Factory Shop Manual For Komatsu Bulldozer. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 677

Number: SEBM007009 (june 2005)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Bulldozer

D41E-6

SN B20001 – B40000; 50001 And Up

D41P-6

SN B20001 – B40000; 50001 And Up

Contents

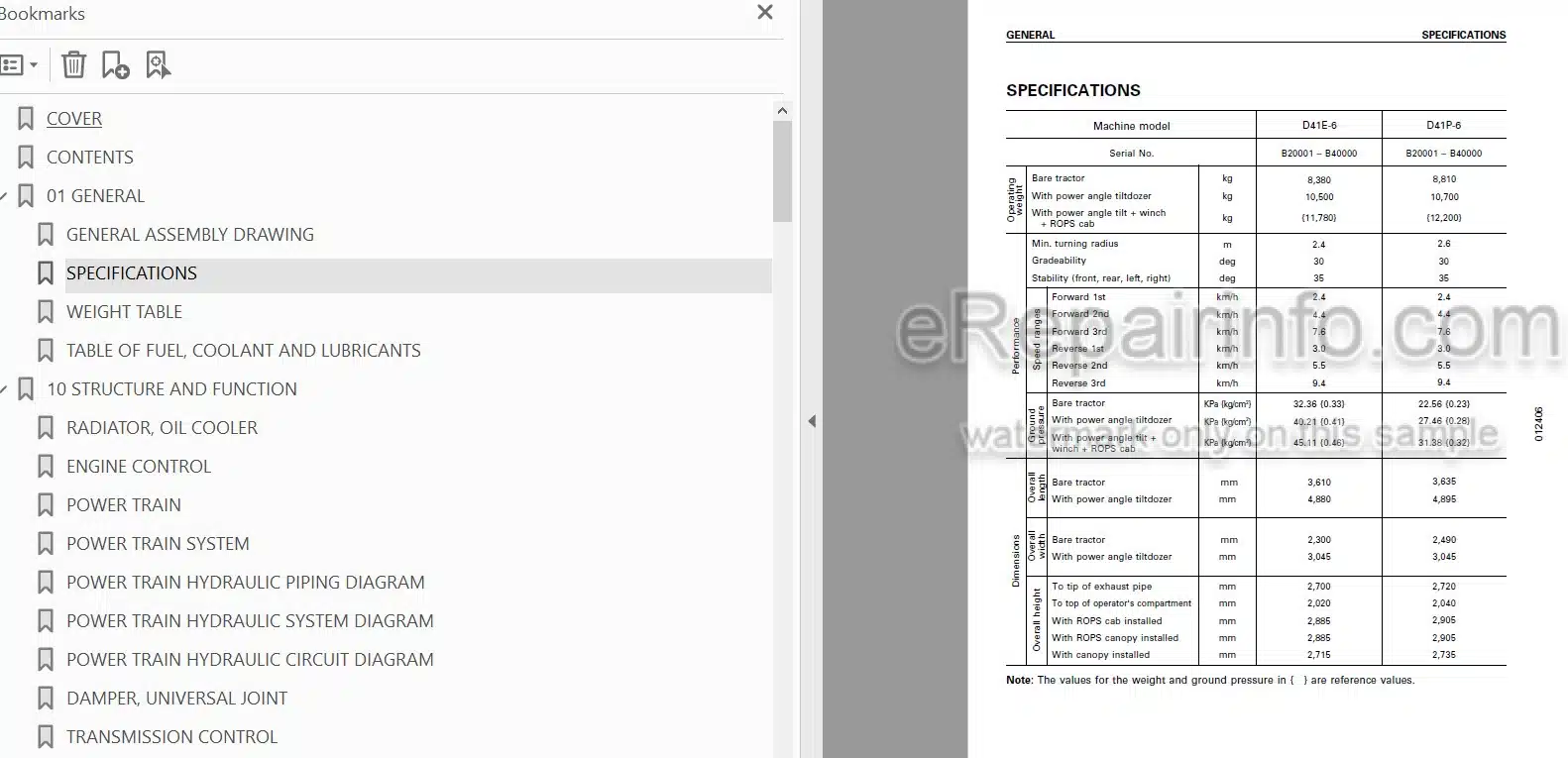

-GENERAL

General Assembly Drawing

Specifications

Weight Table

Table Of Fuel, Coolant And Lubricants

-STRUCTURE AND FUNCTION

Radiator, Oil Cooler

Engine Control

Powertrain

Powertrain System

Powertrain Hydraulic Piping Diagram

Powertrain Hydraulic System Diagram

Power Train Hydraulic Circuit Diagram

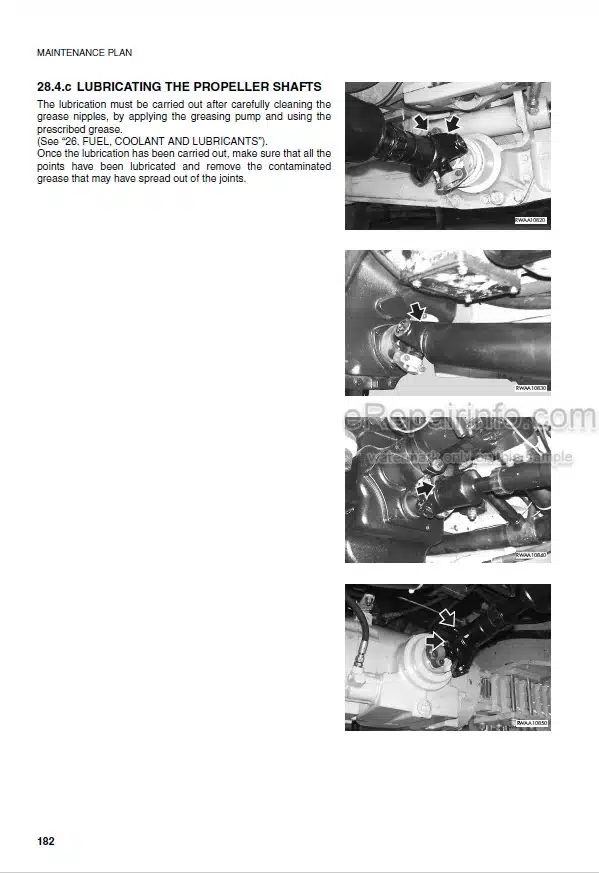

Damper, Universal Joint

Transmission Control

Transmission

Transmission Control Valve

Steering. Brake. Inching Control

Bevel Gear Shaft, Steering Clutch, Steering Brake

Steering PPC Valve

Steering Piston

Priority Valve

Brake Valve

Power Train Oil Filter

Power Train Oil Filter

Final Drive

Frame Assembly

Track Frame

Recoil Spring

Work Equipment Hydraulic Piping Diagram

Work Equipment Control

Work Equipment Hydraulic System Diagram

Work Equipment Hydraulic Circuit Diagram

Hydraulic Tank, Filter

Main Control Valve

CÄÛÛ

Work Equipment

Air Conditioner

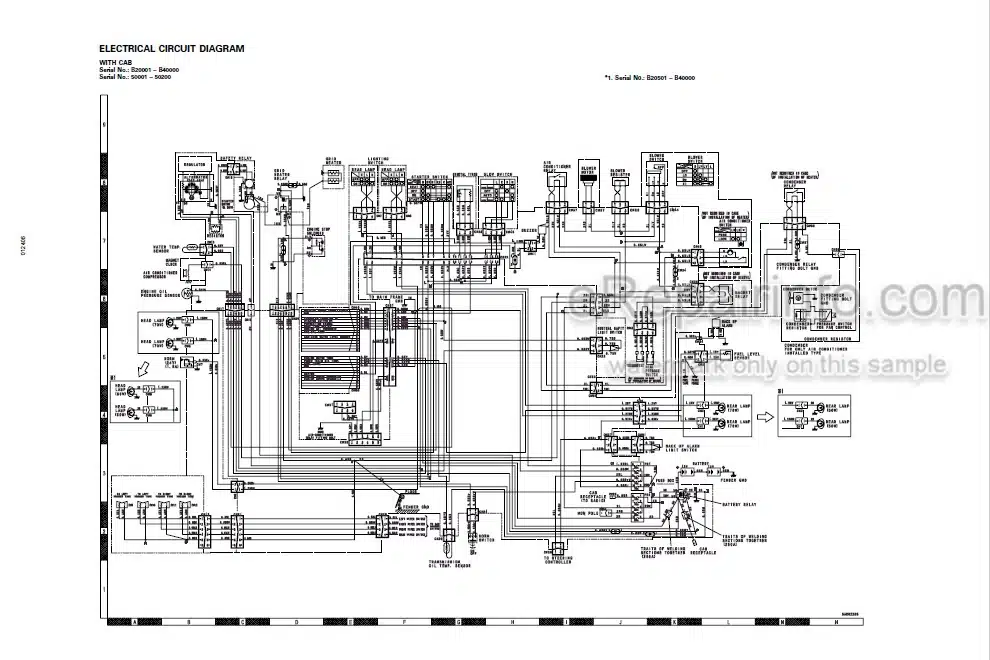

Actual Electric Wiring Diagram

Electrical Circuit Diagram

Engine Control System

Machine Monitor System

Sensors

-TESTING AND ADJUSTING

Standard Value Table For Engine Related Parts

Standard Value Table For Chassis Related Parts

Standard Value Table For Machine Monitor

Testing And Adjusting

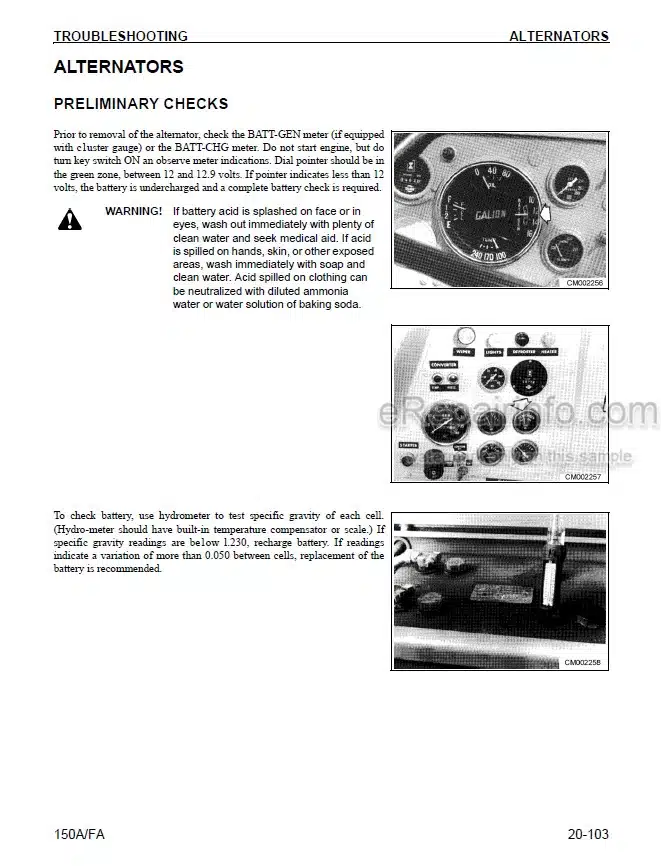

Troubleshooting

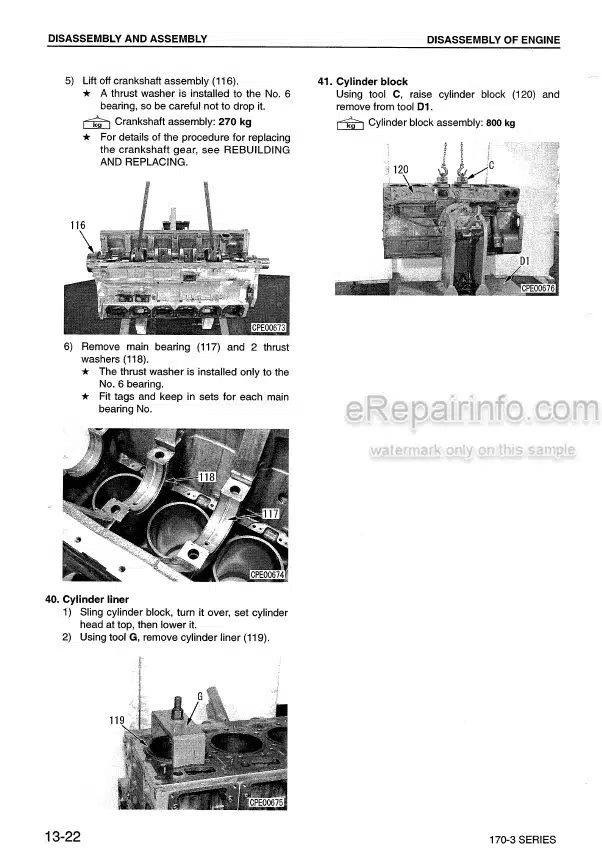

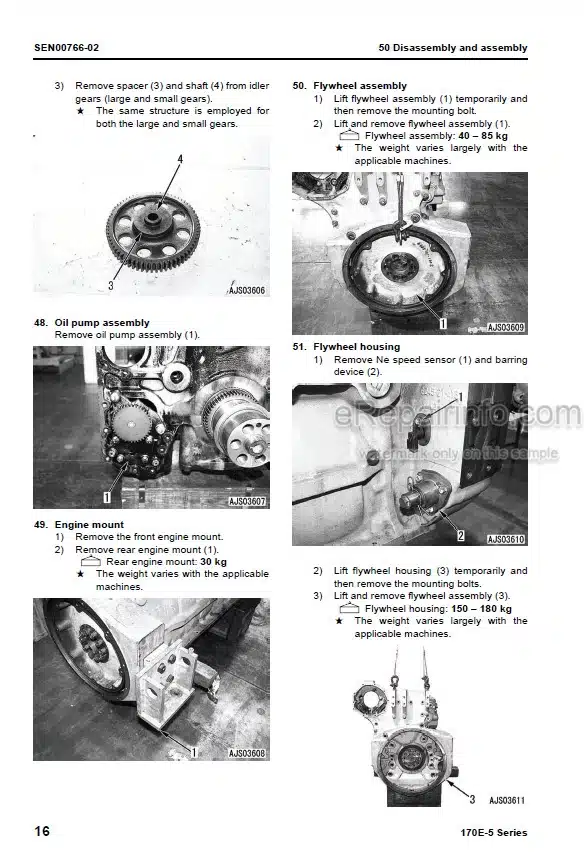

-DISASSEMBLY AND ASSEMBLY

Precautions When Carrying Out Operation

Special Tool List

Sketches Of Special Tools

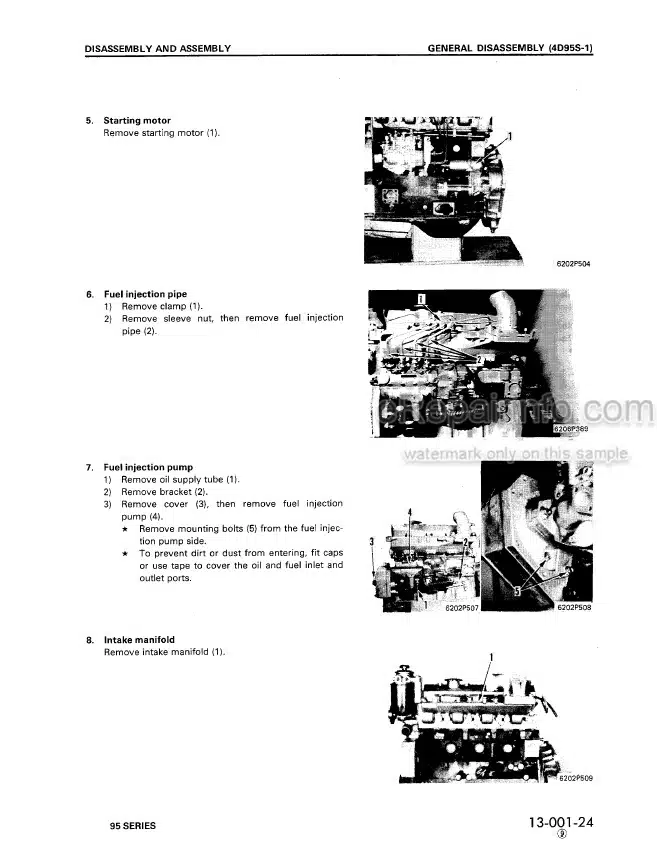

Starting Motor

Alternator

Engine Oil Cooler Core

Fuel Injection Pump Assembly

Water Pump

Turbocharger

Nozzle Holder

Thermostat

Engine Hood

Cylinder Head

Fuel Tank

Radiator, Oil Cooler

Hydraulic

Engine

Radiator, Guard

Damper

Transmission

PTO

Transmission

Steering Case

Priority Valve

Brake Control Valve

Transmission Shift Valve

Transmission Pressure Valve

Steering Piston

Parking Brake Cylinder

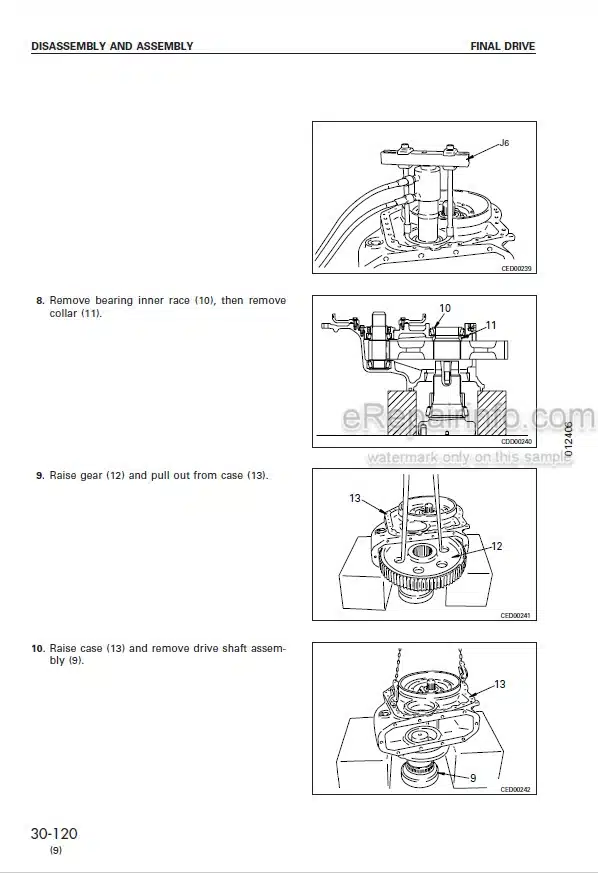

Final Drive

Idler. Recoil Spring

Idler

Track Roller

Carrier Roller

Track Shoe

Press-Fitting Jig Dimension Table For Link Press

One Link

Hydraulic Pump

Main Control Valve

Main Relief Valve

Blade Angle Cylinder

Blade Lift Cylinder

Blade Tilt Cylinder

Hydraulic Cylinder

Work Equipment

Hydraulic

ROPS Roof, Guard

Canopy

Operator Cab

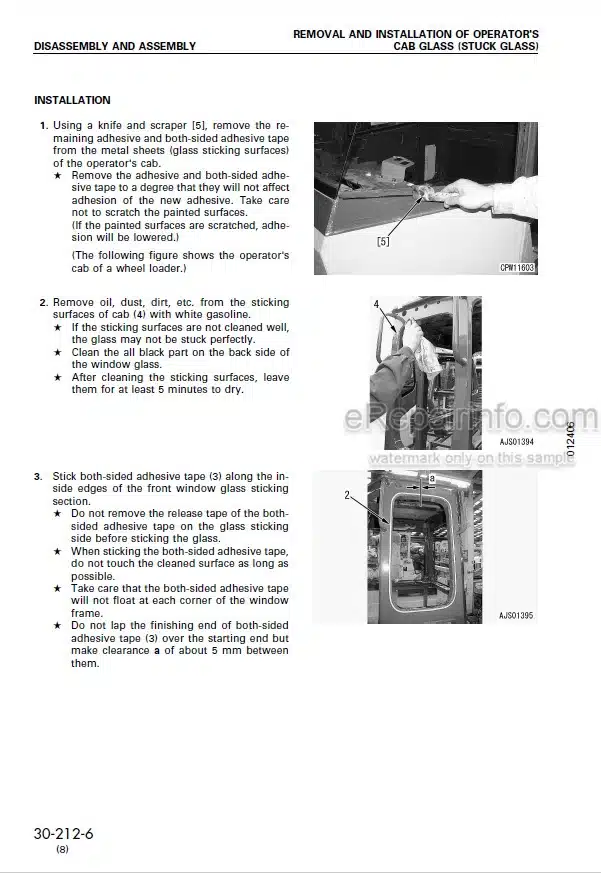

Operator Cab Glass (Stuck Glass)

Floor Frame

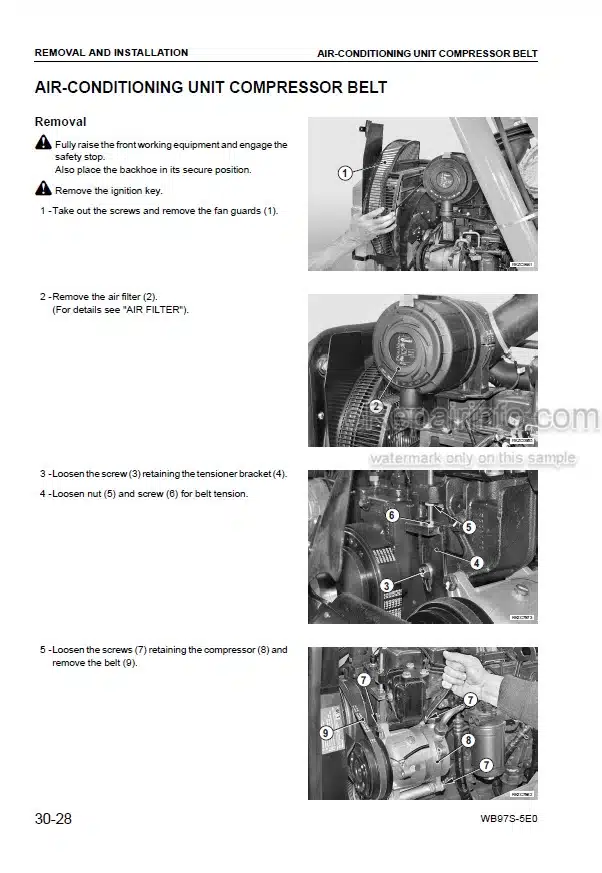

Air Conditioner Compressor

Air Conditioner Condenser

Monitor

DT Connector Pin

DH Connector Pin

Repair Procedure For Wiring Harness

-MAINTENANCE STANDARD

Damper, Universal Joint

Hydraulic + Power Train Pump

Transmission

Transmission Control Valve

Bevel Gear Shaft, Steering Clutch, Steering Brake

Steering PPC Valve

Steering Piston

Priority Valve

Brake Valve

Parking Brake Cylinder

Final Drive

Track Frame, Recoil Spring

Idler

Track Roller

Carrier Roller

Track Shoe

Main Control Valve

Work Equipment Cylinder

Work Equipment

-OTHERS

Powertrain Hydraulic System Diagram

Power Train Hydraulic Circuit Diagram

Work Equipment Hydraulic System Diagram

Work Equipment Hydraulic Circuit Diagram

Actual Electric Wiring Diagram

Electrical Circuit Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.