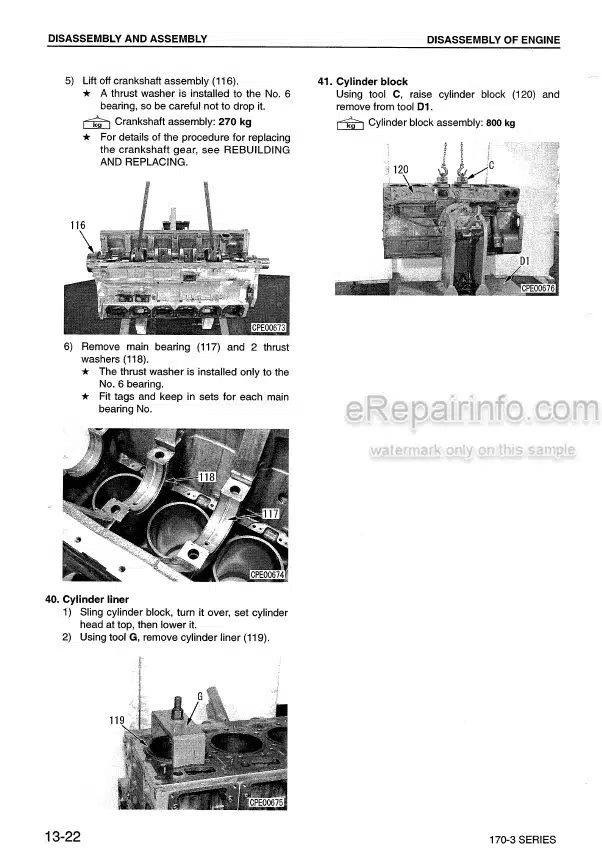

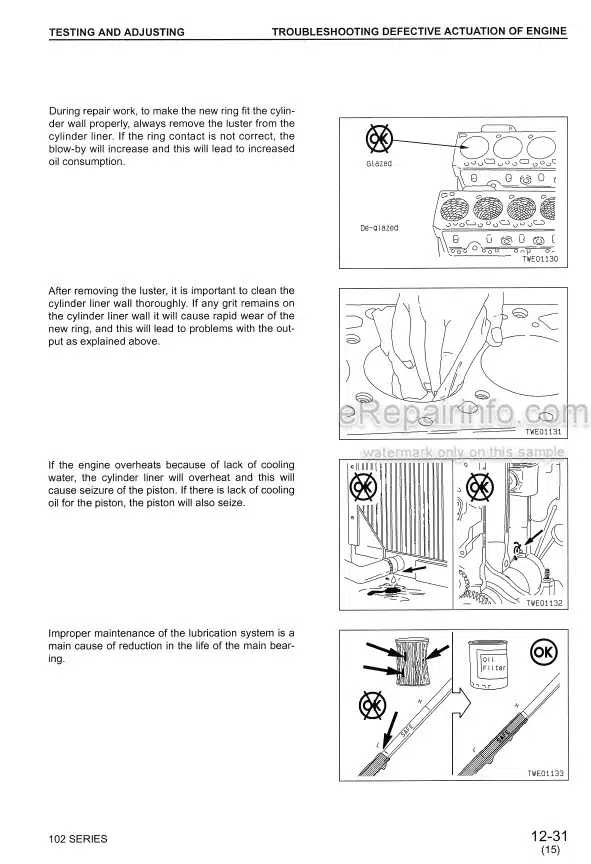

Factory Shop Manual For Komatsu Wheel Excavator. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 435

Number: UEBM002800 (may 2007)

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Komatsu Wheel Excavator

PW130-7K

SN K40001 And Up

Contents

FOREWORD

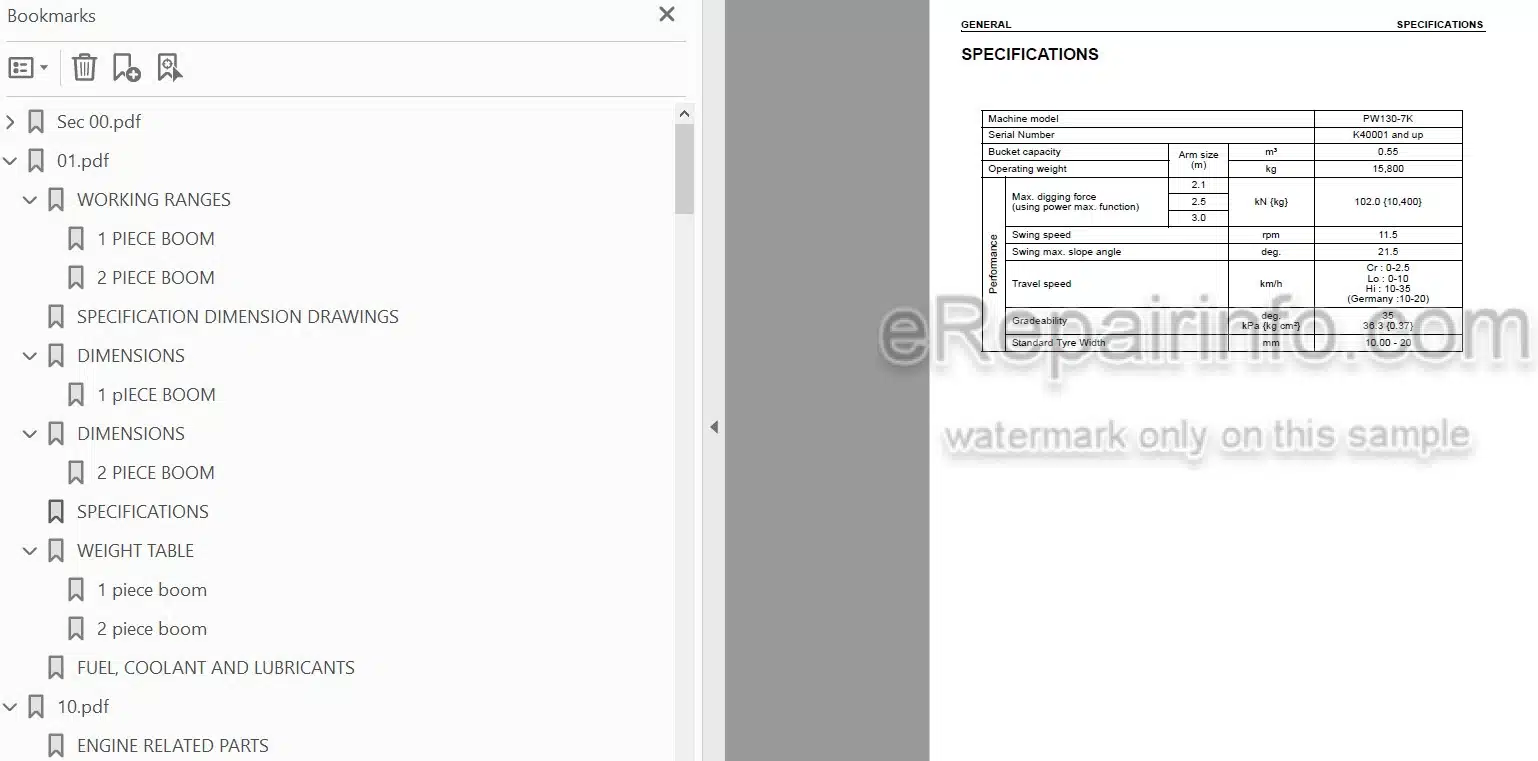

-GENERAL

Specification Dimension Drawings

Working Range

Specifications

Weight Table

Fuel, Coolant, And Lubricants

-STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

Engine Related Parts

PTO (Coupling)

Radiator – Oil Cooler – Charge Air Cooler

Power Train

Swing Circle

Swing Machinery & Motor

Undercarriage

Transmission

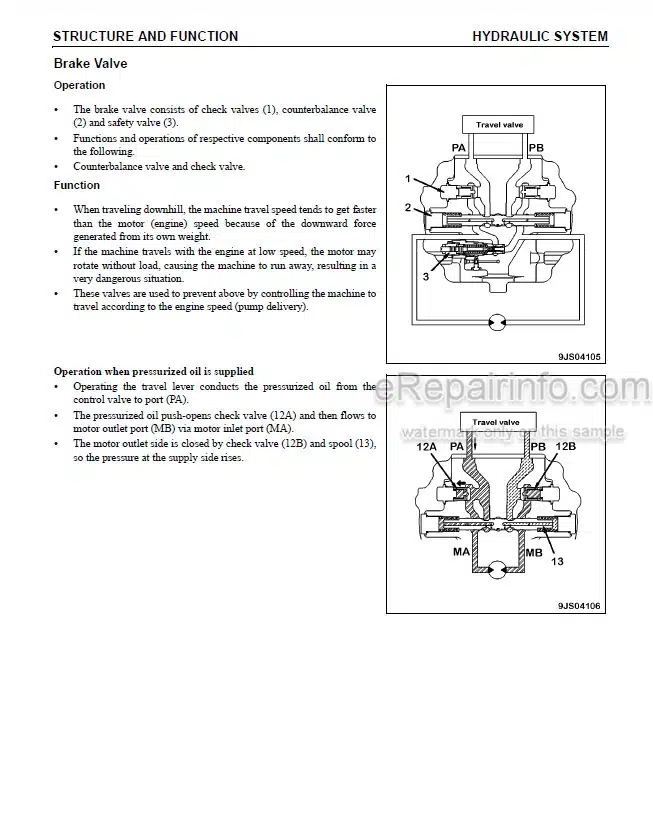

Travel Motor

Clutch Control Circuit

Axle

Suspension Lock Cylinder

Braking System

Brake/Steer Pump

Priority Valve

Power Brake Valve

Accumulator For Brake System

Steering Train

Steering Column

Orbitrol Valve

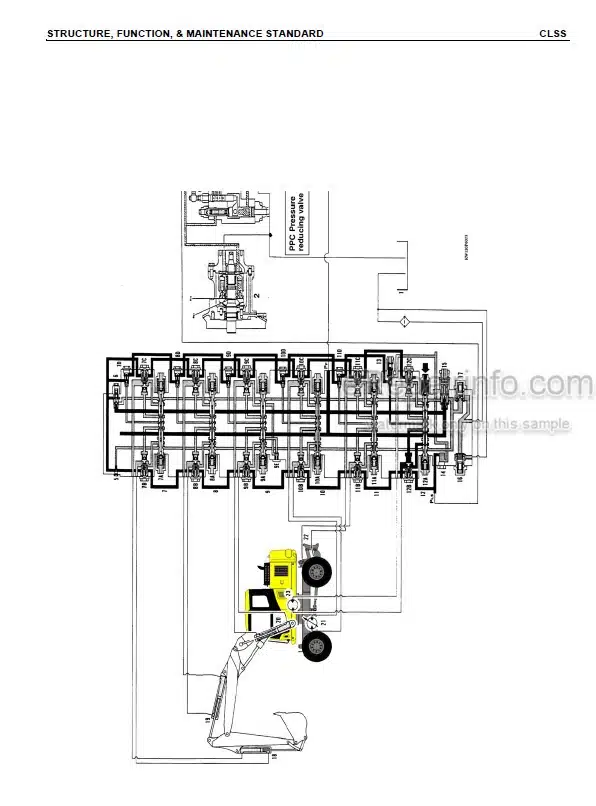

Hydraulic Layout Drawing

Hydraulic Circuit Diagram

Hydraulic Tank

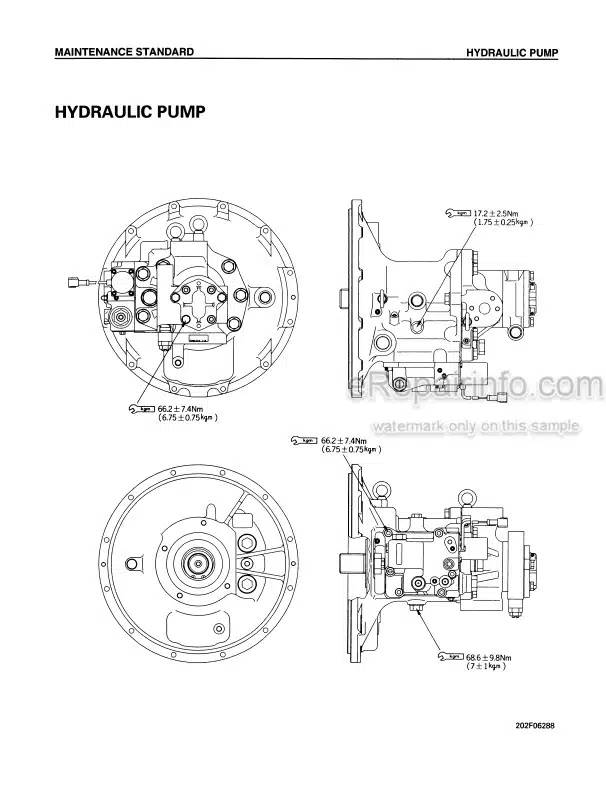

Hydraulic Pump

Pilot Pressure Control System

Control Valve

CLSS

Swing Motor

Centre Swivel Joint

Travel PPC Pedal

Work Equipment – Swing PPC Valve

Service PPC Valve

Solenoid Valve Manifold

Boom Safety Valve

Hydraulic Cylinder (Boom-Arm-Bucket)

Outrigger Cylinder

Dozer Cylinder

Work Equipment

Air Conditioner

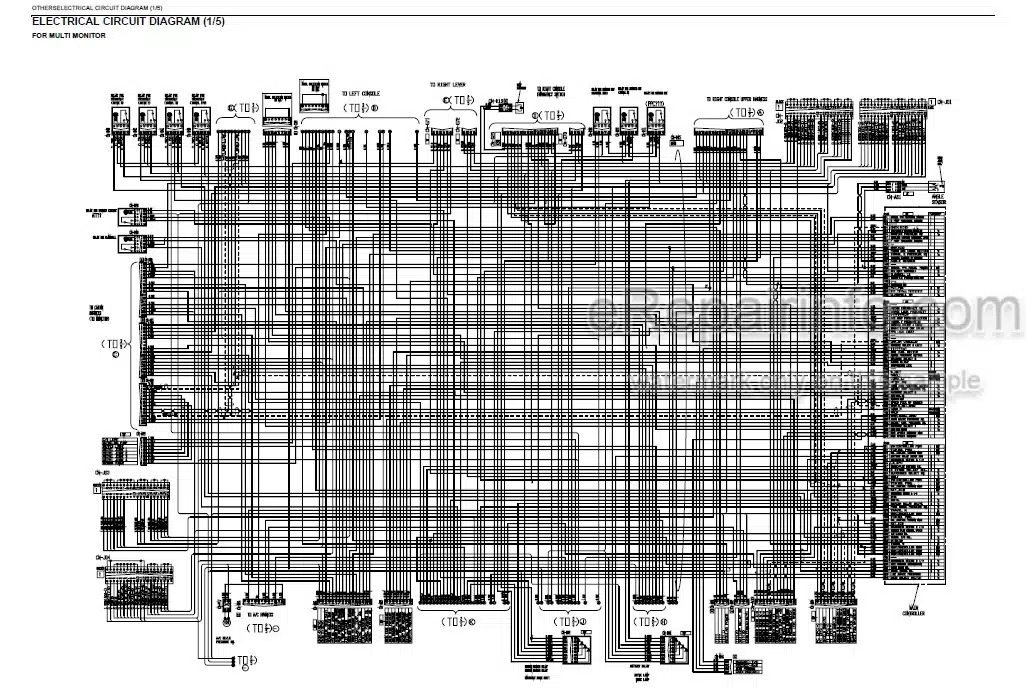

Electrical Wiring Diagram

Engine Control System

Electronic Control System

Machine Monitor System

Overload Warning Device

Sensor

Breaker Mode Hydraulic Performance (Main Valve Bypassed)

Breaker Mode Hydraulic Performance (Via Main Valve)

Travel System

Steering System

Service Brake And Suspension System

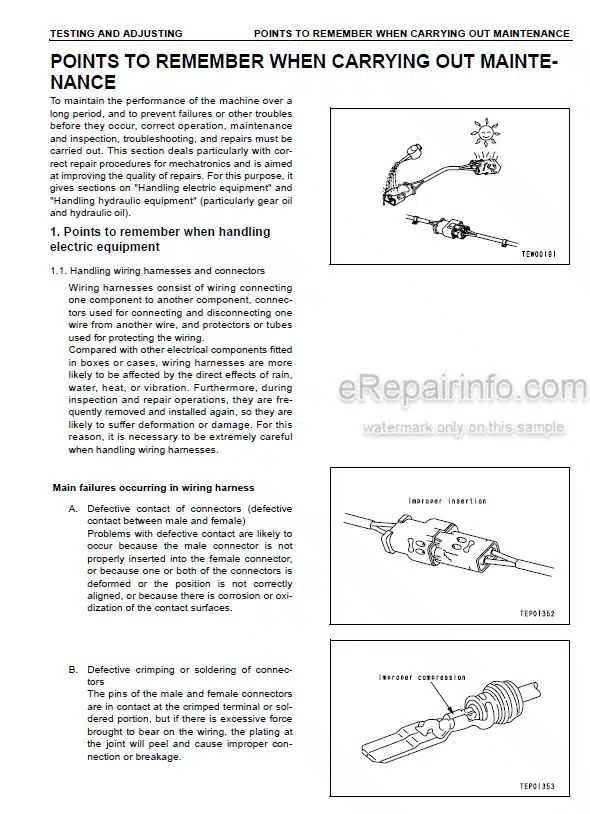

-TESTING AND ADJUSTING

Inspection And Adjustment Of Air Compressor Belt Tension

Adjustment Of Engine Speed Sensor

Testing And Adjusting Governor Motor Lever Stroke

Measurement Of Clearance In Swing Circle Bearings

Testing And Adjusting Hydraulic Pressure In Work Equipment, Swing And Travel Circuit

Testing And Adjusting PC Valve Output Pressure (Servo Piston Input Pressure)

Testing And Adjusting LS Valve Output Pressure (Servo Piston Input Pressure) And LS Differential Pressure

Inspection And Adjustment Of Control Circuit Oil Pressure

Measurement Of Solenoid Valve Output Pressure

Testing Travel Motor Relief Pressure

Adjusting Travel Motor Relief Pressure

Testing Locations Causing Hydraulic Drift Of Work Equipment

Measuring Oil Leakage

Release Of Remaining Pressure In Hydraulic Circuit

Bleeding Air

Inspection Procedures For Diode

Measuring Rotating Speed Of Propshaft

Testing Transmission Clutch Control Circuit

Special Function Of Monitor Panel

Preparations For Troubleshooting Electrical System

-OTHERS

Hydraulic Circuit Diagram

Electrical Circuit Diagram

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.