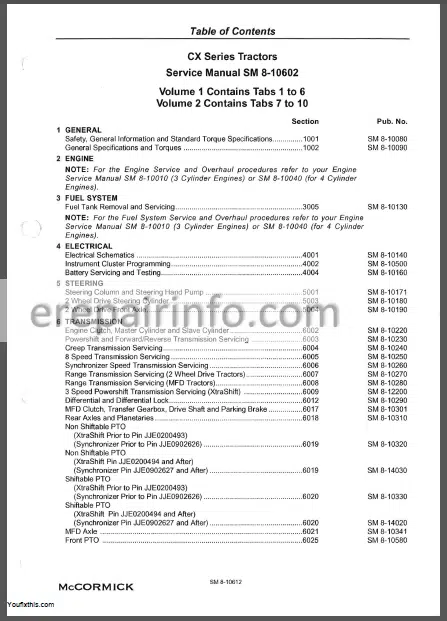

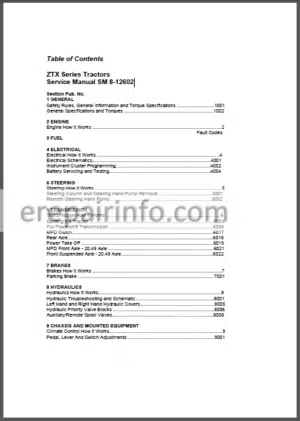

Factory Service Repair Manual For McCormick CX Series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 918

Bookmarks: Yes

Searchable: Yes

Number: SM 8-10602

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

McCormick CX50, CX60, CX70, CX75, CX80, CX85, CX90, CX95, CX100, CX105

Contents

- -GENERAL

–SAFETY, GENERAL INFORMATION AND STANDARD TORQUE SPECIFICATIONS

SAFETY

GENERAL INFORMATION

Cleaning

Inspection

Bearings

Needle Bearings

Gears

Oil Seals, O-Rings And Gaskets

Shafts

Service Parts

Lubrication

STANDARD TORQUE DATA FOR NUTS AND BOLTS

Chart 1 (Plain Nuts/Bolts)

Chart 2 (Phosphate Coated Nuts/Bolts)

Chart 3 (Zinc Or Cadmium Plated Nuts/Bolts)

–GENERAL SPECIFICATIONS AND TORQUES

GENERAL SPECIFICATIONS

Capacities

Electrical Specifications

Steering Specifications

Transmission Specifications

Brake Specifications

Hydraulic Specifications

Air Conditioning System Specifications

Conversion Table

SPECIAL TORQUES

Steering

Transmission

Brakes

Hydraulics

Chassis And Mounted Equipment - -FUEL SYSTEM

–FUEL TANK REMOVAL AND SERVICING

SPECIFICATIONS

SPECIAL TOOLS

FUEL TANK

Removal And Installation

FUEL LEVEL SENDER

Removal And Installation

Fuel Level Sender Testing - -ELECTRICAL

–ELECTRICAL SCHEMATICS

SPECIAL TOOLS

CIRCUIT TESTING

General Information

Schematic Symbols

Schematic Legend

Wire Colour Code

FUSE LOCATION AND IDENTIFICATION- European Specification Tractors

FUSE LOCATION AND IDENTIFICATION – American Specification Tractors

SWITCHES AND CONTROLS

Instrument Panel

Right Hand Console Controls (Upper And Lower)

Deluxe Cab Roof Controls – Operator Environment

European Specification Low Profile Cab Roof Controls (Operator Environment)

HARNESS LAYOUT AND CHASSIS GROUND LOCATION

Instrument Panel Harness Components – Tractors Without Ride Control

Instrument Panel Harness Components – Tractors With Ride Control

Right Hand Console Harness Components – Tractors Without Ride Control

Right Hand Console Harness Components – Tractors With Ride Control

Engine And Hood Harness Components

Transmission Harness Components – Tractors Without Xtrashift

Transmission Harness Components – Tractors With Xtrashift

Deluxe Cab And Rear Fender Harness Components

European Specification Low Profile Cab Harness And

Rear Fender Harness Components

Platform Harness Rear Fender Harness Components

STARTER MOTOR, NEUTRAL START, FUEL SHUT-OFF, COLD START AND CAB POWER RELAy

ALTERNATOR AND INSTRUMENT CLUSTER

WARNING LIGHTS AND GAUGES

PARK BRAKE WARNING, FRONT PTO AND EUROPEAN SPECIFICATION AIR TRAILER BRAKE

TWO-SPEED POWERSHIFT – Tractors Without XtraShift

ROTARY BEACON LIGHT, IMPLEMENT INTERFACE CONNECTOR

AND 3 PIN AUXILIARY POWER CONNECTORS

HORN, CIGAR LIGHTER, EUROPEAN SPECIFICATION SWITCHED FENDER AUXILIARY POWER CONNECTOR, AMERICAN SPECIFICATION 7 POLE SOCKET AUXILIARY POWER AND ELECTRIC AIR SEAT

RADIO AND INTERIOR LIGHT

Blower Motor And Air Conditioning – Deluxe Cab Tractors

Blower Motor And Air Conditioning – Low Profile Cab Tractors

Front And Read Windscreen Wiper/Washer

Differential Lock, Mfd And

European Specification Brake Lights

European Specification Position Lights

And Turn Signal Lights

European Specification Headlights And Rear Fog Lights

American Specification Warning And Turn Signal Lights

American Specification Headlights, Position Lights

And Right Hand Console Light

Work Lights

Main Connectors

–INSTRUMENT CLUSTER PROGRAMMING

DIGITAL INSTRUMENT CLUSTER

GENERAL INFORMATION

PROGRAMMING THE DIGITAL INSTRUMENT CLUSTER (Programme Menus 1 to 6)

Clock Programming (Menu Code 1)

Mph Or Km/H Speed Display Option Programming (Menu Code 2)

Ground Speed Tire Radius Programming (Menu Code 3)

Service Interval Programming (Menu Code 4)

Area Function Mode Programming (Menu Code 5)

Old Hours Programming (Menu Code 6)

PROGRAMMING THE DIGITAL INSTRUMENT CLUSTER (Programme Menu’s 7 to 13)

Pto Option Programming (Menu Code 7)

540 Rpm Pto Programming (Menu Code 8)

750 Rpm Pto Programming (Menu Code 9)

1000 Rpm Pto Programming (Menu Code 10)

Engine Rpm Programming (Menu Code 11)

Axle Ratio (Wheel Speed)

Programming (Menu Code 12)

True Ground Speed (Radar) Programming (Menu Code 13)

Powershift Speed Display Programming (Menu Code 14)

ANALOG INSTRUMENT CLUSTER

GENERAL INFORMATION

PROGRAMMING THE ANALOG INSTRUMENT CLUSTER

Tachometer Programming

Speedometer Programming

–BATTERY SERVICING AND TESTING

SPECIFICATIONS

SPECIAL TOOLS

SAFETY PROCEDURES

MAINTENANCE

Electrolyte Level

Inspecting And Cleaning The Battery, Cables And Terminals

BATTERY TESTING

Method One – Five Step Battery Test

Method Two – Using Heavy Duty Battery Tester

CHARGING THE BATTERY

PREPARING A DRY CHARGED BATTERY FOR USE

BOOSTER BATTERY CONNECTIONS - -STEERING

–STEERING COLUMN AND STEERING HAND PUMP

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

STEERING COLUMN

Removal And Installation

Disassembly And Assembly

STEERING HAND PUMP

Removal And Installation

Disassembly

Inspection

Assembly

STEERING RELIEF VALVE ADJUSTMENT

–2 WHEEL DRIVE STEERING CYLINDER

SPECiFiCATIONS

SPECIAL TORQUES

STEERING CYLINDER PIVOT BUSHINGS

Removal And Installation

STEERING CYLINDER

Removal And Installation

Disassembly And Assembly

Cross-Sectional Drawing Of The Steering Cylinder

–2 WHEEL DRIVE FRONT AXLE

SPECIFICATIONS

SPECIAL TORQUES

FRONT AXLE

WHEEL BEARING

Removal And Installation

Disassembly And Assembly

FRONT AXLE

Removal And Installation

Disassembly And Assembly – Utility Adjustable Straight Axle

Disassembly And Assembly – Row Crop Adjustable Straight Axle

TIE ROD

Removal And Installation

Disassembly And Assembly - -TRANSMISSION

–ENGINE CLUTCH, MASTER CYLINDER AND SLAVE CYLINDER

SPECiFiCATIONS

SPECIAL TORQUES

TOOLS TO BE MADE

CLUTCH MASTER CYLINDER

Removal And Installation

CLUTCH SLAVE CYLINDER

Removal And Installation

Disassembly And Assembly

REMOVING AIR FROM THE CLUTCH HYDRAULIC SYSTEM

ENGINE CLUTCH AND FLYWHEEL

Removal

Inspection

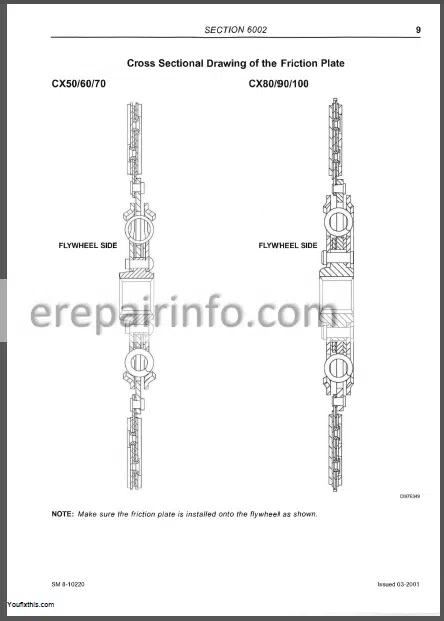

Cross-Sectional Drawing Of The Friction Plate

Cross-Sectional Drawing Of The Pressure Plate, Friction Plate And Flywheel

–2 SPEED POWERSHIFT AND SYNCHRO FORWARD/REVERSE TRANSMISSION SERVICING

SPECIAL TORQUES

SPECiFiCATIONS

SPECIAL TOOLS

TOOLS TO BE MADE

POWERSHIFT AND FORWARD/REVERSE TRANSMISSION

Removal

FORWARD/REVERSE SELECTOR FORK COVER

Disassembly And Assembly

FORWARD/REVERSE IDLER GEAR COVER

Disassembly And Assembly

FORWARD/REVERSE SYNCHRONIZER

Disassembly And Assembly

POWERSHIFT CLUTCH

Disassembly

Assembly

Cross Sectional Drawing Of The Powershift Clutch Assembly

POWERSHIFT AND FORWARD/REVERSE TRANSMISSION

Installation

Cross Sectional Drawing Of The Powershift And Forward/Reverse Transmission

–CREEP TRANSMISSION SERVICING

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

CREEP TRANSMISSION

Disassembly And Assembly Of The Creep Carrier Housing

Removal And Installation Of The Creep Mainshaft And Gears

Cross Sectional Drawing Of The Creep Carrier Housing

Cross Sectional Drawing Of The Creep Mainshaft And Gears

RANGE TRANSMISSION

Disassembly

HIGH/LOW RANGE SYNCHRONIZER

Disassembly And Assembly

CREEP SYNCHRONIZER

Disassembly and Assembly

PINION SHAFT

Inspection And Disassembly

Pinion Shaft Bearing Preload, Mounting Distance And Assembly

RANGE TRANSMISSION

Assembly

Cross Sectional Drawing Of The Creep Transmission

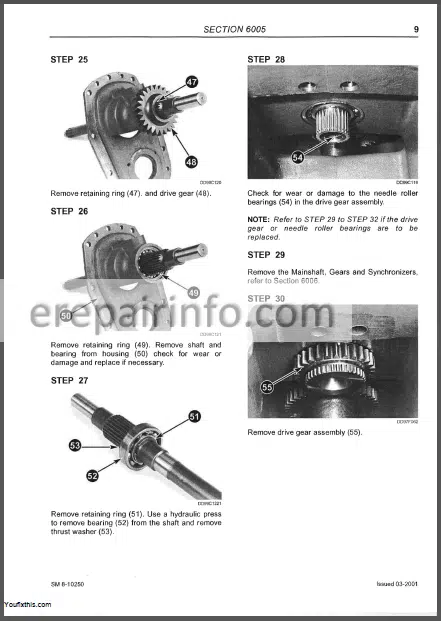

–8 SPEED TRANSMISSION SERVICING

SPECIAL TORQUES

SPECiFiCATIONS

SPECIAL TOOLS

8 SPEED TRANSMISSION

Removal

FORWARD/REVERSE SELECTOR FORK COVER

Disassembly And Assembly

FORWARD/REVERSE IDLER GEAR COVER

Disassembly And Assembly;

FORWARD/REVERSE SYNCHRONIZER

Disassembly And Assembly

8 SPEED TRANSMISSION

Installation

Cross Sectional Drawing Of The 8 Speed Transmission

–SYNCHRONIZER SPEED TRANSMISSION SERVICING

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

SPEED TRANSMISSION

SELECTOR FORKS AND RAILS

Removal

Installation

MAIN SHAFT

Removal

Installation

Cross Sectional Drawing Of The Main Shaft

COUNTERSHAF

Removal ,

Installation

Cross Sectional Drawing Of The Countershaft

–RANGE TRANSMISSION SERVICING-2 WHEEL DRIVE TRACTORS

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS ,

TOOLS TO BE MADE

RANGE TRANSMISSION

Disassembly

SYNCHRONIZER

Disassembly And Assembly

PINION SHAFT

Inspection And Disassembly

Pinion Shaft Bearing Preload, Mounting Distance And Assembly

RANGE TRANSMISSION

Assembly

Cross Sectional Drawing Of The Range Transmission

–RANGE TRANSMISSION SERVICING-MFD Tractors

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

RANGE TRANSMISSION

Disassembly

SYNCHRONIZER

Disassembly And Assembly

PINION SHAFT

Inspection And Disassembly

Pinion Shaft Bearing Preload, Mounting Distance And Assembly

RANGE TRANSMISSION

Assembly

Cross Sectional Drawing Of The Mfd Range Transmission

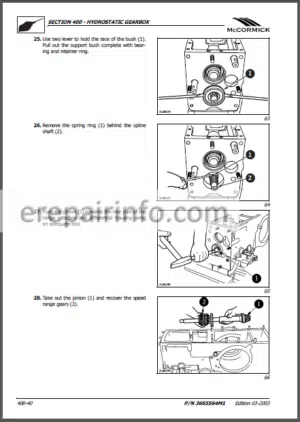

–3 SPEED POWERSHIFT TRANSMISSION SERVICING (XtraShift)

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TRANSMISSION FRONT COVER

Removal And Installation

Shim Setting Of Powershift Main Shaft And Counter Shaft Covers

Powershift Main Shaft

Disassembly And Assembly Of Reverse Clutch

Powershift Main Shaft

Disassembly And Assembly Of Nd And Forward Clutch

Cross Sectional Drawing Of The Powershift Main Shaft

Powershift Counter Shaft

Disassembly And Assembly

Cross Sectional Drawing Of The Counter Shaft

–DIFFERENTIAL AND DIFFERENTIAL LOCK

SPECiFiCATIONS

SPECIAL TORQUES

DIFFERENTIAL

Removal

Disassembly

Assembly

Positioning The Ring Gear Onto The Differential Housing

Cross Sectional Drawing Of The Differential

Setting The Differential Bearing Preload

Setting The Ring Gear To Pinion Backlash

DIFFERENTIAL LOCK

Assembly

Cross Sectional Drawing Of The Differential Lock

DIFFERENTIAL LOCK SOLENOID

–MFD CLUTCH, TRANSFER GEARBOX, DRIVE SHAFT AND PARKING BRAKE

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

CHECKING THE MFD CLUTCH TORQUE

MFD DRIVE SHAFT

Removal And Installation

MFD TRANSFER GEARBOX

Removal And Installation

Disassembly

MFD CLUTCH

Disassembly And Assembly

MFD TRANSFER GEARBOX

Assembly

Setting The Bearing Preload

Cross Sectional Drawing Of The Mfd Transfer Gearbox

–REAR AXLES AND PLANETARIES

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOL TO BE MADE

REAR AXLE

Removal And Installation

Disassembly And Assembly

Planetary Gear Disassembly

Planetary Gear Adjustment

Planetary Gear Assembly

Bearing Preload Adjustment

Cross Sectional Drawing Of The Rear Axle

–NON SHIFTABLE PTO

TABLE OF CONTENTS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

NON SHIFTABLE PTO

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Pto

PTO CLUTCH

Disassembly And Assembly

Cross Sectional Drawing Of The Pto Clutch

–SHIFTABLE PTO(SM8-10330)

TABLE OF CONTENTS

SPECiFiCATIONS

SPECIAL TORQUES

TOOL TO BE MADE

SHIFTABLE PTO

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Shiftable Pto

PTO CLUTCH

Disassembly And Assembly

Cross Sectional Drawing Of The Pto Clutch

–SHIFTABLE PTO(SM8-14020)

TABLE OF CONTENTS

SPECiFiCATIONS

SPECIAL TORQUES

TOOL TO BE MADE

SHIFTABLE PTO

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Shiftable Pto

PTO CLUTC

Disassembly And Assembly

Cross Sectional Drawing Of The Pto Clutch

–MFD AXLE

SPECiFiCATIONS

SPECIAL TORQUES

SPECIAL TOOLS

GENERAL INFORMATION

PLANETARY GEAR

Removal And Installation

Disassembly And Assembly

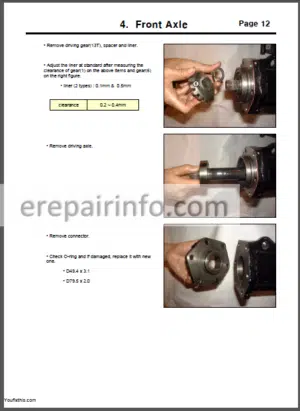

WHEEL HUB

Disassembly And Assembly

SWIVEL HOUSING

Removal And Installation

Disassembly And Assembly

DRIVE SHAFT

Disassembly And Assembly

CROSS SECTIONAL DRAWING OF THE PLANETARY GEAR ASSEMBLY,

WHEEL HUB, SWIVEL HOUSING AND DRIVE SHAFT

MFD AXLE

Removal And Installation

Disassembly And Assembly

DIFFERENTIAL HOUSING

Disassembly

DIFFERENTIAL

Disassembly And Assembly

Cross Sectional Drawing Of The Differential

Setting The Position Of The Pinion Shaft

Pinion Shaft Assembly

Differential Installation

Ring Gear Backlash Adjustment

Differential Bearing Preload Adjustment

STEERING CYLINDER

Disassembly And Assembly

–FRONT PTO

SPECiFiCATIONS

SPECIAL TORQUES

FRONTPTO

Removal And Installation

Cx50 And Cx60 Tractors

Disassembly And Assembly

Cross Sectional Drawing Of The Front Pto

Cx70/75, Cx80/85, Cx90/95 And Cx100/105 Tractors

Disassembly And Assembly

Cross Sectional Drawing Of The Front Pto - -BRAKES

–SERVICE BRAKES

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

BRAKE DISC

Removal And Installation

BRAKE PISTON

Removal

Installation And Pressure Testing

BRAKE SYSTEM LEAKAGE TEST

MASTER CYLINDER (Tractors Without Hydraulic Trailer Brake Valve)

Removal

Installation

MASTER CYLINDER (Tractors With Hydraulic Trailer Brake Valve)

Removal

Installation

MASTER CYLINDER

Disassembly And Assembly

–PARKING BRAKE 2 WHEEL DRIVE TRACTORS

SPECiFiCATIONS

SPECIAL TORQUES

PARKING BRAKE

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Parking Brake

–HYDRAULIC TRAILER BRAKE

SPECIAL TORQUES

HYDRAULIC TRAILER BRAKE

Removal And Installation

Disassembly And Assembly - -HYDRAULICS

–HYDRAULIC TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

SPECiFiCATIONS

HYDRAULIC SYSTEM TROUBLESHOOTING

Steering System Problems

Powershift Problems

Mfd Problems

Pto Problems

Differential Lock Problems

Oil Cooler Problems

Brake Problems

Hydraulic Trailer Brake Problems (If Equipped)

Rear Hitch System Problems

Remote Valve Circuit Problems

HYDRAULIC SYSTEM DIAGNOSTIC TESTING

Test 1 – Main Hydraulic Pump Efficiency

Test 2 – Main Relief Valve

Test 3 – Steering Relief Valve Pressure And Cylinder Internal Leakage

Test 4 – Steering Hydraulic Pump Efficiency

Test 5 – Regulated Pressure

Test 6 – Pto Pressure

Test 7 – Oil Cooler Flow

Test 8 – Regulated Circuit Leakage Test

Test 9 – Remote Detent Kick-Out

CROSS SECTIONAL DRAWINGS AND INDIVIDUAL SCHEMATICS

Hydraulic Filter

Main Hydraulic Pump

Filter Manifold

Unloading Valve

Remote Valves

Hitch Valve

Edc Manifold

Hitch Cylinder And Hitch Relief Valve

Steering Hydraulic Pump

Steering Hand Pump

Pressure Regulator Valve Block

Mfd Solenoid And Clutch

Cx Hydraulic Schematic, Two Speed Power Shift

Cx Xtrashift, Hydraulic Schematic

Cx Xtrashift, Hydraulic Schematic

–FILTER MANIFOLD AND MAIN HYDRAULIC PUMP

SPECiFiCATIONS

SPECIAL TORQUES

FILTER MANIFOLD

Removal And Installation

Disassembly And Assembly

MAIN HYDRAULIC PUMP

Disassembly And Assembly

CROSS SECTION OF FILTER MANIFOLD AND HYDRAULIC FILTER

CROSS SECTION OF MAIN HYDRAULIC PUMP

–STEERING HYDRAULIC PUMP

SPECiFiCATIONS

SPECIAL TORQUES

STEERING PUMP

Removal And Installation

Cx50 And Cx60 Tractors

Cx70/75, Cx80/85, Cx90/95 And Cx100/105 Tractors

–REGULATOR VALVE

SPECIAL TORQUES

REGULATOR VALVE

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Regulator Valve

–UNLOADING VALVE

SPECIAL TORQUES

UNLOADING VALVE

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Unloading Valve

–REMOTE VALVES

SPECiFiCATIONS

SPECIAL TORQUES

REMOTE VALVE

Removal And Installation

Disassembly And Assembly

REMOTE VALVE WITH NO CHECK VALVES

Disassembly And Assembly

REMOTE VALVE WITH ONE CHECK VALVE

Disassembly And Assembly

REMOTE VALVE WITH TWO CHECK VALVES

Disassembly And Assembly

–HITCH VALVE AND EDC MANIFOLD

SPECiFiCATIONS

SPECIAL TORQUES

GENERAL INFORMATION

HITCH VALVE AND EDC MANIFOLD

Removal And Installation

Disassembly And Assembly

Cross Sectional Drawing Of The Hitch Valve

–HYDRAULIC LIFT HOUSING SERVICING

SPECIAL TORQUES

HYDRAULIC HOUSING

Removal And Installation

Disassembly And Assembly

–FRONT HITCH

SPECIAL TORQUES

FRONT HITCH

Removal And Installation

Disassembly And Assembly

HITCH CYLINDER

Removal And Installation

Disassembly And Assembly - -CHASSIS & MOUNTED EQUIPMENT

–PEDAL, LEVER AND SWITCH ADJUSTMENTS

SPECIAL TOOLS

SPECIAL TORQUES

FORWARD/REVERSE LEVER ADJUSTMENT

Forward Position Switch Setting

BRAKE PEDAL ADJUSTMENT

Brake Pedal Stop Adjustment

Cylinder Rod Adjustment

Brake Pedal Maximum Travel Adjustment

Brake Light Switch Adjustment

PTO ADJUSTMENT

PTO Neutral Start Switch Adjustment

SHIFTABLE PTO ADJUSTMENT

HAND AND FOOT THROTTLE ADJUSTMENT

SPEED/RANGE LINKAGE ADJUSTMENT

st/nd Speed Linkage

rd/th Speed Linkage

Range Linkage

Range Switch Adjustment

CREEP LINKAGE ADJUSTMENT

DIFFERENTIAL LOCK SWITCH ADJUSTMENT

CLUTCH PEDAL ADJUSTMENT (Tractors Without XtraShift)

Clutch Slave Cylinder Rod Adjustment

Clutch Cylinder Rod Adjustment

Interlock Cable Adjustment

Clutch Pedal Position Switch

PARKING BRAKE ADJUSTMENT (MFD)

PARKING BRAKE ADJUSTMENT (2WD)

REMOVING AIR FROM THE BRAKE SYSTEM

–CAB MOUNTINGS

SPECIAL TORQUES

SPECIAL TOOLS

CAB MOUNTINGS

Inspection

Removal And Installation - -CONTROLLER SYSTEM

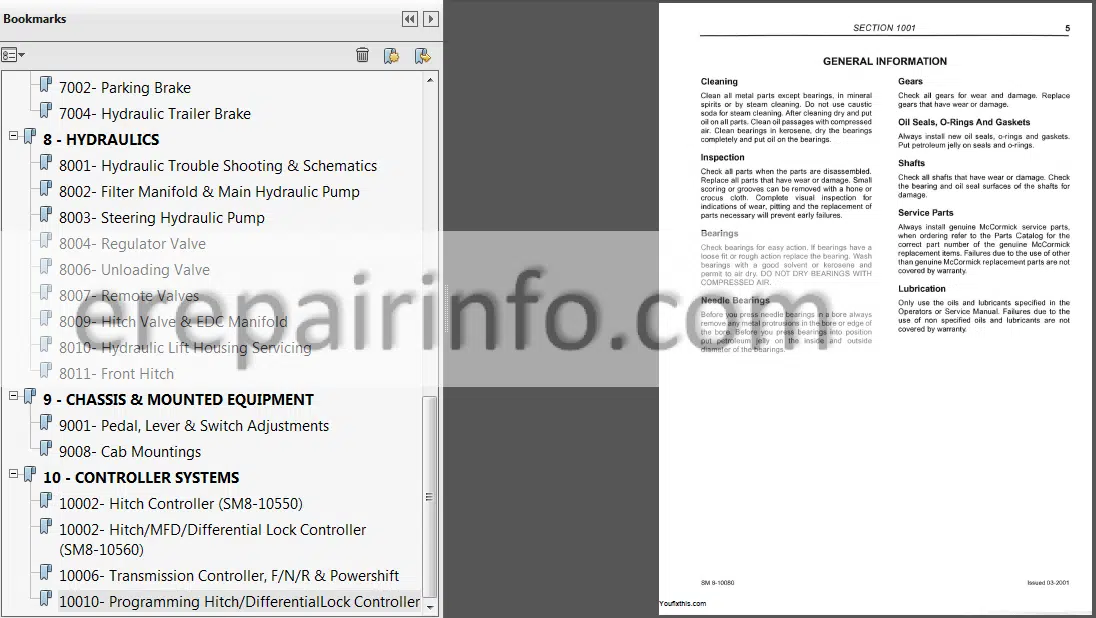

–HITCH CONTROLLER

SPECIAL TOOLS

TOOLS TO BE MADE

GENERAL INFORMATION FOR ELECTRONIC HITCH CIRCUIT

Hitch Operation

Hitch Electrical Supply And Ground

Hitch Component Supply

HITCH CALIBRATION

GENERAL INFORMATION FOR HITCH ERROR CODES

Normal Operation

No Error Codes Displayed But Hitch Is Not Working Correctly

Diagnostic Display is Blank

Failure Modes

General Notes

Error Codes That Disable Hitch Motion

Other Possible Error Indications

Error Codes That Allow Hitch Operation

Failures That Are Checked Once

Double Failures Involving The UP/DOWN Switch

CALIBRATION ERROR CODE CHART

READING AND ERASING ERROR CODES

HITCH SYSTEM PERFORMANCE CODE CHART

CIRCUIT TESTING

General Information

Hitch Operating Circuit

Test 1 – No Power To Controller (Power And Clean Ground)

Test 2 – Circuit Shorted To Ground

Test 3 – Hitch Up/Down Switch And Hitch Enable Lamp

Test 4 – Hitch Up/Down Switch Circuit

Test 5 – Hitch Enable Relay Circuit

Test 6 – Hitch Solenoids Circuit

Test 7 – R/H Hitch Remote Switch

Test 8 – Llh Hitch Remote Switch

Hitch Position Control Circuit

Test 9 – Hitch Position Potentiometer

Test 10 – Hitch Position Command Potentiometer

Test 11 – Hitch Drop Speed Potentiometer

Test 12 – Hitch Upper Height Potentiometer

Hitch Load Control Circuit

Test 13 – Load Pin

Test 14 – Hitch Load Command Potentiometer

Test 15 – Hitch Travel Potentiometer

Test 16 – Hitch Response Potentiometer

Test 17 – Wheel Speed Sensor

HARNESS LAYOUT, SCHEMATICS AND CONNECTORS

Right Hand Console Harness Components

Transmission And Rear Fender Harness Components

Hitch Control Schematic Circuit

Schematic Legend

Wire Colour Code

Main Connectors

–HITCH/MFD/DIFFERENTIAL LOCK CONTROLLER

SPECIAL TOOLS

TOOLS TO BE MADE

DELUXE HITCH CALIBRATION

Tire Size Calibration and Ride Control Enabling/Disabling

GENERAL INFORMATION FOR HITCH ERROR CODES

Normal Operation

No Error Codes Displayed But Hitch Is Not Working Correctly

Controller LED

Failure Modes

General Notes

Error Codes That Disable Hitch Motion

Other Possible Error Indications

Error Codes That Allow Hitch Operation

Failures That Are Checked Once

Double Failures Involving The UP/DOWN Switch

CALIBRATION ERROR CODE CHART

READING AND ERASING ERROR CODES

HITCH SYSTEM PERFORMANCE CODE CHART

CIRCUIT TESTING

General Information

Hitch Operating Circuit

Test 1 – No Power To Controller (Power And Clean Ground)

Test 2 – Circuit Shorted To Ground

Test 3 – Hitch Up/Down Switch And Hitch Enable Lamp

Test 4 – Hitch Up/Down Switch Circuit

Test 5 – Hitch Solenoids Circuit

Test 6 – R/H Hitch Remote Switch

Test 7 – Llh Hitch Remote Switch

Hitch Position Control Circuit

Test 8 – Hitch Position Potentiometer

Test 9 – Hitch Position Command Potentiometer

Test 10 – Hitch Drop Speed Potentiometer

Test 11 – Hitch Upper Height Potentiometer

Hitch Load Control Circuit

Test 12 – Load Pin

Test 13 – Hitch Load Command Potentiometer

Test 14 – Hitch Travel Potentiometer

Test 15 – Wheel Speed Sensor

Slip Limit Control Circuit

Test 16 – Slip Control Switch

Test 17 – Slip Control Switch Circuit

Test 18 – Radar

Ride Control Circuit

Test 19 – Ride Control Switch

Differential Lock Circuit

Test 20 – Differential Lock Solenoid

Test 21 – Differential Lock Switch, Auto Differential And Auto Indicator Lamp

Test 22 – Differential Lock Warning Lamp And Switch

MFD Circuit

Test 23 – MFD Solenoid

Test 24 – MFD Switch and Auto MFD Circuit

Test 25 – MFD Relay Circuit

Test 26 – MFD Indicator Lamp

Brake Switches

Test 27

HARNESS LAYOUT, SCHEMATICS AND CONNECTORS

Instrument Panel Components

Right Hand Console Harness Components

Transmission Harness And Fender Harness Components

Hitch Control Schematic Circuit

Differential Lock And Mfd Schematic Circuit

Schematic Symbols

Schematic Legend

Wire Colour Code

Main Connectors

TIRE RADIUS CONSTANT TABLE

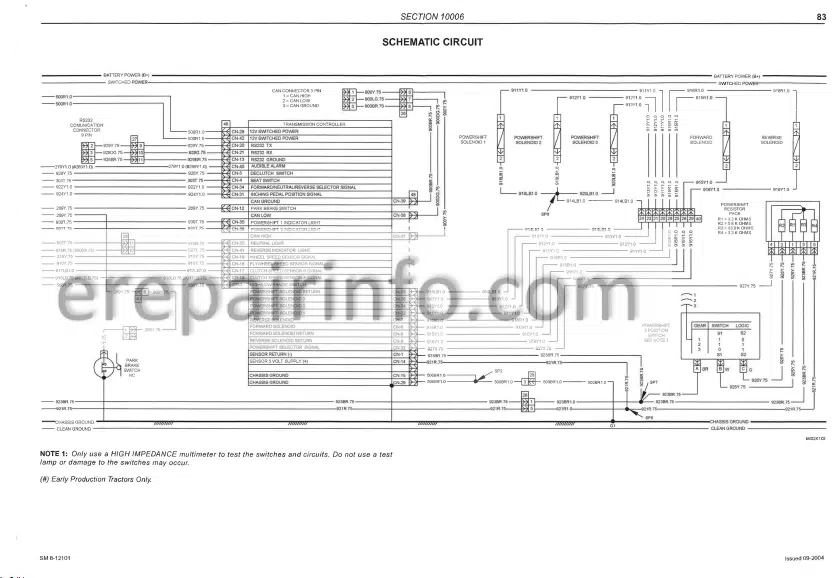

–TRANSMISSION CONTROLLER, F/N/R AND POWERSHIFT

SPECIAL TOOLS

ELECTRONIC TRANSMISSION CONTROL

Transmission Control Functions

Controller LED’s

Error Codes

Operators Seat Switch Monitor, Park Brake and Alarm

CALIBRATION

Calibration Procedure – Method 1 (New Controller)

Calibration Procedure – Method 2 (Existing Controller Recalibration)

Tyre Radius Constant Table

INCHING PEDAL POTENTIOMETER ADJUSTMENT

ERROR CODES

General Information

Retrieving And Identifying Error Codes

Error Code Quick Reference Guide

TROUBLESHOOTING GUIDE

Circuit Testing General Information

Error Code 20/19

Error Code 22/12

Error Code 22/15

Error Code 24/12

Error Code 24/15

Error Code 25/11 & 12

Error Code 25/15 & 16

Error Code 26/12

Error Code 26/15

Error Code 28/12

Error Code 28/15

Error Code 37/23

Error Code 37/24

Error Code 37/25

Multi Error Codes 22/12 , 24/12 And 25/11 & 12

Multi Error Codes 22/15, 24/15 And 25/15 & 16

No Error Code

Controller Led’s Not Illuminated

No Error Code

No Forward Drive

No Error Code

No Reverse Drive

No Error Code

No Forward Or Reverse Drive

No Error Code

Return To Neutral Light On When Forward Or Reverse Selected

No Error Cod

No Drive In 1St Speed Powershift :

No Error Code

No Drive In 2Nd Speed Powershift

No Error Code

No Drive In 3Rd Speed Powershift

No Error Code

No Drive In 1 St, 2Nd Or 3Rd Speed Powershift

No Error Code

Defaults To 1 St Speed Powershift 1 When 2Nd Speed Powershift Selected

No Error Code

Defaults To 3Rd Speed Powershift 3 When 1 St And 2Nd Speed

Powershift Selected

HARNESS LAYOUT AND CHASSIS GROUND LOCATION

Instrument Panel Harness Components – Tractors Without Ride Control

Instrument Panel Harness Components – Tractors With Ride Control

Right Hand Console Harness Components – Tractors Without Ride Control

Right Hand Console Harness Components – Tractors With Ride Control

Transmission Harness Components

SCHEMATIC CIRCUIT

MAIN CONNECTORS

–PROGRAMMING HITCH/MFD/DIFFERENTIAL LOCK CONTROLLER

SPECIAL TOOLS

GENERAL INFORMATION

CONTROLLER PROGRAMMING

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

My only suggestion is need to improve picture quality and definition.

Anonymous (verified owner) –

.