Factory Shop Manual For Komatsu Hydraulic Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 315

Number: WEBMPC9500

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Hydraulic Excavator

PC95-1

SN 5000001 And Up

Contents

-STRUCTURE AND FUNCTION

P.T.O.

Powertrain

Final Drive – Sprocket

Track Frame

Idler And Recoil Spring

Carrier Roller

Track Roller

Track Shoe

Swing Circle

Swing Machinery

Check Valve And Oil Cooler Safety By-Pass

Hydraulic Circuit Diagram

Main Hydraulic Pump

Pump Drive

Summation Horsepower Control

3 Circuit Control Valve

Mode-System

Auxiliary Pump

Control Valve (Ports)

Control Valve (Valve)

Swing Motor

Swing Motor Relief Valve

Center Swivel Joint

Travel Motor

Travel Acceleration Valve

Servocontrol Feed Unit

Swing Motor Braking Circuit Selector Valve

Accumulator

R.H. PPC Valve

L.H. PPC Valve

Travel PPC Valve

2Nd Boom PPC Valve

Boom Swing PPC Valve

Blade PPC Valve

Blade Safety Valve

Solenoid Valves

Electrical Circuit Diagram (Engine Line)

Electrical Circuit Diagram (Solenoid Valve)

Electrical Circuit Diagram (Light Line)

-TESTING AND ADJUSTMENTS

Normal Or Standard Technical Data

Equipment For Testing, Adjusting, And Identifying Faults

Measuring The Engine Speed

Valve Clearance Adjustment

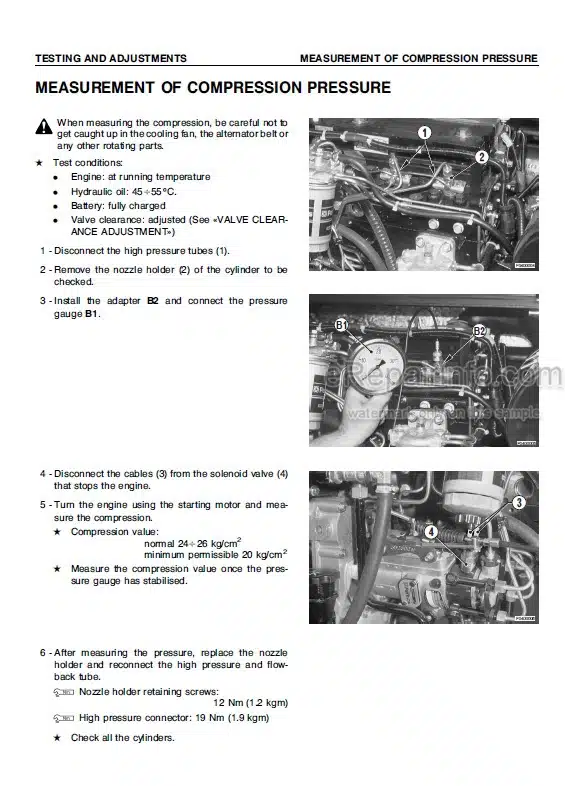

Measurement Of Compression Pressure

Checking And Tightening The Fan-Belt

Adjusting The Stroke Of The Accelerator Lever

Adjusting PPC Valves Clearance

Adjusting The Safety Microswitch

Centering The Stroke Of The Blade Control Lever

Measuring The Swing Circle Axial Clearance

Testing And Adjusting Track-Shoe Tension

Bleeding Air – Releasing Residual Pressure

Checking And Regulating Pressure In The Hydraulic Circuits

Checking The Intervention Point Of The Summation Horsepower Control

Checking The Initial Horsepower Control Point For The 3-Circuit Control Valve

Checking And Adjusting Pressures In The Servocontrol Supply Units

Adjusting The Main Safety Valve Of Pump P4

Measuring Pump Delivery

Measuring Travel Deviation

Adjusting The Maximum Speed Of The Travel Motors

Checking The Correct Functioning Of The Travel Acceleration Valve

Testing For Internal Oil Leakage In The Travel Motors

Adjusting Boom And Arm Safety Valves

Adjusting 2Nd Boom Safety Valves

Measuring The Initial Intervention Point Of The Overload Sensor

Adjusting The Valve That Controls The Closing Speed Of The 2Nd Boom

Measurement Of Internal Oil Leakages In The Swing Motor

Checking For Leakages Inside The Swivel Joint

Analysis Of The Causes Of Hydraulic Drifts

Troubleshooting

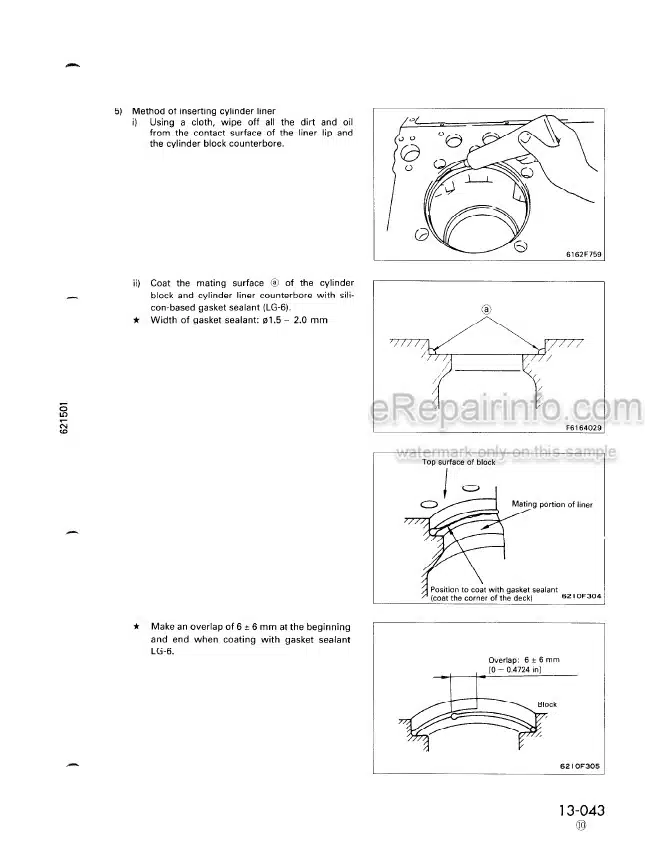

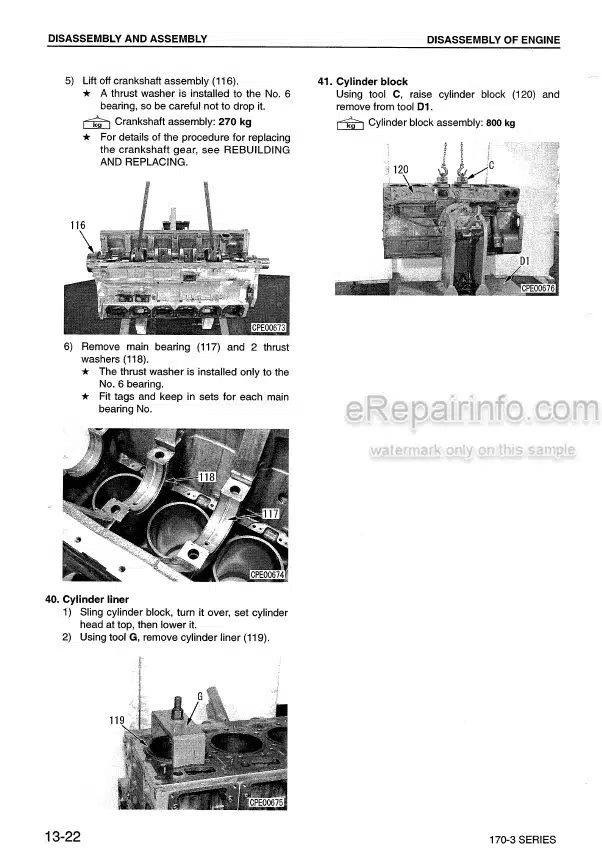

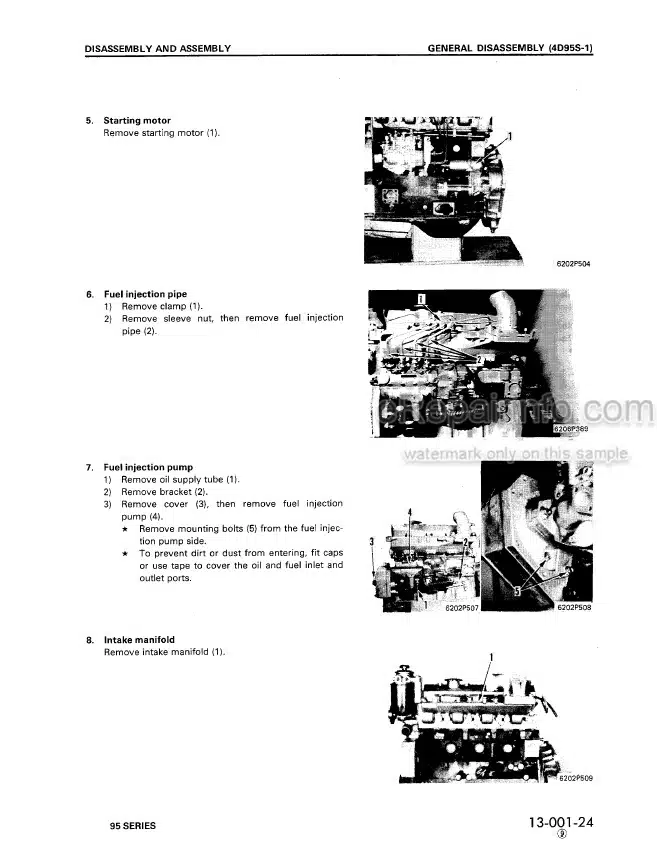

-DISASSEMBLY AND ASSEMBLY

Precautions To Be Taken When Working

Special Tools

Starter Motor

Alternator

Nozzle Holder

Air Filter Group

Muffler

Engine Hood

Fixed Hood

Seat

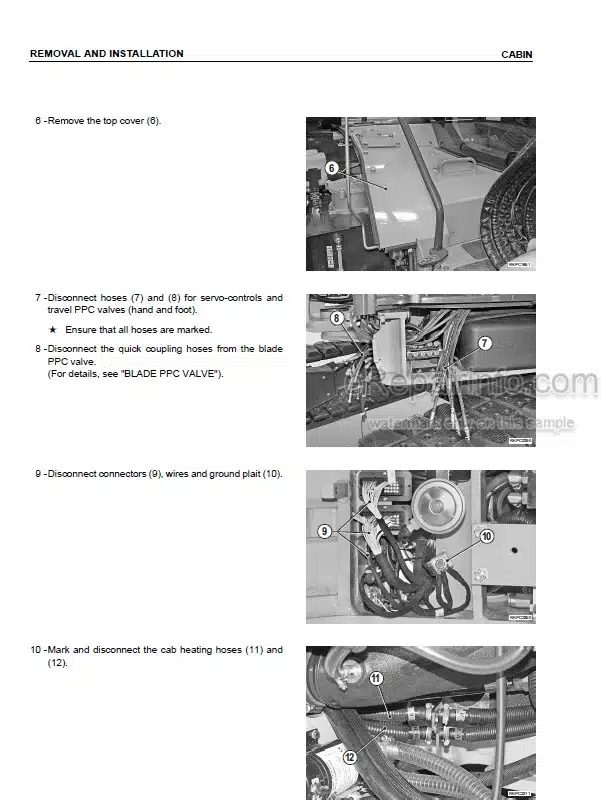

Cabin

Counterweight

Radiator

Hydraulic Oil Cooler

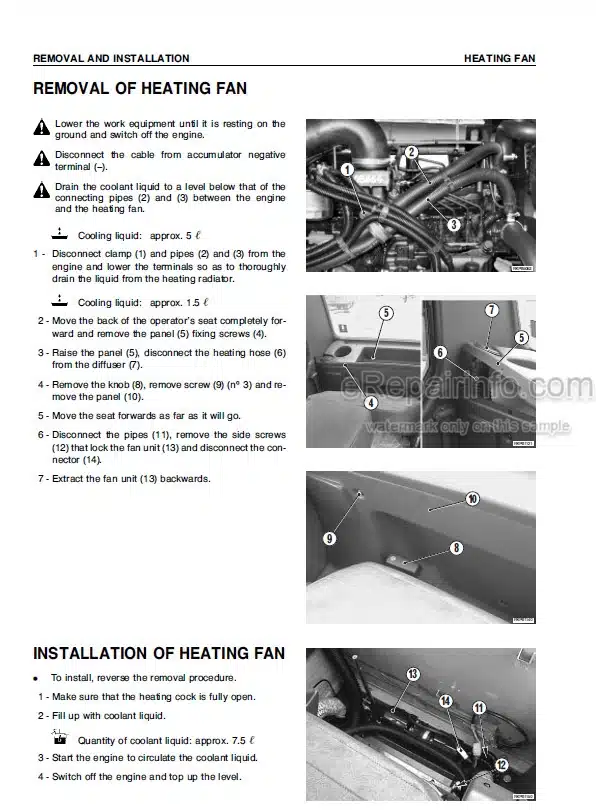

Heating Fan

Fuel Tank

Hydraulic Oil Tank

Engine-Pump Group

Pump Group

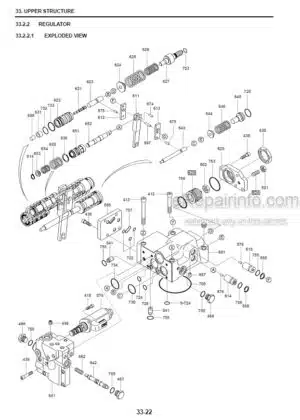

Hydraulic Pump

Gear-Pump

Engine-Pump Coupling Joint

Swivel Joint

Swing Motor

Swing Machinery

Revolving Frame

Swing Circle

Travel Motor

Track Shoes

Sprocket

Final Drive

Idler And Recoil Spring

Idler

Recoil Spring And Cylinder

Track Roller

Carrier Roller

R.H. PPC Valve (Boom – Bucket)

L.H. PPC Valve (Arm-Swing)

Blade PPC Valve

PPC Valve (For Travel, Boom Swing, 2-Piece Boom)

Servocontrol Feed Unit

Control Valve

Boom Cylinder

Boom Cylinder (For 2-Piece Boom)

2-Piece Boom Cylinder

Arm Cylinder

Bucket Cylinder

Boom Swing Cylinder

Blade Cylinder

Work Equipment Cylinders

Overload Sensor

Work Equipment (For The Boom)

Work Equipment (2-Piece Boom Version)

Bucket

Arm

2-Piece Boom

Boom

Boom (2-Piece Boom Version)

Swing Bracket

Blade

-MAINTENANCE STANDARD

P.T.O.

Travel Machinery

Sprocket

Track Frame And Recoil Spring

Idler

Carrier Roller

Track Roller

Track Shoe

Swing Circle

Swing Machinery

Check Valve And Oil Cooler Safety By-Pass

Pump Drive

Summation Horsepower Control – Mode System

Auxiliary Pump

Control Valve

Swing Motor Relief Valve

Travel Motor

Servocontrol Feed Unit

L.H. And R.H. PPC Valve

2Nd Boom, R.H. Travel, L.H. Travel And Boom Swing PPC Valve

Blade PPC Valve

Blade Safety Valve

Cylinders

Work Equipment (1 – Piece Boom)

Work Equipment (2 – Piece Boom)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet