Factory Service Manual For Mitsubishi Diesel Engine For Forklift. Manual Contains Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: English

Pages: 742

Number: SMEEA-AF12C-200

Bookmarks: Yes

Searchable: Yes

Wiring Diagrams: Yes

Model

Mitsubishi Diesel Engine For Forklift

854E

854F

For Use With FD70N Chassis Service Manuals And FD40N1 To FD55N1 And FD40NB To FD55NB Chassis Service Manuals

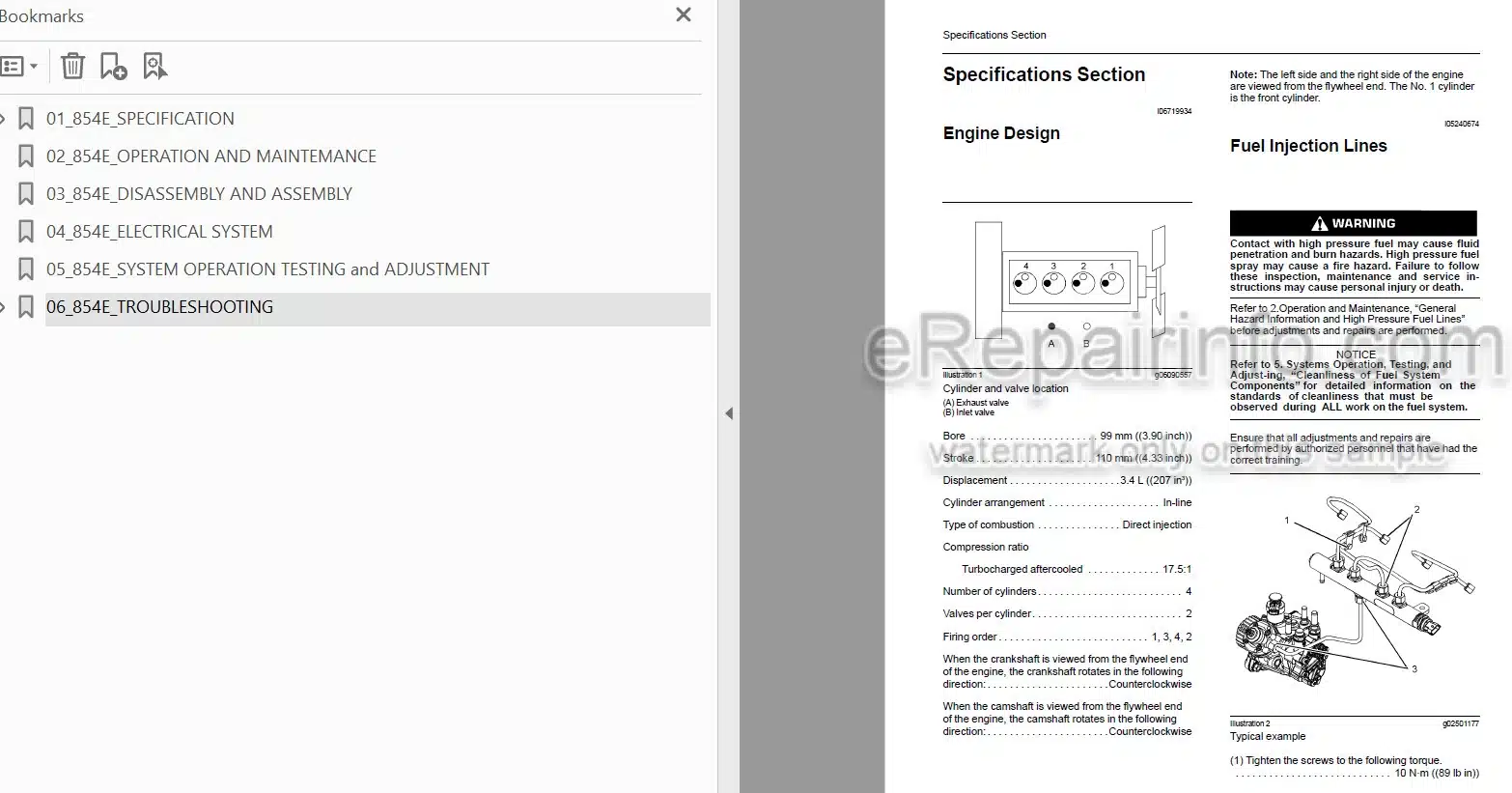

Contents

-SPECIFICATION

Engine Design

Fuel Injection Lines

Fuel Injection Pump

Fuel Injectors

Fuel Filter Base (Secondary Fuel Filter Base)

Fuel Filter Base (Primary Fuel Filter Base)

Fuel Manifold (Rail)

Lifter Group

Rocker Shaft

Valve Mechanism Cover

Cylinder Head Valves

Cylinder Head

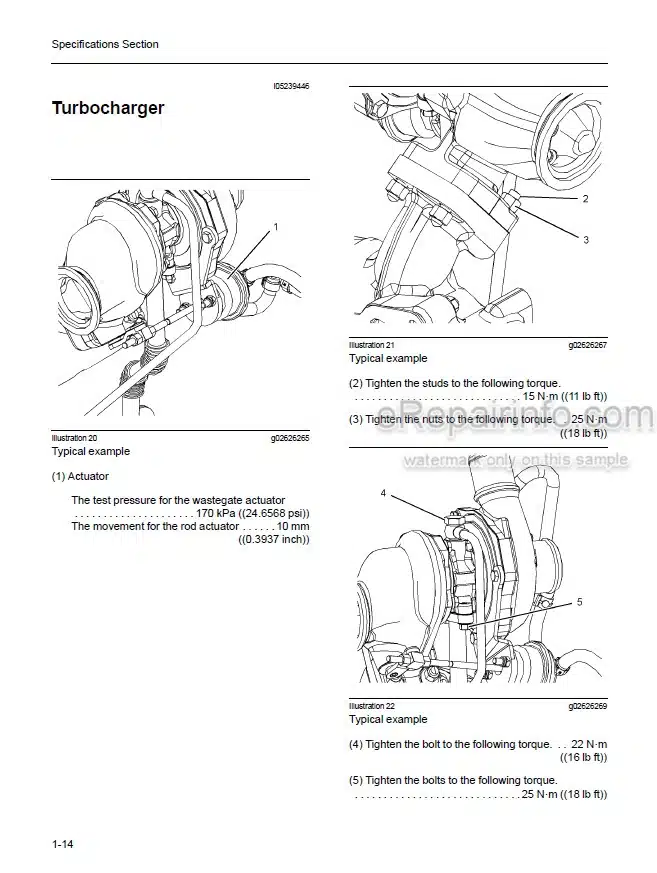

Turbocharger

Exhaust Gas Valve (NRS)

Exhaust Cooler (NRS)

Exhaust Manifold

Flexible Exhaust Pipe

Diesel Particulate Filter (Wall Flow Diesel Particulate Filter (DPF))

Diesel Particulate Filter (Through Flow Diesel Particulate Filter (DPF))

Camshaft

Camshaft Bearings

Engine Oil Filter Base

Engine Oil Cooler

Engine Oil Pump

Engine Oil Pressure

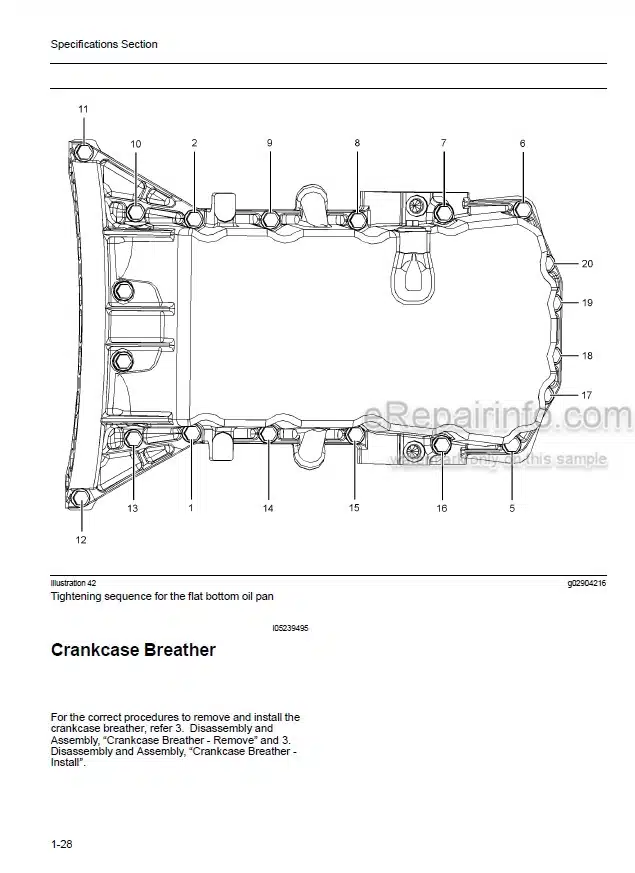

Engine Oil Pan (Pressed Steel Oil Pan)

Engine Oil Pan (Aluminum Oil Pan)

Engine Oil Pan (Cast Iron Oil Pan)

Crankcase Breather

Water Temperature Regulator and Housing

Water Pump

Cylinder Block

Crankshaft

Connecting Rod Bearing Journal

Main Bearing Journal

Connecting Rod

Piston and Rings

Piston Cooling Jet

Balancer

Front Housing and Covers

Gear Group (Front)

Flywheel

Flywheel Housing

Crankshaft Pulley

Fan Drive

Engine Lifting Bracket

Alternator

Starter Motor

Coolant Temperature Sensor

Boost Pressure Sensor (If equipped)

Oxygen Sensor

Inlet Manifold Temperature Sensor (If equipped)

Inlet Manifold Temperature and Pressure Sensor (If equipped)

Temperature Sensor (DPF Inlet)

Temperature Sensor (DOC Inlet)

Pressure Sensor (NOx Reduction System)

Temperature Sensor (NOx Reduction System)

Speed/Timing Sensor

Electronic Control Module

Glow Plugs

-OPERATION AND MAINTENANCE

Safety

Operation

Maintenance

Warranty

Reference Information

-DISASSEMBLY AND ASSEMBLY

Inspection of Parts

Fuel Priming Pump – Remove and Install

Flow Control Valve – Remove and Install

Fuel Filter Base – Remove and Install

Water Separator and Fuel Filter (Primary) – Remove and Install

Fuel Manifold (Rail) – Remove and Install

Fuel Injection Lines – Remove

Fuel Injection Lines – Install

Exhaust Cooler (NRS) – Remove and Install

Throttle Valve (Intake Air) – Remove and Install (Rear Facing Inlet Elbow)

Throttle Valve (Intake Air) – Remove and Install (Side Facing Inlet Elbow)

Fuel Injection Pump – Remove

Fuel Injection Pump – Install

Fuel Injection Pump Gear – Remove

Fuel Injection Pump Gear – Install

Electronic Unit Injector – Remove

Electronic Unit Injector – Install

Turbocharger – Remove (Top Mounted Turbochargers)

Turbocharger – Remove (Side Mounted Turbochargers)

Turbocharger – Install (Top Mounted Turbochargers)

Turbocharger – Install (Side Mounted Turbochargers)

Wastegate Solenoid – Remove and Install

Exhaust Gas Recirculation Valve – Remove and Install

Flexible Exhaust Pipe – Remove and Install

Exhaust Manifold – Remove and Install

Diesel Particulate Filter – Remove (Through Flow Diesel Particulate Filter)

Diesel Particulate Filter – Remove (Wall Flow Diesel Particulate Filter)

Diesel Particulate Filter – Install (Through Flow Diesel Particulate Filter)

Diesel Particulate Filter – Install (Wall Flow Diesel Particulate Filter )

Support and Mounting (CEM) – Remove and Install (Option 3)

Support and Mounting (CEM) – Remove and Install (Option 2)

Support and Mounting (CEM) – Remove and Install (Option 1)

Inlet Manifold – Remove and Install

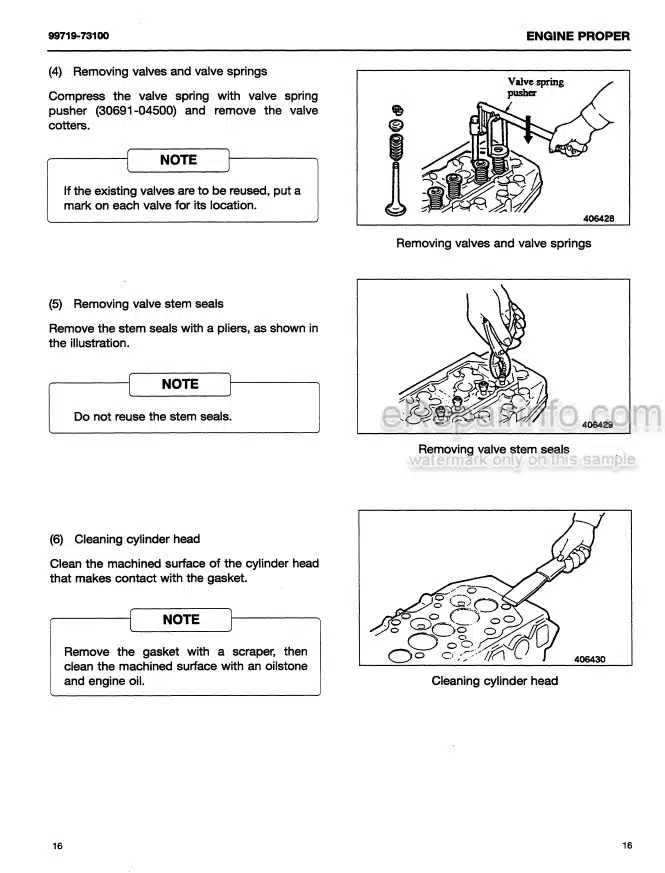

Inlet and Exhaust Valve Springs – Remove and Install

Inlet and Exhaust Valves – Remove and Install

Inlet and Exhaust Valve Guides – Remove and Install

Engine Oil Filter Base – Remove and Install

Engine Oil Cooler – Remove

Engine Oil Cooler – Install

Engine Oil Relief Valve – Remove and Install

Engine Oil Pump – Remove

Engine Oil Pump – Install

Water Pump – Remove

Water Pump – Install

Water Temperature Regulator – Remove and Install

Engine Lifting Bracket – Remove

Engine Lifting Bracket – Install

Flywheel – Remove 1

Flywheel – Install

Crankshaft Rear Seal – Remove and Install

Flywheel Housing – Remove and Install (Stressed Cylinder Block)

Flywheel Housing – Remove and Install (Non- Stressed Cylinder Block)

Power Take-Off Drive – Remove and Install

Crankshaft Pulley – Remove and Install

Crankshaft Front Seal – Remove and Install

Front Cover – Remove and Install

Idler Gear – Remove

Idler Gear – Install

Housing (Front) – Remove

Housing (Front) – Install

Accessory Drive – Remove and Install

Crankcase Breather – Remove

Crankcase Breather – Install

Valve Mechanism Cover – Remove and Install

Rocker Shaft and Pushrod – Remove

Rocker Shaft – Disassemble

Rocker Shaft – Assemble

Rocker Shaft and Pushrod – Install

Cylinder Head – Remove

Cylinder Head – Install

Lifter Group – Remove and Install

Camshaft – Remove and Install

Camshaft Gear – Remove and Install

Camshaft Bearings – Remove and Install

Engine Oil Pan – Remove and Install (Pressed Steel Oil Pan)

Engine Oil Pan – Remove and Install (Cast Iron Engine Oil Pan)

Balancer – Remove

Balancer – Install

Piston Cooling Jets – Remove and Install

Pistons and Connecting Rods – Remove

Pistons and Connecting Rods – Disassemble

Pistons and Connecting Rods – Assemble

Pistons and Connecting Rods – Install

Connecting Rod Bearings – Remove (Connecting rods in position)

Connecting Rod Bearings – Install (Connecting rods in position)

Crankshaft Main Bearings – Remove and Install

Crankshaft – Remove

Crankshaft – Install

Crankshaft Timing Ring – Remove and Install

Bearing Clearance – Check

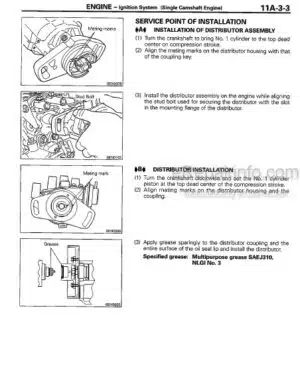

Camshaft Position Sensor – Remove and Install

Crankshaft Position Sensor – Remove and Install

Coolant Temperature Sensor – Remove and Install

Engine Oil Pressure Switch – Remove and Install

Fuel Temperature Sensor – Remove and Install

Oxygen Sensor – Remove and Install (Catalytic Converter)

Temperature Sensor (Exhaust) – Remove and Install

Temperature Sensor (DPF) – Remove and Install

Pressure Sensor (DPF) – Remove and Install

Pressure Sensor (Exhaust Back Pressure) – Remove and Install

Inlet Manifold Temperature Sensor – Remove and Install

Inlet Manifold Pressure Sensor – Remove and Install

Glow Plugs – Remove and Install

Alternator Belt – Remove and Install

Idler Pulley – Remove and Install

Fan – Remove and Install

Fan Drive – Remove and Install

Alternator – Remove

Alternator – Install

Electric Starting Motor – Remove and Install

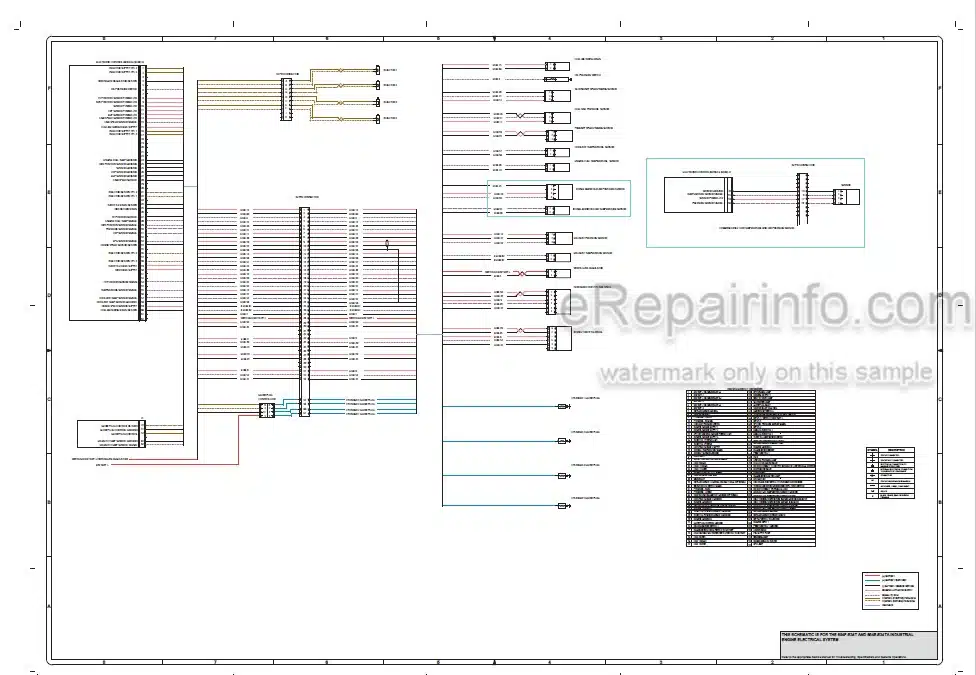

ELECTRICAL SYSTEM

-SYSTEM OPERATION TESTING AND ADJUSTING

General Information

Engine Operation

Testing and Adjusting-Fuel System

Testing and Adjusting-Air Inlet and Exhaust System

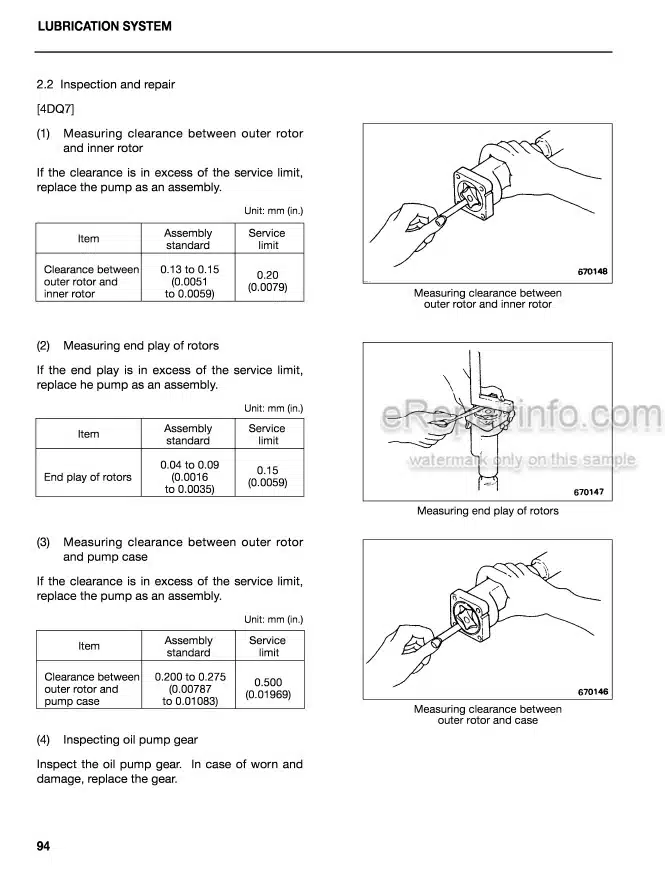

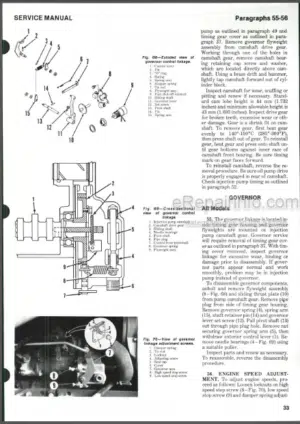

Testing and Adjusting-Lubrication System

Testing and Adjusting-Cooling System

Testing and Adjusting-Basic Engine

Testing and Adjusting-Electrical System

-TROUBLESHOOTING

Introduction

Electronic System Overview

Configuration Parameters

Symptom Troubleshooting

Circuit Tests

Service

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.