Factory Operation And Maintenance Manual For Komatsu Backhoe Loader. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Quantity of Manuals: 2

Pages: 338; 340

Number: WENAM00080 (february 2016); WENAM00081 (july 2016)

Bookmarks: Yes

Searchable: Yes

Model

Komatsu Backhoe Loader

WB97R-5E0

SN F90001 And Up

Contents

FOREWORD

SAFETY INFORMATION

-SAFETY LABELS

Safety Labels Using Pictogram

-NOISE

Noise Outside The Cab

Noise Inside The Cab

Vibrations To Which The Operator Is Subjected

Guide When Working In Areas Where Air Pollution

-INTRODUCTION

Intended Uses

Demolition Work

Improper Or Unauthorized Use

Main Characteristics

Positions And Directions Of The Machine

-PRODUCT IDENTIFICATION

Machine Identification Number (Pin)

Machine Identification Plate And Product Identification Number (PIN)

Machine Serial Number Plate

Engine Serial Number And Exhaust Gas Emission Plate

Front Axle Serial Number

Rear Axle Serial Number

Transmission Serial Number

Cab Serial Number

TABLE TO ENTER SERIAL NO AND DISTRIBUTOR

-SAFETY PLATES

Position Of The Safety Plates

Pictograms And Relevant Meanings

-GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

Precautions Before Starting Operation

Preparations For Safe Operation

Fire Prevention

Precautions When Getting On Or Off Machine

Do Not Get Caught In Work Equipment

Falling Objects, Flying Objects And Intruding Objects Prevention

Cautions Related To ROPS

Unauthorized Modifications

Precautions Related To Attachments And Options

Precautions Related To Cab Glass

Precautions When Running Engine Inside Building

-PRECAUTIONS FOR OPERATION

Precautions For Jobsite

-STARTING THE ENGINE

Use Warning Tags

Checks And Adjustment Before Starting Engine

When Starting Engine

In Cold Areas

Start Engine With Booster Cables

Operation

Transport

Lifting Objects With Lifting Device (Optional Equipment)

-PRECAUTIONS FOR MAINTENANCE

Precautions Before Starting Inspection And Maintenance

Precautions For Inspection And Maintenance

FINAL DISPOSAL OF THE MACHINE

-GENERAL VIEW OF MACHINE

Front General View

Backhoe General View

Cab Inside General View

-EXPLANATION OF COMPONENTS

Instruments And Controls

Push Buttons On The Front Loader Control Lever

Cab Switches And Electric Accessories

Machine Controls

Adjusting The Controls

-FUSES AND RELAYS

Central Unit Fuses – Relays And Engine Line

Ventilation, Heating And Air Conditioning Fuses And Relays

Fuses And Relays

-GUARDS, CAB AND DRIVER S SEAT

Engine Hood

Cab

Ventilation And Heating

Air Conditioner

Seat

Safety Belt

Fire Extinguisher

First Aid Kit

Technical Documentation

Storage Compartment

-SAFETY LOCKS

Front Loader Locks

Backhoe Locks

REFUELLING PUMP

-KOMTRAX SYSTEM

General Precautions

-USE OF THE MACHINE

Checks To Be Carried Out Before Starting The Engine

Starting The Engine

Warming The Engine

Heating The Hydraulic Oil

Running-In

How To Move The Machine

-PARKING THE MACHINE

Parking On Level Ground

Parking On Slopes

STOPPING THE ENGINE

-TRANSPORTATION

Precautions For Transporting Machine

Select Transportation Method

Precautions For Loading And Unloading With Trailer

Procedures For Loading And Securing Machine On The Trailer

-USING THE MACHINE IN COLD WEATHER

Precautions To Be Taken In The Cold Season

Other Precautions

Precautions To Be Taken At The End Of Work

PRECAUTIONS TO BE TAKEN AT THE END OF THE WINTER

-USING THE MACHINE AS A LOADER

Bucket Position Indicator

Organizing The Work Area

Changing The Standard Front Bucket

-USING THE MACHINE AS AN EXCAVATOR

Positioning The Bucket According To The Work That Must Be Carried Out

Positioning The Machine For Digging Operations

Digging Method

Lifting Loads With Equipment

Changing The Backhoe Bucket

-LONG PERIODS OF INACTIVITY

Preparing The Machine

Preparing The Engine

Maintenance During A Period Of Inactivity

Restarting The Engine

After The Period Of Inactivity

Ambient Temperature Range For Operation And Long Term Storage

-TROUBLESHOOTING

How To Remove The Machine

After The Fuel Has Run Out

If The Battery Is Down

-OTHER TROUBLES

Electrical Circuit

Hydraulic System

Articulation Greasing

Converter

Engine

-RULES FOR MAINTENANCE

Service Meter Reading

Komatsu Genuine Replacement Parts

Komatsu Genuine Lubricants

Always Use Clean Washer Fluid

Fresh And Clean Lubricants

Check Drained Oil And Used Filter

Caution For Refilling Oil Or Fuel

Welding Instructions

Do Not Drop Things Inside Machine

Dusty Jobsites

Avoid Mixing Oil

Locking Inspection Covers

Bleed Air From Hydraulic Circuit

Precautions When Installing Hydraulic Hoses

Checks After Inspection And Maintenance

Fuel And Lubricants To Match The Ambient Temperature

Close Engine Hood Securely

-OUTLINE OF MAINTENANCE

Handling Oil, Fuel, Coolant, And Performing Oil Clinic

Handling Electrical Components

-DRIVING TORQUES

Standard Driving Torques For Screws And Nuts

Specific Driving Torques For Screws And Nuts

Standard Driving Torques For Hoses With Orfs

-MAINTENANCE PLAN

Maintenance Plan

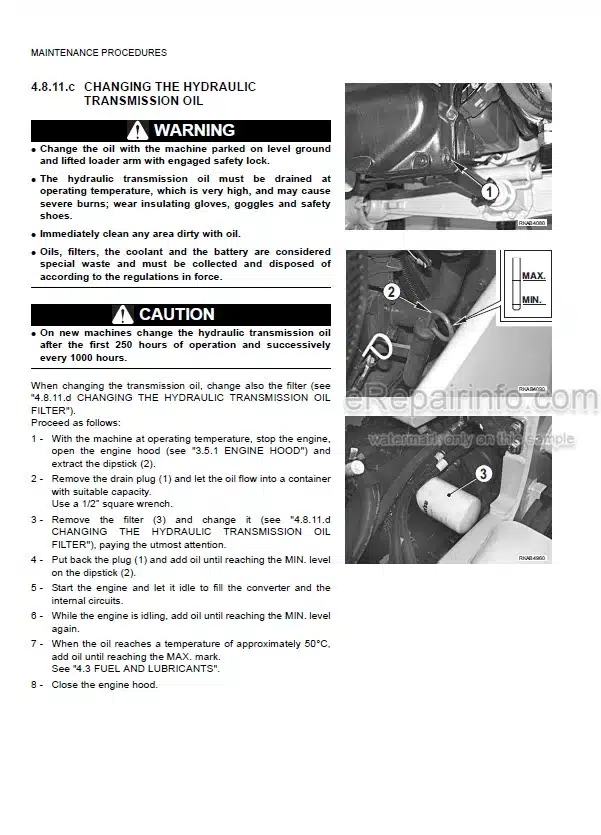

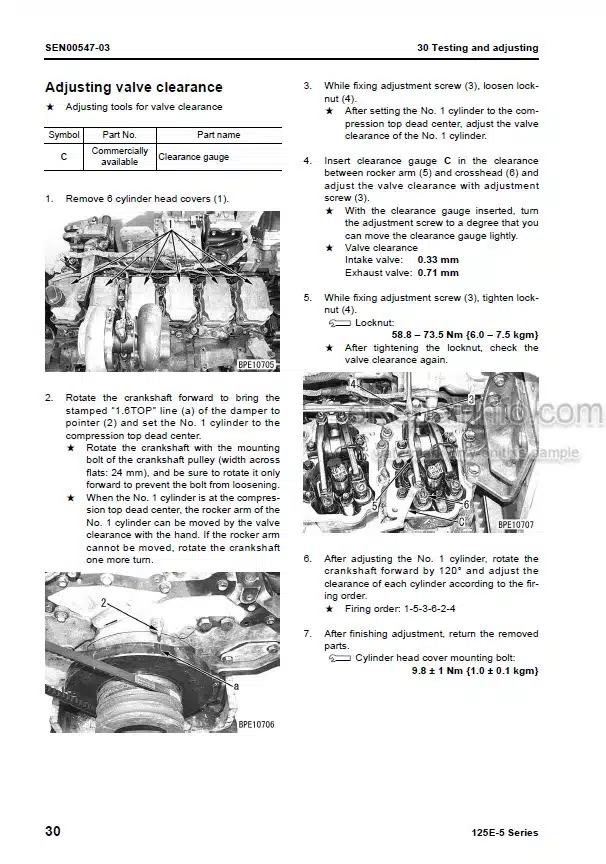

-MAINTENANCE PROCEDURES

When Required

Maintenance Intervals In Case Of Use Of The Hydraulic Breaker

Maintenance Interval According To Fuel Used

Checks To Be Carried Out Before Starting The Engine

Maintenance Every 10 Hours Of Operation

Maintenance After The First 50 Hours Of Operation

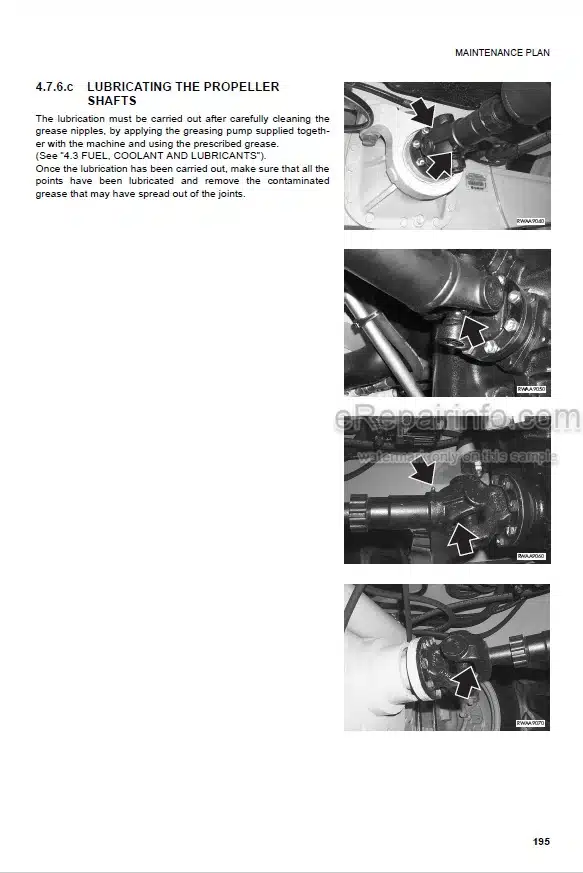

Maintenance Every 50 Hours Of Operation

Maintenance Every 125 Hours Of Operation

Maintenance After The First 250 Hours Of Operation

Maintenance Every 250 Hours Of Operation

Maintenance After The First 500 Hours Of Operation

Maintenance Every 500 Hours Of Operation

Maintenance Every 1000 Hours Of Operation

Maintenance Every 2000 Hours Of Operation

Maintenance Every 3000 Hours Of Operation

Maintenance Every 4000 Hours Of Operation

END OF SERVICE LIFE

-SPECIFICATIONS

Overall Dimensions

Technical Characteristics

Working Ranges

Lifting Capacities

-AUTHORIZED OPTIONAL EQUIPMENT

Precautions Regarding Safety

Precautions Regarding The Installation Of Equipment

-SPECIFICATIONS

Arm-Pin Information

Attachment Guide

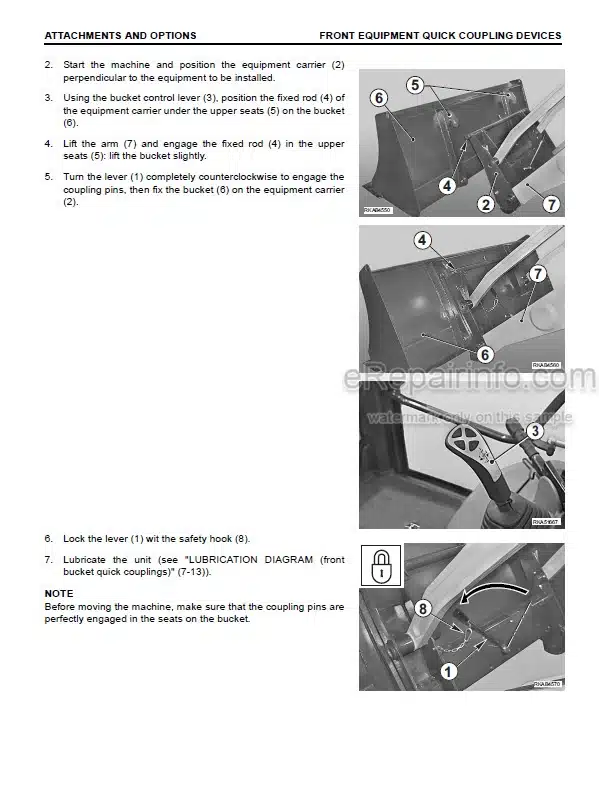

-FRONT EQUIPMENT QUICK COUPLING DEVICES

Manual Quick Coupling

Hydraulic Quick Coupling For Standard Bucket

Hydraulic Quick Coupling For 4In1 Bucket And Optional Equipment

-PALLET FORKS

Lifting Capacities (Pallet Forks)

Description

Using The Forks

Maintenance

-4 IN 1 BUCKET

Description And Controls

Installing The 4In1 Bucket

Using The 4In1 Bucket

Maintenance

-FORKS FOR PALLET ON BUCKET 4 IN 1

Description

Lifting Capacity (Forks For On Bucket 4 In 1)

Using The Forks

Preparing The Pallet Forks For Use

Removing The Forks

Installing The Forks

Maintenance

-BACKHOE TELESCOPIC ARM

Description And Control

Safety Devices

Using The Telescopic Arm

Maintenance

TELESCOPIC BOOM WITH PRE-INSTALLATION FOR HYDRAULIC BREAKER AND OPTIONAL TOOLS

-CONFIGURATION FOR THE INSTALLATION OF THE HYDRAULIC BREAKER

Description And Control

Use Of The Hydraulic Breaker And Rules To Be Observed

Installing And Removing The Hydraulic Breaker

-CONFIGURATION FOR THE USE OF OPTIONAL EQUIPMENT WITH UNIDIRECTIONAL OIL FLOW

Description And Control

Installing And Connecting The Equipment

Maintenance

-CONFIGURATION FOR THE USE OF THE HAND HYDRAULIC HAMMER

Description And Control

Installing And Removing The Hand Hammer

-LOAD STABILIZER SYSTEM (LSS)

Load Stabilizer System (LSS) Accumulator

-REAR EQUIPMENT MECHANICAL QUICK COUPLING DEVICE

Equipment Coupling And Release Procedure

-HYDRAULIC QUICK COUPLER OF THE REAR EQUIPMENT

Safety Devices

Quick Coupler To Backhoe Loader Connection

Control

Adjusting The Quick Coupler Operating Pressure

Quick Release Coupling Hydraulic Connections

Equipment Coupling And Release Procedure

Maintenance

-PERIODIC REPLACEMENT OF DEFINED LIFE PARTS

Defined Life Parts List

Safety Related Parts

Parts Subject To Wear That Periodically Need Changing

RECOMMENDED FUEL, COOLANT AND LUBRICANT

-LUBRICATION

Lubrication Diagram

Lubrication Diagram (4In1 Bucket And Pallet Forks)

Lubrication Diagram (Front Bucket Quick Couplings)

Lubrication Diagram (For Telescopic Boom)

-FUEL AND LUBRICANTS

Homologated Synthetic Biodegradable Lubricants “HEES”

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet