Factory Service Repair Manual For McCormick CT28 CT36 Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 313

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

McCormick CT28, CT36

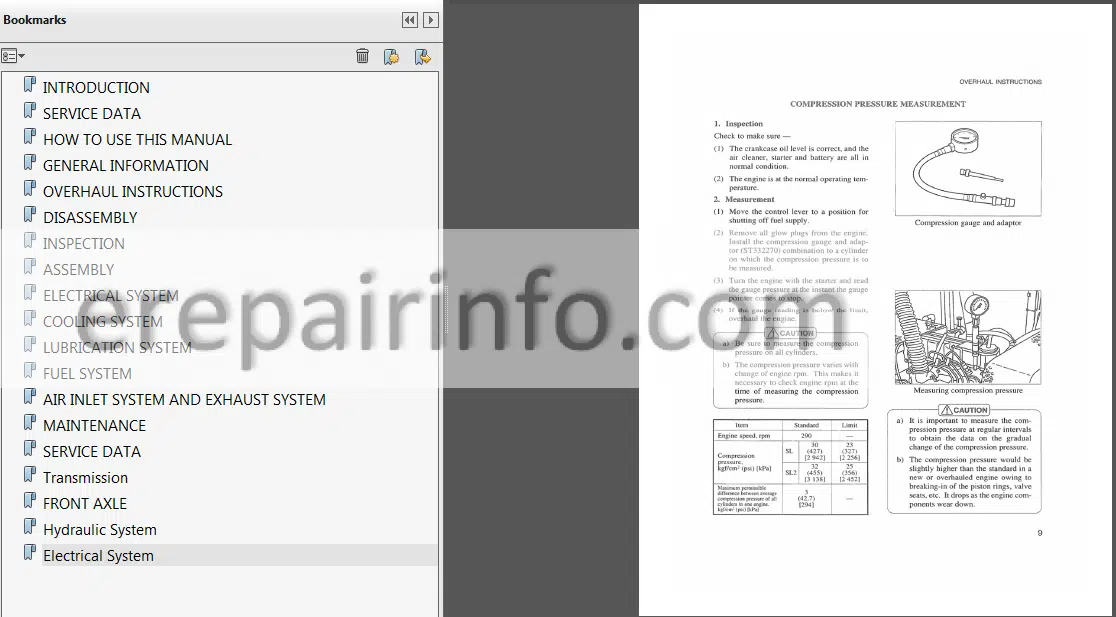

Contents

- INTRODUCTION

SERVICE DATA

HOW TO USE THIS MANUAL - -GENERAL INFORMATION

MODEL IDENTIFICATION AND SERIAL NUMBER LOCATION

Model Identification Location

Serial Number Location

COMPONENT LOCATION

S3L/S3L2

S4L/S4L

SPECIFICATIONS

PERFORMANCE CURVES (ONE-HOUR RATING, WITH FAN)

PRIME POWER OUTPUT CHART - -OVERHAUL INSTRUCTIONS

DETERMINING WHEN TO OVERHAUL THE ENGINE

COMPRESSION PRESSURE MEASUREMENT

Inspection

Measurement

TROUBLES HOOTING

General

Engine Troubleshooting

Problem 1: Hard Starting

Problem 2: Fuel Knock

Problem 3: Overheating

Problem 4: Black Exhaust Smoke

Problem 5: Erratic Idle Speeds

Problem 6: Low Power Or Loss Of Power

Starting System Troubleshooting

BASIC PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY

Disassembly

Assembly - -DISASSEMBLY

PREPARATION FOR DISASSEMBLY

Engine Oil Draining

Coolant Draining

ELECTRICAL SYSTEM

Starter

Alternator

COOLING SYSTEM

Cooling Fan Removal

Thermostat Case Removal

Water Pump Assembly Removal

FUEL SYSTEM

Fuel Injection Pipe Removal

Fuel Injection Nozzle Removal

Governor Assembly Removal

Governor Weight Removal

Fuel Injection Pump Removal

LUBRICATION SYSTEM

Oil Filter Removal

Pressure Relief Valve Removal

Oil Pressure Switch Removal

AIR INLET SYSTEM AND EXHAUST SYSTEM

Exhaust Manifold Removal

Air Inlet Cover Removal

CYLINDER HEAD AND VALVE MECHANISM

Rocker Shaft Assembly Removal

Rocker Shaft Disassembly

Cylinder Head Bolt Removal

Cylinder Head Assembly Removal

Valve And Valve Spring Removal

Valve Stem Seal Removal

TIMING GEARS AND FLYWHEEL

Flywheel Removal

Rear Plate Removal

Oil Seal Case Removal

Tappet Removal

Speedometer Driven Gear Removal

Crankshaft Pulley Removal

Timing Gear Case Removal

Timing Gear Backlash Measurement

Idler Gear Removal

Camshaft Removal

Fuel Injection Pump Camshaft Removal

Gear Removal (When Required)

Oil Pump Removal

Front Plate Removal

CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN

Oil Pan Removal

Oil Screen Removal

Thrust Clearance Measurement For Connecting Rod Big End

Connecting Rod Cap Removal

Piston Removal

End Play Measurement For Crankshaft

Main Bearing Cap Removal

Crankshaft Removal

Piston Separation From Connecting Rod - -INSPECTION

CYLINDER HEAD AND VALVE MECHANISM

Cylinder Head

Rocker Arms And Rocker Shaft

Valve Springs

Valve Push Rods

Valves, Valve Guides And Valve Seats

Combustion Jet Replacement

TIMING GEARS AND FLYWHEEL

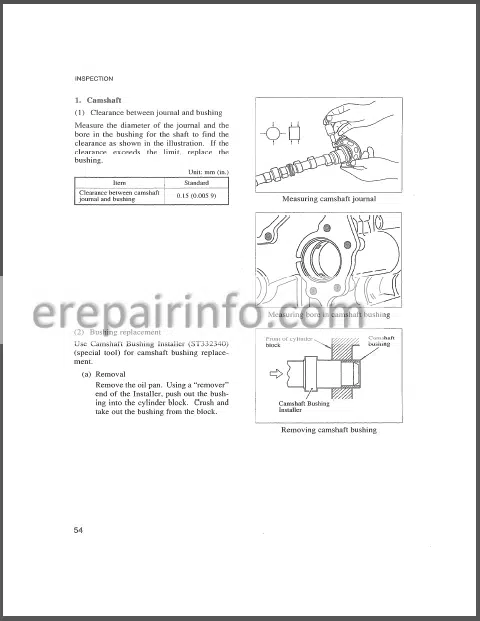

Camshaft

Fuel Injection Pump Camshaft

Tappets

Idler Gear

Flywheel And Ring Gear

CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN

Pistons, Piston Rings And Piston Pins

Connecting Rods

Crankshaft

Cylinder Block - -ASSEMBLY

CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN

Main Bearing Installation

Crankshaft Installation

Main Bearing Cap Installation

Side Seal Installation

Piston Assembling To Connecting Rod

Piston Ring Installation

Piston And Connecting Rod Installation

Connecting Rod Cap Installation

Oil Screen Installation

Oil Pan Installation

TIMING GEARS AND FLYWHEEL

Front Plate Installation

Oil Pump Installation

Engine Turning

Fuel Injection Pump Camshaft Installation

Camshaft Installation

Idler Gear Installation

Timing Gear Case Installation

Crankshaft Pulley Nut Tightening

Ptogear Installation

Speedometer Driven Gear Installation

Tappet Installation

Oil Seal Case Installation

Rear Plate Installation

Flywheel Installation

CYLINDER HEAD AND VALVE MECHANISM

Cylinder Head Bottom Face Cleaning

Valve Stem Seal Installation

Valve Spring Installation

Valve Block Installation

Cylinder Head Gasket Installation

Cylinder Head Installation

Cylinder Head Bolt Tightening

Valve Push Rod Installation

Rocker Shaft Assembling

Rocker Shaft Assembly Installation

Valve Clearance Adjustment

Rocker Cover Installation

AIR INLET SYSTEM AND EXHAUST SYSTEM

Air Inlet Cover Installation

Exhaust Manifold Installation

FUEL SYSTEM

Fuel Injection Nozzle Installation

Fuel Injection Pump Installation

Flyweight Assembly Installation

Sliding Sleeve Installation

Governor Assembly Installation

Fuel Injection Line Installation

LUBRICATION SYSTEM

Pressure Relief Valve Installation

Oil Filter Installation

Oil Pressure Switch Installation

COOLING SYSTEM

Water Pump Installation

Thermostat Installation

Cooling Fan Installation

Thermoswitch And Thermounit Combination Installation

ELECTRICAL SYSTEM

Glow Plug Installation

Alternator Installation - -ELECTRICAL SYSTEM

GENERAL

Schematic

Specifications (Standard)

STARTER

Disassembly

Inspection

Assembly

ALTERNATOR

Disassembly

Inspection

Assembly

KEY SHUTOFF SYSTEM (ETS solenoid type)

General

Cord Color (Standard)

Shutoff Solenoid Installation

Inspection After Assembly

KEY SHUTOFF SYSTEM (ETR solenoid type)

General

Cord Color (Standard)

Shutoff Solenoid Installation

AUTOMATIC GLOW PLUG SYSTEM

General

Glow Plug Timer Specifications (Standard)

Glow Plug Relay Specifications (Standard)

Glow Plug Inspection - -COOLING SYSTEM

GENERAL

Schematic

Specifications (Standard)

INSPECTION

Water Pump

Thermostat (Standard )

Thermoswitch (Standard)

Thermo unit (Standard) - -LUBRICATION SYSTEM

GENERAL

Schematic

Specifications

INSPECTION

Oil Pump

Oil Pressure Switch

Pressure Relief Valve - -FUEL SYSTEM

GENERAL

Schematic

Specifications (Standard) ,

Inspection

Disassembly And Assembly

FUEL INJECTION PUMP

Test On Engine

Disassembly

Inspection

Assembly

GOVERNOR

Disassembly And Inspection

Assembly

Torque Spring Set Installation

FUEL PUMP

Inspection

FUEL FILTER - -AIR INLET SYSTEM AND EXHAUST SYSTEM

GENERAL

Schematic

INSPECTION - -MAINTENANCE

LUBRICATION AND MAINTENANCE CHART

ENGINE OIL AND OIL FILTER

Engine Oil Specifications

Oil Level Check

Oil Change

Oil Filter Change

VALVE CLEARANCE

FUEL INJECTION TIMING

Preparation

Inspection

Adjustment

FUEL FILTER

FUEL SYSTEM PRIMING

IDLE RPM SETTING

FUEL INJECTION NOZZLE

Injection Pressure (Valve Opening Pressure) Test

Orifice Restriction Test

Nozzle Tip Washing And Replacement

Installation

FAN BELT - -SERVICE DATA

SPECIFICATIONS

Basic Engine Components

Lubrication System

Fuel System

Air Inlet System And Exhaust System

Cooling System (Standard)

Electrical System

TIGHTENING TORQUES

Major Bolts And Nuts

Torques For Bolts And Nuts With Standard Threads

Torques For Plugs With Taperlock Threads

SEALANTS

SPECIAL TOOLS - -TRANSMISSION

MAIN GEAR (CENTER CASE)

Notice & Index

Schematic View Of Transmission

Specification

Major Specification Of Appearance

Running Speed

Release Bearing Assembly & Fork

Clutch Disassembling & Assembling

Hst Disassembling & Assembling

Hst Operation Principal

Clutch Pedal (Mechanical)

Neutral Adjustment (Hst)

Break Pedal Gap Adjustment

Forward & Backward

Main Gear Changing

Gear Disassembling Of Main Gear Range Gear Change

Pto Drive

Pto Clutch Disassembling & Assembling

Pto Gear Disassembling & Assembling

Composition Principal Of Mid Pto

RANGE GEAR (AXLE CASE)

Power Map Of Range Gear

Range Gear Disassembling & Assembling

Assembling And Disassembling Of Differential Lock

Pinion Shaft Disassembling

Front Wheel Drive Shaft Disassembling & Assembling

FINAL DRIVE SHAFT ( DIFFERENTIAL & REAR DRIVE SHAFT)

General Notices

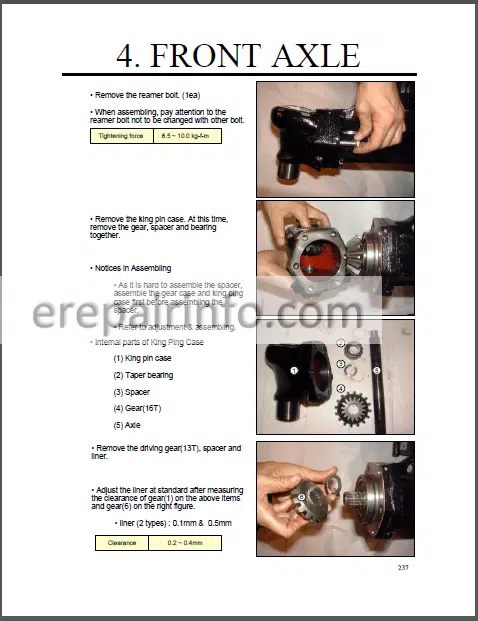

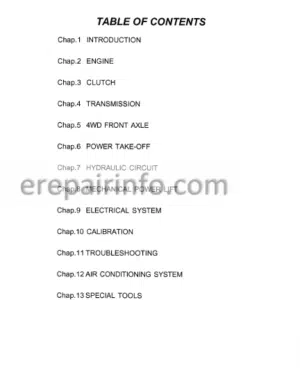

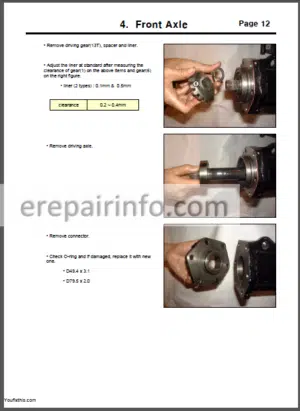

Final Drive Disassembling & Assembling - -FRONT AXLE

- -HYDRAULIC SYSTEM

Main Specification

Construction Of Hydraulic System Of Mechanical Transmission

Schematic Of Hydraulic Circuit Of Mechanical Transmission

Construction Of Hydraulic System Of Hydrostatic Transmission

Schematic Of Hydraulic Circuit Of Hydrostatic Transmission

Hydraulic Pump

Independent Pto

Front Outlet Valve

Control Valve

Neutral Position

Lifting Position

Down Position

Torque For The Bolt Of Hydraulic Housing

Assembly And Disassembly Of Hydraulic Housing

Assembly And Disassembly Of Link

Assembly And Disassembly Of Control Valve

Steering Unit

Schematic Diagram Of Steering Unit

Assembly And Disassembly Of Steering Unit

Trouble Shooting - -ELECTRICAL SYSTEM

Checking Before Disassembly (Starter Motor)

Disassembly Of Starter Motor

Assembly Of Starter Motor

Checking Before Disassembly (Alternator)

Disassembly Of Alternator

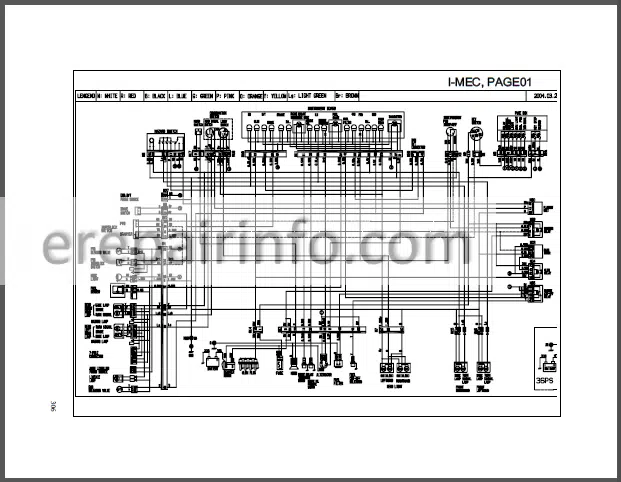

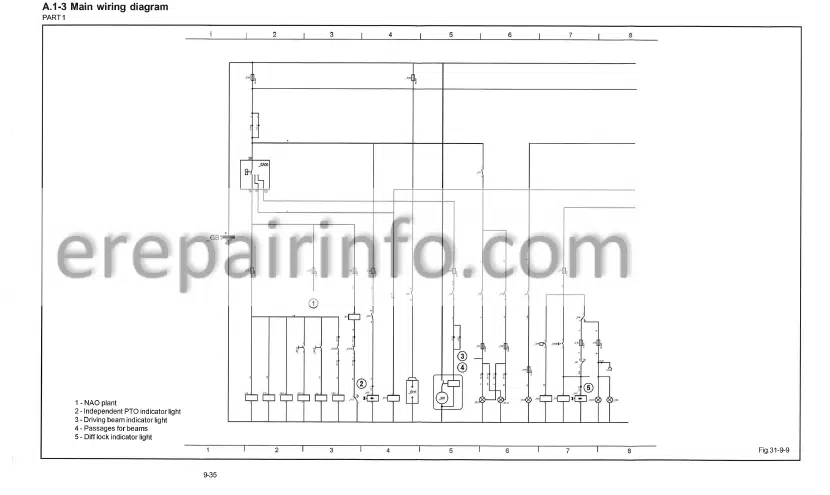

Circuit Diagram Of Hst Tractor

Circuit Diagram Of Mechanical Tractor

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Great service. An excellent product at a good price.