembly And Assembly

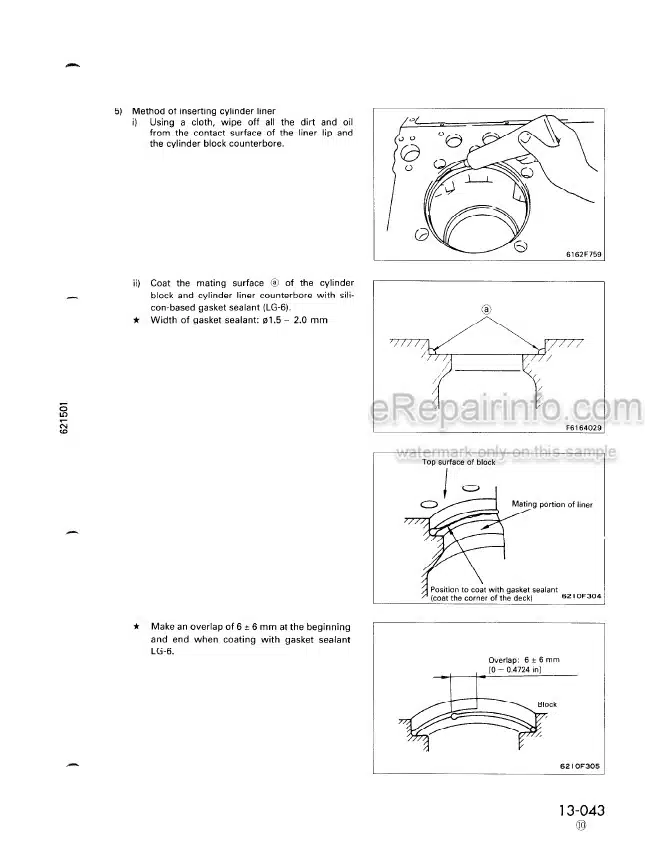

Engine And Cooling System

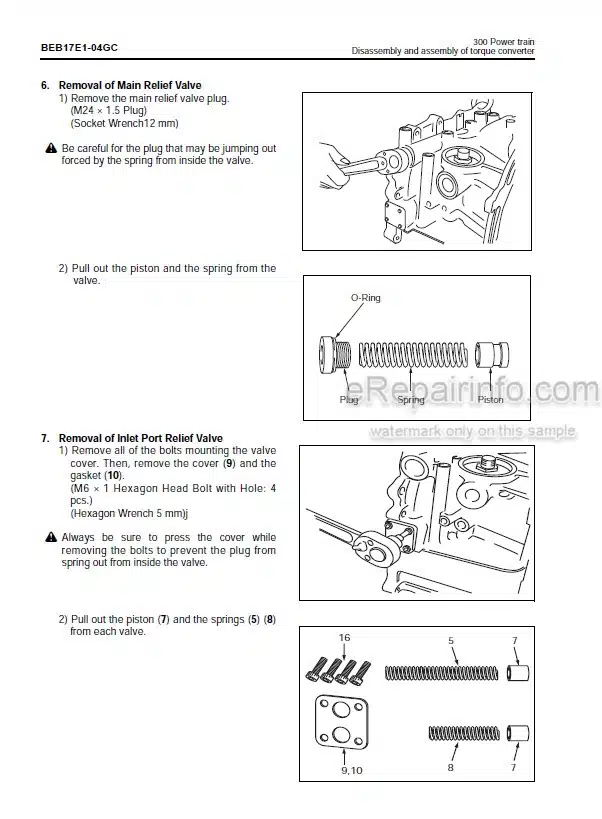

Power Train

Hydraulic Equipment

Work Equipment

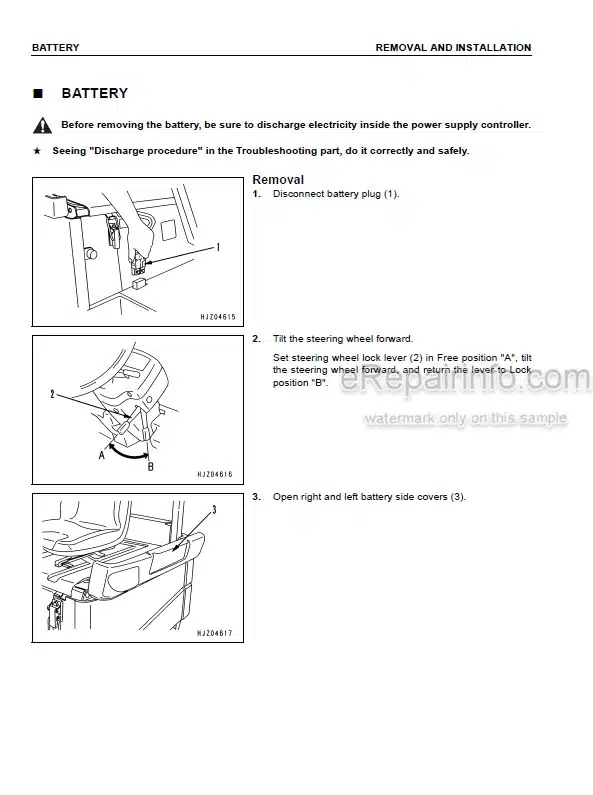

Electric Devices

-YEARLY INSPECTION CRITERIA

Yearly Inspection Criteria

-DIAGRAMS AND DRAWINGS

Power Train Hydraulic Circuit Diagram

Work Equipment Hydraulic Circuit Diagram

Electrical Circuit Diagrams

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet