Factory Service Manual For Mitsubishi S3L S3L2 S4L S4L2 Engine. Tons of illustrations, instructions, diagrams for step by step remove and install, assembly and disassembly, service, inspection, repair, troubleshooting, tune-ups.

Format: PDF

Language: English

Pages: 219

Model

Mitsubishi S3L, S3L2, S4L, S4L2

Contents

-SAFETY CAUTIONS

-GENERAL

Service Standards Table

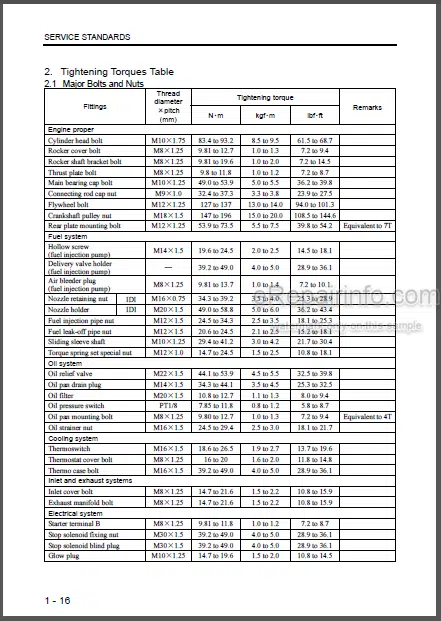

–Tightening Torques Table

Major Bolts and Nuts

Standard Bolts and Nuts

Standard Eyebolts

Standard Union Nuts

Taper Bolts

Sealants List

-SERVICE STANDARTS

Service Standards Table

–Tightening Torques Table

Major Bolts and Nuts

Standard Bolts and Nuts

Standard Eyebolts

Standard Union Nuts

Taper Bolts

Sealants List

-TOOLS LIST

General Tools

Special Tools

-OVERHAUL TIMING

Identifying the Timing for Overhaul

Measuring the Compression Pressure

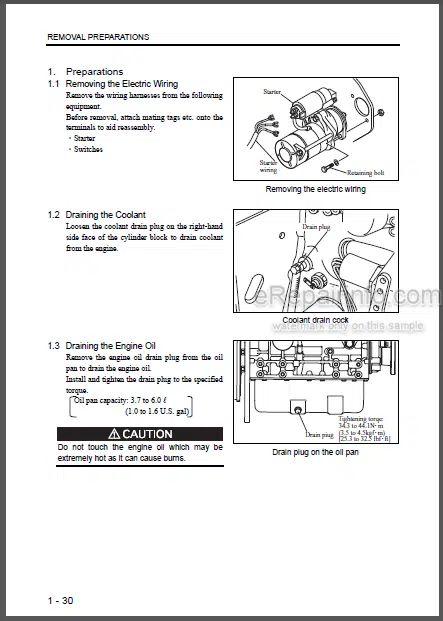

-REMOVAL PREPARATIONS

Preparations

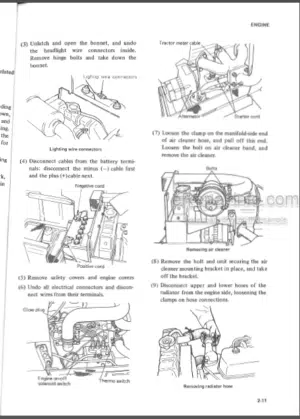

Removing The Electric Wiring

Draining The Coolant

Draining The Engine Oil

-ENGINE MAIN PARTS – DISASSEMBLY

–Cylinder Head, Valve Mechanism

Removing The Rocker Shaft Assembly

Disassembling The Rocker Shaft Assembly

Removing The Cylinder Head Bolts

Removing The Cylinder Head Assembly

Removing The Valves And Valve Springs

Removing The Valve Stem Seals

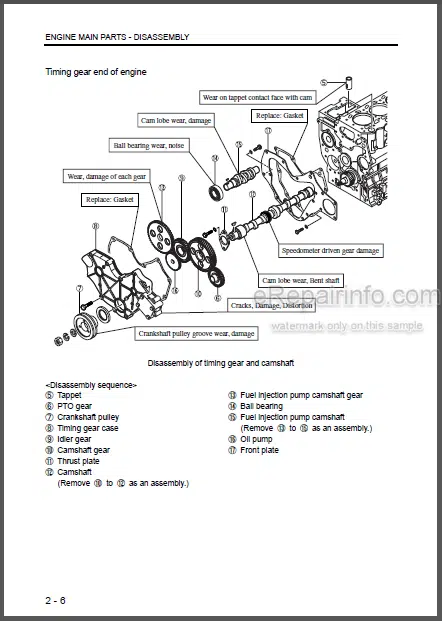

–Flywheel, Timing Gear, Camshaft

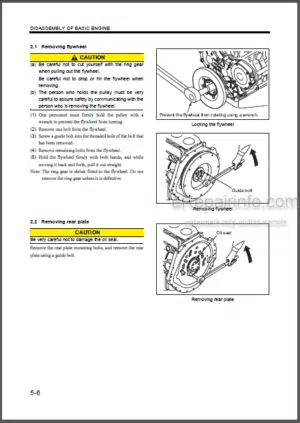

Removing The Flywheel

Removing The Flywheel Housing

Removing The Rear Plate

Removing The Oil Seal Case

Removing The Tappets

Removing The Crankshaft Pulley

Removing The Timing Gear Case

Measuring The Timing Gear Backlash

Removing The Idler Gear

Removing The Camshaft

Removing The Fuel Injection Pump Camshaft

Separating The Gears From The Shafts (As Required)

Removing The Oil Pump

Removing The Front Plate

–Cylinder Block, Crankshaft, Pistons, Oil Pan

Removing The Oil Pan

Removing The Oil Strainer

Removing The Connecting Rod Caps

Removing The Pistons

Measuring The Crankshaft End Play

Removing The Main Bearing Caps

Removing The Crankshaft

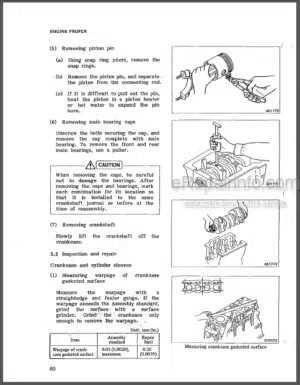

Separating The Piston From The Connecting Rod

-ENGINE MAIN PARTS – INSPECTION AND CORRECTION

–Cylinder Head, Valve Mechanism

Measuring The Cylinder Head Bottom Face Distortion

Measuring The Rocker Arm Bore And The Rocker Shaft Diameter

Measuring The Valve Spring For Squareness And Free Length

Measuring The Push Rod For Bend

Measuring The Valve Stem Diameter

Measuring The Clearance Between The Valve Stem And Guide

Replacing The Valve Guide

Inspecting The Valve Face

Correcting The Valve Face

Correcting The Valve Seat

Lapping The Valve Face Against The Valve Seat

Replacing The Combustion Jets

–Flywheel, Timing Gear, Camshaft

Measuring The Flywheel Flatness

Replacing The Ring Gear

Measuring The Timing Gear Backlash

Measuring The Clearance Between The Idler Gear And The Idler Shaft

Replacing The Idler Shaft

Measuring The Clearance Between The Camshaft Journal And The Bushing

Extracting The Camshaft Bushing

Pressfitting The Camshaft Bushing

Measuring The Camshaft Cam Height

Measuring The Fuel Injection Pump Shaft Cam Height

Inspecting The Camtotappet Contact

Measuring The Clearance Between The Tappet And The Tappet Guide

–Cylinder Block, Crankshaft, Pistons, Oil Pan

Measuring The Piston Diameter

Measuring The Clearance Between The Piston Ring And The Ring Groove

Measuring The Piston Ring Gap

Measuring The Clearance Between The Piston Pin And The Pin Boss

Measuring The Connecting Rod Bend And Twist

Measuring The Connecting Rod End Play

Inspecting The Oil Clearance For Connecting Rod Bearings

Inspecting The Main Bearings Oil Clearance

Measuring The Crankshaft For Bend

Removing The Crankshaft Gear

Installing The Crankshaft Gear

Measuring The Cylinder Bore

Measuring The Cylinder Block Top Face For Distortion

-ENGINE MAIN PARTS – REASSEMBLY

Cylinder Block, Crankshaft, Pistons, Oil Pan

Installing The Main Bearings

Installing The Crankshaft

Installing The Main Bearing Caps

Inserting The Side Seals

Assembling The Piston Onto The Connecting Rod

Installing The Piston Rings

Installing The Piston/Connecting Rod Assemblies

Installing The Connecting Rod Caps

Installing The Oil Strainer

Installing The Oil Pan

Flywheel, Timing Gear, Camshaft

Installing The Front Plate

Installing The Oil Pump

Rotating The Engine

Tapping The Fuel Injection Pump Camshaft Into Place

Installing The Camshaft

Installing The Idler Gear

Installing The Timing Gear Case

Tightening The Crankshaft Pulley Nut

Installing The Pto Gear

Inserting The Tappets

Installing The Oil Seal Case

Installing The Rear Plate

Installing The Flywheel Housing

Installing The Flywheel

Cylinder Head, Valve Mechanism

Cleaning The Bottom Face Of The Cylinder Head

Installing The Valve Stem Seals

Installing The Valve Springs

Installing The Valve Locks

Installing The Cylinder Head Gasket

Installing The Cylinder Head

Tightening The Cylinder Head Bolts

Inserting The Push Rods

Assembling The Rocker Shaft Assembly

Installing The Rocker Shaft Assembly

Adjusting The Valve Clearance

Installing The Rocker Cover

-FUEL SYSTEM – REMOVAL

–Fuel Injection Pipes, Fuel Leak-Off Pipe, Fuel Injection Nozzles

Removing The Fuel Injection Pipes

Removing The Fuel Injection Nozzles

–Governor

Removing The Governor Assembly

Removing The Governor Weights

–Fuel Injection Pumps

Removing The Fuel Injection Pumps

-FUEL SYSTEM – DISASSEMBLY, INSPECTION AND REASSEMBLY

–Fuel Injection Nozzles

Disassembling The Fuel Injection Nozzles

Inspecting The Fuel Injection Nozzle

Reassembling The Fuel Injection Nozzle

–Fuel Injection Pumps

Inspecting The Fuel Injection Pumps On Vehicle

Disassembling The Fuel Injection Pumps

Inspecting The Fuel Injection Pumps

Reassembling The Fuel Injection Pumps

–Governor

Disassembling And Inspecting The Governor

Reassembling The Governor

Installing The Torque Spring Set

–Fuel Pump

Inspecting The Fuel Pump

–Fuel Filter

Disassembling, Inspecting And Reassembling The Fuel Filter (With A Selector Cock)

Inspecting The Fuel Filter (Cartridge Type)

-FUEL SYSTEM – INSTALLATION

–Fuel Injection Pumps

–Installing The Fuel Injection Pumps

Governor

Installing The Governor Weights

Installing The Sliding Sleeve

Installing The Governor Assembly

Fuel Injection Pipes, Fuel Leak-Off Pipe, Fuel Injection Nozzles

Installing The Fuel Injection Nozzles

Installing The Fuel Pipes

-OIL SYSTEM – REMOVAL

–Filter, Relief Valve And Oil Pressure Switch

Removing The Oil Filter

Removing The Relief Valve

Removing The Oil Pressure Switch·

–Oil Pan, Oil Strainer

-OIL SYSTEM – DISASSEMBLY,INSPECTION AND REASSEMBLY

–Oil Pump

–Inspecting The Oil Pump

–Relief Valve

Inspecting The Relief Valve

–Oil Pressure Switch

Inspecting The Oil Pressure Switch

-OIL SYSTEM – INSTALLATION

–Oil Filter, Relief Valve And Oil Pressure Switch

Installing The Oil Pressure Switch

Installing The Relief Valve

Installing The Oil Filter

–Oil Pan And Oil Strainer

-COOLING SYSTEM – REMOVAL

Cooling Fan, Fan Pulley And V-Belt

Removing The Cooling Fan

–Thermostat And Thermoswitch

Removing The Thermostat Case

–Water Pump

Removing The Water Pump

-COOLING SYSTEM – DISASSEMBLY, INSPECTION AND REASSEMBLY

–Thermostat

Disassembling The Thermostat

Inspecting The Thermostat

–Thermoswitch

Inspecting The Thermoswitch

Water Pump

Inspecting The Water Pump

-COOLING SYSTEM – INSTALLATION

Water Pump

Installing The Water Pump

–Thermostat And Thermoswitch

Installing The Thermostat Case

Installing The Thermoswitch

–Cooling Fan, Fan Pulley And V-Belt

Installing The Cooling Fan

-INLET AND EXHAUST SYSTEMS – REMOVAL

Inlet Cover

Removing The Inlet Cover

–Exhaust Manifold

Removing The Exhaust Manifold

-INLET AND EXHAUST SYSTEMS – DISASSEMBLY, INSPECTION AND REASSEMBLY

–Inlet Cover And Exhaust Manifold

Inspecting The Inlet Cover And Exhaust Manifold

Measuring The Exhaust Manifold Mounting Face Distortion

-INLET AND EXHAUST SYSTEMS – INSTALLATION

–Exhaust Manifold

Installing The Exhaust Manifold

–Inlet Cover

Installing The Inlet Cover

-ELECTRICAL SYSTEM – REMOVAL

Starter

Alternator

Stop Solenoid

Glow Plug

-ELECTRICAL SYSTEM – DISASSEMBLY, INSPECTION AND REASSEMBLY

–Starter

Removing The Starter

Inspecting And Correcting The Starter

Reassembling The Starter

–Alternator

Disassembling The Alternator

Inspecting And Correcting The Alternator

Reassembling The Alternator

–Stop Solenoid

Reassembling The Stop Solenoid

Checks After Reassembly

–Glow Plug

Inspecting The Glow Plug

-ELECTRICAL SYSTEM – INSTALLATION

Glow Plug

Stop Solenoid

Altemato

Starter

-ENGINE – INSPECTION / ADJUSTMENT, RUNNING-IN TRIAL AND PERFORMANCE TEST

–Inspection And Adjustment Of Engine

Preparations For Valve Clearance Inspection And Adjustment

Inspecting The Valve Clearance

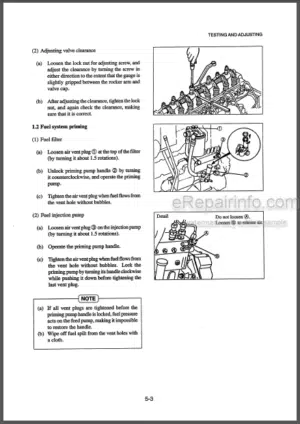

Adjusting The Valve Clearance

Inspecting And Adjusting The Fuel Injection Timing

Alternative Adjustment Method

Replacing The Fuel Filter

Bleeding The Fuel Filter Of Air

Adjusting The Low And High Idle Speeds

Inspecting The Fuel Injection Nozzle

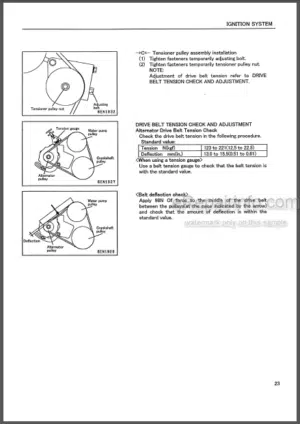

Inspecting The Vbelt Tension

–Runningin Trial

Starting The Engine

Inspecting The Engine During Runningin

Runningin Timetable

Inspection And Adjustment After Runningin

–Performance Test

Standard Ancillaries

Test Items And Purposes

Other Tests

Adjusting The Engine Power

-MISCELLANEOUS

–Disassembly and Reassembly of General Parts

Oil seals

O-rings

Bearings

Lock plates

Split pins, Spring pins

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.