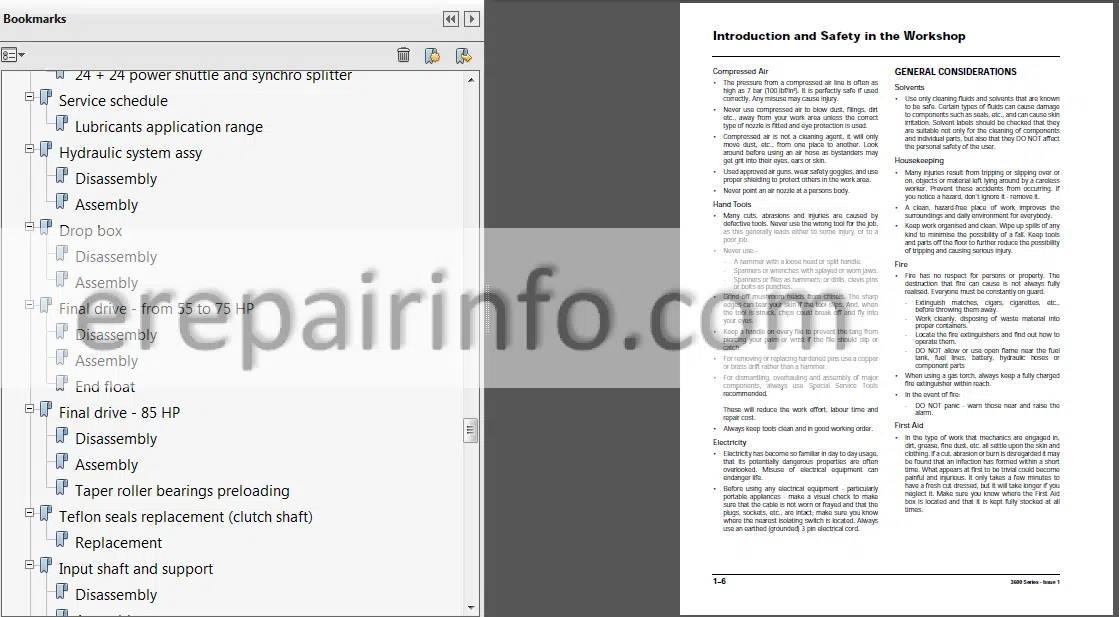

Factory Service Repair Manual For Massey Ferguson 3600 Series Tractors. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 762

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Hydraulic Diagrams: Yes

Model

Massey Ferguson 3600 Series

Contents

- -INTRODUCTION AND SAFETY IN THE WORKSHOP

Introduction

Safety Alert Symbol And Terms

Safety In The Workshop

Safety – A Word To The Mechanic

Safety – Danger Warning And Caution

Safety Decals

General

Personal Considerations

Equipment Considerations

General Considerations

Operational Considerations

Servicing Techniques - -Tractor

–General information

MANUAL USE

Maintenance

Repair

Information Property

AGREEMENTS AND DEFINITIONS

Agreements

Definitions

Typographic Agreements

Measurements

Symbology

GENERAL DESCRIPTION

General

Hoses And Tubes

O-Ring Flat Face Seal Fittings

Shimming

Rotating Shaft Seals

O-Rings

Bearings

Spring Pins

Hardware Torque Values

Notes For Spare Parts

Notes For Equipment

Notices

How To Move The Machine With The Battery Removed

–General Specification

Product Identification

Cab

Platform Tractors

Platform Tractors

General Description

Tare Weights Kg (Lb)*

Max Permissible Weights Kg (Lb)

Tare Weights Kg (Lb)*

Max Permissible Weights Kg (Lb)

Dimensions With Platform

Dimensions With Cab

Steering Angle

Steering Radius

Travel Speed

Tyre

Tyre Pressure

Battery

Description And Operation

Battery Replacement

Maintenance

Servicing

Dry Charged

Charging The Battery

Normal (Top-Up) Charging

Recharging Deeply Discharged

Tests

Specific Gravity

Performance Test

Test Charging

Common Causes Of Battery Failures

Emergency Starting Through Another Battery

Battery Connection Using Suitable Cables

Alternator

General Maintenance Table

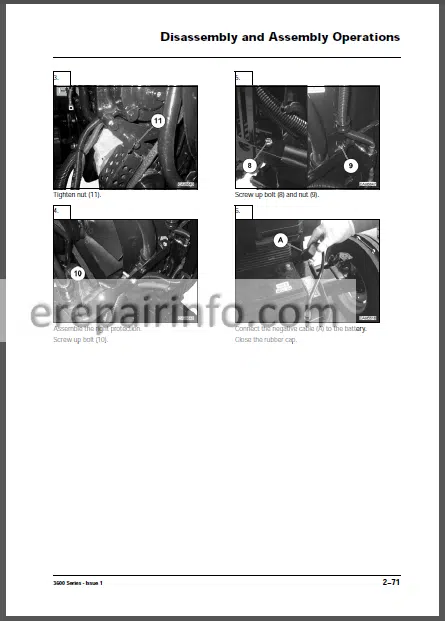

–DISASSEMBLY AND ASSEMBLY OPERATIONS

Air Filter

Air Filter Line

Battery

Alternator

Radiator

Fan

Exhaust Pipe

Fan Belt

Air Filter Assy Replacement

Bonnet

Front Weight

Oil Cooler

Muffler

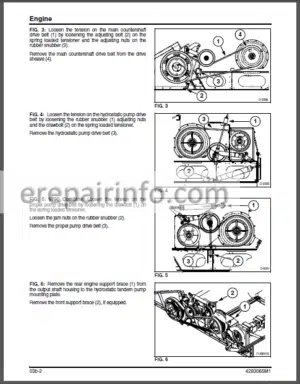

Hydraulic Pump

Starting Motor

Engine Removal

Front Axle Wd

Fuel Tank

Brake Cylinder

Hand Brake Adjustment

Lock Valve

Rockshaft Valve

Rear Wheels

Auxiliary Distributors

Oil Suction Strainer

Oil Filter Cartridge Replacement

Side Auxiliary Distributors

Powershuttle Hydraulic Valve

Oil Filter Sensor

Clutch Box

Rockshaft

Platform

Steering Valve

Brake Circuit Bleeding - -Electrical System

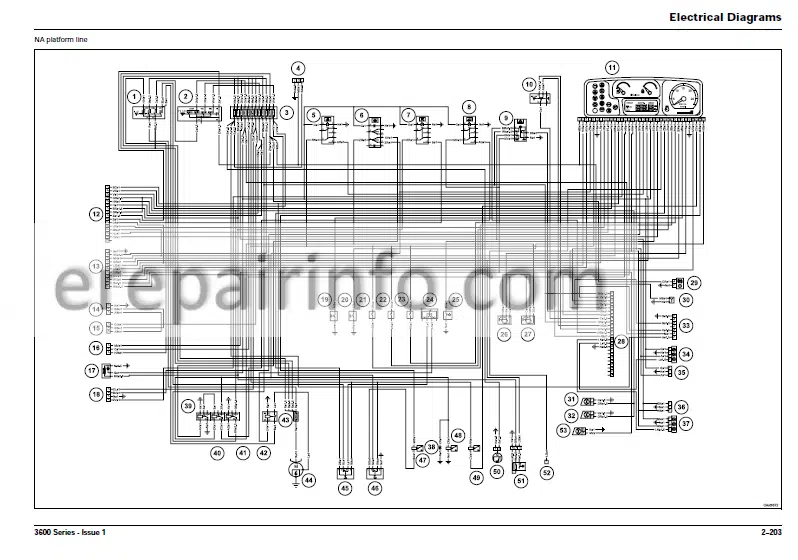

–Electrical Diagrams

Colour Abbreviation

Hi-Lo Power Harness

Hi-Lo Power Harness

Trailer Brake Valve Italy Harness

Trailer Brake Valve Italy Harness

Massey Ferguson Bonnet Line

Massey Ferguson Bonnet Line

A/C Power Harness

A/C Power Harness

Preheating Harness

Preheating Harness

Mf Engine Line

Mf Engine Line

Na Platform Line

Na Platform Line

Row Platform Line

Row Platform Line

V Powershuttle Harness

V Powershuttle Harness

Cab Electric System

Powershuttle Line - -Hydraulic System

–Hydraulic System Components

Major Components

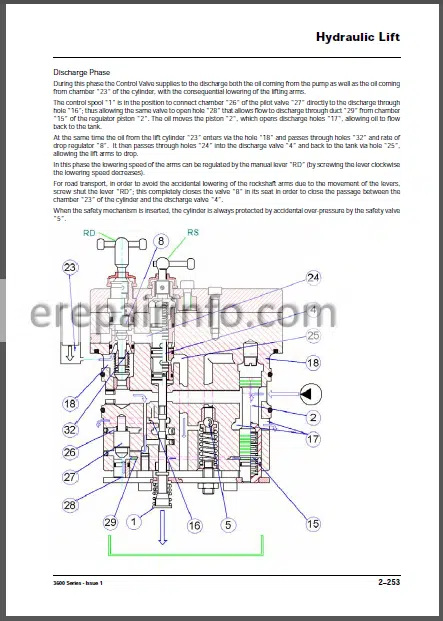

–Hydraulic Lift

SPECIFICATIONS

Technical Features

Dimensional Features

Calibration Settings Of Control Valve

DIAGRAM

CIRCUIT DIAGRAM OF HYDRAULIC LIFTING DEVICE

FUNCTIONING OF CONTROL VALVE

Neutral Phase

Delivery Phase

Discharge Phase

HOW THE INTERNAL LEVERAGE SYSTEM FUNCTIONS

Functioning With Position Control (Fig Page 52)

Functioning Of Draft Control (Fig Page 52 – 54)

Combined Functioning Of Position And Draft Control (Fig Page 52-54)

USE OF CONTROL LEVERS

Position Control (Lever 1)

Draft Control (Lever 2)

Combined Operation For Position And Draft Control

ADJUSTMENT OF CONTROL VALVE SENSITIVITY

Functioning Of The Sensitivity Of The Control Valve

ADJUSTMENT OF POSITION CONTROL LEVER

ADJUSTMENT OF DRAFT CONTROL LEVER

CONTROL OF ASSEMBLY OF REACTION SPRING

MEASUREMENT CONTROL OF PUSH ROD

DIAGNOSTIC

–DIFFERENTIAL ASSEMBLY

Disassembly

Assembly - -TRANSMISSION 506 HTR

Intended Use

Product Identification

Technical Features

Tightening Torques, Sealants And Grease Application

Hi/Lo Power Flows

Assembly Typical Data

Filling And Checks

Service Schedule

–DISASSEMBLY AND ASSEMBLY OPERATIONS

Hydraulic System Assy

Drop Box

Final Drive – From 55 To 75 Hp

Final Drive – 85 Hp

Teflon Seals Replacement (Clutch Shaft)

Input Shaft And Support

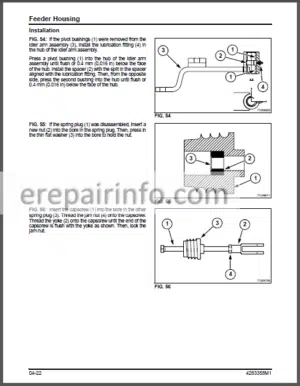

Upper Covers And Rockshaft

Speed And Ranges Levers

Clutch Housing – Synchro Shuttle

Clutch Housing – Synchro Splitter

Synchro Shuttle And Power Splitter

Power Shuttle – Power Shuttle And Synchro Splitter

Air Compressor

Wet Clutch – Power Splitter

Wet Clutch – Power Shuttle

Hi-Lo Synchronizer (Synchro Splitter)

Cover And Pto Wet Clutch

Pto – Power Take Off

Pto Input Shaft

Pto Output Shaft

Pto Brake

Ground Drive Pto

Slave Cylinder

Parking Brake

Housing Sensors Assy

Differential Locking Control

Inner Control Assy

Idle Gear

Power Shuttle

Range Gears (Primary Shaft)

Input Shaft – Synchro Shuttle

Input Shaft – 12+12 Power Shuttle

Synchronizer Shuttle (Replacement)

Speed Gears (Primary Shaft)

Differential Assy

Pinion – Ranges Pinion – Ranges (Secondary Shaft)

Secondary Shaft

Speed Gears (Secondary Shaft)

–Special Tools

SPECIAL TOOLS

Drop Box

Gear Box

Clutch Housing (12+12 Power Shuttle)

Wet Clutch (Power Shuttle)

Wet Clutch (Power Splitter)

Final Drive – From 55 To 75 Hp

Final Drive – 85 Hp

Clutch Housing (Synchro Shuttle – Synchro Splitter

Cover And Pto Wet Clutch

Clutch Housing (Synchro Shuttle – Synchro Splitter

Clutch Housing (Synchro Shuttle And Power Splitter)

Clutch Housing (Synchro Shuttle) - -2WD AXLE

–General Information

MANUAL USE

Maintenance

Repair

INFORMATION PROPERTY

AGREEMENTS AND DEFINITIONS

Agreements

Definitions

Typographic Agreements

Measurements

Conversion Table

Symbology

GENERAL DESCRIPTION

RECOMMENDATIONS FOR REPAIR OPERATIONS

Shafts Seals

O-Rings

Bearings

Sealing

Cleaning

Checks

Ends Of Flanges And Tools

Assembly Methods

–Genral Specifications

INTENDED USE

PRODUCT IDENTIFICATION

Axle Tag

GENERAL DESCRIPTION

TECHNICAL FEATURES

Main Dimensions (Mm)

MAINTENANCE

Service Schedule

Lubricants Application Range

GREASE IN ASSEMBLY

ADHESIVE AND SEALANT

Sealing Compounds And Adhesives

TIGHTENING TORQUES

–DISASSEMBLY AND ASSEMBLY OPERATIONS

STEERING CYLINDER GROUP

Disassembly

Assembly

WHEEL HUB GROUP

Disassembly

Assembly

WHEEL HUB SUPPORT GROUP

Disassembly

Assembly

AXLE BEAM GROUP

Disassembly

Assembly

TOE-IN/STEERING ANGLE

Toe-In Adjustment

Steering Angle Adjustment

–Troubleshooting

Troubleshooting

Axle Problem And Diagnosis - -Front Axle

–General Information

MANUAL USE

Maintenance

Repair

INFORMATION PROPERTY

AGREEMENTS AND DEFINITIONS

Agreements

Definitions

Typographic Agreements

Measurements

Conversion Table

Symbology

GENERAL DESCRIPTION

RECOMMENDATIONS FOR REPAIR OPERATIONS

Shafts Seals

O-Rings

Adjusting Shims

Bearings

Split Pins

Sealing

Oil Drain

Cleaning

Checks

Ends Of Flanges And Tools

Lubricant Use

–General Specifications

INTENDED USE

PRODUCT IDENTIFICATION

Axle Serial Plate

GENERAL DESCRIPTION

TECHNICAL FEATURES

Limited Slip Differential Disks Specifications

Principal Dimensions (Mm)

MAINTENANCE AND OIL CHANGE

Service Schedule

Lubricants Application Range

GREASE IN ASSEMBLY

ADHESIVE AND SEALANT

Sealing Compounds And Adhesives

TIGHTENING TORQUES

–DISASSEMBLY AND ASSEMBLY OPERATIONS

STEERING CYLINDER GROUP

Disassembly

Assembly

EPICYCLIC REDUCTION GEAR GROUP

Disassembly

Assembly

WHEEL HUB GROUP

Disassembly

Assembly

AXLE BEAM GROUP

Disassembly

Assembly

TRUNNIONS GROUP

Disassembly

Assembly

DIFFERENTIAL SUPPORT GROUP

Disassembly

Assembly

BEVEL GEAR MARKING TEST

DIFFERENTIAL GROUP

Disassembly

Assembly

PINION GROUP

Disassembly

Assembly

TOE-IN/STEERING ANGLE

Toe-In Adjustment

Steering Angle Adjustment

SPECIAL REPAIR OPERATIONS

Wheel And Double U-Joint Group Disassembly

Wheel And Double U-Joint Group Assembly

Double U-Joint Seal Ring Replacement On Axle Beam Side

Double U-Joint Bushing Replacement On Axle Beam Side

TESTING AFTER ASSEMBLY

Testing Methods

–Troubleshooting

Troubleshooting

Axle Problem And Diagnosis

–SPECIAL TOLLS

–SERVICE OPERATIONS TIME

SERVICE OPERATIONS TIME SCHEDULE

Steering Cylinder Group (G3)

Epicyclic Reduction Gear Group (G1)

Wheel Hub Group (G1)

Axle Beam Group (G4)

Trunnions Group (G2-G4)

Differential Support Group (G2)

Differential Group (G2)

Pinion Group

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.