7Factory Service Manual For Kramer Telehandler. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 420

Issued: november 2011

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Kramer Telehandler

2506

Contents

-CAB OVERVIEW, USE, OPERATION

Machine Outside View

Inside Of Cab (Overview)

Instrument Panel, Multifunctional Lever, Switch Consoles (Overview)

Fields Of Application And Using A Machine With An Attachment

Legal Regulations Regarding Machine Operation

Type Labels And Component Numbers

Key-Based Drive Interlock (Option)

Drive Interlock With Code Input (Option)

Battery Master Switch (Option)

Avoiding Running The Engine Under Low-Load Conditions

Stopping The Diesel Engine

Jump-Starting The Diesel Engine (External Battery)

Pressure Relief On The Quickhitch Couplers

Overview Of Steering Modes (Option)

Steering Synchronisation (Wheels Front/Rear Axles)

Low-Speed Control (Option)

Rear Hydraulic Additional Control Circuit (Option)

Hydraulic Connection For Tipping Trailer (Option)

Autohitch Trailer Coupling (Option)

Automatic Trailer Coupling (Option)

Hydraulic Trailer Brake Connection (Option)

Fitting Attachments From Other Manufacturers (Option)

Towing The Machine

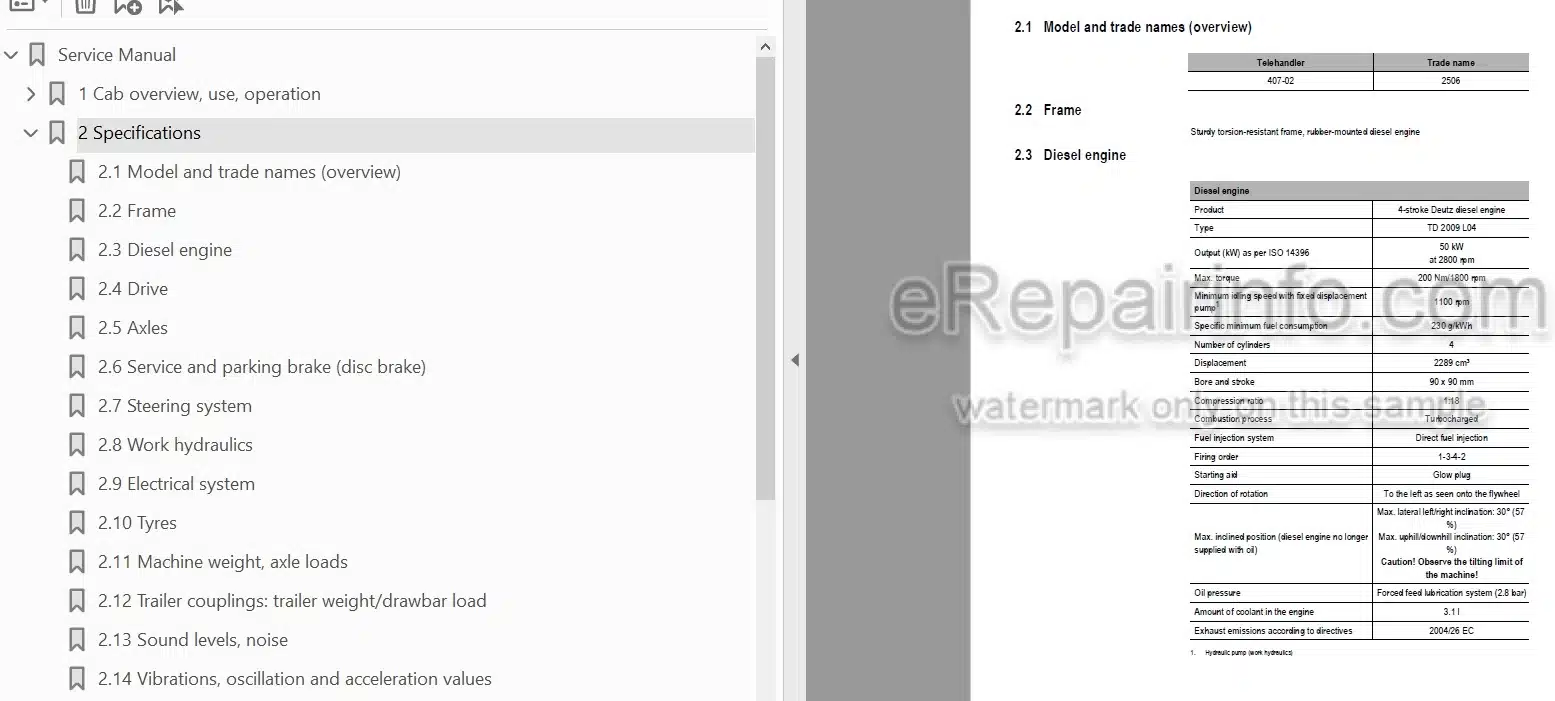

-SPECIFICATIONS

Model And Trade Names (Overview)

Frame

Diesel Engine

Drive

Axles

Service And Parking Brake (Disc Brake)

Steering System

Work Hydraulics

Electrical System

Tyres

Machine Weight, Axle Loads

Trailer Couplings: Trailer Weight/Drawbar Load

Sound Levels, Noise

Vibrations, Oscillation And Acceleration Values

Coolant Compound Table

Tightening Torques

Standard Bucket Payloads

Pallet Forks Payloads

Dimensions With Standard Bucket

Dimensions With Pallet Forks

-MAINTENANCE AND SERVICE WORK

Explanation Of Symbols On The Maintenance Label

Maintenance Label

Fluids And Lubricants

Maintenance Plan (Overview)

Important Notice Regarding Maintenance Work

Safety Strut For Telescopic Boom

Fuel System

Refuelling

Checking/Cleaning The Additional Fuel Filter (Water Separator, Option)

Bleeding The Fuel System

Replacing The Fuel Filter

Diesel Engine Lubrication System

Filling Up Engine Oil

Change The Engine Oil

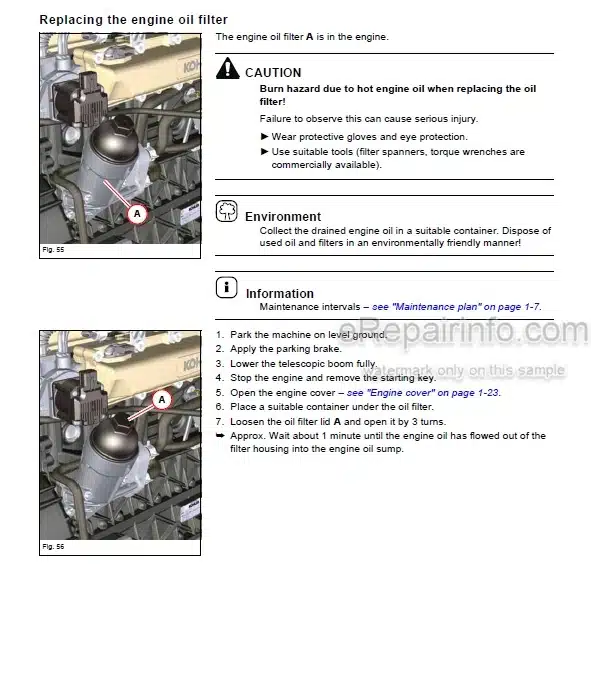

Replacing The Engine Oil Filter Cartridge

Diesel Engine And Hydraulics Cooling System

Temperature Gauge: Diesel Engine Coolant

Filling Up Coolant

Cleaning The Radiator Fins

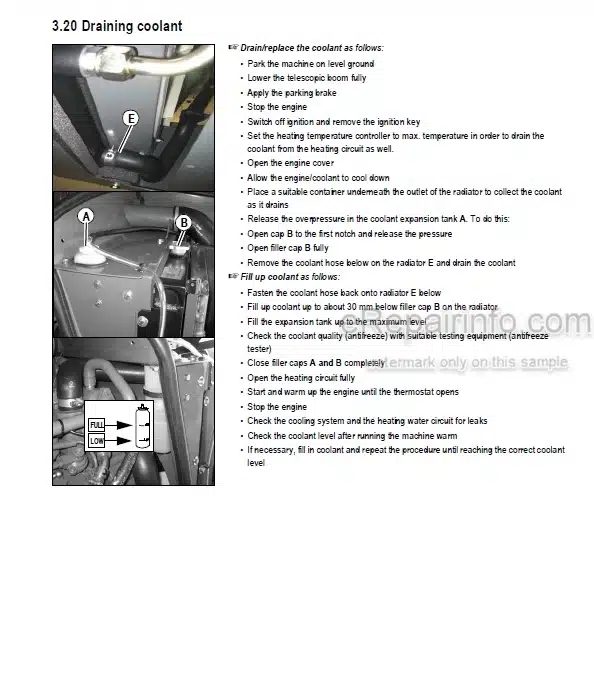

Draining Coolant

Air Filter

Replacing The Filter Cartridge

V-Belts

Hydraulic System

Monitoring The Hydraulic Oil And The Return Filter Indicator Lights

Checking The Hydraulic Oil Level Once A Day

Filling Up Hydraulic Oil

Changing The Filter Insert

Replacing Hydraulic Oil

Important Notices On The Use Of Biodegradable Oil

Checking Hydraulic Pressure Lines

Oil Levels: Rear Axle Transfer Gearbox

Oil Levels: Front And Rear Axle Differentials

Oil Levels: Front And Rear Axle Planetary Drives

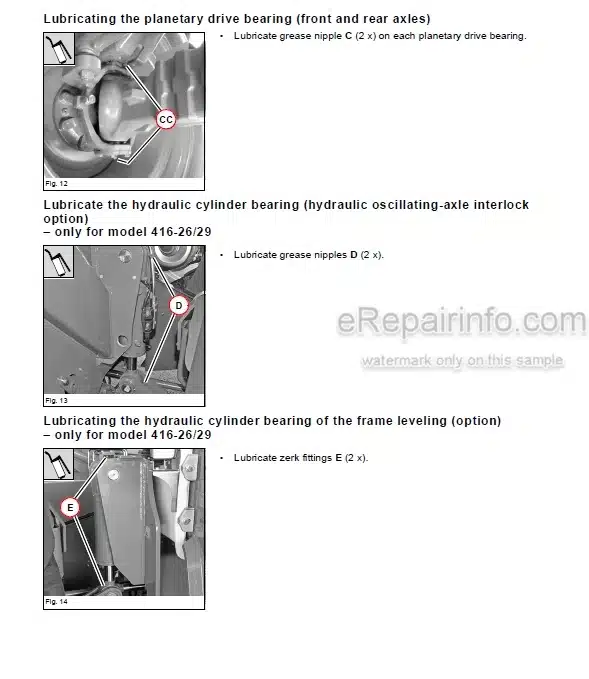

Lubrication Work

Lubrication Points On The Telescopic Boom (Overview)

Lubricating With The Central Lubrication System (Option)

Setting The Lubrication And Break Times

Central Lubrication System Diagram

Installing The High-Pressure Hoses On The Central Lubrication System

Instructions For Troubleshooting In Case Of Central Lubrication System Blocking

Repairing A Blocking Distributor Of The Central Lubrication System

Troubleshooting Table For Central Lubrication System

Maintenance Of The Brake System

Tyres

Changing Wheels

Heating/Cab Ventilation

Air Conditioning (Option): Maintenance

Functional And Visual Checks Of The Air Conditioning

Cleaning The Heat Exchanger (Condenser)

Maintenance Of The Electrical System

Maintenance Of The Automatic Trailer Coupling (Option)

General Maintenance And Cleaning Work

Maintenance Of Attachments And Of The Work Equipment

-ENGINE

Diesel Engine Diagrams

Diagnosis/Fuel Preheater (Electrical Diagrams)

Manual Throttle Diagrams

Engine Designation

Fuel Specification

Coolant Specification

Diesel Engine TD 2009 L04 (Overview)

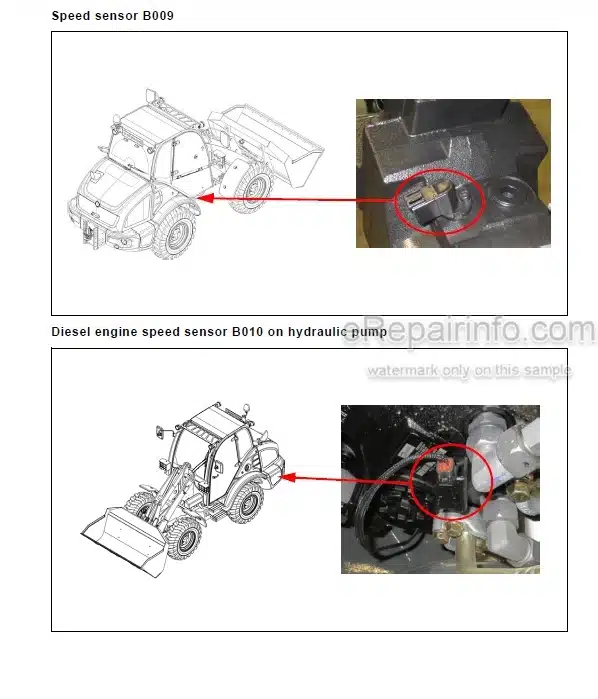

Electric Components On Engine (Overview)

Lube Oil Circuit

Cooling

Adjusting The Cable Pull For Speed Regulation

Fuel System

Replacing The Cylinder Head Gasket

Removing/Installing The Fuel Injection Pump

Mounting The Fuel Injection Pump

Removing/Installing The Fuel Injectors

Sealing The Coolant Pump

Removing/Installing The Thermostat

Checking The Thermostat

Assembly Instructions: Replacing The Visco Clutch

Tightening Torque Table

Diesel Engine Malfunctions

-DRIVE

Drive (Hydraulic Diagram)

Drive Diagrams

Making Settings With The Laptop

Error: Incorrect Tool Key

Importing New Data

Drive Electronics Plus+1 Mode Description

Reading Out/Deleting The Error History

Deleting The Error History

Switching The Inching Potentiometer On/Off

Reading In The Inching Potentiometer Again

Reading In The Inching Potentiometer

Switching The Creep Gear Potentiometer On/Off

Switching On The Creep Gear Potentiometer

Reading In The Creep Gear Potentiometer

Modifying The Load Stabiliser Settings

Error Code Table

Towing And Transporting The Machine

Hydraulic Pump H1 (Model 407 02) Test Ports And HP Valves (Overview)

Hydraulic Pump H1 (Model 407 02) Proportional Valve And Electronics (Overview)

Variable Displacement Motor H1110 Cm3/Rev (Overview)

Variable Displacement Motor H1B (Overview)

Model 407 02 Test Report

Error Description For Test Report Model 407 02

Drive With Hydraulic Pump H1 (Hydraulic Circuit)

Checking The Idling Speed

Checking/Adjusting Starting Speed

Adjusting Boost Pressure

Checking High Pressure

Checking Driving Direction Identification

Checking The Energisation Of The Driving Direction Identification

Checking Engine Droop (Variable Displacement Pump)

Setting The Pump Droop Speed

Setting Engine Droop/Control Initiation Of The Hydraulic Motor

Setting Maximum Speed

Troubleshooting Boost-Pressure Errors (Diagram)

Checking High Pressure (HP Valves)

Checking Pump Engine Droop, Driving Direction Identification, Differential Pressure Measurement

-AXLES

Differential Lock Diagrams

Axle Type Label

Front Axle Screw Connections

Rear Axle Screw Connections

Drain, Fill And Check Plug – Front Axle

Drain, Fill And Check Plug – Rear Axle

Front Axle Tightening Torques (Nm)

Rear Axle Tightening Torques (Nm)

Sealing Work

-BRAKES

Brake Diagrams

Brakes (Hydraulic Diagram)

Brake Circuit

Trailer Brake Valve Circuit

Service Brake Function

Parking Brake Circuit

Service Brake

Sealing The Brake Calliper

Bleeding The Brake System With Bleed Equipment

Setting The Brake Pedal With The Inching Potentiometer

-STEERING SYSTEM

Steering System (Hydraulic Diagram)

Steering Circuit With Final-Position Synchronisation

Steering Circuit With Front, 4 Wheel And Crab Steering

Steering System Adjustment

Hydraulic Ports On Servostat

Pressure Relief Valve: Adjustment

Sealing Steering Rams

Sealing Steering Rams

Checking The Steering Mode Valve

Checking A Steering Ram

Overview Of Steering Ram Setting

How To Check And Set The Steering Rams

Checking The Track Setting (1)

Correcting The Track Setting (2)

Steering Misalignment During Final-Position Synchronisation (3)

Adjustment Work

Checking Steering Synchronisation (4)

-WORK HYDRAULICS

20 Kph 4-Fold Control Valve (Hydraulic Diagram)

30 Kph 5-Fold Control Valve (Hydraulic Diagram)

Hydraulics Legend

Raising/Lowering (Diagrams)

Raising/Lowering The Telescopic Boom (Hydraulic Diagram)

Raising/Lowering The Telescopic Boom, Bad Stabiliser (Hydraulic Diagram)

Dumping In/Out, Tilt Ram Lock (Electrical Diagrams)

Dumping Out (Hydraulic Diagram)

Tilt Ram Lock (Hydraulic Diagram)

Extending/Retracting The Telescopic Boom (Black/White) (Electrical Diagrams)

Extending/Retracting The Telescopic Boom/Proportional (Electrical Diagrams)

Retracting/Extending The Telescopic Boom (Hydraulic Diagram)

Locking/Unlocking The Quickhitch (Black/White) (Electrical Diagrams)

Quickhitch Diagram Designations (Black/White, Lock/Unlock)

Locking/Unlocking The Quickhitch Proportionally (Electrical Diagrams)

Quickhitch Diagram Designations (Proportional, Lock/Unlock)

Locking (Hydraulic Diagram)

Locking/Additional Control Circuit (Hydraulic Diagram)

Locking/Return Without Pressure (Hydraulic Diagram)

Safe Load Indicator (Electrical Diagrams)

Overload Cutoff (Hydraulic Diagram)

Load Stabiliser (Electrical Diagrams)

Additional Control Circuit/Tipping Trailer (Hydraulic Diagram)

Tipping Trailer (Hydraulic Diagram)

Autohitch (Hydraulic Diagram)

Autohitch/Tipping Trailer (Hydraulic Diagram)

Additbnal Function (Electrical Diagrams)

Autohitch/Additional Control Circuit/Tipping Trailer (Hydraulic Diagram)

Test Report For Hydraulics 407-02 (2506)

Work Hydraulics Oil Supply

Pump Pressure/Work Hydraulics Test Port

Control Valve (Overview)

Control Valve Design

Checking And Setting The Work Hydraulics

7-Fold Pilot Valve (Overview)

4-Fold Pilot Valve (Overview)

Pilot Control Circuit

Load Stabiliser Circuit

Lift Ram Circuit

Tilt Ram Circuit

3Rd Control Circuit

Circuit: Additional Control Circuit And Rear Tipping Trailer

Tilt Ram Lock Circuit

Circuit: Autohitch And Tipping Trailer Ports

Overload Cutoff Circuit

Load Stabiliser

Valve For Tilt Ram Lock

Tipping Trailer And Additional Control Circuit Valve

Work Hydraulics/Steering System Priority Valve

Valves (General Overview)

Lift Ram (Sealing Work)

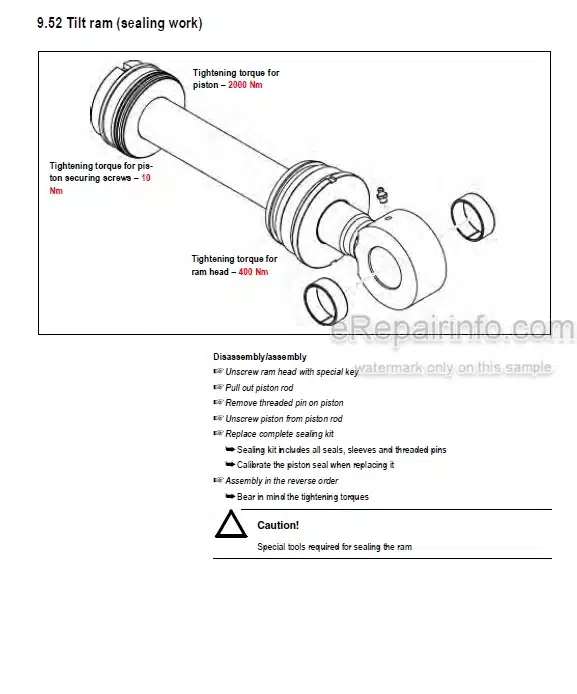

Tilt Ram (Sealing Work)

Push-Out Ram

Compensating Ram

Control Ram (Quickhitch Frame) (Sealing Work)

Lift, Tilt And Push-Out Rams: Velocity

Usable Consumer Pressure At Additional Control Circuit (Option)

Overload Control (“Smart Handling”)

Overview Of Safe Load Indicator

Setting The Safe Load Indicator (0 % Point)

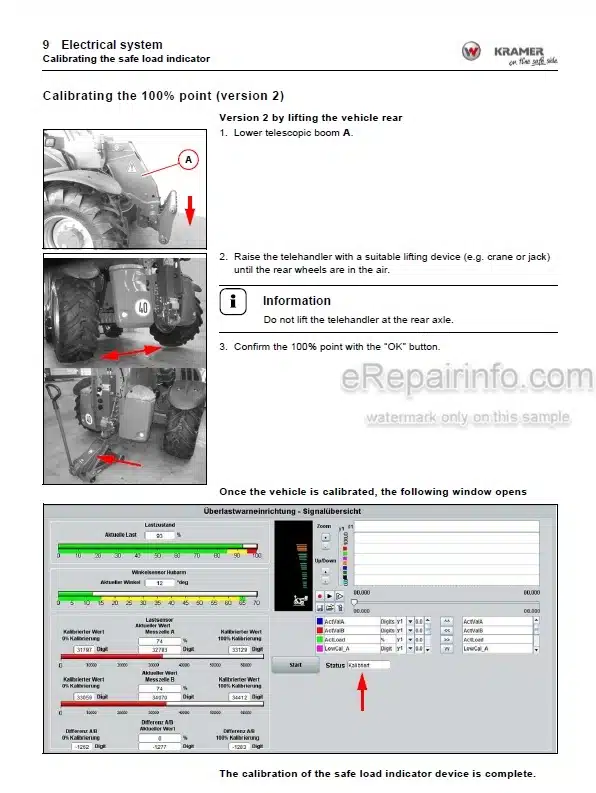

Setting The Safe Load Indicator (100 % Point Stability)

Inspection Plan For Overload Control (Model 407 Telehandler)

Testing Without Any Load

Testing With Load

Functional Description Of Overload Control (Smart Handling)

Electric Components

Circuit Diagram: Overload Control Enabled

Circuit Diagram: Automatic Retraction Off

Overview Of Valves

Overview Of Valve Connections And Ports

Circuit Diagram: Overload Control

Circuit Diagram Legend

Extend (Solenoid Valve Y102) (Circuit Diagram)

Pallet Forks Mode (Circuit Diagram)

Tip Switch S084 Pressed (Circuit Diagram)

Electric Components

Overload Control Relay

Installation Position: Overload Control Relay

-ELECTRICAL SYSTEM

Lights (Diagrams)

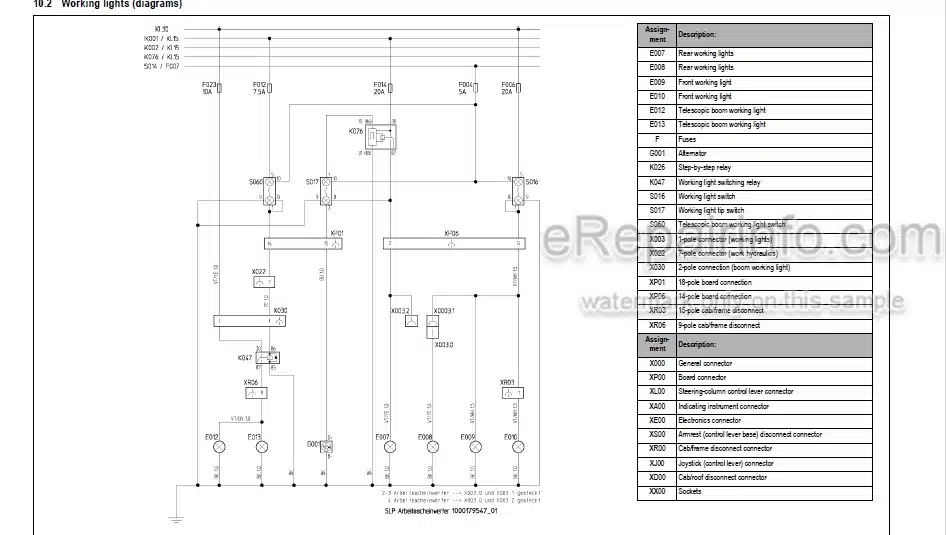

Working Lights (Diagrams)

Turn Indicators/Horn/Rotating Beacon (Diagrams)

Window Heating/Front Socket (Electrical Diagrams)

Wipe/Wash System (Electrical Diagrams)

Seat/Air Conditioning System (Diagrams)

Multimedia/Monitoring/Cigarette Lighter (Electrical Diagrams)

Cab Wiring Harness 1000256306-01

Cab Wiring Harness Legend

Engine Wiring Harness 1000245802

Engine Wiring Harness Legend

Frame Wiring Harness 1000256307

Frame Wiring Harness (Legend)

Cab Wiring Harness (Overload Control)

Cab Wiring Harness Legend

Frame Wiring Harness (Overload Control)

Frame Wiring Harness (Overload Control) (Legend)

Ohm’S Law (Current, Voltage, Resistance); Power

Measuring Equipment, Measuring Methods

Terminal Description

Color Coding Of Electric Lines

Switching Relay Function

Fuse Assignment

Switching Relay Assignment On Board

Switching Relay Assignment On Bracket

Main Fuse Box With Relays In The Engine Compartment

Electric Units

Connector Description

Switch Assignment On Board

Switch Assignment On Instrument Panel (Overview)

Control Lever (Black/White Control)

Joystick (Black/White Function)

Joystick: Retracting/Extending The Telescopic Boom (Black/White)

Joystick: Unlocking/Locking The Telescopic Boom (Black/White)

Control Lever (Proportional Control)

Joystick (Proportional Function)

Joystick: Retracting/Extending The Telescopic Boom (Proportional)

Joystick: Unlocking/Locking The Telescopic Boom (Proportional)

Additional Control Circuit With Potentiometer (Proportional)

Proportional Controls Connector Assignment (Overview)

Proportional Controls (Overview And Connections)

Retrofitting A Rotating Beacon

Retrofitting The Backup Warning System

Retrofitting 2 Front Working Lights

Retrofitting 2 Rear Working Lights

Retrofitting A Rear 7-Pole Socket

Retrofitting A Front 4-Pole Socket

Retrofitting 2 Working Lights On The Telescopic Boom (From Mid 2011)

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.