Factory Service Manual For Komatsu Hydraulic Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 512

Issued: august 2002

Searchable: Yes

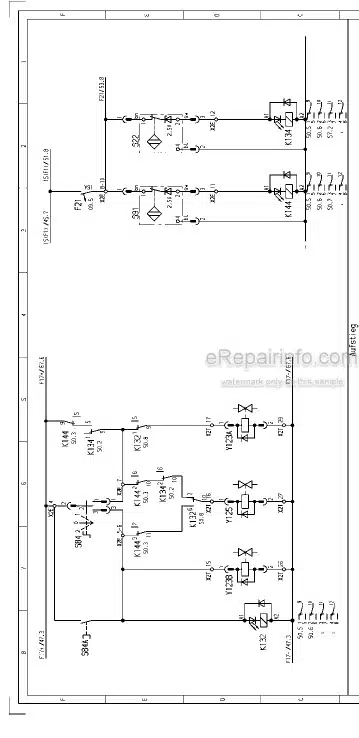

Wiring Diagrams: Yes

Model

Komatsu Hydraulic Excavator

PC5500-6 Diesel

SN 15012; 15013

Contents

SAFETY – FOREWORD

TECHNICAL DATA (LEAFLET)

ASSEMBLY PROC EDURE (BROCHURE)

-MAIN ASSEMBLY GROUPS

Superstructure

Under Carriage

Attachment

-DRIVE

Engine And PTO Mounts

Coupling

Air- Filter

Fan Drive And Radiator Assembly

Radiator Fan Drive Speed Adjustment

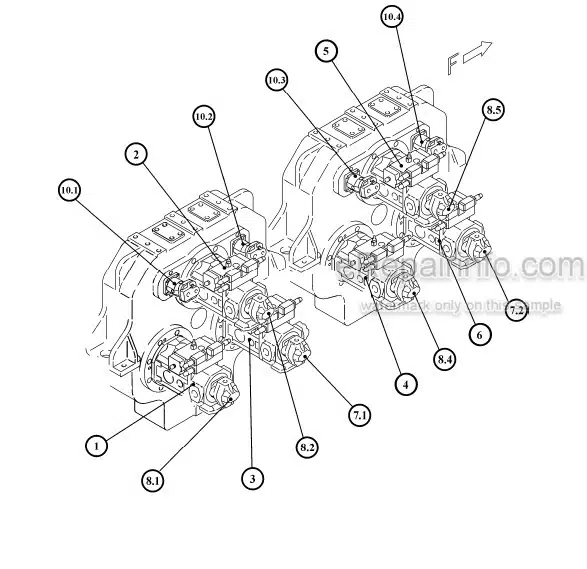

Pump Distributor Gearbox (PTO)

Pump-Spline Lubrication

PTO Lubrication And Cooling

Hydraulic Pumps – Location, Drive Speed And Flow Rates

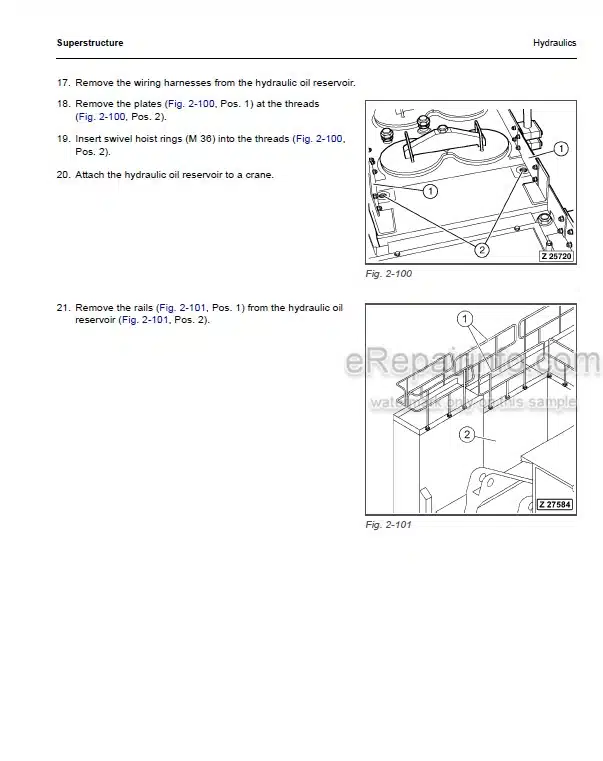

-HYDRAULIC OIL TANK

Main Oil Tank, Location Of Switches, Sensors Etc.

Suction Oil Tank With Strainers

Return Oil Collector Tube With Strainer

Back Pressure Valve

Return And Leak Oil Filter

Breather Filter

-HYDRAULIC OIL COOLING

General

Function Of The Hydraulic Oil Cooling Circuit

Adjustment Of The Back Pressure Valve

Fan Drive (Two Stage Cooler Fan RPM Control)

Pressure Relief Valves And Solenoid Valve

Fixed Displacement Pump, With Variable Setting

-CONTROLLING

Control And Filter Panel Location Of Components (Valves, Switches, Sensors Etc.)

Pilot Pressure Supply And Adjustments

Remote Control Valves Arrangement

Function Principle Of The Electro-Hydraulic- Proportional Control

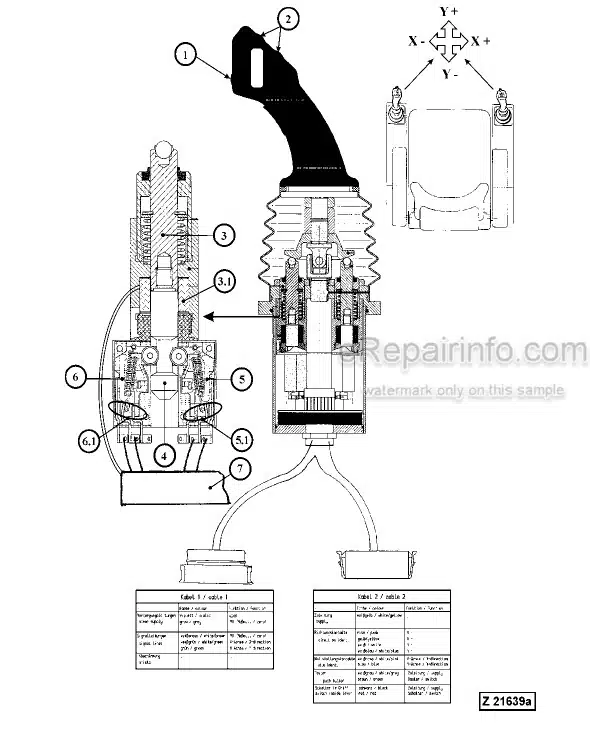

Potentiometer Control (Lever, Joy Stick)

Potentiometer Control (Pedal)

Proportional Amplifier Module, Type A (For Swing Brake Only)

Proportional Amplifier Module, Type B (For Boom, Stick, Bucket, Swing And Travel)

Ramp Tune Module (Analogue Command Value Module For Boom, Stick, Travel And Swing Function)

Adjustments Of Amplifier Modules (General)

Adjusting The Amplifiers Type B

Adjusting The Amplifiers Type A

Adjusting The Ramp Tune Module

-COMPONENTS-HYDRAULIC

Main Control Blocks And High Pressure Filter FSA

Main Control Blocks And High Pressure Filter BHA

Distributor Manifold – Restrictor Blocks FSA

Distributor Manifold – Restrictor Blocks BHA

Restrictor Block With Pressure Relief Valve

Anti Cavitation Valve Block

Remote Control Valves

Directional Solenoid Valves (4 Way / 3 Positions)

Proportional Solenoid Valves

High Pressure Filter

Control Blocks And Valves

Load Holding Valve

Travel Brake Valve

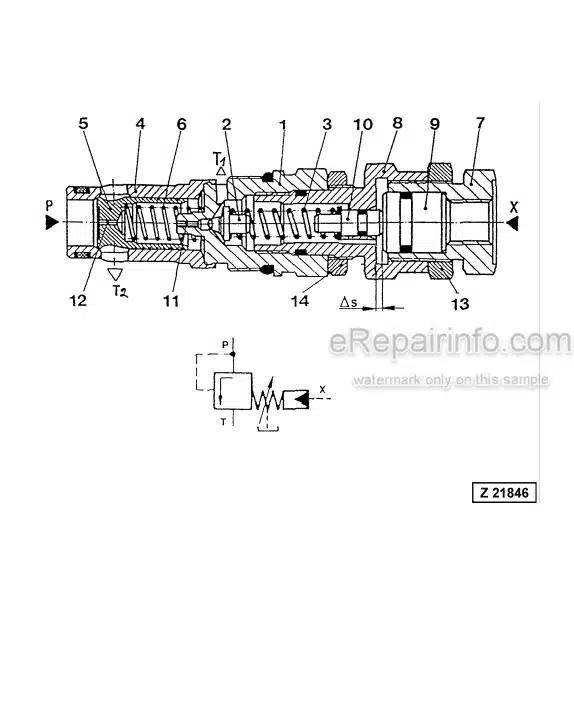

Pressure Reducing Valve

Directional Solenoid Valves (2 Positions / 4-Ways)

Pressure Increasing Valve

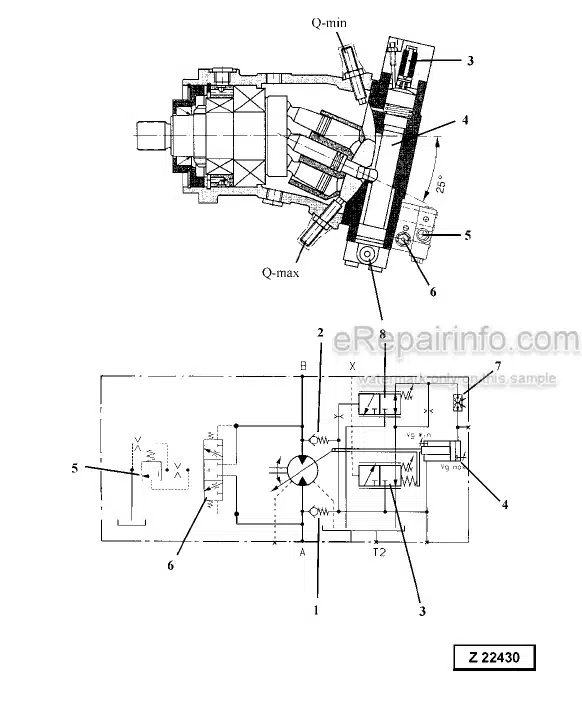

-MAIN HYDRAULIC PUMPS AND PUMP REGULATION

Main Pumps

Electronic Pump Regulation System

Hydraulic Constant Regulation System

Determination Of The Peak Point

-OPERATING HYDRAULIC

Hydraulic For The Attachment Cylinder FSA And BHA

Hydraulic For The Swing Circuit

Hydraulic For The Travel Circuit

Hydraulically Oil Heating System FSA

-HYDRAULIC TRACK TENSIONING SYSTEM

Functional Description

Pressure Increasing Valve

Tensioning Cylinder

Adjustments / Checks

Functional Test

-HYDRAULIC OPERATED ACCESS LADDER

General

Function Of Hydraulic Operated Access Ladder

-CENTRAL REFILLING SYSTEM

General

Function

-HINTS FOR THE HYDRAULIC CIRCUIT DIAGRAM

General

Function

APPENDIX

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.