Factory Shop Manual For Komatsu Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 836

Number: SEBM031307 (june 2005)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Excavator

PC750-7 Serial No.20001 and up

PC750SE-7 Serial No.20001 and up

PC750LC-7 Serial No.20001 and up

PC800-7 Serial No.40001 and up

PC800SE-7 Serial No.40001 and up

Contents

-GENERAL

Specification Drawings

Specifications

Weight Table

Fuel, Coolant And Lubricants

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

PTO

PTO Lubrication System

Power Train

Swing Machinery

Swing Circle

Final Drive

Sprocket

Track Frame And Recoil Spring

Idler

Carrier Roller

Track Roller

Track Shoe

Motor Grease Pump

Hydraulic Tank

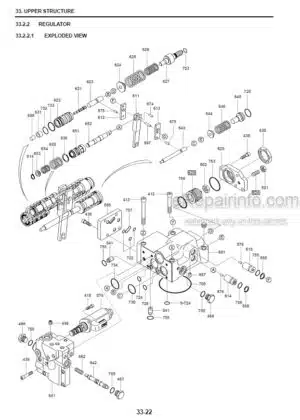

Hydraulic Pump

Return Oil Filter

Line Oil Filter

Drain Oil Filter

L.H. 5-Spool Control Valve

R.H. 4-Spool Control Valve

Straight-Travel Valve

Swing Motor

Center Swivel Joint

Travel Motor

PPC Control Relief Valve

PPC Accumulator

Valve Control

Work Equipment, Swing PPC Valve

Travel PPC Valve

Solenoid Valve

Hydraulic Cylinder

Work Equipment

Dimensions Of Work Equipment

Air Conditioner

Engine Control

Machine Control System

Monitor System

Sensors

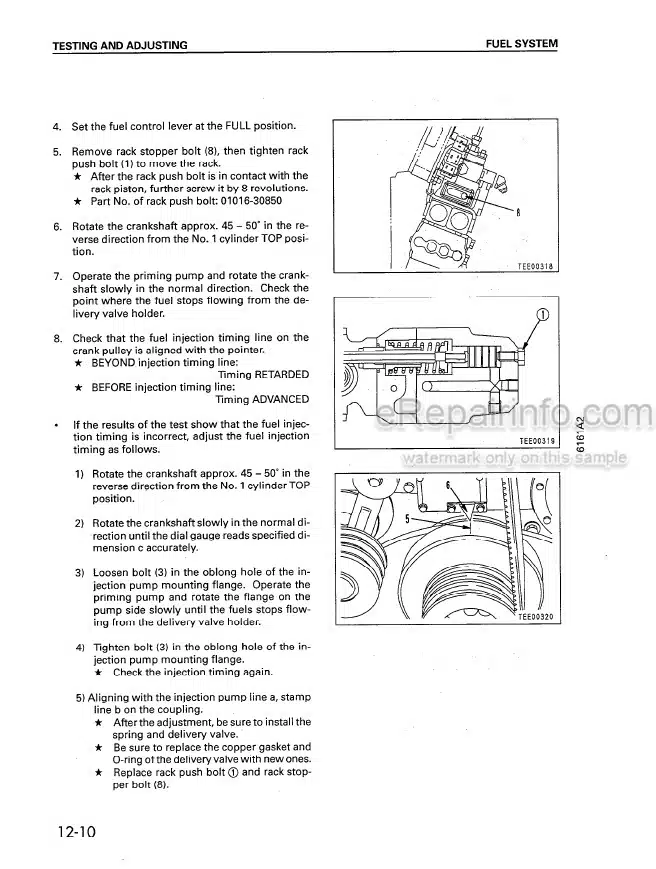

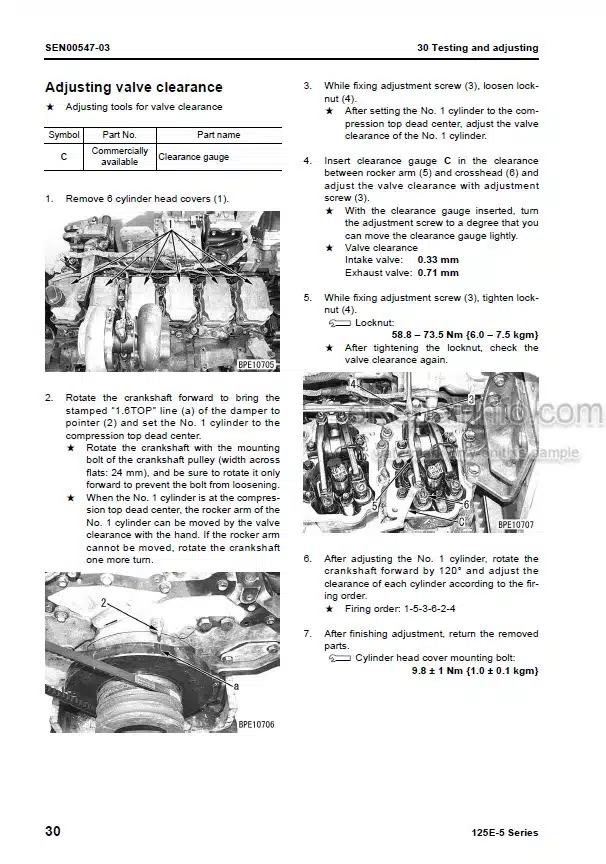

-TESTING AND ADJUSTING

Standard Value Table For Engine

Standard Value Table For Chassis

Testing And Adjusting

Troubleshooting

-DISASSEMBLY AND ASSEMBLY

Method Of Using Manual

Precautions When Carrying Out Operation

Special Tool List

Removal And Installation Of Fuel Supply Pump Assembly

Removal And Installation Of Fuel Injector Assembly

Removal And Installation Of Nozzle Tip

Removal And Installation Of Engine Front Seal

Removal And Installation Of Engine Rear Seal

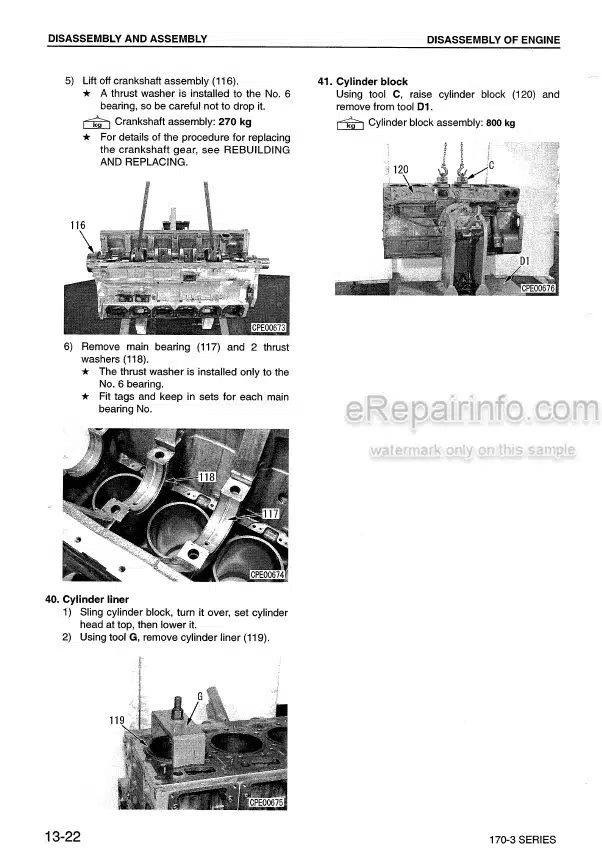

Removal And Installation Of Cylinder Head Assembly

Removal And Installation Of Aftercooler Core

Removal And Installation Of Fan Guard, Radiator And Hydraulic Oil Cooler Assembly

Removal And Installation Of Fuel Cooler And Air Conditioner Condenser Assembly

Removal And Installation Of Fuel Tank Assembly

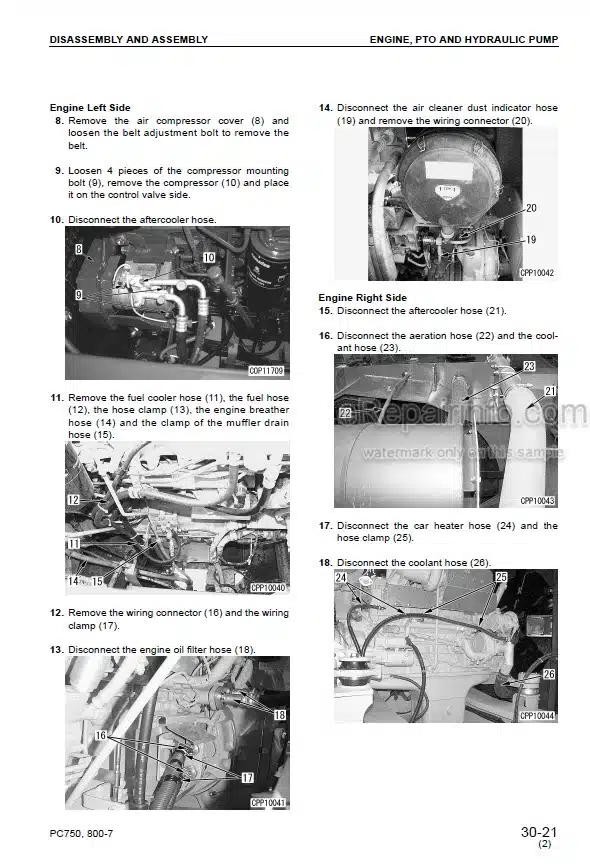

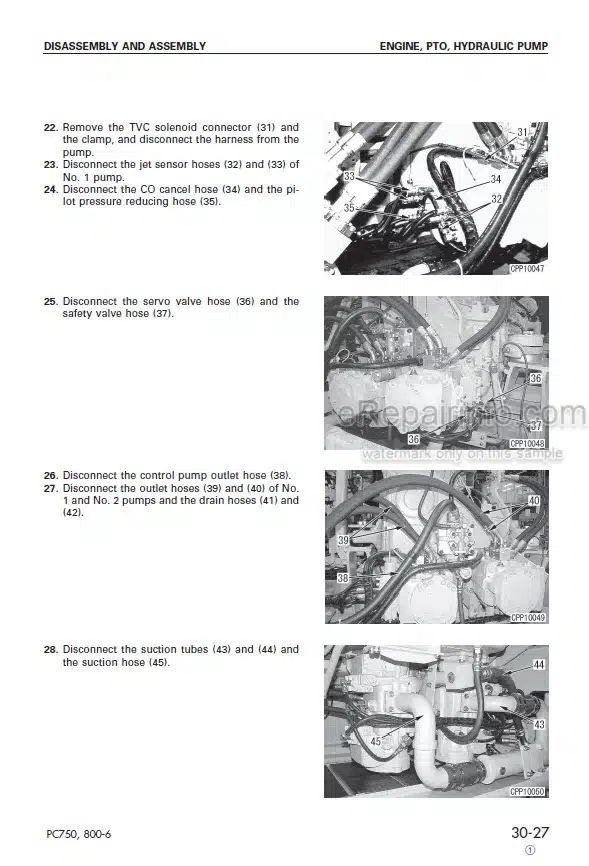

Removal And Installation Of Engine, PTO And Hydraulic Pump Assembly

Removal And Installation Of PTO Assembly

Disassembly And Assembly Of PTO Assembly

Disassembly And Assembly Of Final Drive Assembly

Removal And Installation Of Revolving Frame Assembly

Removal And Installation Of Swing Machinery Assembly

Disassembly And Assembly Of Swing Machinery Assembly

Removal And Installation Of Swing Circle Assembly

Removal And Installation Of Track Shoe Assembly

Disassembly And Assembly Of One Link In Field

Removal And Installation Of Idler Assembly

Disassembly And Assembly Of Idler Assembly

Disassembly And Assembly Of Idler Adjustment Cylinder Assembly

Removal And Installation Of Recoil Spring Assembly

Disassembly And Assembly Of Recoil Spring Assembly

Removal And Installation Of Carrier Roller Assembly

Disassembly And Assembly Of Carrier Roller Assembly

Removal And Installation Of Track Roller Assembly

Disassembly And Assembly Of Track Roller Assembly

Removal And Installation Of Hydraulic Tank Assembly

Removal And Installation Of Main Pump (No.1 Pump) Assembly

Removal And Installation Of Main Pump (No.2 Pump)

Removal And Installation Of Main Pump Input Shaft Oil Seal

Removal And Installation Of Control And PTO Lubrication Pump Assembly

Disassembly And Assembly Of Main Relief Valve Assembly

Removal And Installation Of Control Valve Assembly

Disassembly And Assembly Of Control Valve Assembly (Work Equipment)

Removal And Installation Of Solenoid Valve Assembly

Removal And Installation Of Boom Damping Valve Assembly

Removal And Installation Of Swing Motor Assembly

Removal And Installation Of Center Swivel Joint

Disassembly And Assembly Of Center Swivel Joint Assembly

Removal And Installation Of Travel Motor Assembly

Disassembly And Assembly Of Work Equipment PPC Valve Assembly

Disassembly And Assembly Of Travel PPC Valve Assembly

Removal And Installation Of Bucket Cylinder Assembly (Back Hoe)

Removal And Installation Of Bucket Cylinder Assembly (Loading Shovel)

Removal And Installation Of Arm Cylinder Assembly (Back Hoe)

Removal And Installation Of Arm Cylinder Assembly (Loading Shovel)

Removal And Installation Of Boom Cylinder Assembly (Back Hoe)

Removal And Installation Of Boom Cylinder Assembly (Loading Shovel)

Removal And Installation Of Bottom Dump Cylinder Assembly (Loading Shovel)

Disassembly And Assembly Of Hydraulic Cylinder Assembly

Removal And Installation Of Bucket Assembly (Back Hoe)

Removal And Installation Of Bucket Assembly (Loading Shovel)

Removal And Installation Of Arm Assembly (Back Hoe)

Removal And Installation Of Arm Assembly (Loading Shovel)

Removal And Installation Of Boom Assembly (Back Hoe)

Removal And Installation Of Boom Assembly (Loading Shovel)

Removal And Installation Of Work Equipment (Back Hoe)

Removal And Installation Of Work Equipment (Loading Shovel)

Removal And Installation Of Operator’s Cab Assembly

Removal And Installation Of Operator’s Cab Glass (Stuck Glass)

Removal And Installation Of Front Window Assembly

Removal And Installation Of Counterweight Assembly

-OTHERS

Hydraulic Circuit Diagram

Electrical Circuit Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet