Factory Operators Manual For Link-Belt Rubber Tired Material Handler. Manual For Owners And Operators. It Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Description Of Possible Faults / Problems And Their Solution.

Format: PDF

Language: English

Pages: 88

Bookmarks: Yes

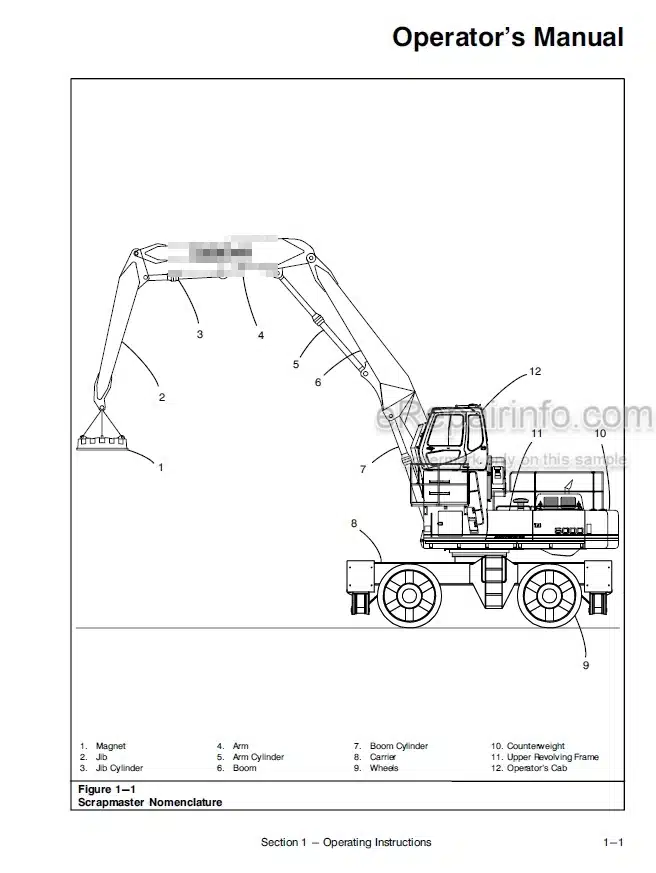

Model

Link-Belt Rubber Tired Material Handler

6000RT Quantum

6000SL Quantum

Contents

-OPERATING SAFETY

General Safety Rules

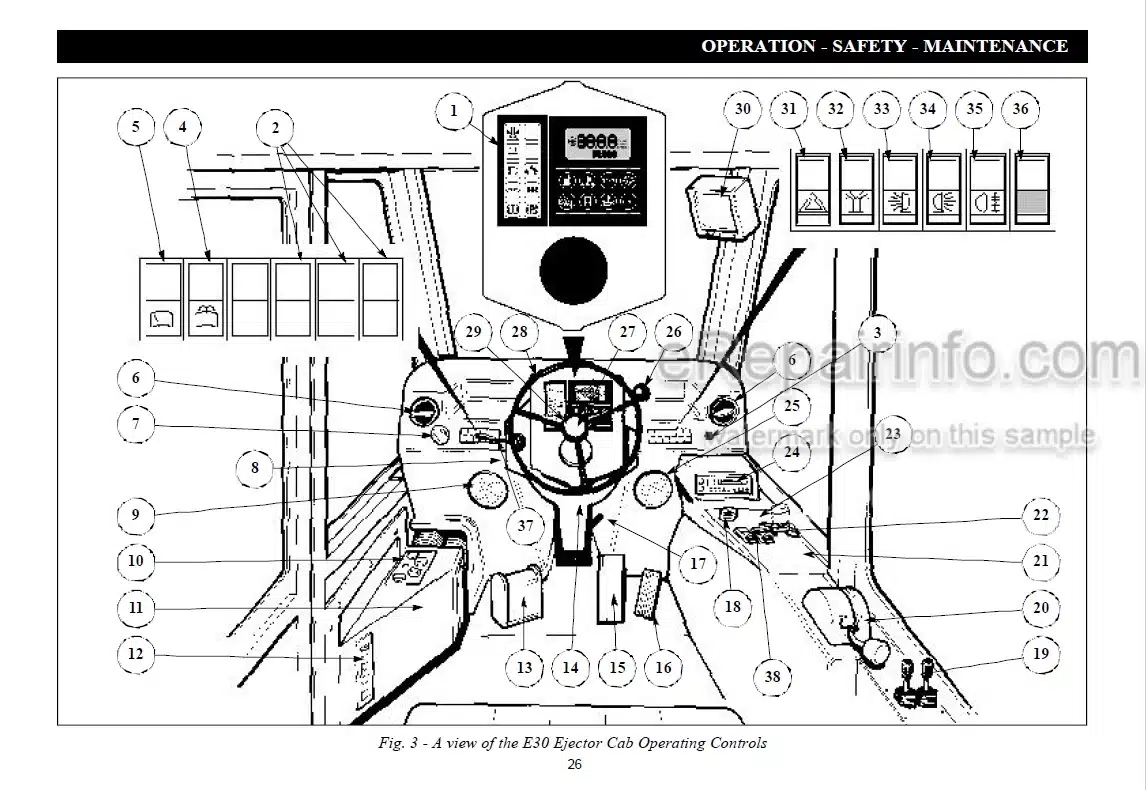

-OPERATOR’S CAB CONTROLS

Right Control Console

Left Control Console

SYSTEMS CONTROL MONITOR

OUTRIGGER CONTROLS

-OUTRIGGER OPERATION

To Extend Outriggers

To Retract Outriggers

-OPERATING SYSTEM CONTROLS

Engine Throttle Control

Joystick Controllers

Steering And Traveling The Machine

Axle Oscillation System

-TRAVELLING THE CRANE

Pick And Cany Operation

Job Site Travel

-GENERAL OPERATION

P Magnet Operation

P Grapple Operation

HAND SIGNALS

CAB HEATER SHUTOFF VALVE

OPERATOR’S SEAT

ENTERING AND EXITING CAB

BREAK-IN PERIOD

BEFORE STARTING OPERATIONS

-ENGINE STARTING PROCEDURE

To Start The Engine

Ether Start

ENGINE SHUTDOWN

FUSE PANEL

-FRONT WINDOWS

Opening the Upper Window

Closing the Upper Window

Removing Lower Window

Installing Lower Window

-TRANSPORTING THE MACHINE

Counterweight Removal/Installation

Attachment Removal/Installation

Machine Loading And Unloading

Tilting/Lifting Of Elevated Cab

-MACHINE STORAGE

Short Term Storage

Long Term Storage

Anti-Vandal Guard

LUBRICATION, INSPECTION & MAINTENANCE

GENERAL LUBRICATION INFORMATION

-GENERAL INSPECTION & MAINTENANCE INFORMATION

Inspection Preparation

Inspection Safety Precautions

How to Bleed Hydraulic Pressure

Cleaning Parts

Maintenance Under the Machine

Watch Falling Objects

Safety Protection

Scaffold or Catwalks

Daily (Before Operating) Inspection And Maintenance Check List

Regular Inspection And Maintenance Chart

Regular Lubrication Chart

-LUBRICATION

Axle Differentials Lubrication

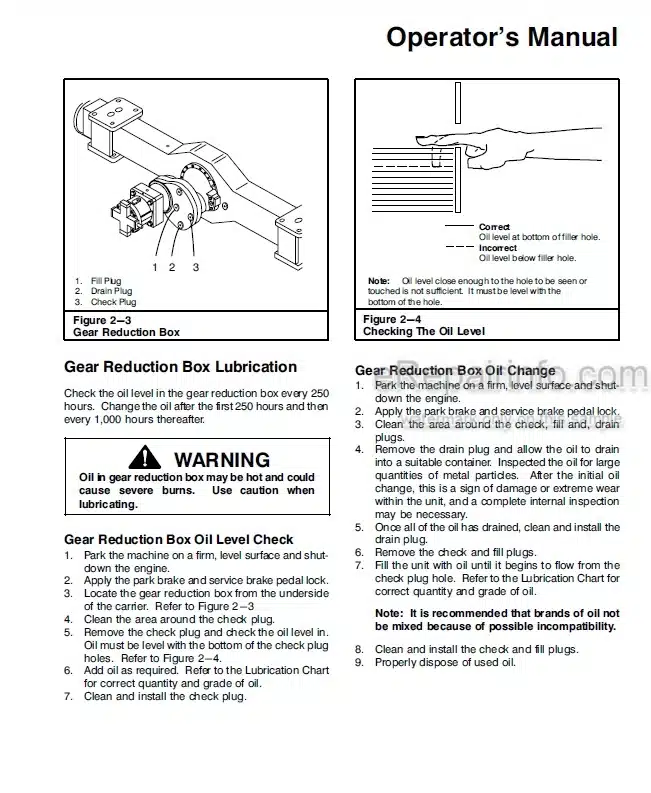

Gear Reduction Box Lubrication

Planetary Wheel End Lubrication

Swing Speed Reducer

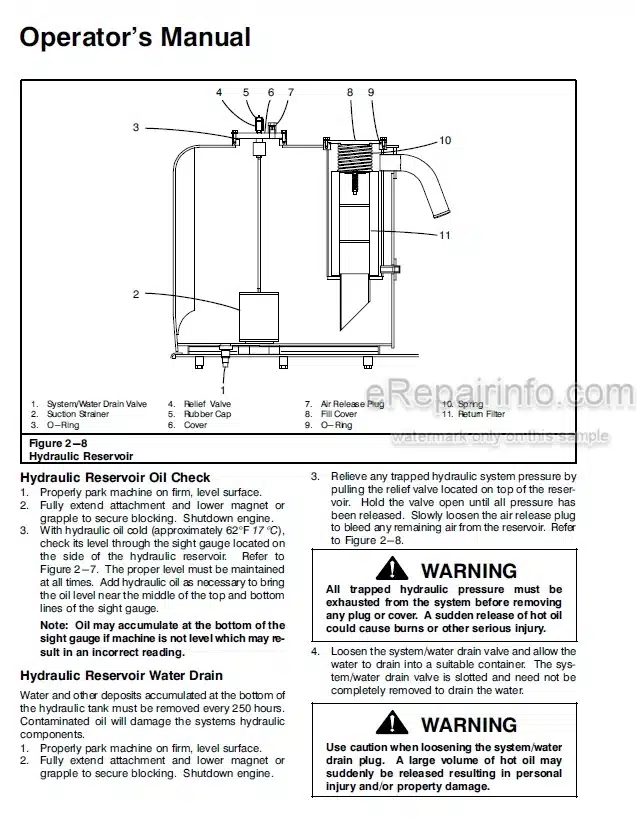

Hydraulic System

-PERIODIC MAINTENANCE

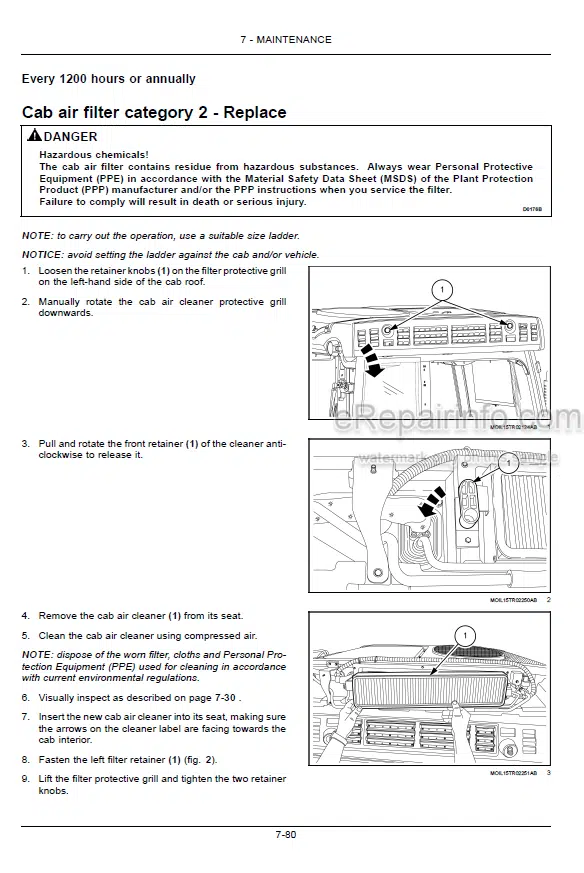

Engine Air Cleaner

Bolt Torque Check

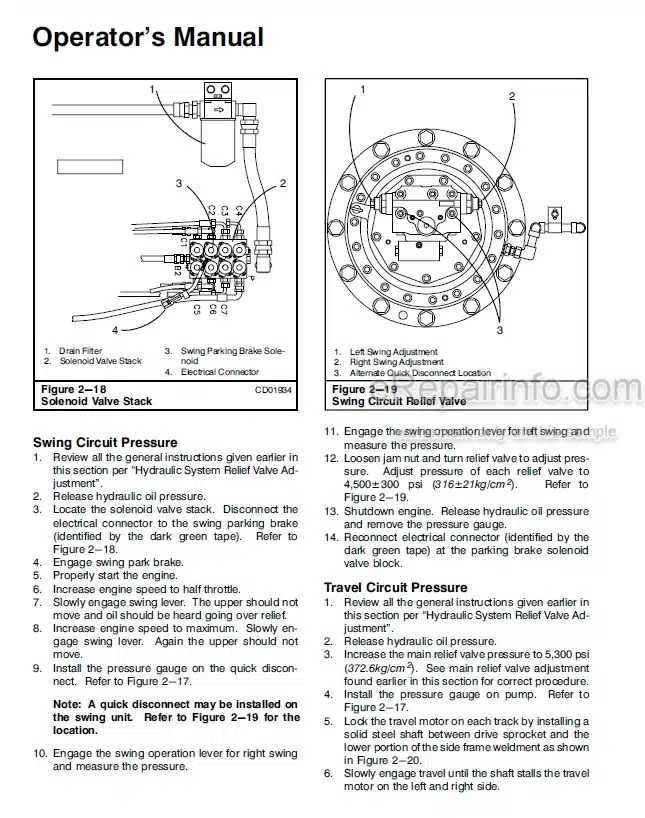

Hydraulic System Relief Valve Adjustment

Accumulator Pressure Verification

Remote Oil Cooler Fan Speed Adjustment

Generator Belt Tension Check

Generator Belt Adjustment

Generator Belt Replacement

Paint Maintenance

Cab Dash Cleaning

INSPECTIONS

TROUBLESHOOTING

INSPECTIONS

TROUBLESHOOTING

FUEL AND LUBRICANT PER AMBIENT TEMPERATURE CHART

HOUR METER

SERVICE AND PARTS ASSISTANCE

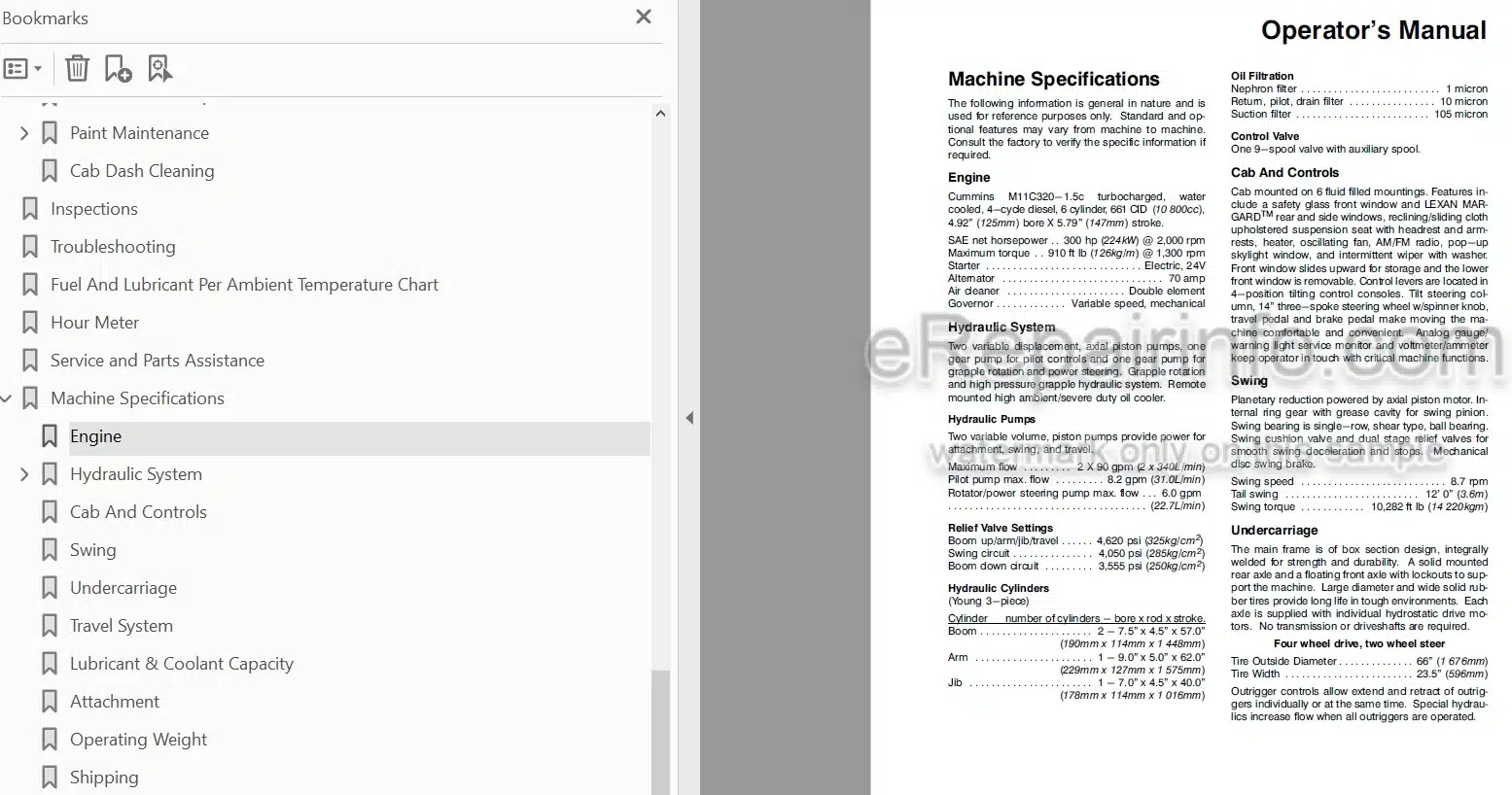

-MACHINE SPECIFICATIONS

Engine

Hydraulic System

Cab And Controls

Swing

Undercarriage

Travel System

Lubricant & Coolant Capacity

Attachment

Operating Weight

Shipping

Standard Equipment

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.