Factory Shop Manual For Komatsu Crawler Tractor. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 1235

Number: CEBM019106

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Crawler Tractor

D51EX-22

SN B10001 And Up

D51PX-22

SN B10001 And Up

Contents

-FOREWORD

Safety

How To Read The Shop Manual

Hoisting Instructions

Push Pull Coupler

Explanation Of Maintenance Standard Terms

Standard Tightening Torque

Electric Wire Code

Conversion Tables

Coating Materials

-GENERAL

Specification Drawing

Specification

Weight Table

Table Of Fuel, Coolant And Lubricants

-STRUCTURE AND FUNCTION

Engine And Cooling System

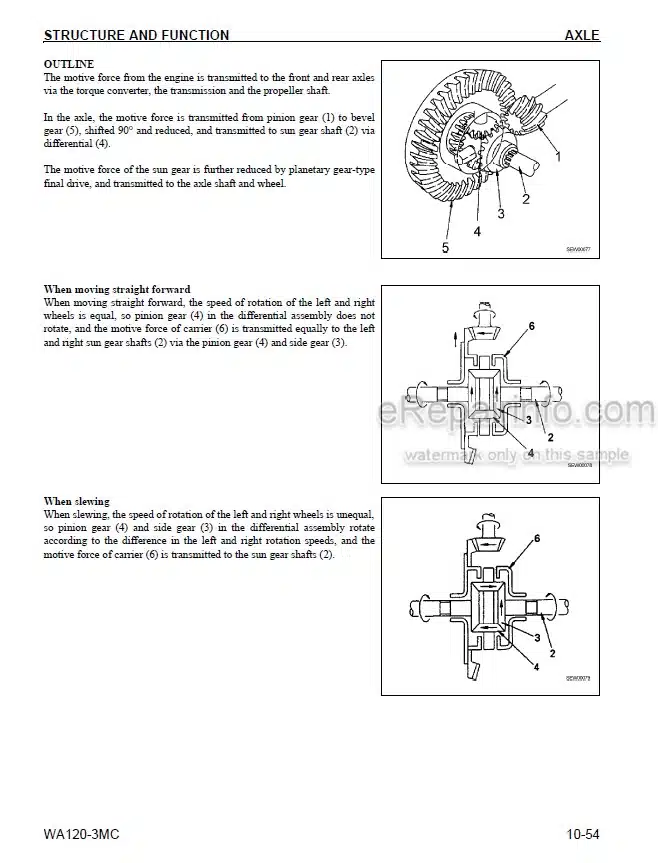

Powertrain

Under Carriage And Frame

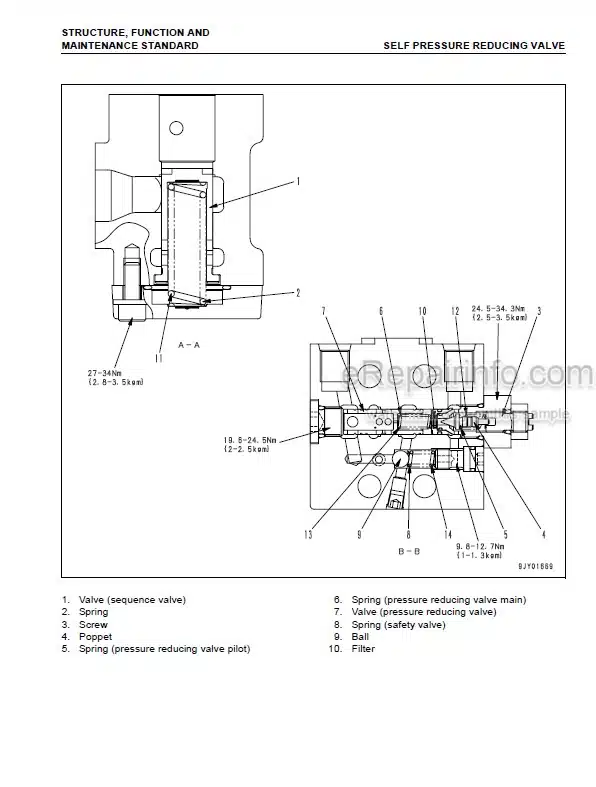

Hydraulic System 1 (HST)

Hydraulic System 2 (Work Equipment)

Work Equipment

Cab And Its Attachments

Electrical System

-STANDARD VALUES TABLE

Standard Value Table For Engine

Standard Value Table For Chassis

Performance Measuring Posture And Method

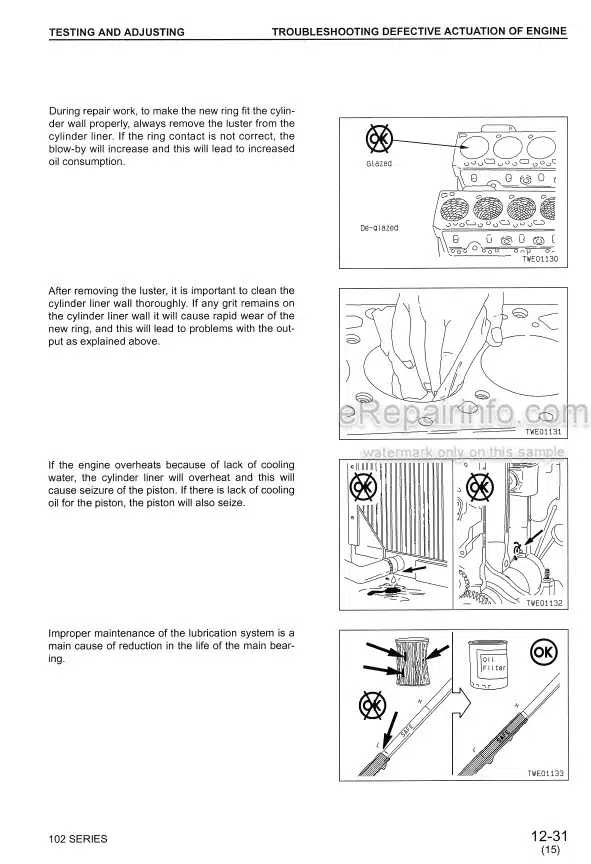

-TEST AND ADJUSTING

List Of Tools

Engine

Handling Controller High-Voltage Circuit

Fuel System

Fan (Work Equipment) Pump Pressure

Fan Speed

Decelerator Pedal

HST Oil Pressure

Motor Control Valve Outlet Pressure

Parking Brake Lever

Brake Performance

Brake Pedal Linkage

Emergency Release Of Parking Brake

Idler Clearance

Track Shoe Tension

Work Equipment

Hydraulic Circuit

Blade Center Ball Adjustment

Blade Pitch Ball Adjustment

Diodes

Monitor Panel (EMMS) – Special Functions

Preparation Work For Troubleshooting For Electrical System

Electric/Hydraulic Devices Are Adjusted/Replaced

PM-Clinic

-TROUBLESHOOTING

Points To Remember When Troubleshooting

Sequence Of Events In Troubleshooting

Precautions When Carrying Out Maintenance

Electric Wire Code

Classification By Thickness

Checks Before Troubleshooting

Categories And Method Of Using Troubleshooting Charts

T-Adapter Table

Mode Chart

Troubleshooting By Error Code

Information In Troubleshooting Table

Error Codes

Before Carrying Out Troubleshooting (E-Mode)

Information In Troubleshooting Table

Method Of Using Troubleshooting Charts

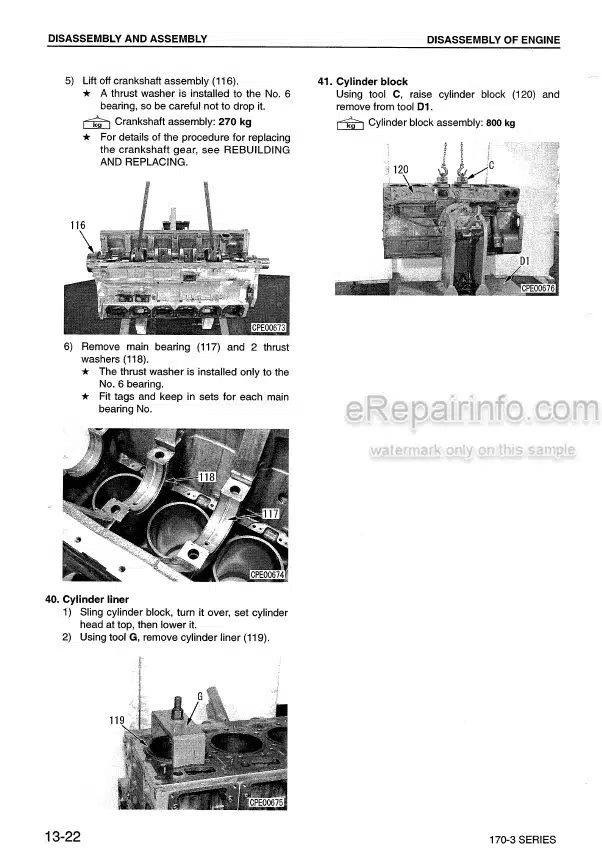

-DISASSEMBLY AND ASSEMBLY

Precautions When Carrying Out An Operation

Special Tool List

Connector Repair Procedures

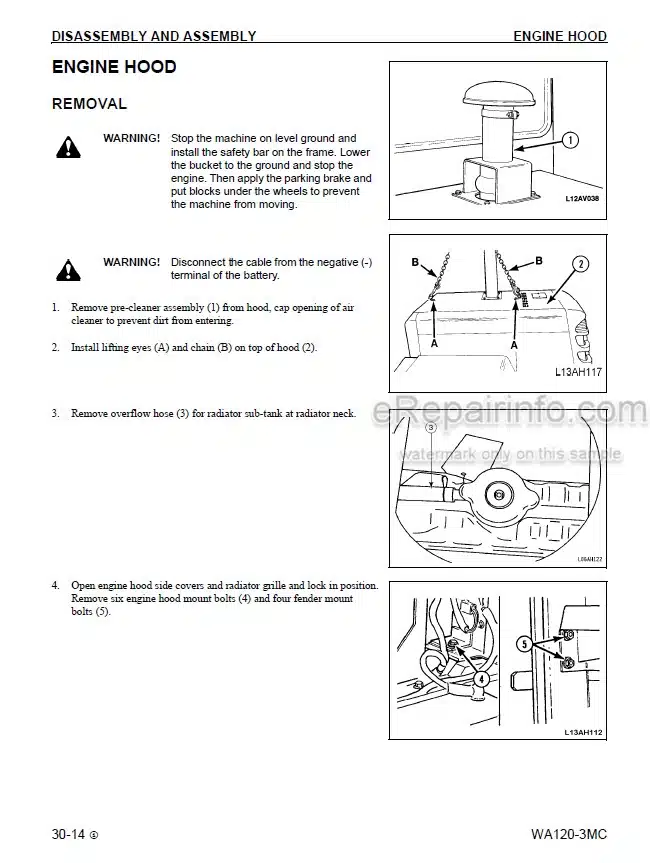

Nose Guard (Hood)

Muffler And Exhaust Stack

Cab

Monitor Panel And HST Controller

Komtrax Controller

Seat

Air Conditioner/Heater

Foot Heater

Foot Heater Overhaul Procedures

Engine And HST Pump

Drive Dampener

HST Pump Overhaul Procedures

Work Equipment Pump Overhaul Procedures

Diesel Engine Overhaul Procedures

Track System

Whole Disassembly And Assembly Of Track Shoe (Plus Type Track Shoe)

Field Disassembly And Assembly Of One Link (Conventional Type Track Shoe)

Field Disassembly And Assembly Of One Link (Plus Type Track Shoe)

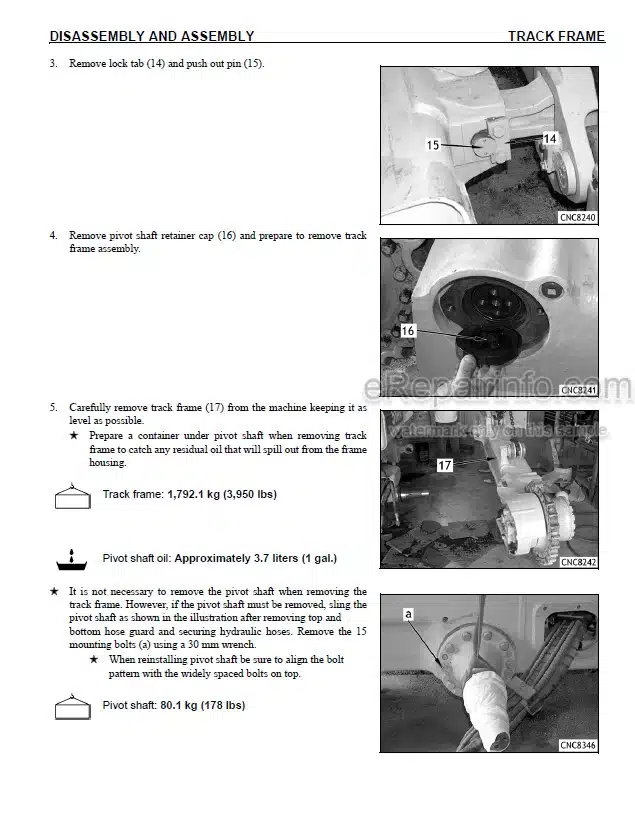

Track Frame

Front Track Idler

Track Roller

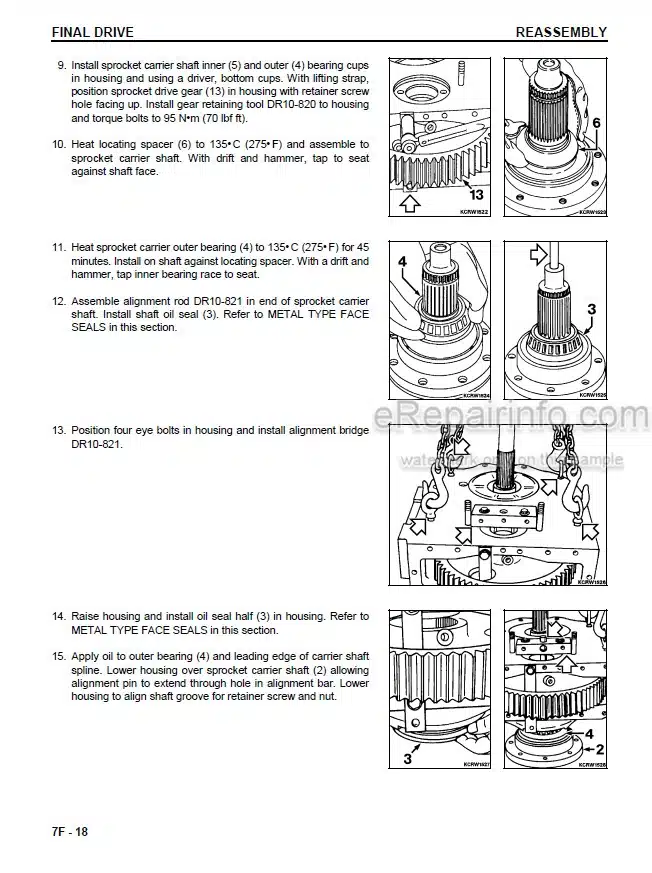

Final Drive

Final Drive Overhaul Procedures

Travel Motor Overhaul Procedures

Fan Motor

Fan Motor Overhaul Procedures

DB 12 Valve

Cooling Package

Fuel Tank

Hydraulic Tank

Work Equipment

Cylinder Overhaul Procedures

-OTHERS

Connector Arrangement Drawing And Electrical Circuit Diagram

Connector Location View

Cab Electrical Accessories

Air Conditioner And Heater Unit

Hydraulic System

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.