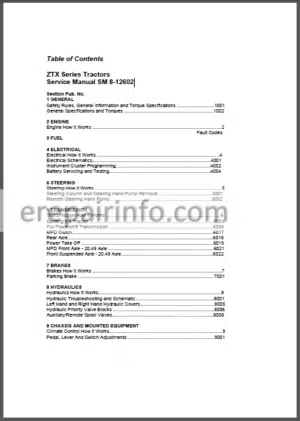

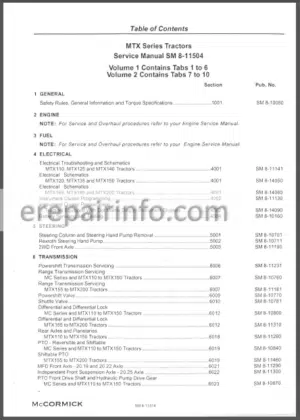

Factory Service Repair Manual For McCormick XTX Series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 1540

Bookmarks: Yes

Searchable: Yes

Number: SM 8-15002

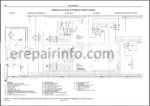

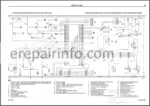

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

McCormick XTX145 XTX165 XTX185 XTX200 XTX215

Contents

- Introduction

- Engine

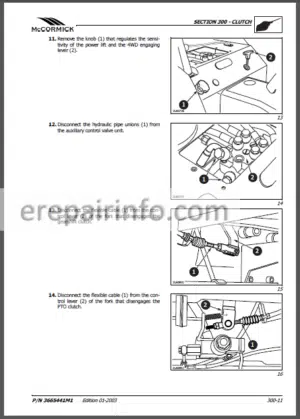

- Clutch

- Transmission

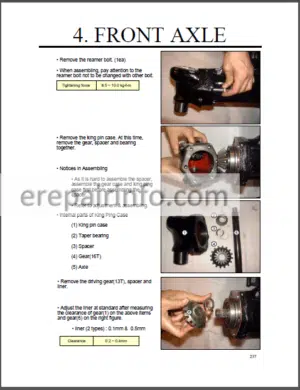

- 4wd Front Axle

- Power Take-Off

- Hydraulic Circuit

- Mechanical Power Lift

- Electrical System

- Calibration

- Troubleshooting

- Air Conditioning System

- Special Tools

-GENERAL

–SAFETY, GENERAL INFORMATION AND STANDARD TORQUE SPECIFICATIONS

SAFETY

GENERAL INFORMATION

Cleaning

Inspection

Bearings

Needle Bearings

Gears

Oil Seals O-Rings And Gaskets

Shafts

Service Parts

Lubrication

STANDARD TORQUE DATA FOR NUTS AND BOLTS

Chart 1 (Plain Nuts/Bolts)

Chart 2 (Phosphate Coated Nuts/Bolts)

Chart 3 (Zinc or Cadmium Plated Nuts/Bolts)

-ENGINE

General Information

Fuel

Duty – Industrial Applications

Common Rail Engines

Overhaul And Technical Specifications

Tools

Safety Prescriptions

–Error Codes Tier II

–Error Codes Tier III

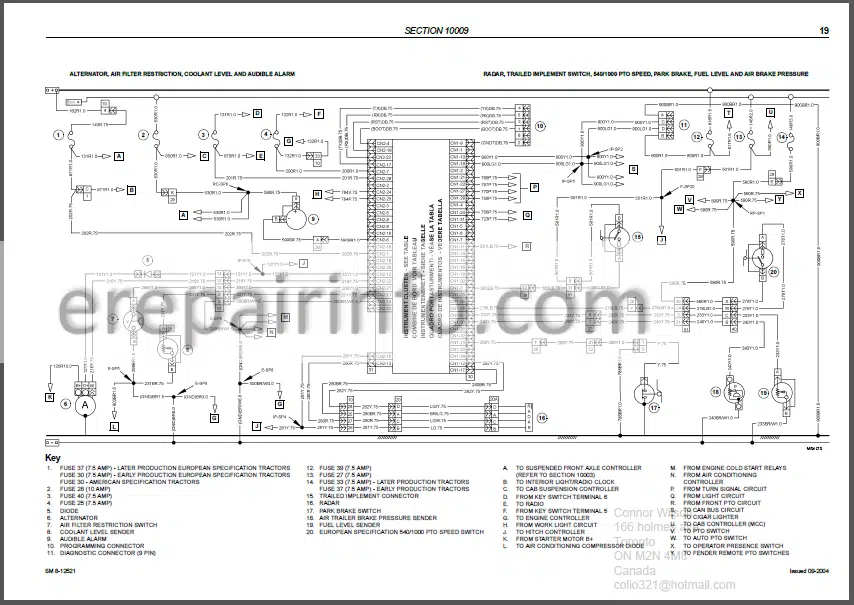

-ELECTRICAL

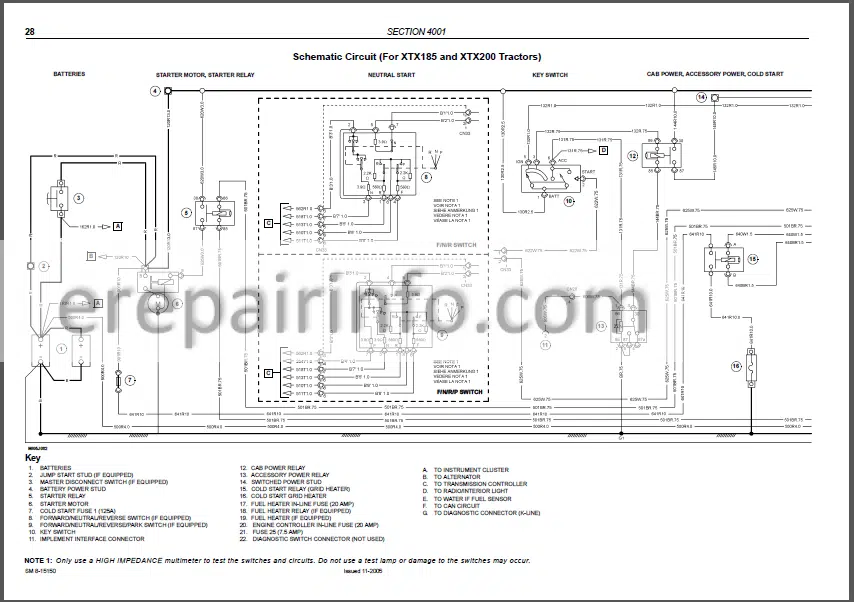

–ELECTRICAL SCHEMATICS XTX185, XTX200 TRACTORS AND XTX215 (CUMMINS ENGINE) TRACTORS

SPECIAL TOOLS

CIRCUIT TESTING

General Information

Schematic Symbols

Schematic Legend

Wire Colour Code

EUROPEAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION

AMERICAN SPECIFICATION FUSE LOCATION AND IDENTIFICATION

COMPONENT IDENTIFICATION

Hood Components

XTX185 and XTX200 Engine Components

XTX215 Engine Components

Instrument Panel Components

Right Hand Console Components

(XtraSpeed and XtraSpeed – E Tractors Only)

Right Hand Console Components

(XtraSpeed – E Plus Tractors Only)

Transmission Components

Fender Components (XtraSpeed and XtraSpeed – E Tractors)

Fender Components (XtraSpeed – E Plus Tractors)

Cab Components

Cab Roof Panel Components

NEUTRAL START, COLD START, KEY SWITCH,

CAB POWER, FUEL HEATER

(For XTX185 and XTX200 Tractors)

Neutral Start Circuit

Cold Start Circuit

Fuel Heater

Accessory Power Relay Circuit

Cab Power Relay Circuit

Schematic Circuit (For XTX185 and XTX200 Tractors)

NEUTRAL START, COLD START, KEY SWITCH,

CAB POWER AND WATER IN FUEL (For XTX215 Tractors)

Starter Circuit

Cold Start Circuit

Water in Fuel Circuit

Accessory Power Relay

Cab Power Relay

Schematic Circuit (For XTX215 Tractors)

4TH AUXILIARY/REMOTE VALVE, IMPLEMENT INTERFACE CONNECTOR,

AUXILIARY POWER CONNECTORS AND BEACON LIGHT

4TH Auxiliary/Remote Valve Circuit(XtraSpeed and XtraSpeed – E Tractors Only)

Implement Interface Connector Circuit

Front and Rear 3 Pin Auxiliary Power Connector Circuit

Switched Fender Auxiliary Power Connector Circuit

Beacon Light

Schematic Circuit (For European Specification Tractors)

Schematic Circuit (For American Specification Tractors)

HORN, CIGAR LIGHTER AND SEAT

Horn Circuit

Cigar Lighter Circuit

Electric Air Seat Circuit

Schematic Circuit

RADIO AND INTERIOR LIGHT

Radio Circuit

Interior Light Circuit

Schematic Circuit

BLOWER AND AIR CONDITIONING

(For Tractors Without Automatic Temperature Control)

Blower Circuit

Air Conditioning Circuit

Schematic Circuit

ELECTRIC MIRRORS AND WINDSHIELD WIPER/WASHERS

Electric Mirror Circuit

Front Windscreen Wiper/Washer Circuit

Rear Windscreen Wiper/Washer Circuit

Schematic Circuit (For Tractors Not Equipped With Automatic Temperature Control)

Schematic Circuit (For Tractors Equipped With Automatic Temperature Control)

BRAKE LIGHTS AND AIR TRAILER BRAKE

Brake Light Circuit

Air Trailer Brake Solenoid Circuit

Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

Schematic Circuit (For XtraSpeed – E Plus Tractors)

SIDE/TAIL LIGHTS, NUMBER PLATE LIGHTS, RIGHT HAND CONSOLE

LIGHT, TURN SIGNAL AND HAZARD WARNING LIGHTS

(European Specification Tractors Only)

Side/Tail Light, Number Plate Light and

Right Hand Console Light Circuits

Turn Signal and Hazard Warning Light Circuits

Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

Schematic Circuit (For XtraSpeed – E Plus Tractors)

WARNING AND TURN SIGNAL LIGHTS (American Specification Tractors Only)

Turn Signal and Warning Light Circuits

Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

Schematic Circuit (For XtraSpeed – E Plus Tractors)

GRILLE HEADLIGHTS, CAB MOUNTED HEADLIGHTS

AND REAR FOG LIGHTS

(European Specification Tractors Only)

Grille Headlight Circuit

Cab Mounted Headlight Circuit

Rear Fog Light Circuit

Schematic Circuit

HEADLIGHTS, RIGHT HAND CONSOLE LIGHT

AND TAIL LIGHTS

(American Specification Tractors Only)

Headlights Circuit

Right Hand Console Light Circuit

Rear Tail Light Circuits

Schematic Circuit

WORK LIGHTS

(European Specification Tractors Only)

Rear Work Lights

Front Work Lights

Schematic Circuit

WORK LIGHTS

(American Specification Tractors Only)

Rear Work Lights

Front Work Lights

Schematic Circuit

MAIN CONNECTORS

NOTE: For the controller system circuits, refer to the following sections within the XTX Service Manual

Auxiliary/Remote Valve Controller

Hitch/PTO Controller

Indedendent Front Suspension Axle Controller

Cab and Transmission Controller

Instrument Cluster Controller

Cab Suspension Controller

Automatic Temperature Control

–INSTRUMENT CLUSTER PROGRAMMING XTX Series Tractors

GENERAL INFORMATION

IGNITION ON/RUN MODE

During normal operation

Entering The Programming Mode

Area Function (Menu 1)

Distance Function (Menu 2)

Percentage Wheel Slip (Menu 3)

Electrical System Voltage (Menu 4)

Cluster Hitch Position Display Calibration (Menu 5)

Rear Hitch Calibration (Menu 6)

Rear PTO Calibration (Menu 7)

Transmission Calibration (Menu 8)

Dynamic Calibration (Menu 9)

Cab Suspension Calibration (Menu 10)

Timer Function (If Equipped) (Menu 11)

ACCESSORY MODE

Entering The Programming Mode

Programming MPH or km/h (Menu 1)

Programming Tyre Radius (Menu 2)

Tire Radius Constant Table

Programming the Service Intervals (Menu 3)

Service Reminders (Menu 4)

Programming Implement Width (Menu 5)

Programming the “OLd” Instrument Cluster Hours (Menu 6)

Programming the PTO Constants

(ALL PTO options) (Menu 7)

Programming A True Ground Speed Sensor (Radar) Constant (Menu 8)

Programming the Axle Ratio Constants (Menu 9)

Programming the Auxiliary/Remote Valve Constants (Menu10)

–BATTERY SERVICING AND TESTING

SPECIAL TOOLS

SAFETY PROCEDURES

MAINTENANCE

Electrolyte Level

Inspecting and Cleaning the Battery, Cables and Terminals

BATTERY TESTING

Method One – Five Step Battery Test

Method Two – Using Heavy Duty Battery Tester

CHARGING THE BATTERY

PREPARING A DRY CHARGED BATTERY FOR USE

BOOSTER BATTERY CONNECTIONS

-STEERING

–STEERING COLUMN AND STEERING HAND PUMP REMOVAL

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

STEERING COLUMN

Removal and Installation

Disassembly and Assembly

STEERING HAND PUMP

Removal

Installation

–REXROTH STEERING HAND PUMP XTX 185, 200 AND 215 TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

STEERING HAND PUMP

Disassembly

Inspection

Assembly

-TRANSMISSION

–HOW IT WORKS

Introduction

Transmission Construction

Drive Path Description

Transmission Layouts

Powershift Clutch Pressure Testing

Powershift Solenoid Location

Creeper Speed

Forward And Reverse Shuttle

Forward Reverse Manifold

Transmission Control

Four Speed Range Section

Range Selection Xtraspeed-E & E Plus Tractors

Mfd Drive And Park Brake

Rear Axle

Differential

Rear Axle Options

Pto And Hydraulic Pump Drive

Pto Clutch

Shiftable Two Speed Pto / Or E/ Rpm

(Europe Only)

Shiftable Two Speed Pto / Or E/ Rpm

(Europe Only)

Mfd Clutch

Mfd Axles

Mfd Differential

Park Lock Assembly

–GUIDELINES FOR SEPARATING THE SPEED AND RANGE TRANSMISSIONS XTX185, 200 AND 215 TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

GUIDELINES FOR SEPARATING THE SPEED AND RANGE TRANSMISSION

–POWERSHIFT TRANSMISSION SERVICING XTX SERIES TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TRANSMISSION FRONT COVER

Removal and Installation

Front Cover Oil Seal

INPUT SHAFT AND DROPSHAFT

Removal

Installation

INPUT SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Input Shaft

DROPSHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Dropshaft

Cross Sectional Drawing of the Powershift Transmission

HIGH AND LOW SPEED CLUTCH SHAFTS

Removal

Installation

LOW SPEED CLUTCH SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Low Speed Clutch Shaft

HIGH SPEED CLUTCH SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the High Speed Clutch Shaft

Cross Sectional Drawing of the High and Low Speed Transmission

–RANGE TRANSMISSION SERVICING XTX185, 200 AND 215 TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

BEARING CARRIER HOUSING

Removal

Installation

PINION AND SHUTTLE SHAFT

Removal

Installation

INTERMEDIATE SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Intermediate Shaft

SHUTTLE SHAFT

Disassembly

Assembly

Cross Sectional Drawing of the Shuttle Shaft

PINION SHAFT

Disassembly and Assembly

First Gear Shimming Procedure

Synchronizer

Disassembly and Assembly

Pinion Shaft Centre Support

Disassembly and Assembly

Cross Sectional Drawing of the Pinion Shaft

PINION SHAFT SETTINGS

Pinion Shaft Mounting Distance

Pinion Shaft Bearing Preload Setting

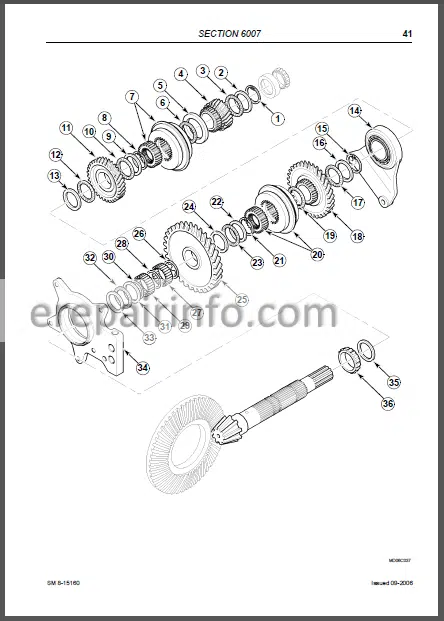

–DIFFERENTIAL AND DIFFERENTIAL LOCK SERVICING XTX185, 200 AND 215 TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DIFFERENTIAL AND DIFFERENTIAL LOCK

GENERAL INFORMATION

DIFFERENTIAL AND DIFFERENTIAL LOCK

Removal

Disassembly

Assembly

Installation

Cross Sectional Drawing of the Differential Assembly

DIFFERENTIAL ADJUSTMENTS

Differential Bearing Preload Adjustment

Pinion/Ring Gear Backlash Adjustment

PINION/RING GEAR TOOTH PATTERN

Correct Tooth Pattern

Incorrect Tooth Pattern

–MFD CLUTCH SERVICING XTX SERIES TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

MFD CLUTCH SERVICING

Removal

Disassembly

Assembly

Installation

Cross Sectional Drawing of the Type 1 MFD Clutch

Cross Sectional Drawing of the Type 2 MFD Clutch

–REAR AXLE REMOVAL XTX185, 200 AND 215 TRACTORS

SPECIAL TORQUES

AXLE REMOVAL

Removal

Installation

–PTO SERVICING – SHIFTABLE/REVERSIBLE XTX185, 200 AND 215 TRACTORS

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

TOOLS TO BE MADE

PTO HOUSING

Removal

Installation

PTO CLUTCH

Removal and Disassembly

Assembly and Installation

Cross Sectional Drawing of the PTO Clutch

SHIFTABLE PTO

Disassembly

Assembly

Cross Sectional Drawing of the Shiftable PTO

REVERSIBLE PTO

Disassembly

Assembly

Cross Sectional Drawing of the Reversible PTO

–MFD FRONT AXLE XTX SERIES TRACTORS 20.29 AXLES

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DISASSEMBLY OPERATIONS

Steering cylinder group

Epicyclic reduction gear

Wheel hub group

Axle beam group

Differential support group

Pinion group

Differential group

ASSEMBLY OPERATIONS

Pinion group

Differential group

Differential carrier group

Axle beam group

Wheel hub group

Epicyclic reduction gear

Steering cylinders group

Toe-in adjustment

Steering angle adjustment

Testing after assembly

–MFD FRONT AXLE XTX SERIES TRACTORS 20.43 AXLES

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DISASSEMBLY OPERATIONS

Steering cylinder group

Epicyclic reduction gear group

Wheel hub group

Axle beam group

Differential support group

Differential group

Pinion group

ASSEMBLY OPERATIONS

Pinion group

Differential group

Differential support group

Axle beam group

Wheel hub group

Epicyclic reduction gear group

Steering cylinder group

Toe-in adjustment

Steering angle adjustment

Testing after assembly

–FRONT SUSPENDED AXLE XTX SERIES TRACTORS 20.29 AXLES

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DISASSEMBLY OPERATIONS

Potentiometer

Steering cylinder unit

Epicyclic reduction gear

Wheel hub unit

Torsion bar unit

Swivel housing unit

Universal joints

Suspension cylinder

Upper arm

Lower arm

Differential support unit

Pinion unit

Differential unit

ASSEMBLY OPERATIONS

Differential unit

Pinion unit

Differential unit support

Lower arm

Upper arm

Suspension cylinder

Universal Joint

Swivel housing unit

Torsion bar unit

Torsion bar preload adjustment

Wheel hub unit

Epicyclic reduction gear unit

Steering cylinder unit

Toe-in and steering angle adjustment

Arms sensor

–FRONT SUSPENDED AXLE XTX SERIES TRACTORS 20.43 AXLES

SPECIFICATIONS

SPECIAL TORQUES

SPECIAL TOOLS

DISASSEMBLY OPERATIONS

potentiometer

Steering cylinder unit

Epicyclic reduction gear

Wheel hub unit

Torsion bar unit

Swivel housing unit

Universal joints

Suspension cylinder

Upper arm

Lower arm

Differential support unit

Pinion unit

Differential unit

ASSEMBLY OPERATIONS

Differential unit

Pinion unit assembly

Differential unit support

Lower arm

Upper arm

Suspension cylinder

Universal Joint

Swivel housing unit

Torsion bar unit

Torsion bar preload adjustment

Wheel hub unit

Epicyclic reduction gear unit

Steering cylinder unit

Toe-in and steering angle adjustment

Arms sensor group

-BRAKES

–XTX BRAKES HOW IT WORKS

BRAKE SYSTEM

Service Brakes General

Park Brake

Optional Park Lock

Brake Disc Housing

BRAKE ACTUATION

General Description

SERVICE BRAKES

General Description

Brake Application

Self Adjusting Mechanism

PARKING BRAKE

General Description

Operation

Optional Mechanical Parking Lock

HYDRAULIC TRAILER BRAKE

General Description

REXROTH VALVE

Brakes Off

Brakes Applied

Maximum Trailer Brake Pressure

Rexroth Hydraulic Trailer Brake Valve Schematic

HUSCO HYDRAULIC TRAILER BRAKE VALVE

General Description

Brakes in Off Position

Brakes Applied

Brakes at Maximum Pressure

Husco Hydraulic Trailer Brake Valve Schematic

SLANZI TRAILER BRAKE VALVE

General Description

Trailer brakes connected and tractor brakes not applied

Trailer brakes connected and tractor brakes applied

Schematic Drawing Of Slanzi Hydraulic Trailer Brake Valve

REMOVING AIR FROM THE TRACTOR SERVICE BRAKES

PNEUMATIC (AIR) TRAILER BRAKING SYSTEM

General Description

Inshot System

SYSTEM LAYOUT

Compressor

Pressure Control Valve

Air Storage

Air Pressure Warning

Fluid Reaction Valves

Trailer Park Brake Operation

Activation of the Air Trailer Brakes

Single Line System

AIR TRAILER BRAKE SCHEMATIC

–SERVICE BRAKES XTX185, 200 and 215 Tractors

SERVICE BRAKES

Tractors With Three Separator Plates

Removal

Installation

Tractors With Two Separator Plates

Removal

Installation

-HYDRAULICS

–XTX HYDRAULICS HOW IT WORKS

INTRODUCTION

General Information

Hydraulic Circuits

Hydraulic Pumps

Hydraulic Pipe Seals

XTX185 to 215 HYDRAULIC SYSTEM – BASIC LAYOUT

General Description

Specifications

HYDRAULIC SCHEMATIC

Legend

XTX Hydraulic Schematic (Rexroth PFC Pump)

TRANSMISSION LUBRICATION CIRCUIT AND PFC PUMP SUPPLY

General Description

Oil Inlet Suction Screen

Charge/lubrication Pump

Pump Location and Drive

Charge/Lubrication Pump flow and pressure

Main Filter Housing

Main Filter Specifications

Filter By-pass

Differential Pressure Switch

Lubrication Pressure Relief Valve

PFC HYDRAULIC PUMP

Rexroth PFC Pump

PFC Axle Piston Pump

PFC Piston Pump Signal Circuit

PFC PUMP SIGNAL CIRCUIT

General Description

Operating Modes

Low Pressure Stand-by – (at engine start up)

Pressure and Flow Supply

Increased Flow Demand

Decreased Flow Demand

Maximum Pressure Limitation

Return to Low Pressure Stand-by

PRIORITY AND REGULATOR VALVE

General Description

Steering Priority Spool

Steering Main Relief Valve

Dynamic Orifice

REGULATED PRESSURE CONTROL CIRCUIT (P1)

General Description

Regulated Pressure Control Spool

Circuit description

POWERSHIFT CONTROL VALVE

General Description

Solenoids

Electronic Control Module (ECM)

Pulse Width Modulation (PWM)

FORWARD/REVERSE MANIFOLD

General Description

Electronic Control System

FORWARD/REVERSE SOLENOID OPERATION

Solenoid Off – Diagram 1

Solenoid On – Diagram 2

FORWARD AND REVERSE CONTROL

General description

Automatic Clutch Control

Forward Drive Engaged

Reverse Drive Engaged

Direction Change Without using the Clutch Pedal

PTO CONTROL

General Description

Pulse Width Modulation (PWM)

PTO OFF – Diagram 1

PTO ON – Diagram 2

DIFFERENTIAL LOCK & MFD CONTROL

Differential Lock General Description

Differential Lock OFF

Differential Lock ON

MFD Control General Description

MFD Off

MFD On

SERVO POWER RANGE SELECTOR

RANGE SELECTION (XtraSpeed-E & XtraSpeed-Eplus Tractors)

General Description

Control

CREEP SPEED SELECTION

General Description

Creeper Disengaged

Creeper Engaged

PARK LOCK

General Description

Park Lock Disengaged

Park Lock Engaged

Manual Operation Of The Park Lock

REMOTE AUXILIARY VALVES

General Description

High Pressure Main Circuit

4 SECTION 8

DT30-10203 Issued 09-2006

MECHANICALLY OPERATED AUXILIARY REMOTE VALVES

Raise position (Diagram 1)

Lower Position (Diagram 2)

Float Position (Diagram 3)

Signal Check Valves

Operation of the Priority Flow Control Spool (21h)

Operation of the Detent mechanism

MECHANICALLY OPERATED AUXILIARY REMOTE VALVES (Non Priority)

General Description

Operation of the flow control spool (22i)

Operating more than one remote valve

ELECTRICALLY OPERATED AUXILIARY REMOTE VALVES

General Description

Auxiliary Solenoid Valve(23p)

XtraSpeed & XtraSpeed-E 4th valve

Neutral Position

Raise Position

Lower Position

XtraSpeed-Eplus Valves Position 1 to 4

Valve operation (raise)

Valve operation (lower)

Valve operation (float)

Motor Remote Spool Operation

HYDRAULIC POWER BEYOND

General Description

Hydraulic Test points

ELECTRONIC HITCH AND PTO CONTROLLER (EHC)

General Description

Pulse Width Modulation (PWM)

Operator Control of the Hitch

Operating in Position Control

Operating in Load Control (Lower Link Sensing)

HITCH HYDRAULIC CIRCUIT

General Description

Hitch in Neutral

Hitch Raising

Hitch Lowering

–CHARGE/LUBRICATION PUMP XTX185, 200 AND 215 TRACTORS

CHARGE/LUBRICATION PUMP

Removal

Installation

–BOSCH REMOTE VALVES XTX SERIES TRACTORS

SPECIAL TORQUES

REMOTE VALVES

Removal and Installation

REMOTE VALVE

Disassembly and Assembly

REMOTE VALVE (ELECTRONIC)

Disassembly and Assembly

CHECK VALVE

Disassembly and Assembly

Check valve pin

REMOTE VALVE END PLATE

Disassembly and Assembly

REMOTE VALVE END PLATE WITH FORTH REMOTE VALVE

Disassembly and Assembly

REMOTE VALVE END PLATE MANIFOLD

Disassembly and Assembly

-PEDAL, LEVER AND SWITCH ADJUSTMENTS XTX SERIES TRACTORS

SPECIAL TORQUES

SPECIAL TOOLS

HAND AND FOOT THROTTLE ADJUSTMENT

PARKING BRAKE ADJUSTMENT

BRAKE PEDAL

Brake Pedal Stop Adjustment

Master Cylinder Rod Adjustment

Brake Pedal Maximum Travel Adjustment

Brake Light Switch Adjustment

DROMONE AUTO HITCH ADJUSTMENT (if Equipped)

Cable Adjustment

Lift Rod Adjustment

CBM AXLA AUTO HITCH ADJUSTMENT (if Equipped)

Cable Adjustment

Lift Rod Adjustment

SHIFTABLE PTO ADJUSTMENT

REMOTE CONTROL VALVE LINKAGE

RANGE SELECTOR LINKAGE

(XtraSpeed Tractors)

RANGE SELECTOR SWITCHES

(XtraSpeed Tractors)

RANGE SELECTOR LINKAGE

(XtraSpeed – E and XtraSpeed – E Plus Tractors)

REMOVING AIR FROM THE BRAKE SYSTEM

-CONTROLS

–XTX ELECTRONIC CONTROLLER HOW IT WORKS

INTRODUCTION

XTX Tractor electrical system

What is CAN BUS

XTX TRACTOR CAN BUS LAYOUT

General Description

Control modules

CONTROLLER LOCATIONS

Engine Controller

Transmission Controller

Hitch/PTO and Cab Controllers (XtraSpeed and XtraSpeed-E)

Hitch/PTO Controller, Cab Controller and Auxiliary Valve Controller (XtraSpeed-Eplus)

Instrument Cluster

Automatic Temperature Control (ATC) – (If Equipped)

Cab Suspension Controller- (If Equipped)

Independent Front Suspension (IFS) Controller – (If Equipped)

INSTRUMENT CLUSTER

General Description

ERROR CODES

General Description

Instrument cluster displayed error codes

“McCORMICK DIAGNOSTIC CENTRE” (MDC) ELECTRONIC SERVICE TOOL

CONTROLLER LOGIC

CAN MESSAGES FOR CAB CONTROLLER (CC 4)

CAB CONTROLLER (CC4) LOGIC CHART

CAN MESSAGES FOR TRANSMISSION CONTROLLER (TC 4)

TRANSMISSION CONTROLLER (TC 4) LOGIC CHART

ENGINE CONTROLLER CAN MESSAGES

ENGINE ELECTRONIC CONTROLLER LOGIC CHART XTX185 & 200 ONLY

ENGINE CONTROLLER CAN MESSAGES

ENGINE ELECTRONIC CONTROLLER LOGIC CHART XTX215 ONLY

CAN MESSAGES FOR INSTRUMENT CLUSTER

XTX TRACTOR INSTRUMENT CLUSTER LOGIC CHART

CAN MESSAGES FOR HITCH & PTO CONTROLLER

COMBINED HITCH & PTO CONTROLLER LOGIC CHART

CAN MESSAGES FOR AUXILIARY VALVE CONTROLLER (E-Plus only)

AUXILIARY VALVE CONTROLLER AND VALVE SLICE LOGIC CHART (E-Plus only)

–AUXILIARY/REMOTE VALVE CONTROLLER ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

GENERAL INFORMATION FOR ELECTRONIC

AUXILIARY/REMOTE VALVE CONTROL

Auxiliary/Remote Valve Operation

CAN Bus Communication

ERROR CODES GENERAL INFORMATION

Retrieving Instrument Cluster Displayed Active Error Codes

AUXILIARY/REMOTE VALVE MANUAL OPERATION

CIRCUIT TESTING

General Information

ERROR CODE TROUBLESHOOTING GUIDE

Auxiliary/Remote Valve Controller Error Codes

No Auxiliary/Remote Valve Controller Error

(No Power to Auxiliary/Remote Valve Controller)

Controller Error Code 10

Controller Error Code 11

Controller Error Code 12

Controller Error Code 13

Controller Error Code 14

Controller Error Code 15

Controller Error Code 16

Controller Error Code 17

Controller Error Code 20

Controller Error Code 21

Controller Error Code 22

Controller Error Code 23

Controller Error Code 24

Controller Error Code 25

Controller Error Code 26

Controller Error Code 27

Controller Error Code 30

Controller Error Code 31

Controller Error Code 32

Controller Error Code 33

Controller Error Code 34

Controller Error Code 35

Controller Error Code 36

Controller Error Code 37

Controller Error Code 40

Controller Error Code 41

Controller Error Code 42

Controller Error Code 43

Controller Error Code 44

Controller Error Code 45

Controller Error Code 46

Controller Error Code 47

Controller Error Code 50

Controller Error Code 51

Controller Error Code 52

Controller Error Code 53

Controller Error Code 54

Controller Error Code 55

Controller Error Code 56

Controller Error Code 57

Controller Error Code 60

Controller Error Code 61

Controller Error Code 62

Controller Error Code 63

Controller Error Code 64

Controller Error Code 65

Controller Error Code 73

Controller Error Code 74

Controller Error Code 75

Controller Error Code 76

Controller Error Code 77

Multiple Controller Potentiometer Low Signal Error Codes

Multiple Controller Potentiometer High Signal Error Codes

Auxiliary/Remote Valve Error Codes

Valve Error Code 17 and 18

Valve Error Code 19 and 20

Valve Error Code 21

Valve Error Code 22

Valve Error Code 23

Valve Error Code 33

Valve Error Code 34

Valve Error Code 35

Valve Error Code 36

Valve Error Code 37

Valve Error Code 38

Valve Error Code 65

Valve Error Code 66

Valve Error Code 67

Valve Error Code 129

Valve Error Code 130

Valve Error Code 131

COMPONENT IDENTIFICATION

Right Hand Console and Armrest Components

Rear Fender and Transmission Components

SCHEMATIC CIRCUIT

MAIN CONNECTORS

–HITCH/PTO CONTROLLER (HITCH, PTO, MFD AND DIFFERENTIAL LOCK) CALIBRATION, ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

ELECTRONIC HITCH AND PTO CONTROL GENERAL INFORMATION

CAN Bus Communication

Hitch Operation

PTO Control Operation

Operators Seat Switch Monitor and Alarm

ERROR CODES GENERAL INFORMATION

Retrieving Instrument Cluster Displayed Active Error Codes

HITCH CALIBRATION

PTO CALIBRATION

CIRCUIT TESTING

General Information

CONTROLLER ERROR CODE TROUBLESHOOTING GUIDE

PTO Error Codes

PTO Error Code 1104

PTO Error Code 1105

PTO Error Code 1106

PTO Error Code 1201

PTO Error Code 1202

PTO Error Code 1204

PTO Error Code 1205

PTO Error Code 1206

PTO Error Code 1303

PTO Error Code 1304

PTO Error Code 1401

PTO Error Code 1402

PTO Error Code 1501

PTO Error Code 1502

PTO Error Code 1503

PTO Error Code 1601

PTO Error Code 1602

PTO Error Code 1603

PTO Error Code 1604

PTO Error Code 1605

PTO Error Code 1606

PTO Error Code 1607

PTO Error Code 1608

PTO Error Code 1609

PTO Error Code 1701

PTO Error Code 1702

PTO Error Code 1703

PTO Error Code 1704

PTO Error Code 1706

PTO Error Code 1707

PTO Error Code 1801

PTO Error Code 1803

PTO Error Code 1804

PTO Error Code 1805

PTO Error Code 1806

PTO Error Code 1807

PTO Error Code 1808

PTO Error Code 1809

PTO Error Code 1810

PTO Error Code 1811

Hitch Error Codes

Hitch Error Code 2164

Hitch Error Code 2165

Hitch Error Code 2166

Hitch Error Code 2167

Hitch Error Code 2168

Hitch Error Code 2169

Hitch Error Code 2170

Hitch Error Code 2171

Hitch Error Code 2173

Hitch Error Code 2174

Hitch Error Code 2175

Hitch Error Code 2176

Hitch Error Code 2177

Hitch Error Code 2178

Hitch Error Code 2201

Hitch Error Code 2202

Hitch Error Code 2203

Hitch Error Code 2206

Hitch Error Code 2207

Hitch Error Code 2208

Hitch Error Code 2209

Hitch Error Code 2210

Hitch Error Code 2211

Hitch Error Code 2212

Hitch Error Code 2213

Hitch Error Code 2214

Hitch Error Code 2215

Hitch Error Code 2300

Hitch Error Code 2301

Hitch Error Code 2302

Hitch Error Code 2303

Hitch Error Code 2304

Hitch Error Code 2305

Hitch Error Code 2306

Hitch Error Code 2307

Hitch Error Code 2308

Hitch Error Code 2309

Hitch Error Code 2310

Hitch Error Code 2311

Hitch Error Code 2313

Hitch Error Code 2314

Hitch Error Code 2401

Hitch Error Code 2402

Hitch Error Code 2403

Hitch Error Code 2404

Hitch Error Code 2405

Hitch Error Code 2406

Hitch Error Code 2407

Hitch Error Code 2408

Hitch Error Code 2409

Hitch Error Code 2410

Hitch Error Code 2411

Hitch Error Code 2412

COMPONENT IDENTIFICATION

Instrument Panel Components

Right Hand Console Components (XtraSpeed Tractors Only)

Right Hand Console Components (XtraSpeed – E Tractors Only)

Right Hand Console and Armrest Components

(XtraSpeed – E Plus Tractors Only)

Rear Fender Components (XtraSpeed – E Plus Tractors Only)

Transmission Components (European Specification Tractors)

Transmission Components (American Specification Tractors)

HITCH/PTO CONTROLLER SCHEMATIC CIRCUITS

Hitch/PTO Controller Pin Identification

Hitch/PTO Schematic Circuit (For XtraSpeed Tractors)

Hitch/PTO Schematic Circuit (For XtraSpeed – E Tractors)

Hitch/PTO Schematic Circuit (For XtraSpeed – E Plus Tractors)

Differential and MFD Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

Differential and MFD Schematic Circuit (For XtraSpeed – E Plus Tractors)

CAN BUS SCHEMATIC CIRCUITS

CAN Bus Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

CAN Bus Schematic Circuit (For XtraSpeed – E Plus Tractors)

MAIN CONNECTORS

–INDEPENDENT FRONT SUSPENSION AXLE CONTROLLER CALIBRATION, ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

GENERAL INFORMATION AXLE CONTROL

CALIBRATION

General Information

Calibration Procedure

AXLE POSITION SENSORS

Position Sensor Check

Axle Position Sensor Adjustment

MANUAL LOWERING OF THE FRONT AXLE

CIRCUIT TESTING

General Information

ERROR CODE TROUBLESHOOTING GUIDE

Error Code 21

Error Code 22

Error Code 31

Error Code 32

No Error Code –

Axle Suspension Does Not Operate (XtraSpeed and XtraSpeed – E Tractors Only)

No Error Code – Axle Suspension Does Not Operate (XtraSpeed – E Plus Tractors Only)

No Error Code – Axle Will Not Operate in Manual Mode

No Error Code – Axle Will Not Raise to Mid position in Suspension Mode,

Only Right Hand Side of Axle Raises in Manual Mode

No Error Code – Axle Will Not Raise to Mid position in Suspension Mode,

Only Left Hand Side of Axle Raises in Manual Mode

No Error Code – Axle Will Not Remain at the Lowest Position in the Manual Mode

No Error Code – Axle Will Not Remain at the Highest Position in the Manual Mode

No Error Code – Axle Will Not Automatically go into Suspension Mode Above 14 Km/h

COMPONENT IDENTIFICATION

Right Hand Console Components

(XtraSpeed and XtraSpeed – E Tractors Only)

Right Hand Console Components (XtraSpeed – E Plus Tractors Only)

Transmission Components

Front Axle Components

Front Axle Suspension Controller Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

Front Axle Suspension Controller Schematic Circuit (For XtraSpeed – E Plus Tractors)

MAIN CONNECTORS

–CAB CONTROLLER AND TRANSMISSION CONTROLLER CALIBRATION, ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

SPECIFICATIONS

GENERAL INFORMATION FOR ELECTRONIC TRANSMISSION CONTROL

Cab Controller

Transmission Controller

CAN Bus Communication

TRANSMISSION CALIBRATION

Transmission Calibration – General Information

Transmission Calibration – Selection Procedure

Transmission Calibration For XtraSpeed Tractors up to PIN JJE3500983 Only

Transmission Calibration For XtraSpeed Tractors From PIN JJE3500983 Only

Transmission Calibration For XtraSpeed – E and E Plus Tractors Only

Transmission Calibration Error Codes

ERROR CODES GENERAL INFORMATION

Retrieving Instrument Cluster Displayed Active Error Codes

ERROR CODE TROUBLESHOOTING GUIDE

Transmission Controller Error Codes

Transmission Error Code 5000 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5001 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5002 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5003 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5004 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5005 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5006 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5007 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5008 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5009 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5010 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5011 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5012 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5013 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5014 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5015 (XtraSpeed E and XtraSpeed E-Plus Tractors Only)

Transmission Error Code 5016

Transmission Error Code 5017

Transmission Error Code 5018

Transmission Error Code 5019

Transmission Error Code 5020

Transmission Error Code 5021

Transmission Error Code 5022

Transmission Error Code 5023

Transmission Error Code 5024

Transmission Error Code 5025

Transmission Error Code 5026

Transmission Error Code 5027

Transmission Error Code 5028

Transmission Error Code 5029

Transmission Error Code 5030

Transmission Error Code 5031

Transmission Error Code 5032

Transmission Error Code 5033

Transmission Error Code 5034

Transmission Error Code 5035

Transmission Error Code 5036

Transmission Error Code 5037

Transmission Error Code 5038

Transmission Error Code 5039

Transmission Error Code 5040

Transmission Error Code 5041

Transmission Error Code 5042

Transmission Error Code 5043

Transmission Error Code 5044

Transmission Error Code 5045

Transmission Error Code 5046

Transmission Error Code 5047

Transmission Error Code 5048

Transmission Error Code 5049

Transmission Error Code 5050

Transmission Error Code 5051

Transmission Error Code 5052

Transmission Error Code 5053

Transmission Error Code 5062

Transmission Error Code 5063

Transmission Error Code 5064

Transmission Error Code 5065

Transmission Error Code 5066

Transmission Error Code 5067

Transmission Error Code 5068

Transmission Error Code 5069 (XtraSpeed Tractors from PIN JJE3500983,

XtraSpeed – E and XtraSpeed – E Plus Tractors)

Transmission Error Code 5070 (XtraSpeed Tractors from PIN JJE3500983, XtraSpeed – E and XtraSpeed – E Plus Tractors)

Transmission Error Code 5071 (XtraSpeed Tractors from PIN JJE3500983, XtraSpeed – E and XtraSpeed – E Plus Tractors)

Transmission Error Code 5072 (XtraSpeed Tractors from PIN JJE3500983, XtraSpeed – E and XtraSpeed – E Plus Tractors)

Transmission Error Code 5081

Transmission Error Code 5082

Transmission Error Code 5083

Transmission Error Code 5084

Transmission Error Code 5085

Transmission Error Code 5087

Transmission Error Code 5088

Transmission Error Code 5089

Transmission Error Code 5091

Transmission Error Code 5093

Transmission Error Code 5095/5096

Transmission Error Code 5098

Transmission Error Code 5099

Transmission Error Code 5100

Transmission Error Code 5101

Transmission Error Code 5102

Transmission Error Code 5103

Transmission Error Code 5105

Transmission Error Code 5106

Transmission Error Code 5107

Cab Controller Error Codes

Cab Error Code 5300

Cab Error Code 5301

Cab Error Code 5302

Cab Error Code 5303

Cab Error Code 5304

Cab Error Code 5305

Cab Error Code 5307

Cab Error Code 5309

Cab Error Code 5311

Cab Error Code 5315

Cab Error Code 5316

Cab Error Code 531 (XtraSpeed – E Plus Tractors Only)

Cab Error Code 5318 (XtraSpeed – E Plus Tractors Only)

Cab Error Code 5319

Cab Error Code 5320

Cab Error Code 5321

Cab Error Code 5322

Cab Error Code 5323

Cab Error Code 5324

Cab Error Code 5326

Cab Error Code 5327

Cab Error Code 5328

CIRCUIT TESTING

General Information

COMPONENT IDENTIFICATION

Instrument Panel Components

Right Hand Console Components (XtraSpeed Tractors Only)

Right Hand Console Components (XtraSpeed – E Tractors Only)

Right Hand Console Components (XtraSpeed – E Plus Tractors Only)

Rear Fender Components (XtraSpeed – E Plus Tractors Only)

Transmission Components

TRANSMISSION CONTROLLER SCHEMATIC CIRCUITS

Transmission Controller Pin Identification

Transmission Controller Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

Transmission Controller Schematic Circuit (For XtraSpeed – E Plus Tractors)

CAB CONTROLLER SCHEMATIC CIRCUITS

Cab Controller Pin Identification

Cab Controller Schematic Circuit (For XtraSpeed Tractors up to PIN JJE3500311)

Cab Controller Schematic Circuit (For XtraSpeed Tractors from PIN JJE3500312 to JJE3500982)

Cab Controller Schematic Circuit (For XtraSpeed Tractors from PIN JJE3500983)

Cab Controller Schematic Circuit (For XtraSpeed – E Tractors up to PIN JJE3500311)

Cab Controller Schematic Circuit (For XtraSpeed – E Tractors from PIN JJE3500312)

Cab Controller Schematic Circuit (For XtraSpeed – E Plus Tractors up to PIN JJE3500311)

Cab Controller Schematic Circuit (For XtraSpeed – E Plus Tractors from PIN JJE3500312)

CAN BUS SCHEMATIC CIRCUITS

CAN Bus Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

CAN Bus Schematic Circuit (For XtraSpeed – E Plus Tractors)

MAIN CONNECTORS

–INSTRUMENT CLUSTER CONTROLLER ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

INSTRUMENT CLUSTER GENERAL INFORMATION

CAN Bus Communication

ERROR CODES GENERAL INFORMATION

Retrieving Instrument Cluster Displayed Active Error Codes

CIRCUIT TESTING

General Information

ERROR CODE TROUBLESHOOTING GUIDE

Error Code 100

Error Code 101

Error Code 102

Error Code 103

Error Code 103

Error Code 200

Error Code 201

Error Code 202

Error Code 300

Error Code 301 (XTX185 and XTX200 Tractors Only)

Error Code 301 (XTX215 Tractors Only)

Error Code 302

Error Code 303

Error Code 304 (XtraSpeed – E Plus Tractors Only)

Error Code 305

COMPONENT IDENTIFICATION

Instrument Pзпe! Components

Right Hand Console Components (XtraSpeed and XtraSpeed – E Tractors Only)

Right Hand Console and Armrest Components (XtraSpeed – E Plus Tractors Only)

Engine Components – XTX185 3nd XTX200 Tractors

Engine Components – XTX215 Tractors

Transmission Components

INSTRUMENT CLUSTER SCHEMATIC CIRCUIT

CAN BUS SCHEMATIC CIRCUIT

CAN Bus Schematic Circuit (For XtraSpeed 3nd XtraSpeed – E Tractors)

CAN Bus Schematic Circuit (For XtraSpeed – E Plus Tractors)

MAIN CONNECTORS

–CONTROLLER AND INSTRUMENT CLUSTER SOFTWARE REPROGRAMMING (USING THE MCCORMICK DIAGNOSTIC CENTRE)

SPECIAL TOOLS

GE NERAL INFORMATION

1O14T1AVG COMMUNICATIONS ADAPTERCONNECTION

AUXILIARY REMOTE VALVE

CONTROLLER PROGRAMMING

AUXILIARY REMOTE VALVE CONFIGURATION

AUXILIARY REMOTE VALVE NUMBERING

INSTRUkENT CLUSTER PROGRAMMING

HITCH CAB, TRANSMSSION AND CAB SUSPENSION CONTROLLER PROGRAMMING

HITCH CONTROLLER CONFIGURATION

TRANSMSSION CONTROLLER CONFIGURATION

–CAB SUSPENSION CONTROLLER ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

CAB SUSPENSION CONTROLLER GENERAL INFORMATION

CAN Bus Communication

ERROR CODES GENERAL INFORMATION

Retrieving Instrument Cluster Displayed Active Error Codes

CAB SUSPENSION CALIBRATION

CAB LOWERING PROCEDURE

CIRCUIT TESTING

General Information

ERROR CODE TROUBLESHOOTING GUIDE

Error Code 66

Error Code 67

Error Code 68

Error Code 69

Error Code 70

Error Code 71

Error Code 72

Error Code 73

Error Code 74

Error Code 75

Error Code 76

Error Code 77

Error Code 78

CAB SUSPENSION COMPONENT IDENTIFICATION

CAB SUSPENSION SCHEMATIC CIRCUIT

CAN BUS SCHEMATIC CIRCUIT

CAN Bus Schematic Circuit (For XtraSpeed and XtraSpeed – E Tractors)

CAN Bus Schematic Circuit (For XtraSpeed – E Plus Tractors)

MAIN CONNECTORS

–AUTOMATIC TEMPERATURE CONTROL ERROR CODES, TROUBLESHOOTING AND SCHEMATICS

SPECIAL TOOLS

AUTOMATIC TEMPERATURE CONTROL GENERAL INFORMATION

SYSTEM OPERATION

CENTIGRADE FAHRENHEIT DISPLAY

CIRCUIT TESTING General Information

ERROR CODE TROUBLESHOOTING GUIDE

Temperature Control Module Error Codes

Error Code 01

Error Code 02

Error Code 03

Error Code 04

Error Code 05

Error Code 06

Error Code 07

Error Code 08

Error Code 10

COMPONENT IDENTIFICATION AND SCHEMATIC CIRCUITS

Air Conditioning Components (Cab Front)

Air Conditioning Components (Rear and Left Hand Side of Cab)

Automatic Temperature Control Schematic Circuit (XTX185 and XTX200 Tractors)

Automatic Temperature Control Schematic Circuit (XTX215 Tractors)

MAIN CONNECTORS

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Anonymous (verified owner) –

Very good website