Factory Supplements And Operators Service Manual For National Crane Crane. Manual Contains Important Information And Instructions For Maintenance Description Of The Functions And Capabilities Of The System. Illustrations, Instructions, Diagrams For Step By Step Remove And Install, Assembly And Disassembly, Service, Inspection, Repair, Troubleshooting, Tune-Ups.

Format: PDF

Language: ENG; ESP

Quantity of Manuals: 2

Pages: 204; 210

Number: CTRL031-07 (october 2011)

Bookmarks: Yes

Searchable: Yes

Model

National Crane Crane

900A

Contents

-BOOM CABLE TENSIONING-SUPPLEMENT

General

Cable Tensioning

Cable Tension Sequence

5 – Section Boom w/ 2 Stage Cylinder Cable Positioning

4- Section Boom w/ 2 Stage Cylinder Cable Positioning

4- Section Boom w/ 1 Stage Cylinder Cable Positioning

3- Section Boom w/ 1 Stage Cylinder Cable Positioning

Cable Retention

-WARM-UP PROCEDURES—SUPPLEMENT

Crane Warm-up Procedures

-SUPPLEMENT

Outrigger Monitoring System (OMS) (Optional—Standard in North America)

Side Folding Swing-Around Jib Operation

-SAFETY INFORMATION

Safety Messages

General

Accidents

Operator’s Information

Operator’s Qualifications

Operational Aids

Crane Stability/Structural Strength

Electrocution Hazard

Personnel Handling

Environmental Protection

Maintenance

Transporting the Crane

Travel Operation

Work Practices

Boom Extension

Parking and Securing

Shut-Down

Cold Weather Operation

Temperature Effects on Hydraulic Cylinders

Overload Inspection

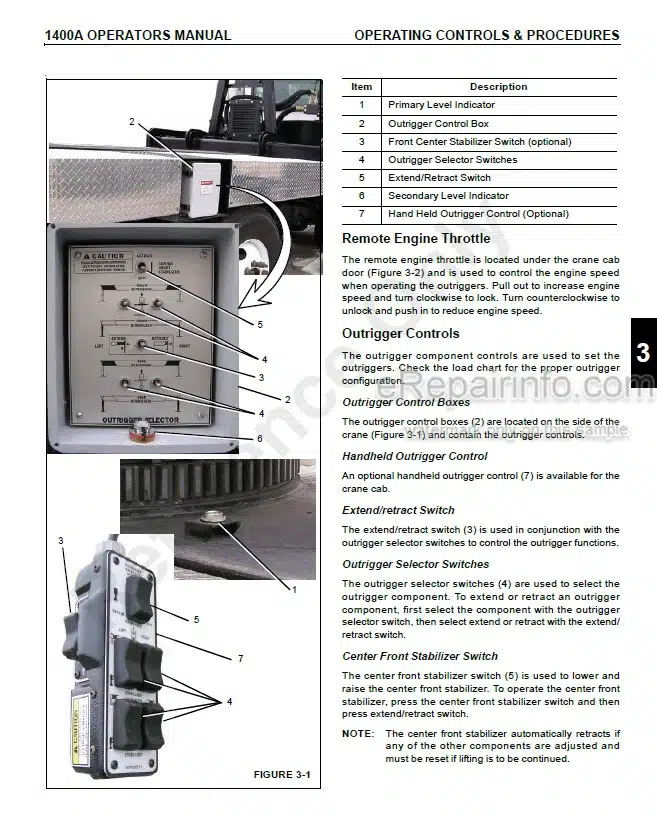

-OPERATING CONTROLS AND PROCEDURES

Controls

Operating Procedures

Anti-Two-Block System

Optional Hydraulic Capacity Alert System

Optional Wireline Hydraulic Capacity Alert System

Hydraulic Capacity Alert System Adjustment

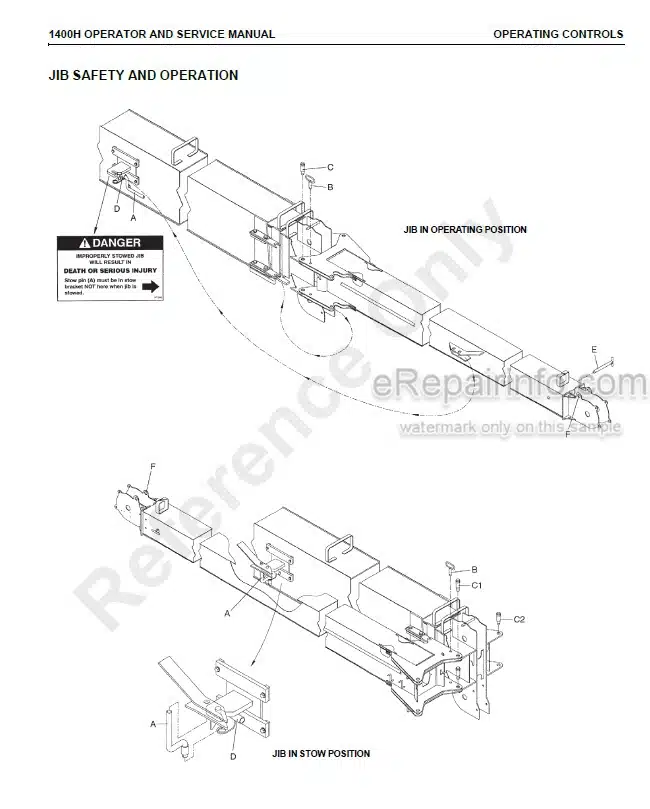

Jib Safety and Operation

Jib Jack

Adjustable Swing Speed Valve

Standard Hand Signals for Controlling Crane Operations

Optional Hydraulic Capacity Alert System

-MAINTENANCE

Inspection and Maintenance

Wire Rope Inspection and Maintenance

Tire Load and Inflation Table

-LUBRICATION

Lubrication Procedures and Charts

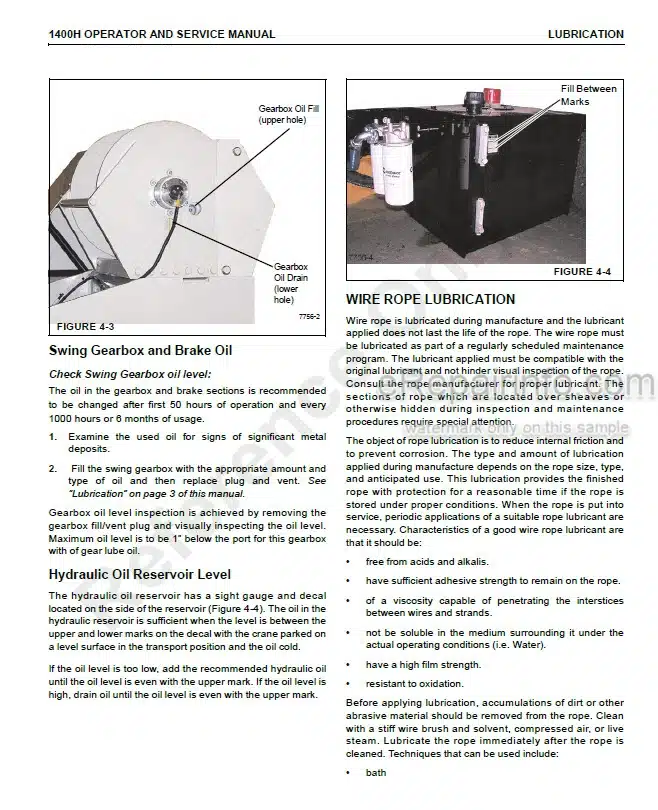

Hydraulic Oil Reservoir Level

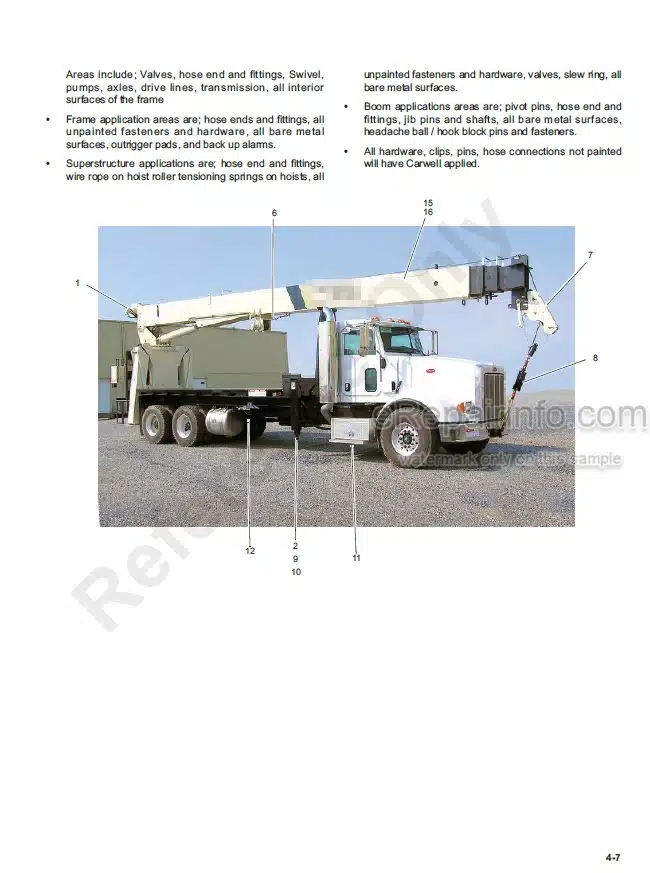

Carwell Rust Inhibitor

-SERVICE

Service and Repair

Fatigue of Welded Structures

Loctite

Fasteners and Torque Values

Weld Studs

Using Torque Wrench Extensions

Winch Oil Level

Brake Oil Level

Trouble Diagnosis

Anti-Two Block Trouble Diagnosis – Electrical

Anti-Two Block Trouble Diagnosis – Hydraulic

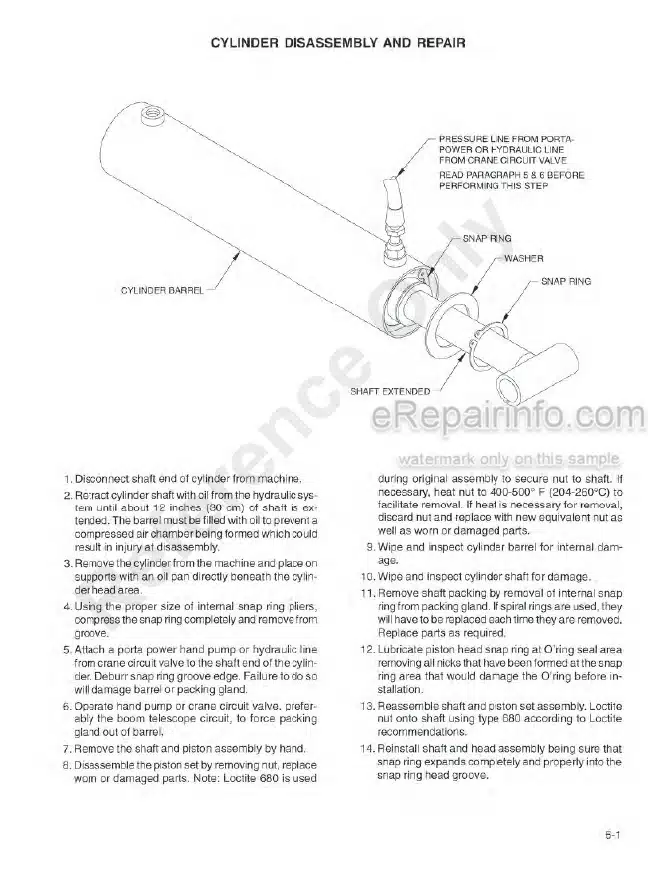

Cylinder Disassembly and Repair

Single-Stage Extend Cylinder Disassembly and Repair

Four Section Boom Operation

Four Section Boom Maintenance

Four Section Boom Service

Four Section Boom Assembly

Four Section Top/Bottom Pad Replacement, Assembled Boom

Three Section Boom Operation

Boom Illustrations

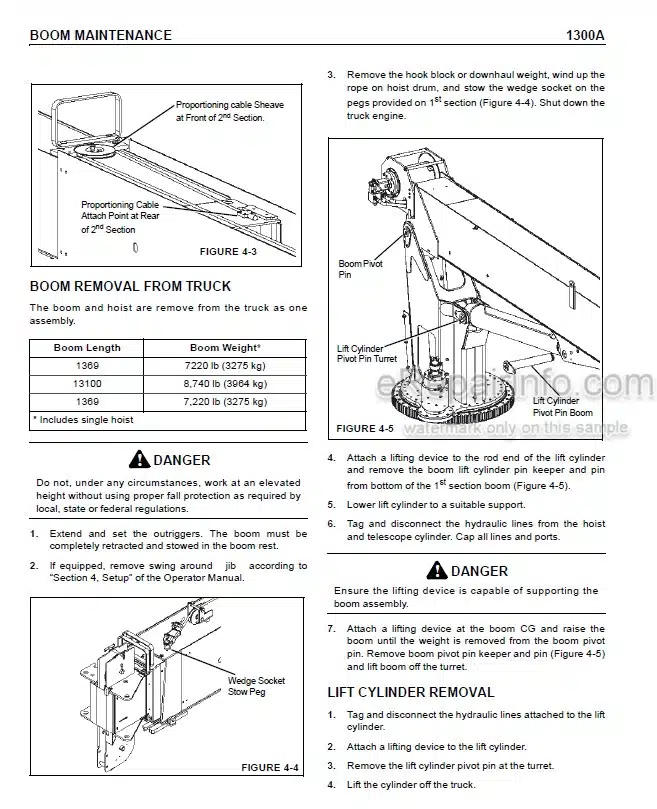

Three Section Boom Maintenance

Three Section Boom Service

Three Section Boom Assembly

Three Section Top/Bottom Pad Replacement, Assembled Boom

Inner Wear Pad Calibration

Inner Boom Pad Lubrication

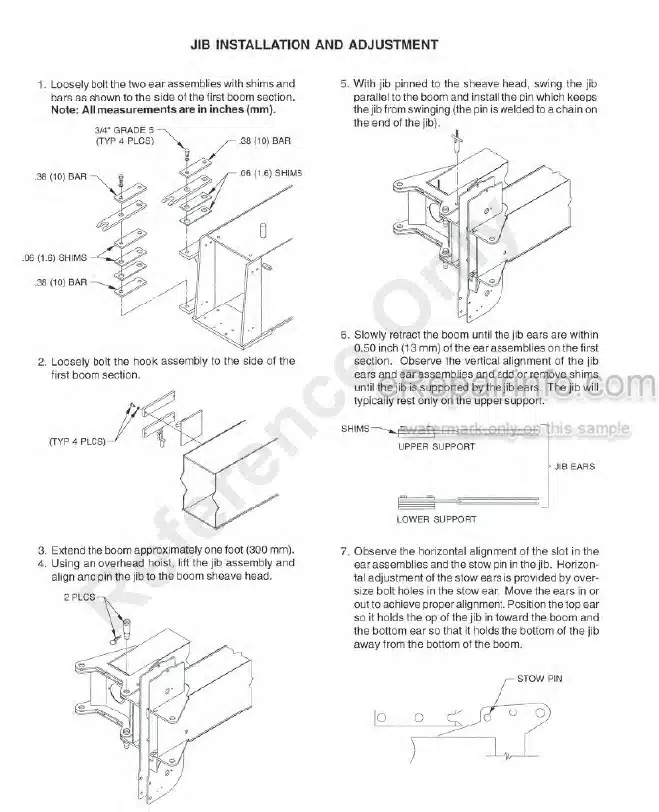

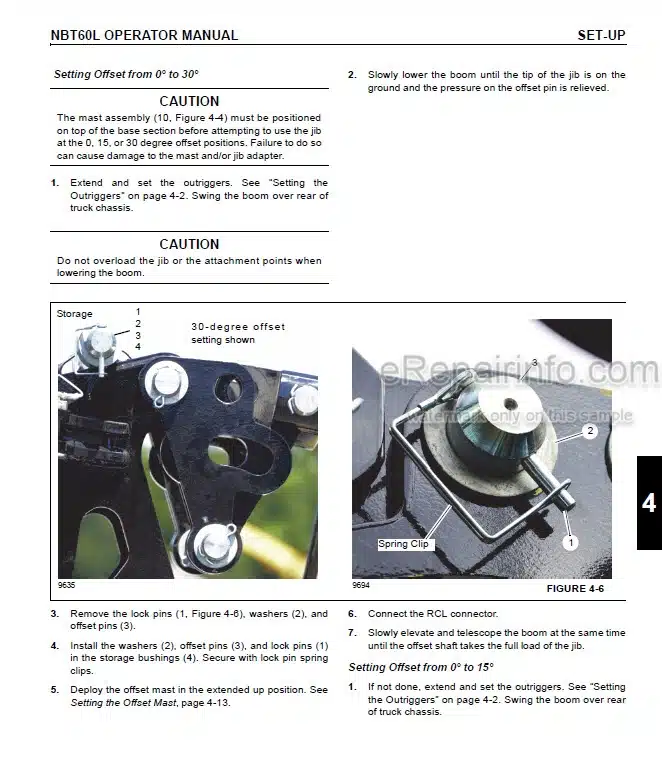

Jib Installation and Adjustment

Jib Jack Service and Maintenance

(Optional) Oil Cooler Service and Maintenance

Rotation Gearbox and Brake Illustration

Swing Drive Service

Servicing the Control Valves

Control Valve Relief Adjustment

Unloader Dump Valve – Air Purging Instructions

Hydraulic System Description

Service Manual for Pump

Service Manual for Load Moment Indicator

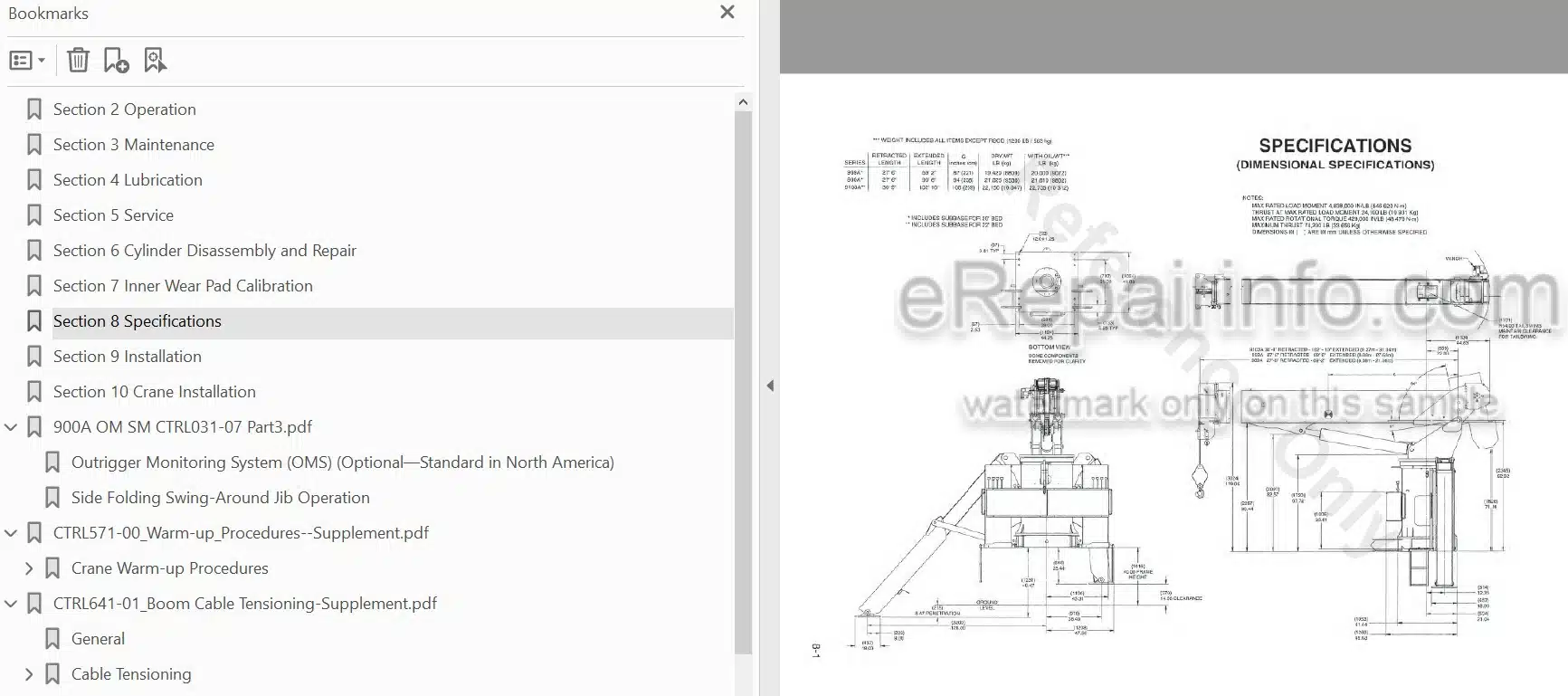

-SPECIFICATIONS

Dimensional Specification

Dimensional Specification Tractor Mount

Specifications

Capacity Chart

-INSTALLATION

Typical Locations/Serial Number Identification

Minimum Truck Requirements

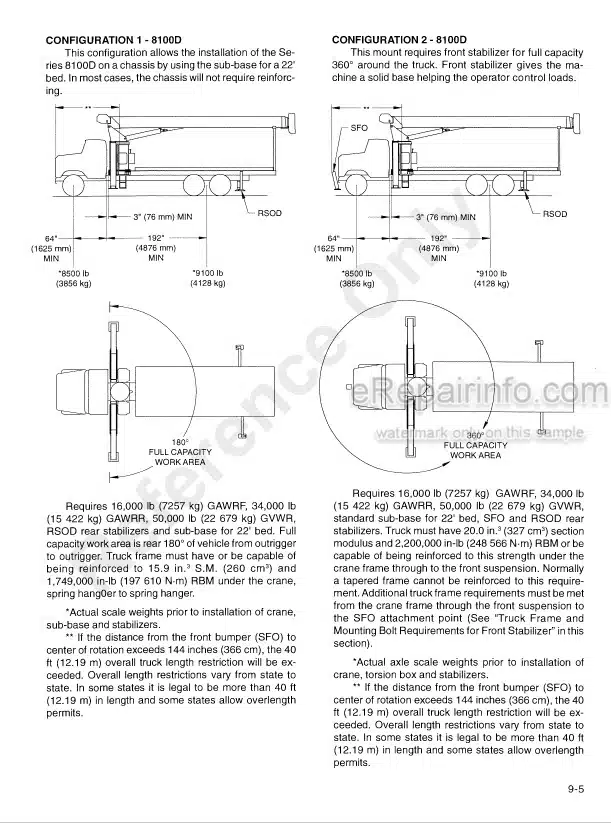

Mounting Configurations

PTO Horsepower Requirements

PTO Selection

Truck Frame Strength

Truck Preparation

After Frame Modification

Crane Installation

Pin Bearing Inspection and Installation Procedure

Counterweighting

Counterweighting New York City Approved

Counterweighting Methods for Stability Around the Rear 180°

Anti-Two-Block Load Moment Indicator Installation and Function Verification

Initial Crane Run-In Procedure

Boom Rests

Stability Check

Stability Check New York City Approved

What you get

You will receive PDF file with high-quality manual on your email immediately after the payment.

Reviews

There are no reviews yet.